TeleVideo 955 Guide

TELEVIDEO®

955

VIDEO DISPLAY TERMINAL

MAINTENANCE

MANUAL

Document

l3l968-00-C

September

1987

Copyright

Copyright

(c)

1987

by

TeleVideo

Systems,

Inc.

All

rights

reserved~

No

part

of

this

publication

may

be

reproduced:

transmitted,

transcribed,

stored

in

a

retrieval

system,

or

translated

into

any

language

or

computer

language,

in

any

form

or

by

any

means,

electronic,

mechanical,

magnetic,

optical,

chemical,

manual,

or

otherwise,

without

the

prior

written

permission

of

TeleVideo

Systems,

Inc.,

1170

Morse

Avenue,

P.O.

Box

3568,

Sunnyvale,

California

94088-3568.

Disclaimer

TeleVideo

Systems,

Inc.

makes

no

representations

or

warranties

with

respect

to

this

manual.

Further,

TeleVideo

Systems,

Inc.

reserves

the

right

to

make

changes

in

the

specifications

of

the

product

described

within

this

manual

at

any

time

without

notice

and

without

obligation

of

TeleVideo

Systems,

Inc.

to

notify

any

person

of

such

revision

or

changes.

TeleVideo

is

a

registered

trademark

of

TeleVideo

Systems,

Inc.

TeleVideo

Systems,·

Inc.,

Sunnyvale,

CA

94088-3568

1170

Morse

Avenue,

P.O.

Box

3568,

408/745-7760

TABLE OF CONTENTS

l.

2.

3.

4.

Troubleshooting

Guide

Overvi~w

Description

of

the

Modules

Logic

Board

Power

Supply

Video

Module

(Video

Monitor

Board)

Kp.yboard

Removinq

the

Modules

Ooening

the

Case

Removing

the

Power

Supply

Replacing

the

Power

Supply

Removing

the

Video

Module

Replacing

the

Video

Module

Removing

the

Logic

Board

and

Shroud

Replacing

the

Logic

Board

and

Shroud

Closing

the

Case

Opening

the

Keyboard

Case

Removing

the

Keyboard

Circuit

Visual

Inspection

Terminal

and

Keyboard

Exterior

Terminal

and

Keyboard

Interior

Fault

Isolation

at

the

Module

Level

Troubleshooting

the

Logic

Board

and

Keyboard

Troubleshooting

the

Video

Module

Visual

Inspection

Adjustments

Schematics

Ordering

Spare

Parts

955

Terminal

Spare

Parts

List

955

Parts

Reference

List

Theory

of

Operation

Overview

Gate

Array

Logic

Board

Theory

of

Operation

Clock

Circui.t

Clock

Switching

Clock

Stretch

Timing

CPU

System

and

Control

Character

Generation

Display

Generation

Screen

Data

Storage

Communications

Enhanced

Gate

A.rray

I.Jogic

Board

Theory

of

Operation

Clock

Circuit

CPU

System

and

Control

Character

Generation

Display

Generation

Screen

Data

Storage

Communications

iii

1-1

1-1

1-2

1-2

1-3

1-3

1-3

1-4

1-4

1-6

1-6

1-8

1-9

1-10

1-10

1-11

1-12

1-12

1-12

1-12

1-13

1-13

1-17

1-22

1-22

1-22

2-1

3-1

3-2

3-5

4-1

4-1

4-1

4-1

4-3

4-4

4-6

4-9

4-10

4-11

4-12

4-13

4-13

4-15

4-19

4-20

4-21

4-22

5 •

Service

Information

Regional

S~les

Offices

6.

Operator's

Mnnual

7.A.ddenda

Specifications

Bulletins

LIST

OF

TABLES

1-1

1-2

1-3

2-1

2-2

3-1

3-2

4-1

4-2

Fault

Isolation

Guide

Gate

Array

Logic

Board

and

Keyboard

Troubleshooting

Guide

Enhanced

Gate

A.rray

Logic

Board

and

Keyboard

Troubleshooting

Guide

IC

Reference

(Gate

Array

Logic

Board)

IC

Reference

(Enhanced

Gate

Array

Logic

Board)

955

Terminal

Spare

Parts

List

955

Parts

Reference

List

Memory

Map

Memory

Map

LIST

OF

FIGURES

1-1

1-2

1-3

1-4

1-5

1-6

1-7

4-1

4-2

4-3

4-4

955

Terminal,

Front

View

955

Terminal,

Rear

View

Discharging

Voltages

Opening

the

Case

Removing

the

Power

Supply

Removing

the

Video

Module

Removing

the

Logic

Board

and

Shroud

955

Block

Diagram

(Gate

Array

Logic

Board)

Clock

Switchinq

CPU

Clock

Stretch

Timing

955

B10ck

Diagram

(Enhanced

Gate

A.rray

Logic

Board)

iv

5-1

5-1

1-13

1-17

1-20

2-1

2-4

3-2

3-5

4-7

4-16

1-1

1-2

1-4

1-5

1-7

1-9

1-11

4-2

4-4

4-5

4-14

TROUBLESHOOTING GUIDE

This

troubleshooting

guide

was

designed

for

qualified

repair

personnel.

Using

this

guide,

the

schematics

in

Section

2,

and

an

Operator's

Manual,

you

can

repair

most

failures

quickly.

If

difficulty

arises,

contact

your

dealer.

STOP!

Do

not

open

the

case

as

described

in

this

manual

unless

you

are

a

qualified

service

technician.

The

components

exposed

during

this

procedure

retain

hazardous

voltages

that

are

present

even

after

the

power

cord

has

been

disconnected.

OVERVIEW

TeleVideo's

955,

a

general-purpose

ASCII

terminal,

is

fully

code-

compatible

with

our

925/950

family

of

terminals.

The

main

element

in

the

system

is

a

65C02

CMOS

custom

microprocessor.

For

CRT

control,

the

955

uses

an

advanced

alphanumeric

VLSI

CRT

controller

chip.

Figures

1-1

and

1-2

show

front

and

rear

views

of

the

terminal.

Ports,

switches

and

connectors

are

marked.

Figure

1-1

955

Terminal,

Front

View

CONTRAST

ADJUSTOR

ON/OFF

SWITCH

KEYBOARD

CONNECTOR

1-1

Figure

1-2

955

Terminal,

Rear

View

POWER

CABLE---=:=:::::-_~l""'"

SOCKET

--

__

~===-~_

Terminal

hardware

is

divided

into

four

main

modules:

Main

logic

board

Power

supply

Video

module

(video

monitor

board)

Keyboard

This

design

permits

fast

fault

isolation

and

keeps

repair

time

to

a

minimum.

To

isolate

a

faulty

module,

swap

a

suspected

module

with

a

known-good

one.

DESCRIPTION

OF

THE

MODULES

Logic

Board

The

logic

board

fits

inside

a

tray

that

slides

into

the

base

of

the

terminal.

It

is

easily

reached

by

removing

two

screws

from

the

base.

The

65C02

microprocessor-based

control

circuitry

on

the

logic

board,

acting

on

its

own

internal

system

program,

stores

and

processes

data

received

and

data

to

be

transmitted.

The

circuitry

also

generates

the

video

and

sync

signals

needed

to

display

data

on

the

screen.

1-2

The

logic

board

has

four

distinct

interconnected

divisions

that

are

discussed

in

this

manualls

Theory

of

Operation

section.

They

are:

Main

processor

Display

circuitry-processor

Random

Access

Memory

(RAM)

Interface

for

external

input/output

Power

Supply

A

switching

power

supply

is

located

in

the

pedestal

below

the

CRT.

It

provides

the

following

voltages

for

the

terminalls

electronic

circuitry:

+

5V

for

TTL

logic

+12V

for

the

video

signals

and

RS-232C

communications

-12V

for

RS-232C

communications

-

5V

for

the

optional

modem

Two

user-replaceable

fuses--Fl

on

the

power

supply

and

a

line

fuse

in

back

of

the

terminal--protect

the

circuitry.

Video

Module

(Video

Monitor

Board)

The

video

module

is

located

behind

the

CRT.

It

contains

horizontal

and

vertical

sweep

and

video

amplification

circuitry.

This

circuitry

produces

a

television-type

noninterlaced

raster

display.

The

video

signals

generated

by

the

display

circuitry

cause

pixels

to

appear

at

designated

positions

across

scan

lines.

These

pixels

form

a

character

when

selectively

combined

in

a 7 x 9

dot

rna

tr

ix.

Keyboard

The

955

has

a

detachable

keyboard

connected

to

the

terminal

by

a

coiled

keyboard

cable.

The

keyboard

consists

of

an

array

of

keyswitches

mounted

on

a

printed

circui~

board

with

an

8049

microcomputer

and

other

leis.

The

8049

microprocessor

on

the

keyboard

scans

the

keyboard

matrix,

encodes

the

data

and

transmits

two

bytes

per

character

requested.

Data

is

sent

through

a

6-wire

coiled

cable

over

an

asynchronous

serial

channel

at

9600

baud

to

the

main

logic

board.

The

keyboard

microprocessor

also

activates

an

audio

transducer

for

the

bell

and

the

simulated

keyclick.

1-3

On

the

main

logic

board,

the

serial

data

is

converted

to

parallel

data

and

decoded

by

the

main

microprocessor

and

its

firmware.

REMOVING

THE

MODULES

Opening

the

Case

STOPl

The

CRT

and

capacitors

retain

high

voltages

even

after

power

has

been

turned

off.

As

soon

as

you

open

the

case,

discharge

the

CRT

by

connecting

one

end

of

a

grounding

l~ad

to

the

metal

chassis

and

the

other

end

to

a

screwdriver

with

an

insulated

handle.

Slip

the

metal

end

of

the

screwdriver

under

the

plastic

cap

of

the

anode,

as

shown

in

Figure

1-3.

Be

careful

not

to

touch

the

metal

portion

of

the

screwdriver

or

the

ground

lead.

Figure

1-3

Discharging

Voltages

CRT

ANODE

1

INSULATED

HANDlE

SCREWDRIVER

METAL

FRAME

Use

Figure

1-4

as

reference

for

opening

the

case.

1.

Turn

off

the

terminal.

2.

Disconnect

the

power

cord

and

data

cable(s)

from

the

back

of

the

termina17

disconnect

the

keyboard

cable

from

the

front

of

the

terminal.

3.

Turn

the

terminal

so

the

screen

faces

away

from

you.

1-4

4.

Remove

the

three

screws

securing

the

monitor

rear

housing

to

the

case

(remove

the

screw

under

tne

power

cora

r1rst,

then

remove

the

two

screws

near

the

top

of

the

housing).

NOTE:

Remove

the

screws

completely.

If

necessary,

tip

the

unit

backwards

slightly.

5.

To

release

the

clamp

holding

the

bezel

and

monitor

rear

housing

together

(See

Figure

1-4):

a.

Grasp

the

housing

with

your

left

hand.

b.

Sharply

tap

the

right

side

of

the

housing

with

the

heel

of

your

right

hand.

6.

Lift

off

the

monitor

rear

housing.

Figure

1-4

Opening

the

Case

PRINTER

PORT

1-5

Removing

the

Power

Supply

STOPl

The

CRT

retains

high

voltages,

even

after

the

power

has

been

turned

off,

and

poses

a

potential

shock

hazard.

Follow

the

CRT

discharge

procedure

on

page

1-4

of

this

section

before

removing

and

replacing

the

power

supply.

Use

Figure

1-5

as

reference

for

removing

and

replacing

the

power

supply.

1.

Turn

off

the

terminal

and

open

the

case

(See

page

1-4).

2.

Turn

the

terminal

so

the

screen

faces

away

from

you.

3.

Remove

the

two

Phillips

screws

securing

the

bezel

to

the

case

(the

screws

are

located

inside

the

case,

one

on

each

side

of

the

power

supply).

4.

Disconnect

the

Ground

connector,

the

power

connector

(P4)

and

the

DC

connectors

(P1,

P2

and/or

P3)

from

the

power

supply.

NOTE:

Only

two

connectors

are

attached

at

PI,

P2

and

P3.

Pay

close

attention

to

the

polarity

for

reference

during

reassembly.

5.

Turn

the

unit

so

the

screen

faces

you.

Remove

the

two

Phillips

screws

securing

the

power

supply

to

the

case.

6.

Slide

the

power

supply

toward

you

to

remove

it

from

the

case.

Replacing

the

Power

Supply

1.

Turn

the

unit

so

the

screen

faces

you.

Slide

the

power

supply

into

the

terminal

until

it

locks

into

the

plastic

support

bracket.

2.

Reconnect

the

Ground

connector,

the

power

connector

(P4)

and

the

DC

connectors

(PI,

P2

and

P3).

NOTE: Any

of

the

three

connectors

may

be

used.

For

example,

you

may

take

the

connectors

off

Pl

and

P2

and

replace

them

on

P2

and

P3.

3.

Insert

and

tighten

the

two

Phillips

screws

securing

the

power

supply

to

the

case.

4.

Replace

the

bezel

and

monitor

rear

housing

and

close

the

case

(See

page

1-11).

1-6

Figure

1-5

Removing

the

Power

Supply

•

FRONT

VIEW

Pi

P2

POWER

SUPPLY

POWER CONNECTOR

(P4)

__

:::::::::---tii"~"",,!!!!!,;;::."~!!!!!!!!!!!!!~~-:;

BACK

VIEW

1-7

Removing

the

Video

Module

STOPI

The

CRT

retains

high

voltages,

even

after

the

power

has

been

turned

off,

and

poses

a

potential

shock

hazard.

Follow

the

CRT

discharge

procedure

on

page

1-4

of

this

section

before

removing

and

replacing

the

video

module.

Use

Figure

1-6

as

reference

for

removing

and

replacing

the

video

module.

1.

Turn

off

the

terminal

and

open

the

case

(See

page

1-4).

2.

Turn

the

unit

so

the

screen

faces

away

from

you.

3.

Disconnect

the

voltage

lead

at

the

anode

by

gently

lifting

the

rubber

cap

and

unhinging

the

metal

lead.

4.

Carefully

remove

the

CRT

connector

(small

PC

board

at

the

back

of

the

CRT).

5.

Remove

the

power

connector

(red),

the

video

connector

(white)

and

the

yoke

connector

(blue)

from

the

video

board.

6.

NOTE:

In

some

955

terminals

the

video

module

is

on

a

base

that

slides

up

and

down~

in

others,

the

video

module

is

on

a

hinged

base.

To

determine

which

model

you

are

working

on,

check

below

the

video

module.

If

there

are

three

screws

below

the

module,

go

on

to

the

next

step.

If

not,

go

to

step

9.

7.

Remove

the

two

Phillips

screws

(one

on

each

upper

support

bracket)

holding

the

video

module

in

place.

8.

Remove

the

middle

screw

below

the

module

and

loosen

the

screw

on

each

side

of

it.

This

allows

the

video

module

to

slide

down.

9.

If

the

model

you

are

working

on

is

hinged,

you

must

remove

four

screws.

a.

Remove

the

screw

on

each

side

of

the

plate

holding

the

video

module

in

place.

b.

Remove

the

two

screws

(one

below

the

other)

on

the

right

side

plate.

10.

Remove

the

four

Phillips

screws

holding

the

video

board

to

its

base~

slide

the

board

out

of

the

terminal.

1-8

Figure

1-6

Removing

the

Video

Module

t+----VIDEO

MODULE

Replacing

the

Video

Module

1.

Turn

the

terminal

so

the

screen

faces

away

from

you.

2.

Slide

the

video

module

onto

its

base

(See

Figure

1-6)

until

the

four

screw

holes

in

the

board

line

up

with

the

four

screw

holes

in

the

base.

3.

Insert

and

tighten

the

four

Phillips

screws

holding

the

video

module

to

its

base.

4.

Reconnect

the

power

connector

(red),

the

video

connector

(white)

and

the

yoke

connector

(blue)

on

the

video

module.

5.

Carefully

replace

the

CRT

connector

(small

PCB

at

the

back

of

the

CRT).

6.

Replace

the

anode

cap:

a.

Pull

back

the

rubber

portion

of

the

anode

cap,

exposing

the

metal

leads.

1-9

b.

Pinch

the

two

leads

together

and

insert

them

into

the

opening

for

the

anode

cap

in

the

CRT.

Release

the

leads.

c.

Secure

the

rubber

portion

of

the

anode

cap.

7.

Insert

and

tighten

the

Phillips

screws

securing

the

module

to

the

case.

See

step

6

(Removing

the

Video

Module)

if

you

are

replacing

the

sliding

module.

See

step

9

if

you

are

replacing

the

hinged

module.

8.

Replace

the

bezel

(if

removed)

and

monitor

rear

housing:

close

the

case

(See

page

1-11).

Removing

the

Logic

Board

and

Shroud

Use

Figure

1-7

as

reference

for

removing

and

replacing

the

logic

board

and

shroud.

1.

Turn

off

the

terminal.

Disconnect

the

power

cord

and

data

cable(s)

from

the

back

of

the

terminal:

disconnect

the

keyboard

cable

from

the

front

of

the

terminal.

2.

Rotate

the

complete

unit

so

the

back

faces

you.

Remove

the

two

Phillips

screws

(in

the

base)

holding

the

logic

board

tray

in

place.

3.

Grasp

the

logic

board

tray

by

its

center

tab~

pull

the

tray

toward

you.

Disconnect

the

red

(P5)

and

white

(P2)

logic

board

connectors

to

slide

the

tray

completely

out

of

the

terminal.

4.

Remove

the

four

brass

screws

securing

the

shroud

to

the

logic

board;

remove

the

six

Phillips

screws

securing

the

logic

board

to

the

tray.

5.

Lift

the

logic

board

out

of

the

tray.

Replacing

the

Logic

Board

and

Shroud

1.

Align

the

six

screw

holes

in

the

logic

board

with

the

screw

holes

in

the

tray.

2.

Loosely

mount

the

six

Phillips

screws

holding

the

logic

board

in

place:

insert

and

tighten

the

four

brass

screws

holding

the

shroud

to

the

logic

board,

then

tighten

the

six

Phillips

screws

securing

the

logic

board.

3.

Replace

the

logic

board

tray

in

the

base:

a.

Fit

the

metal

flanges

on

the

logic

board

tray

into

the

guides

at

the

back

of

the

terminal.

Hold

the

connector

cables

up

so

t.hey

do

not

interfere

as

you

replace

the

tray.

1-10

b.

Reattach

the

red

connector

(P5)

and

the

white

connector

I _

"'"

\ _ __

I'

__ , _

__..!

_

'-

_ _

__

~

\~~J

on

~ne

LOgl~

UUdLU.

c.

Align

the

keyboard

connector

with

the

opening

in

the

front

of

the

terminal.

4.

Insert

and

tighten

the

two

Phillips

screws

holding

the

logic

board

tray

in

the

base.

Figure

1-7

Removing

the

Logic

Board

and

Shroud

•

9

LOGIC

BOARD

~J~iiiiii~'ii~~~~~~:::~

'~~

LOGICBOARDTRAY/

" /

'------PHILLIPS

SCREW

Closing

the

Case

1.

Replace

the

bezel:

a.

Place

the

bezel

face

down

in

front

of

the

terminal.

Raise

the

bezel

slightly

and

hook

its

two

bottom

tabs

into

the

openings

(one

under

the

contrast

adjustor;

one

under

the

ON/OFF

switch)

in

the

lower

case.

b.

Swing

the

bezel

up

to

frame

the

screen,

matching

the

ON/OFF

switch

and

contrast

adjustor

with

the

openings

in

the

bezel.

1-11

c.

Carefully

turn

the

screen

away

from

you

while

holding

the

bezel

in

place.

Insert

and

tighten

the

two

Phillips

screws

securing

the

bezel

to

the

case

(these

screws

are

located

inside

the

case,

on

on

each

side

of

the

power

supply).

2.

Replace

the

monitor

rear

housing:

a.

Position

the

monitor

rear

housing

on

the

case,

as

shown

in

Figure

1-4.

b.

Al

ign

the

screw

hole

under

the

power

cord

wi

th

the

lower

screw

hole

in

the

housing.

c.

Fi

t

the

four

tabs

in

the

hous

ing

over

the

edge

of

the

lower

case.

d.

Fi

t

the

tab

in

the

top

of

the

beze

1

into

the

s

lot

in

the

top

of

the

monitor

rear

housing.

Squeeze

the

bezel

and

housing

together.

e.

Insert

and

tighten

the

Phillips

screw

under

the

power

cord

and

the

two

Phi

11

ips

screws

near

the

top

of

the

housing.

Opening

the

Keyboard

Case

1.

Disconnect

the

coiled

keyboard

cable

from

the

front

of

the

terminal.

2.

Turn

the

keyboard

upside

down

and

remove

the

six

Phillips

screws.

3.

Turn

the

keyboard

rightside

up

and

remove

the

top

cover.

Removing

the

Keyboard

Circuit

1.

Remove

the

four

Phillips

screws

securing

the

keyboard

circuit.

2.

Lift

the

entire

assembly

out

of

the

keyboard

case.

VISUAL INSPECTION

A

thorough

visual

inspection

often

makes

the

difference

between

success

and

failure

in

a

repair

attempt.

Often

a

problem

can

be

located

just

by

close

visual

examination.

Terminal

and

Keyboard

Exterior

Look

for

signs

of

accidental

damage,

abuse,

or

neglect.

Keyboard

failures

are

often

caused

by

spilled

liquids,

sprayed

cleaning

solvents,

staples,

or

paperclips.

1-12

Are

there

any

dents

or

deep

scratches

on

the

exterior

of

the

terminal

or

keyboard?

If

so,

ask

the

user

how

and

when

the

damage

occurred.

It

may

contribute

to

the

problem

with

the

unit.

Terminal

and

Keyboard

Interior

Open

the

cases

and

inspect

the

keyboard

and

terminal

interiors.

Keyboard:

Check

for

signs

of

spilled

liquids,

foreign

objects,

unplugged

devices,

defective

traces,

and

signs

of

overheating

and

burning.

Check

the

telephone-style

connectors

(located

on

the

back

of

the

keyboard

case

and

on

the

front

of

the

terminal).

Wiring

Harness:

Check

the

condition

of

the

wires

and

look

for

crushed

insulation,

exposed

wires,

and

loose

or

broken

connectors.

Unplug

the

connectors

and

check

that

the

pins

are

intact.

Logic

Board:

Check

for

loose

chips,

bent

pins

on

chips,

defective

chip

sockets,

signs

of

overheating

and

burning,

defective

traces,

and

poor

solder

joints.

Check

that

devices

are

properly

installed.

Power

Supply:

Check

for

open

fuses,

defective

components,

and

signs

of

overheating

and

burning.

Video

Module:

Check

for

defective

components,

signs

of

overheating,

and

defective

traces.

Remove

all

defective

modules

for

closer

inspection

and

repair.

When

you

finish

the

repairs,

replace

the

module(s)

and

test

them.

FAULT

ISOLATION

AT

THE

MODULE

LEVEL

TeleVideo's

modular

terminal

design

makes

isolating

a

problem

to

a

particular

module

easy.

You

can

either

follow

Table

1-1,

Fault

Isolation

Guide,

or

replace

each

module

in

turn

until

the

fault

is

corrected.

To

use

Table

1-1,

find

the

description

that

resembles

the

problem

in

the

terminal.

Then,

if

applicable,

refer

to

the

troubleshooting

guide

for

the

suspected

module.

Table

1-1

Fault

Isolation

Guide

Symptom

No

beep

on

power

up

1-13

Suspected

Module

Logic

board

Line

fuse

Power

supply

Keyboard

Table

1-1

(Continued)

Fault

Isolation

Guide

Sywaptom.

No

video,

no

cursor

No

external

communication

Incorrect

characters

Incorrect

attributes

No

keyboard

communication

Fails

to

reset

properly

when

CTRL RESET

is

pressed

No

baud-rate

selection

Power

supply

fuse

blowing

Line

fuse

blowing

High-pitched

whine

Distorted

video

Characters

missing

dots

Display

too

dim/can't

adjust

Video

fades

Suspected

Module

Logic

board

Power

supply

Video

module

CRT

Cable

to

host

Logic

board

Power

supply

(-12V)

Logic

board

Keyboard

Logic

board

Logic

board

Keyboard

cable

Keyboard

(See

Service

Bulletin

number

65*

Logic

board

Video

module

Power

supply

See

Service

Bulletin

Number

63*

Video

module

Video

module

Power

supply

Logic

board

Logic

board

Defective

CRT

Video

module

Power

supply

Check

that

video

module

has

been

modified

as

described

in

Service

Bulletin

Number

67*

*Section

7

(Addenda)

contains

Service

Bulletins

applicable

to

the

955

terminal.

1-14

Table

1-1

(Continued)

Fault

Isolation

Guide

Symptom

Online

communication

problem

Garbled

date,

missing

data,

"p3ER"

error

message

(revision

C

and

D

logic

board

only)

False

"p3ER"

error

when

using

main

RS232

port

(in

block

mode

and

half-duplex

with

pins

4

and

5

jumpered)

Jittery

screen

Wavy

screen

Incorrect

voltages

No

light

at

cathode

filament

Display

not

equal

to

key

entry

Visible

retrace

scanlines

Keyboard

locked

up

Fails

Some

keys

inoperative

Suspected

Module

Logic

board

Cable

to

host

Host

Logic

Board

(See

Service

Bulletin

Number

64*)

Logic

board

(See

Service

Bulletin

Number

58*)

Video

module

Hertz

setting

Video

module

Power

supply

External

interference

Power

supply

Video

module

Power

supply

Defective

CRT

Logic

board

Keyboard

cable

Cable

to

host

Host

Brightness

adjustment

Video

module

Logic

board

Keyboard

cable

Keyboard

Logic

board

Software

command

Logic

board

Power

supply

(+5V)

Keyboard

Keyboard

Logic

board

*Section

7

(Addenda)

contains

Service

Bulletins

applicable

to

the

955

terminal.

1-15

Table

1-1

(Continued)

Fault

Isolation

Guide

Symptom

Horizontal

bar

across

screen

Poor

linearity

Cursor

moves,

no

characters

Vertical

line

across

screen

Crackling

sound

with

distorted

video

1-16

Suspected

Module

Logic

board

Video

module

Video

module

Logic

board

Logic

board

Video

module

Yoke

Video

module

Other manuals for 955

2

Table of contents

Other TeleVideo Touch Terminal manuals

TeleVideo

TeleVideo 910 User manual

TeleVideo

TeleVideo 925 User manual

TeleVideo

TeleVideo 965 User manual

TeleVideo

TeleVideo TeleCLIENT TC7370 User manual

TeleVideo

TeleVideo 955 User manual

TeleVideo

TeleVideo 9220 User manual

TeleVideo

TeleVideo TVI-912 User manual

TeleVideo

TeleVideo 950 User manual

TeleVideo

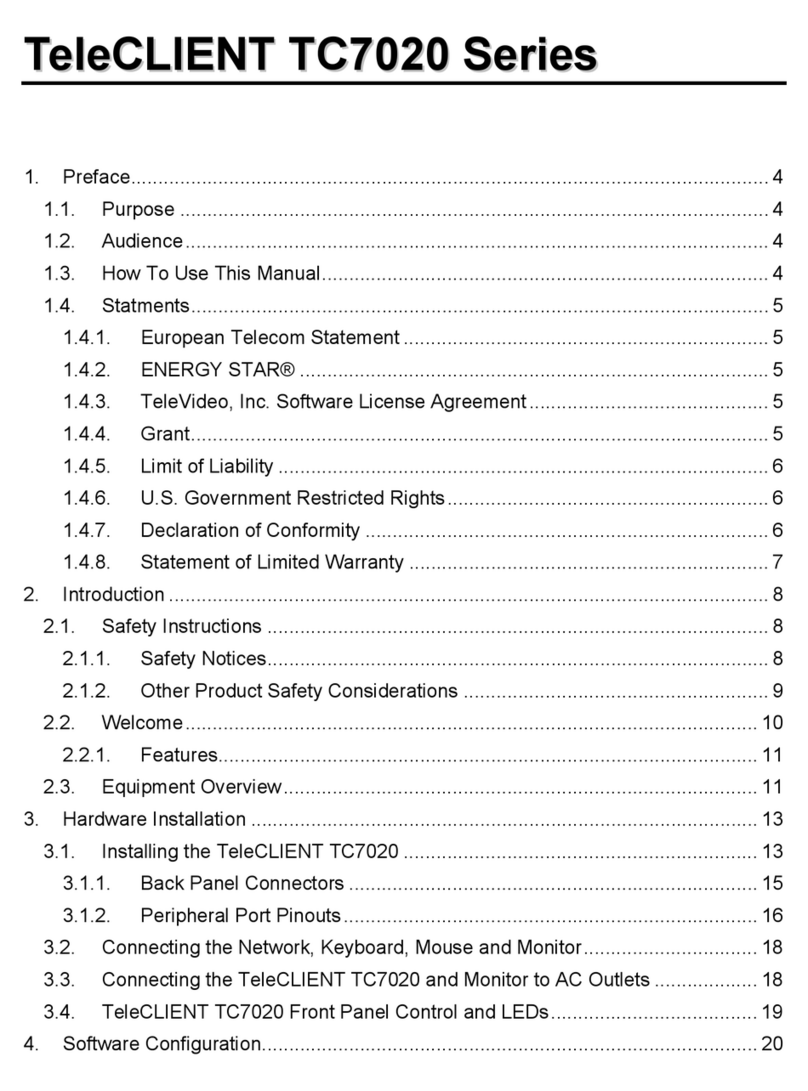

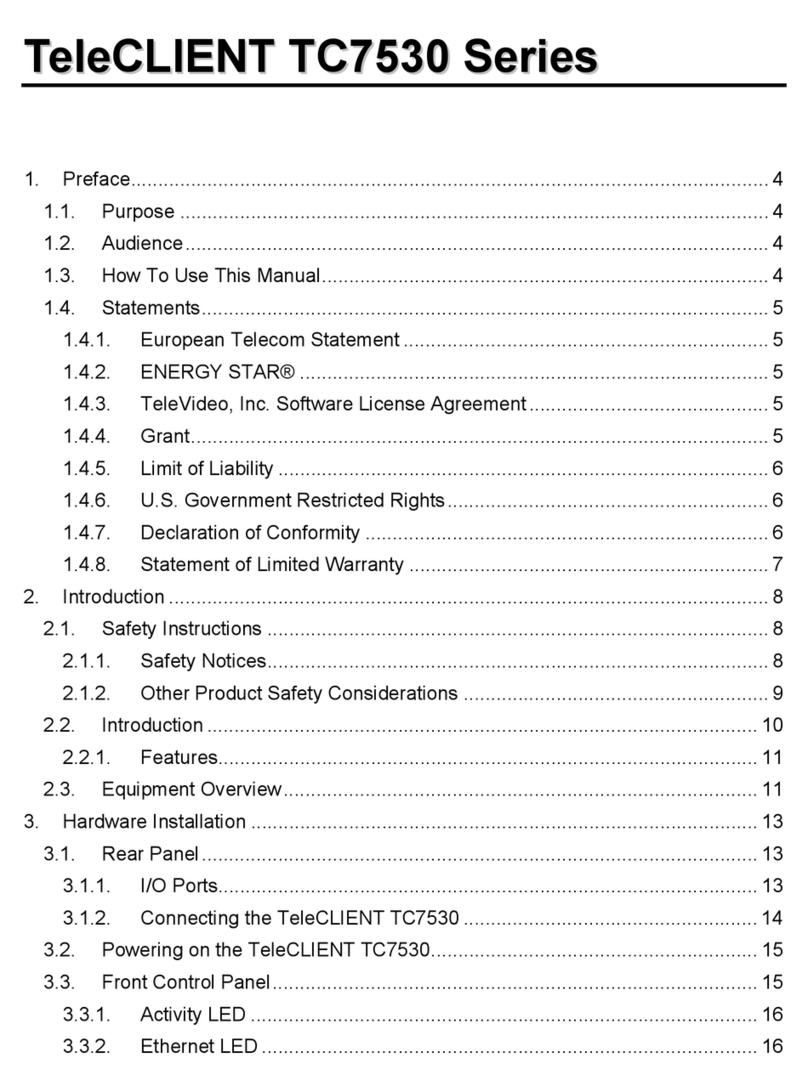

TeleVideo TeleCLIENT TC7020 Series User manual

TeleVideo

TeleVideo TeleCLIENT TC7530 Series User manual