Tellabs 293 User manual

system-installation practice section

81293-2

©Tellabs, Inc., 1

June

1982

all rights reserved, printed

in

USA

Plos

293

One-Way

Alerting

System

Installation

'irtellabs

technical manual

76-81293-2

rev A

h.

-

s5n

"m·

.

figure

1.

293

One-Way

Alerting

System

ing, and features connectorized shelves. When

the

293 System

is

located near

the

switching equip-

ment, connectorized cables permit quick intercon·

nection between

the

293

System and

the

switching-

equipment

cross-connect frame.

Station

and

switching-equipment connections to

the

293

Sys-

tem

are made via Universal Service Order Code

(USOC) RJ71C connectors. This arrangement

allows bridging plugs

to

take

the

place

of

the

293

System connectors, allowing normal

telephone

ser-

vice both before

the

System

is

installed

and

after

the

293

System

is

taken

out

of

service.

installation

and

power

1.06

The

standard 293-System Mounting Assem-

bly

is

aprewired Tellabs

Type

10

Mounting Shelf

with aconnectorized backplate.

Thisconnectorized

configuration allows quick interconnection

to

the

cross-connect frame

and

associated peripheral equip·

ment. The Mounting Assembly

or

Assemblies

mount

in

astandard 19-inch

or

23-inch relay rack

or

in

acabinet, either

of

which

is

optionally avail-

able with

the

System.

The

System

is

powered from

-48Vdc

filtered, ground-referenced

power

supply

or

battery. This voltage source can be provided

via

astandard telephone-type power supply

or

by

shar-

ing

the

PBX's

battery,

as desired.

page 1

page 1

page

19

page

11

page9

page9

contents

section 1general information

section 2installation

section 3system wiring diagram

section 4module block diagrams

section 5system specifications

section 6testing

and

troubleshooting

1. general

information

1.01

The

Tellabs

293

One-Way Alerting System

(figure

1)

is

amultistation ringdown

telephone

cir-

cuit

used

in

emergency-alerting applications. With

the

293

System, large numbers

of

people can be

simuItaneously alerted via their telephones when

emergencies such as fires, industrial accidents,

or

threatening

weather

conditions

occur. Thus,

the

293

System can serve small communities, hotels,

motels,

apartment

buildings, condominiums, high-

rise buildings, hospitals,

department

stores, shop-

ping malls, schools,

campus

facilities, factories,

chemical and nuclear facilities, and numerous

other

applications where personnel require immediate

notification

of

emergency

and/or

evacuation pro-

cedures when disaster

threatens

or

strikes.

1.02

In

the

event

that

this Practice section

is

re-

issued,

the

reason

for

reissue will be stated

in

this

paragraph.

system configuration

1.03

The

293

System

is

modular

in

design and

configured

in

100-station increments. Each fully

autonomous

1DO-station

increment

is

subdivided

into 10-station increments, 10 stations being

the

number

accommodated

by each line-circuit module

in

a

293

Mounting Assembly. Aminimum-size 293

System consists

of

one

293 Mounting Assembly

equipped with 2common-control modules and 1

to

10

line circuit modules, aringing generator, and

apower supply. Optional

backup

batteries, a

message-announcement device, awall-mounted

activation panel,

and

a

cabinet

that

houses

all

of

the

above

equipment

(except

the

activation panel)

can be provided

if

required. 2. installation

system application site preparation

1.04

The

293

System can be used with any con- 2.01

As

defined

in

Part

68

of

the

FCC rules,

ventional PBX switching system; maximum length registered terminal

equipment

can

be

directly con-

of

each station loop

is

1000

ohms. Generally,

the

nected

to

the

telephone

network

through

standard

293

System

is

used

in

either

of

two

on-premises

connectors

referred

to

as Universal Service Order

applications. Specifically,

the

System can be

in-

Code (USOC) connectors. It

is

the

customer's

re-

stalled

in

series with

station

telephones served by asponsibility

to

inform

the

telephone

company

of

PBX, such as

in

ahotel

or

office building,

or

the

the

quantities

and

types

of USOC

connectors

that

System can be installed

in

series with

CO

lines, are required.

In

addition,

the

sequence

of

PBX ex-

such as

in

an

apartment

complex.

tension numbers for each USOC

connector

must

293-to-PBX

interconnection

be identified by cable pair

and

pin numbers. The

1.05

The

293

System

is

easy

to

install because it 293 System

is

connectorized and wired

in

accor-

is

compact

in

size, does

not

require extensive wir- dance with USOC RJ71C.

page 1

IIII

II

r

2.02

Two

blank

"293

USOC Assignment Work-

sheets" (table

1)

are

provided at the back

of

th

is

Practice

(page

15)

to

help the customer obtain the

necessary

information

to

determine equipment

re-

quirements, establish zoning groups, and provide

the necessary

information

for

the telephone com-

pany. Before ordering a293 System, one

or

more

293 USOC Assignment Worksheets must

be

filled

out

(100

stations per worksheet).

Additional

work-

sheets

are

available at no charge.

Please

call Tellabs'

Application

Engineering Group at one

of

the tele-

phone numbers listed in paragraph 6.03

of

this

Practice

for

additional

copies_

To

complete this

worksheet, the

following

is

required:

(1) The

total

number

of

stations must

be

determined.

(2) The PBX extension numbers

of

all stations

must

be

determined.

(3) The desired zone arrangements (the tele-

phone numbers

within

each

zone) must

be

defined.

These worksheets should

be

retained

for

System

troubleshooting

if

and when needed.

2.03 The customer data (table

2,

below) and

an

example

of

acompleted worksheet (table 3on

page

17

of

this Practice)

for

atheoretical three-

floor

hotel alerting application

are

provided

as

a

guide.

Please

notice

that

zones in which the

total

number

of

stations

is

not

a

multiple

of

10

causes

the remaining circuitson

that

module

to

be

reserved

for

future

stations

within

that

particular zone. This

is

because

each

module (10 circuits)

has

only

one

group

(control)

lead

to

ac-tivate all 10 cirCUits on

that

modu

Ie.

These groups

are

connected together

on the cross-connect field

to

form

zones. This in-

formation

can also

be

obtained

from

the

work-

sheet under the zone sections.

!

room

and

floor

zone

extension

numbers

1,

AI 8

administrative

phones

1

ext.

301

through

308

BI

47

rooms

2

ext.

001

through

047

C)

1

alerting

panel

2'

100

rooms

3

ext.

100

through

199

3'

25

rooms 4

ext.

200

through

224

Notes:

1) For

simplicity,

the

room

numbers

are

equivalent

to

the

room

extension

numbers.

2)

In

some applications,

the

zoning requirements

may

be

defined

bV

local

ordinances.

table 2. Customer data

for

three-floor

hotel

Note: One

8108

Ringing Generator provides

ring-

ing for 100ringers. This

must

be

taken into account

whendetermining ringing requirements where two or

more telephonesshare thesame extension number.

2.04 Once all customer data

is

determined,

the

293

USOC Assignment Worksheet

can

be

com-

pleted.

After

completing the worksheet, equipment

requirements and

the

information

necessary

for

the

telephone company can

be

obtained,

as

shown in

table 4. Table 4also contains

callout

numbers which

are correlated

with

numbers on

the

completed

worksheet (table 3)

for

easy

identification.

page 2

equipment

requirements

CD

shelf

requirements:

2

®

9391

Line

Circuit

Modules:

19

telephone

company

information

@

total

number

of

RJ71 eusoe

connectors:

17

®usoe

connector

number

and

cable

appearance

for

each

extension

number

example:

ext.

301:

tip

and

ring in

are

pins

26

and

27,

respectively,

and

tip

and

ring

out

are

pins

1

and

2,

respectively,

of

connector

J1,

shelf

1.

Note:

J1

of

shelf

2

should

be

designated

J10

(as

reported

to

the

telephone

company),

since

J9

is the

last

con-

nector

on

shelf

1.

The

telephone

company

labels

connectors

in

this

configuration

as

J1

through

J17.

zoning

information

®

zone

1

appears

on

J12,

pin

27,

W/O

wire;

zone

2

appears

on

J12,

pin

28,

WIG

wire,

strapped

to

J12,

pin

29,

W/BR

wire,

strapped

to

J12,

pin

30,

WIS

wire,

strapped

to

J12,

pin

31,

RIB L

wire,

strapped

to

J12,

pin

32,

RID

wire

zone

3(etc.)

table

4.

Summary

of

information

from

completed

worksheet

Note: Under

FCC

rules, this information

must

be

supplied to the serving telephone company.

Please

referto section7

of

the293System Description

Prac-

tice, section 8X293-1, for additional information.

inspection

2.05 The 293 One-Way

Alerting

System and its

component modules should

be

inspected upon

ar-

rival

to

find

possible damage incurred during ship-

ment.

If

damage

is

noted, aclaim should immedi-

ately

be

filed

with

the carrier.

If

stored, the equip-

ment

should

be

inspected again

prior

to

installation.

2.06

293

Systemscan vary greatly in size and con-

figuration. Therefore, theSystem shown in

th

is

sec-

tion

is

ahypothetical

"typical"

System. Th

is

System

is

configured

for

four

zones

with

varied numbers

of

stations in

each

zone. This installation

is

also

equipped

with

awall-mounted activation panel.

All

equipment

is

relay-rack mounted except the activa-

tion

panel, which

is

wall mounted. The

following

list

will

assist

in verifying

that

all necessary equip-

ment

for

this particular installation

has

been pro-

vided, and

will

familiarize

you

with

the various

mounting

assemblies, modules, and hardware.

equipment list

A. Rack-mounted equipment:

oRelay rack, 5.5 feet

high/19

inches

wide/17

inches deep.

o

Two

293A-1

Mounting

Assemblies.

DOne

8007

48Vdc

Power Supply.

DOne

8001

24Vdc

Power Supply.

o

Two

8108

20Hz Ringing Generators.

oOne pair 14-9002 (19-inch)

mounting

bars

for

ringing generators and 8001 Power

Supply.

B.

System modules and cables:

o

Two

9332

Ringing

Interrupter

and

Fuse

Modules.

system-installation practice section 81293-2

NEG.

BA

TT.

terminals on the

two

8108

20Hz Ringing Generators.

oConnect

the

negative

(-)

output

of

the

8007

Power

Supply

to

the

negative

(-)

power terminals on the

two

293

Mounting

Assemblies.

DNineteen 9391 Ten-Line One-Way

ARD

Line

Circuit

Modules.

D

Two

9394

Conference

Distribution

Am-

plifier

modules.

DOne

79-0098

Type

66

Quick-Connect

Terminal Block.

D

Twenty

50-5721

25-foot

System interface ringing

cables. 2.10 Make the

following

connections between

DMiscellaneous

22,18,

and 14 AWG wire,

the

8108

20Hz Ringing Generators and

the

293

as

needed. Mounting Assemblies (reference

to

figure 3

will

aid

C.

External

equipment:

in completing

this

wiring

procedure):

DWall-mounted activation panel. D

Use

18AWG wire

for

all ringing connections.

D

Mounting

hardware. DConnect the

RG

output

terminal

of

the first

DRequired

amount

of

25-pair 24 AWG cable

8108

to

the

RING GEN (RG) terminal on

(Belden

Type

9585

or

equivalent).

the

first 293

Mounting

Assembly.

DRequired

amount

of

two-conductor

18 DConnect

the

RG

output

terminal

of

the

AWG cable (Belden

Type

8461

or

second

8108

to

the

RING

GEN(RG)

termi-

equivalent). nal

on

the second 293

Mounting

Assembly.

mounting

cabling

2.07 The

293

System

is

designed

for

installation 2.11 Make the

following

connections via male

in aPBX

equipment

room.

All

equipment

except connectorized cables

to

the

corresponding female

the

wall-mounted activation panel

is

mounted in aconnectors (reference

to

figure 4

will

aid in com-

standard 19-inch

equipment

rack. The activation pleting

this

procedure):

panel should

be

mounted

so

that

it

is

out

of

the D

Mount

the Type

66

Quick-ConnectTerminal

way

of

equipment

used

for

everyday operations Blocks on the existing cross-connect

field.

yet

easily accessible in

the

event

of

an

emergency. DConnect a cable between

each

common-

2.08 The required

mounting

arrangement

for

control

connector

(J

12)

of

each

293

Mount-

this

typical

293

System's

equipment

is

shown in ing Assembly

to

the

connector

on

the

Type

figure 2. The

two

293

Mounting

Assemblies

mount

66

Terminal Blocks.

at

the

top

of

the

equipment

rack. The ringing

gen-

DConnect the

18

station interface cables

erators and

power

supplies

mount

below

the

last

from

the

USOC demarcation

point

(supplied

(lowermost)

equipment

shelf.

by

the

local telephone company)

to

the

installer connections correct female connectors

on

the

293

power

Mounting

Assemblies.

2.09 Before beginning the power wIring proce- activation panel

dure, ensure

that

input

power

is

not

applied

to

the

2.12 Perform

the

following

procedures

to

mount

power supplies

and/or

ringing generators. Power

the

activation panel and wire

it

to

the

293

equip-

must

be

applied

only

after

all

wiring

is

completed

ment

shelves:

and all modules

are

properly

optioned. Reference D

Mount

the activation panel on

the

wall,

fol-

to

figure 3

will

aid in

completing

this

wiring

pro- lowing

the

supplied instructions and using

cedure. Wire

the

System's

power

connections

ac-

the hardware supplied

with

the

unit.

It

cording

to

the

following

list: should

be

located in arestricted

area

to

en-

A. System

power

connections (ground

return):

sure

access

by

authorized personnel

only.

D

Use

14AWG wire

for

all ground-return D

Use

two-conductor

18AWG cable

to

wire

power

connections.

power

cable

from

the

8001

24Vdc

Power

oConnect

the

two

terminals labeled

POS.

Supply

to

the

activation panel(see figure 4).

BATT. on

the

8108

20Hz Ringing Genera- DMake connections

to

the

activation panel,

tors

to

the positive (+)

output

of

the

8007 using 24AWG 25-pair cable.

Power Supply. DRoute the cable (in accordance

with

local

DConnect

the

+

power

terminals on

each

of

codes)

to

the

Type

66 Terminal Blocks

the

two

293

Mounting

Assemblies

to

the

mounted

on

the

cross-connect

field.

positive

(+)

output

of

the 8007 Power DConnect the 24AWG 25-pair cable

to

the

Supply.

Type

66 Terminal Block

to

provide

the

oConnect

the

positive

(+)

terminal

of

the activation panel

with

the zone-assignment,

8001 Power

Supply

to

the

common

termi- trOUble, and audio connections.

Please

nal on

the

8001 and also

to

the

positive (+) refer

to

figure 5and table 5

for

wiring

terminal

of

the 8007 Power Supply. instructions and

to

the

paragraphs

below

B.

System

power

connections

(-48Vdc):

for

additional

information.

D

Use

18AWG wire

for

all

-48Vdc

power

zone assignments

connections. 2.13 Zone assignments are made

by

following

DConnect

the

negative

(-)

output

of

the

the

293

USOC Assignment Worksheets

that

were

8007 Power Supply

to

the

RG

COMM and

filled

out

in

the

site preparation section. Table 6

page

3

LINES91100

LINES4960

J9

«['6

ffl))

L1NES112

J5

«~

LAMP

lfADS

l-SO

293

~W

}J1)Jl

L1NE561-72

Jl0

QI:

I~~

i~J),

ONE-WAY

LINES

13-2.

J6

~

1~6

~gl~

Al.ERTlHGSHElFd,~

'I"""

~.

'".p

lAMPlEADS51·100

'Ir

~Jo

2!i,»VJ2

LINES

73 84 J11

QI

w

m»

teIabs

LINES

2!'>-36

J7

QI

1~6

iW]) COMMON

CONTROL

«I~

MJ9J3

liNES

85·96

J12

QI

t~6

nO§>

LINES 37-48

J'

«I"

1~}9>

, ", ",

"&lUIi'

~(!~

.1}9J

J4

,,-,

101·1·1·lel·I·§·I,~·I·101

_O·"·-"DO".·~""'''·'··'''''''''''''''

LINES97100

LlNES4960

JI

«:or"

lij»

L1NES112

J5

nl~

~

~:I~

'J~J'

~

~

LAMP

LEADS

1-50

293

~

?

.bP

L1NES6172

J10

QI

W

~~

~

ONE-WAY

LINES

13 24

J6

*""'T'~6

~l~

-.t>"...u:RTINGSHB.Fa<Tli 'I)§)

\,,-\..

="bJJ

LAMPlEADS51-'OO,..

~

2!i

J2

LINES

73-84

Jl1

Q(

t::'

~~19>

teIabs

LINES

25-36

J7,.;TII'

l~"'"

"""'I~

'1""-

\(.\ ,

-"J>P

COMMON

CONTROL

\oI..L

2'lj

pJ3

LINES

8596

J12

QI

t~6

tll)g)

LINES

37 ..8

J8«:1~

~~)9

T~'~T"tij~~Gfi+-

~I1~

;Ji]9>J4

,,-,

1·1·1·1·lel,·1~21~1'J·I·101

.....

o·'.·

.....

".·.......,..",

......

y

••

_..",..

8001 8108(2) 8108(1)

~

'00

I'" a

~

POS. BATT. 1

OO

POS. BATT.

off

NEG.BATT. 1

OO

NEG BATT.

24V0RIIID48V

RG

COM. 1

OO

RG

COM.

1°0

RG 1

00

RG

,

~

1°0

FUSE

Al.M. '0o FUSE Al.M.

~

@~

1°0

SYNC.

b0

SYNC.

\

L£.£!

1

00

~

8

FEE

T

~

-j:l

eO

n'

~

h

00

I

,

~lj

~

,

~

\-

./

,

'()l.?O

81-8007

t-------

,"'-

•

• F

EET

QQ

DU

I

1°

•

-GND l.UG

figure

2.

Typica/200-/ine

293

System

page 4

system installation practice section 81293-2

'10'(1)

8

FEET

8

FEET

-

,."'lS.96O

J$

or

t~

1e

J9

------

=POWER

WIRING

-------

=

GROUND

WIRING

--

-

--

'"

RING.

GEN.

WIRING

figure

3.

Power, ground, andringing generator wiring

page

5

I

POS. BATT I

NEG BATT

AG

COM

I

.l!.G

I

FUSE~

SYNC.

8007

TO WALL-MOUNTED

79-0098

TYPE 66

____

CONNECTORIZED

~

TERMINAL

BLOCKS (2)

/

'"

~

Cl.

J1

THRU

J4

ARE

BROUGHT

OUT

ON

25-FOOT 25-PAIR CABLE,

PART NO. (50-5721),

FOR EACH

ASSEMBLY_

I

~j

a::J

I

J§J

l

"NtS

1

1]

IINlS

I

12

.cr~

IlNlS91100

..............-

"Nt

S

49

6~

L'Nl;

YI

100

"

CiI

rc::ro

};l>

l~MP

loADS

1

5.0

293

-

Jl0

4'1','0

.~

D

"-!l

l:ll

;:jI bJl

Jl

"I...

"_---,,'

O~~

WA~

l'NISIJU

,,,,

....

PtUI,DSSl

......

fIl"TNGS01(LF

k"'\llS1324

H

CiI

~

};l>

'"

~::iJg,

'l'teIabs

(g

Iii

.1)9>"

lI"1ES

1536

L,NE$8,96

cO

......

O"'.'-'-ONIIlDL

€

it

I

a

c.eLE

~

.1

)9>"

@t'"-'-

•

--~~

11"115310

0~\§':-j;ot~f$~

61

II

::

___

_,,_._

..

,'="=,_.

0

1,,,,561

'I

o:n::

ni}§)

"'

.

----

liNtS

49

60

"em:

:,'lilJ

i_

~;tlll~~ml;:

-I

-

__

I I

1001 II8108(2) 8101(1)

" 0 " °

00

POS.BATT.

00

POS. BATT.

...

0NEG.BATT.

00

NEG

BATT.

TO

(

:MY~48V

0

RG

COM.

00

RG

COM.

ACTIVATION

00

RG

00

RG

PANEL

'000·

00

FUSE

AlM.

00

FUSE

ALM

=D=1

-

+-

00

SYNC.

00

SYNC.

00 00

•

FEET

RING

GEN.

RING

GEN.

r~

I

J5

THRU

J9 ARE

BROUGHT OUT ON

25-FOOT 25-PAIR CABLE,

PART NO. (50-5721),

FOR EACH

ASSEMBLY.

I

lQC

"=ro

figure

4.

Cabling connections

system-installation practice section 81293-2

output

This

is

the

interrupter

enable. This

output

transfers

to

an

active

ground

state

whenever

any

of

the

group

in-

puts

are

active.

This

output

is nor-

mally

not

used

and

is

prOVided

for

special-purpose

applications

only.

T

and

R

input

(tip

and

fing)

Gl,

GND

inputs

to

G10,

GNO

"

ACTIVATlm,

PANEL

SHELF 2: SECOND

100

STATlO'1S

TERMINAL

BLOCK

1

/SHELF 2SHELF 1

J12 J12

TO 293 SYSTEM

In

small

system

applications

(less

than

100

stations)

a

standard

telephone

con-

nected

to

these

terminals

can

be

used

to

activate

the

system

by

going

off·

hook.

Please refer

to

the

Tellabs

9394

module

Practice

for

additional

infor-

mation.

This

is

the

tip

and

ring

input

for

audio

bus

A.

Audio

connected

to

this

input

is

connected

to

the

first five

9391

modules.

This

is

the

tip

and

ring

input

for

audio

bus

B.

Audio

connected

to

this

input

is

connected

to

the

second

five 9391

modules.

description

A

ground

connected

to

the

ALC (all

call)

input

activates

all 9391

modules

in

the

293

Mounting

Assembly.

These

are

group

activation

inputs. A

ground

appl ied

to

G1

activates

the

9391

module

in

shelf

position

2, a

ground

applied

to

G2

activates

the

9391

module

in

shelf

position

3,

etc.

All

connections

labeled

GND

are

con-

nected

internally

(via

the

293

prewired

Mounting

Assembly)

to

the

positive

(+)

side

of

the

-48Vdc

power

supply.

input

input

input

function

IE

T-A

and

R-A

T-B

and

R-B

ALe

GND

symbol

designation

floor

(zone)

pushbutton group leads

1

to

Gl

(shelf 1)

2

to

G2, G3, G4, G5, G6 (shelf 1)

3

to

G7, G8, G9,

Gl0

(shelf 1) and

G1, G2, G3, G4, G5, G6 (shelf

2)

4

to

G7, G8, G9 (shelf 2)

shows

the

strapping

that

must be

done

for each

zone, and figure 6shows

the

locations

of

the

group leads

on

the

activation panel.

trouble

connections

2,14

For

the

293

System

to

indicate afuse,

power supply,

or

ringing generator failure, make

the

following connections: Bridge

the

trouble con-

tacts

on shelf 1with

the

trouble contacts on shelf 2

and wire them

to

the

activation panel. Please refer

to

figure 6

for

atypical wiring configuration.

N.O.

COM.

N.C.

output

These

are

normally

open,

common,

and

normally

closed

form

Crelay

contacts.

This

relay

output

is

nor-

mally used

to

indicate

system

trouble

(fault!

to

a

remote

location.

A

blown

fuse,

loss

of

ringing

generator,

or

a

loss

of

the

--48Vdc

power

supply

on

the

corresponding

293

System

Mount-

ing

Assembly

causes

th

is

relay

to

change

states.

table 5.

J12

connections

and

descriptions

table 6. Zone strapping

'--

SHELF 1:

FIRST

l00STATION$

figure

5.

293

System terminal block configuration

page

7figure

6.

Typical activation-panel interface wiring

III~

I'

I

audio connections

2.15

Each prewired

293

Mounting Assembly

is

factory wired

to

accept a

common

audio bus for

all

100

stations.

In

our

hypothetical installation,

one

common

audio message

is

used for all

lones.

To

ac-

complish this, bridge

the

T(tip) and R(ring) audio

from

the

activation panel

to

both

293

Mou.nting

Assemblies

by

making appropriate connections

to

the

Type

66

Terminal Block. Then jumper

the

tip

and ring audio from

the

terminals associated with

the

first

100

stations

to

the

terminals associated

with

the

second 100 stations. Last,

connect

the

tip

and ring audio from

the

activation panel

to

the

tip

and ring audio

on

Assembly 2. Please refer

to

fig-

ure 6

for

additional details.

must be

in

the MA5TE Rposition); set

53

to the

OFF position when manual

or

zone activation

is

being used.

DSet switch S2

(-6dB/-12dB

switch)

on

both

modules

to

the

-12dB

position.

Note: Switch S2 controls the loudness

of

the broad-

casted

message.

Setswitch S2 to the -12dBposition

for

most local applications; set S2 to the

-6dB

position

for

applications that require additional

loudness.

module mounting

2.17

After

the

9394

modules are properly op-

tioned, install

all

modules

in

their

proper positions

in

the

two

Mounting Assemblies, as shown

in

figure

8.

The

9394

module

is

factory aligned; no further

alignment

of

the

293

System

is

required.

option

switch selection

2.16

The

only optioning required

forthe

293

Sys-

tem

is

the

setting

of

three

slide switches on

the

9394

module's printed circuit board and

the

set-

ting

of

one

slide switch on

the

back

of

the

8001

Power Supply. Locations

of

these

option

switches

are shown

in

figure 7.

The

9332

and 9391 modules,

8108

Ringing Generators, and

8007

Power Supply

have

no

options. For

our

hypothetical

293

System

application, set

the

option

switches

in

accordance

with

the

following checklist (tne

9394

modules are

located

in

position

12

of

the

two

mounting shelves):

D

Set

the

24V/OFF/48Vswitch

on

the

8001

Power Supply to

the

24Vposition.

D

Set

switch

SI

(MASTER/SLAVE switch)

on

the

first

9394

module

to

the

MASTER

position.

D

Set

switch

SI

(MASTER/SLAVE switch)

on

the

second

9394

module

to

the

SLA

VE

position.

Note:

For

applications that require additional

9394 modules (Systems

larger

than 200 lines),

set S1 to the MAST ER position on only one 9394

module.

For

all

other 9394 modules, set

Sl

to the

SLAVE position.

D

Set

switch

S3

(OFF-HOOK

ALL-CALL

switch) on

both

modules

to

the

OFF

position.

Note: Switch S3 is used

in

conjunction with S1.

For other applications, set S3

to

the

ON

position

when

live

hot-line announcements

are

made

(Sl

figure

7.

Option switch locations

99999 9 9 9999 9

3 3 3 3 3 3333333

39999999999 9

2111111111 1 4

99 9 99999999 9

3 3 3 3 3 3333333

39 9 999999999

21 1 1 1111111 4

figure

8.

Module positions in Mounting Assemblies

system

test

2.18

When

all

wiring

is

completed and all cables

and modules are installed, apply power

to

the

Sys-

tem

by

plugging

the

line cords

of

the

Power Sup-

plies into aconventional 117Vac, earth-grounded

power receptacle.

To

verify

proper

operation

of

the

293 System, complete

the

checklist below.

If

any difficulties are encountered, please refer

to

the

Troubleshooting Checklist

in

section 6

of

this

Practice.

Note: Some

of

these tests require two people, one

to control the activation panel and one to verify

the System's operation.

DWith

the

System idle, verify

that

all tele-

phones connected

to

the

293

System are

functioning normally.

D

Use

a

VOM

to

verify

proper

operation

of

the

8001 and

8007

Power Supplies (nominal

-24Vdc

and

-48Vdc,

respectively).

DFrom

the

remote activation panel, verify

that

the

green power on indicator

is

on.

DWith

the

System idle, go

off-hook

with

the

telephone

set

in

the

activation panel. Con-

nect a

test

telephone

equipped with astan-

dard 31Q-type

test

plug first

to

the

audio

out

1jack and

then

to

the

audio

out

2jack

on

the

9394

module

in

the

first Mounting

Assembly. Verify

that

there

is

an audio

path

to

the

audio

out

1and audio

out

2

jacks. Repeat this

test

for

the

9394

in

the

second Mounting Assembly. (This

test

may

require

two

people.)

8001

off

24V

CEl!iD

48V

~

- +

com

8FEET

"'~

B"

0»

Off

HOOK

ALL CALL

SLAVE

_12dB

~:,

page

8

oRemove each ringing generator's fuse (lo-

cated

on

the

front

panel

of

the

8108

Ring-

ing

Generator)

one

at

atime, and verify

that

the

trouble indicator

on

the

activation

panel and

the

audible alarm

go

on. (Replace

each .fuse after the test

is

completed.)

oActivate each zone and broadcast atest

message. Verify

that

the

message

is

received

at

each telephone connected

to

that

zone.

Return

the

System

to

the

idle state when

testing

is

completed.

o

If

the

System functions normally, with no

fault signals generated, no further testing

is

required.

If

faults are encountered, refer

to

the

Troubleshooting Checklist

in

section 6

of

th

is

Practice.

5. system specifications

system

capacity

10

stations per 9391 module;

100

stations per

293

Mount-

ing Assembly; any size system can be configured by using

multiple shelves

transmission

idle System has

no

effect on normal telephone service

(because

of

direct metallic connection through module

and lack

of

bridging elements

in

System)

ringing

ring

trip loop limit:

lOOG-ohm

loop between module

and

telephone set

interruption rate:

0.5

second on,

2.0

seconds off,

±10%

(others optionally available)

voltage output: 90Vac ±15%, negatively biased at --48Vdc

frequency:

20Hz

±O.2Hz

harmonic distortion:

less

than 5%

ringing capacity: 1watt per station average; 100 stations

total per

293

Mounting Assembly

audio

compression range:

-25

to

-5dBm

output

level:

-6dBm

or

-12dBm,

switch selectable

frequency response: ±1.0dB.

re

1000Hz,

300

to

3000Hz

answered-eallloop current

approximately

5mA

lamp-lead drive current

SOmA

maximum to anegative-dc voltage return

power

requirements

dc input voltage:

~4

to

-56Vdc,

filtered, positive-

ground-referenced

dc input current: (per 10o-station Mounting Assembly

and

ringing generator) system idle,

0.25

amperes maximum;

system active, 3amperes maximum

operating environment

32'

to

122'F

(0'

to

50'CI.

humidity

to

95%

(no condensation)

dimensions

Mounting Assembly:

5.92

inches (15.04cml high

17.5 inches

(44.45cm)

wide (exclUding mounting ears)

9.5 inches (24.1cml deep

ringing generator:

4.75 inches (12.07cm) high

7.0

inches (17.78cm) wide

7.25

inches (18.42cml deep

page 9

system-installation practice section 81293-2

weight

approximately

19

pounds (8.7kg) (for a100-line System

with

no

ringing or power)

mounting

prewired

293

Mounting Assembly: 19-inch

or

23-inch relay

rack and 6inches

of

vertical rack space

ringing generator: KTU apparatus case or relay

rack

via

mounting bars

6. testing and troubleshooting

6.01 The test procedures and Troubleshooting

Checklist

in

this section may be used

to

assist

in

the

installation, testing,

or

troubleshooting

of

the

293

One-Way Alerting System.

The

tests and Check-

list are intended

as

an aid

in

the localization

of

trouble

to

aspecific Mounting Assembly

and/or

module.

If

a293-System Assembly

or

module

is

suspected

of

being defective, anew

one

should be

substituted and

the

test conducted again.

If

the

substitute item operates correctly,

the

original

should be considered defective and returned

to

Tellabs for repair

or

replacement.

In

compliance

with FCC Registration, no internal (component-

level) testing

or

repairs must be

attempted

on

the

modules

or

Assemblies

in

the

293

System. Return

malfunctioning items

to

Tellabs for repair

or

re-

placement. Unauthorized testing

or

repairs may

void

the

item's warranty.

6.02

Tellabs warrants

the

293

System Assemblies

and modules

to

be free

of

defective components,

workmanship, and design for aperiod

of

two

years

from the date

of

manufacture, when applied

as

outlined

in

our

Practices, subject

to

handling and

installation commensurate with industry standards

for solid-state electronic equipment.

If

a293-System

Assembly

or

module does

not

prove

to

be free

of

defective components, workmanship, and design

under these criteria, Tellabs will replace

or

repair it

free

of

charge.

Note: Warranty service does

not

include

removal

of

permanent

customer

markings

on

the

front

panels

of

Tellabs modules,

although

an

attempt

will

be

made

to

do

so.

If

a

module

must

be

marked

defective,

we

recommend

that

it

be done

on

a

piece

of

tape

or

on

aremovable

stick-on

label.

6.03

If

asituation arises

that

is

not

covered

in

the

tests and Checklist,

contact

Tellabs Customer

Service

at

your

Tellabs Regional Office

or

at

our

Lisle, Illinois,

or

Mississauga, Ontario, Headquarters.

Telephone numbers are

as

follows:

US

central region: (312) 969-8800

US

northeast region: (412) 787-7860

US

southeast region: (305) 645-5888

US

western region: (702) 827-3400

Lisle Headquarters: (312) 969-8800

Mississauga Headquarters: (416) 624-0052

6.04

If

a293-System Assembly

or

module

is

diagnosed

as

defective,

the

situation may be reme-

died by either replacement

or

repair

and

return.

Because it

is

more expedient,

the

replacement

page 10

procedure should be followed whenever time

is

acritical factor (e.g., service outages, etc.).

replacement

6.05 To obtain areplacement

293

System Assem-

bly

or

module, notify Tellabs

via

letter (see ad-

dresses below), telephone (see numbers above),

or

twx

(910-695-3530

in

the

USA,

610-492-4387

in

Canada).

Be

sure

to

provide

all

relevant informa-

tion, including

the

8XXXX(X) part number

that

indicates the issue

of

the

item

in

question. Upon

notification, we shall ship areplacement item

to

you.

If

the

item

in

question

is

in

warranty,

the

replacement

will

be shipped

at

no charge. Pack

the

defective 293 System Assembly

or

module

in

the

replacement item's carton, sign

the

packing slip

included with the replacement, and enclose it with

the

defective item (this

is

your return authoriza-

tion). Affix

the

preaddressed label provided with

the

replacement item

to

the

carton being returned,

and ship

the

item prepaid

to

Tellabs.

repair and return

6.06 Return

the

defective 293-System Assembly

or

module, shipment prepaid,

to

Tellabs (attn:

repair and return).

in

the

USA:

Tellabs Incorporated

4951 Indiana Avenue

Lisle, Illinois

60532

in

Canada: Tellabs Communications Canada, Ltd.

1200 Aerowood Drive, Unit

39

Mississauga, Ontario,Canada

L4W

2S7

Enclose an explanation

of

the

item's malfunction.

Follow

your

company's standard procedure with

regard

to

administrative paperwork. Tellabs

will

repair

the

item and ship it back

to

you.

If

the

item

is

in

warranty, no invoice

will

be issued.

293 System testing

6.07 After

the

293 System

is

installed and op-

tioned, it must be tested

to

verify proper System

operation. Two sets of tests are required. The first

set

of

tests

is

performed with

the

System

in

the

idle condition (power applied

but

not

in

the

alert-

ing

state). The second set

of

tests requires

the

293

System

to

be activated (in the alerting state). The

second set

of

tests should include

the

broadcasting

of

a

live

or

recorded test message

to

all

stations.

6.08

As

acourtesy, be sure

to

give

prior notice

to

System station users

that

testing

will

be con-

ducted

at

aprescribed time. The station users should

be informed

that

they will be involved

in

the

test

of

the

emergency alerting system and

that

it

is

only

atest. They should also be told

that

when

the

test

begins, they

will

hear distinctive ringing on their

telephones and

that

calls

in

progress

will

be

cut

off;

when

the

calls are answered, atest alerting message

will be received.

idle System

test

procedure

Note: This

first

set

of

tests

is

made

with

the Sys-

tem in the idle state. Some

of

these tests

may

re-

quire

two

people

to

complete.

If

the System fails

any

of

the

following

tests, proceed

to

the Trouble-

shooting

Checklist

for

specific procedures.

6.09

To

test

the

System

in

the

idle state, proceed

as follows:

A)

Verify

that

all

telephones connected

to

the

293 System function normally

D.

B)

Use

a

VOM

to

verify

that

the

proper out-

puts

of

all

power supplies and ringing genera-

tors are present

D.

C)

Verify

that

all

of

the

fault

indicators

on

the

front

panels

of

the

9332

modules are

off

D.

D)

Verify

that

all

of

the

trouble

indicators

on

the

System's activation panel are

off

D.

E)

Disable

the

8108

Ringing Generators

one

at

atime by removing their front-panel fuses.

Ver-

ify

that

the

fault

indicators

on

the

associated

9332

modules and

the

trouble

indicators

on

the

activation panel are

on

D.

F)

Go

off-hook with

the

telephone set

in

the

activation panel. Connect atest telephone

equipped with astandard

310

test plug first

to

the

audio

out

1and then

to

the

audio

out

2jacks on a

9394

module. Verify

that

there

is

an audio path

to

the

audio

out

1and audio

out

2jacks (audio Aand audio

B)

D.

Repeat this test for

the

other

9394

modules

used

in

the

System

D.

This test may require

two

people,

one

to

broad-

cast amessage from

the

activation panel and

one

to

perform

the

tests

in

the

equipment room.

active System

test

procedure

Note: This second set

of

tests requires

activation

of

the

293

System. Some

of

these tests

may

re-

quire

two

people to complete. Before

starting

this

test,

notify

station users

that

their

telephone ser-

vice

WI'll

be

interrupted

and

that

atest alerting

message

will

be broadcast.

If

the System fails

any

of

the

following

tests, proceed

to

the Trouble-

shooting

Checklist

for

specific procedures.

6.10 To test

the

System

in

the

active state, pro-

ceed

as

follows:

A)

1.

If

the

293 System

is

equipped with a

recorder, record

the

following message:

"This

is

atest

of

the

emergency alerting

system.

In

the event

of

an actual emer-

gency, you would be given specific instruc-

tions. Thank

you."

2.

If

the

293 System

is

not

equipped with a

recorder,

the

message

in

step Amust be

verbally repeated while steps Bthrough D

are conducted.

B)

Activate each zone (floor, room, etc.) one

at

atime and verify

that

only

the

stations with-

in

that

zone are ringing

at

adistinctive rate D.

Note:

Any

stations

that

are engaged

in

normal

telephone calls

at

this

time

are disconnected

and

immediately

transferred

to

the

audio

message.

C)

As

the

stations with

in

an activated zone are

answered, verify

that

they receive

the

one-way

alerting test message D.

D)

Deactivate

the

zone and verify

that

normal

telephone service

is

restored

D.

system-installation practice section 81293-2

(33

-48vdcl

~5

56

RING. GEN.

OUT

PHASE 1

54

RING, GEN.

OUT

PHASE 2

52

RING. GEN,

OUT

PHASE 3

50

RING.

GEN.

OUT

PHASE 4

4B

RING. GEN.

OUT

PHASE 5

18

INTERRUPTER

ENABLE

17

GNO

/

"-

/

"-

GJ

/

"-

INTERRUPTER

1

I--

'-l,

[2]

"-

"-

INTERRUPTER

hJ

2/

~l0

/

fot----

"-

"-

INTERRUPTER

ru

3/

~l,

0

/

fot----

"

"-

INTERRUPTER

~

4/

---L0

I--

"-

"-

INTERRUPTER

n::;

r5/

....

1,0

,

GATING /

LOGIC

INTERRUPTER

CONTROL

~L[2]

AND

TIMING

(0.5 SECOND ON. ,

2SECONDS

OFF

/

'----

IN

SEQUENCE,

/PHASES 1

THROUGH

5)

---L0

"-

/

-Yin

1-+1,0

,

/

---L~

"-

/

1-+1,

G2J

"

lrv

/

LEJ

FAULT

"

-V,,_ POWER

DETECTOR

/

SUPPLY

//

Kl'8

[fAULT

(

(NORMALLY

K

ENERG.ZEDl 1

Kl'

/,-

~

.. CONTACTS SHOWN

55

RING

GEN IN

44

42

40

38

36

34

32

30

28

24

25

N.C.

27

COM.

29

N.D.

ENERGIZED

9332

Ringing

Interrupter

and

Fuse

Module

4. module

block

diagrams

page

11

819332

I

~I~f----,A~U~D~IOINPUT

,---

--

ISTATION

,

-48Vdc

AUDIO

INPUT

RING

TRIP

RELAY

NEG

RING

GEN

RING

TRIP

DETECTOR

,---'-------------7

~IN

rt-------------7~;

IN

1----t-f--<~------__::~~-j_1-._---------:,~~

OUT

TRANSFER

RELAY

LAMP

LEAD1~

,,-~---------------------'

LAMP

LEAD

~

"--------------~----------'

'"-'~.---;;R~IN~G=TR=IP-~---~+~,-t--.,...~------7~~

OUT

RELAY

TRANSFER

RELAY I0 0

I

~

I2J

IISTATION

1

ONLY)

-"'-

J

LATCH

[

AUDIO

INPUTS

ITO

EACH

STATION)

-48Vdc

DRIVER

I

R~N~Lr~IP

L _

3e

,/------,11<.1-----<

••

-.48Vdc

-48Vdc

'"

GJ6

'~------l'

36

L/c----------~

... NEG.

RING

GEN

INPUTS

NEG.

BIAS"

ITO

EACH

STATION)

RING

GEN

AUDIO[':J

INPUT

,

GROUP

LEA1~

<;------/

LAMP

LEAD

~

<C-----~--~-----------------'

LAMP

L

EAD

1

~

<e---t-+olt_--i

ISTATION

11

LAMP

LEAD

~

"-------------------------~--!

LAMP

LEAD

j

<;-

J

LAMP

LEAD:

<;-------~--~------------~---!

r-

- --

-"lC-,

---c;;''>~~

IN

I

I)

~11N

,---------1

STA~ION

I

~

50

I

,/R20UT

II

~

52

L _ --.J 7T2 OUT

1-

- -

---'L---'1>~~

IN

, 1

"

'~48

I

STATION

,-

7

T3

IN

,--------;

3 ' "

I

7~~OUT

It

......

47

L--.J 7T3 OUT

,---i

'\.42

II7

R41N

I

,,,

43

,

--j

STArlON

I7

T4

IN

I

)~10UT

I

'"

L

~

7~OUT

,-

- -

-"

-----»'37

I

:-

7

R5lN

1 I

I-

__

~"

39

I 7 T5

IN

r-~--,

STA~ION

I

~

38

I 7

R50UT

I I

~

40

l-

J

/T50UT

,-

- - - -"

__

'~3'

:-

7

R6

IN

I '

I

If------?'

33

r--~,

STATION

I

/T6IN

6

"---"7

32

, 7

R60UT

I I

~

34

L

----.J

/T60UT

,----l

"27

II7

R71N

I

STATION

I )

~~

IN

c---1,

'1

"-

II

7~~OUT

LJ

>~~OUT

i---

-j

)

~~

IN

I

I)

~~

IN

STA;ION

I " 23

I I

/R80UT

I I

~

25

L

-.J

/T80UT

i - - -

~

1 )

~~

IN

1I "

21

n

STATION

I7

T91N

3~

19I\2R090UT

LAMP

"AD:

1 7

~~

L~~_~~r---->7~~OUT

LAMP

LEAD9

<;--------~--~-------------------

i - - -

~-'f-i

----;;.7

~~o

IN

II " 15

./'--

~ ~ ~ ~

___J!

STATION

I7

T10

IN

LAMP

LEAD

16 \

110

:

~14

Ii

/R100UT

L

~_~_J

)

i~OOUT

9391 Ten-Line One-Way

ARD

Line Circuit Module 819391

4. module block diagrams

page

12

system-installation practice section 81293-2

"

cow

IMPEDANCE

OUTPUT

,

l

;'

REMOTE T

CONSOLE

""

t'

AUDIO

1

INPUT

"

(

,

AUDIO 2

INPUT

"

<II

AUDIO

(

L~

~

~

OUTl

-'(

)

,7

V-

V

t=:y

<I

£----A

0

-~

)

-12dB "

l: --

-=-,

1

1

<I1I

'0",0

I

L~

~

I

~

OUT

2

I'( )

,7

V-

IV

t=:y

<I1

£----A

0

1

-6dB

I

-1~

")

~

~

--

-

7-

~

V

c

~

~

SLAVE

/"BATTERY I----

-v

..

FEED

"

~

:MASTER

,"0

~

0

fiLTER

I

II-

0"

I

SLAVE

", IOFF-HOOK ""

"MASTER

-I

DETECTOR (OFF-HOOK

ON

I/

ALL

CALLI

"

I"

j/

r"

I/

"

v, I/

POWER

"-

"- SUPPLY

v,

/

"

/II/

"

J-

"

r/

-

"-

I/

I/

"

I/

"

/

'J

lOW

IMPEDANCE

OUTPUT

•

"

ALL

CALL

"

GROUP 1

"

GROUP2

"

GRQUP3

"

GROUP4

"

GROUP

5

"

GROUP

6

"

GROUP 7

,

GROUP B

,

GROUP

9

,

GROUP 10

,

RINGING

INTERRUPTER

ENABLE

;,II~

I'

I

9394 Conference Distribution Amplifier module

4. module block diagrams

page

13

819394

troubleshooting checklist

Note:

If

afault

is

isolated to aparticular module in the

293

System

but

cannot

be

corrected with the information provided in

this checklist, please refer

to

the rellabs

module

Practice

for

detailed testing information.

problem steps toward solution

normal

telephone

service

is

dis- 0Remove the 9391 module

that

controls

the

defective telephone circuits. (Refer

to

rupted

when

System

is

idle. the

"293

usce Assignment Worksheet" for

the

exact

module location,)

Note: Because special spring-loaded card-edge connectors are used, the System is

effectively bypassed when the 9391 module

is

removed.

D

If

normal telephone service

is

restored, replace with anew 9391 module and retest.

If

normal telephone service remains disrupted:

oVerify cable assignments on worksheet(s).

oVerify cabling

on

the

RJ71C

USOCconnectors.

oUse aYOM (set

to

ohmmeter

function)

to

verify

continuity

through the

293

System

(T

in

to

Tout,

R

in

to

Rout, etc.).

power supply's

output

voltage 0Use aYOM (set

to

voltmeter

function)

to

verify

115Vac

input

(105

to

120Vac).

is

low

or

not

present 0Verify wiring from power supply

to

equipment

shelves.

Disconnect the

output

wiring from

the

power supply and check

the

following:

o

If

voltage

is

still

out

of

range, replace power supply.

o

If

voltage

is

present, remove

all

modules from System and recheck voltage.

o

If

voltage

is

out

of

range, verify wiring.

trouble condition present on 0Replace blown fuse

in

the

9332

module.

one

of

the

9332

modules

or

on

If

ringing generator

input

to

shelf

is

not

present, check

the

following:

the System's activation panel o

Use

a

VOM

(set

to

voltmeterfunction)

to

verify ringing voltage on rear terminal strip.

o

If

correct voltage

not

present, verify wiring.

D

If

wiring

is

correct, replace ringing generator and retest.

D

-48Vdc

input

is

out

of

range; refer

to

previous

step

("power

supply's

output

voltage

is

low

or

not

present").

0Verify wiring

to

System's activation panel.

loss

of

ringing generator does (When

the

fuse on aringing generator

is

blown

or

removed, afault indication

is

present

not

generate afault condition on both the associated

9332

module's

fault

LEO

and on

the

System's activation panel.)

o

If

the

9332

module does

not

indicate afault, replace and retest the

9332

module.

If

the

activation panel does

not

indicate afault, check the following:

oVerify wiring

to

the

activation panel.

oReplace and retest

the

trouble

indicator

section

of

the activation panel.

one

of

the audio distribution 0Verify wiring

to

the

293

prewired Mounting Assembly.

busses

is

inoperative 0Replace

the

9394

module

and

retest.

station telephones outside

of

the

0Verify zone wiring.

selected zone are being alerted 0Replace

9394

module associated with the affected lines and retest.

station telephones within a

se-

DVerify zone wiring.

lected zone fail

to

ring 0Replace associated 9391 module and retest.

0Replace associated

9332

module and retest.

alerted stations within aselected 0Replace the associated 9391 module and retest.

zone

do

not

hear

the

alerting

message

normal telephone service

is

not

oReplace

the

associated 9391 module and retest.

restored when the

293

System

is

deactivated

page

14

_._-_.~

NOTE'

CABLE PAIRS SPARE

293

usoe

939

I ( ri

s;;;;;

m

Jl

8K/S

Y/O

17

O/Y

V/BR

19

SR/Y

VlBl

21

BLiV

V/G

23

GIV

49

V/SR

W/BL

IBL/W

21

WIO

WIG

3

G/W

29

W/8R

#,"21,,","1 f.>}

I')

]l.,pv 1

W/S

5

S/W

31

R/Bl

939

"""

RIO

7

OIR

33

RIG

R/BR 9BR/R

35

RIS

BK/BL

II

BL/BK

37

BK/O

BK/G

13

G/BI<

39

SK/BR

SKiS

15

SlBI<

41

YI

BL

Y/O

17

O/Y

43

Y/G

2

22

Ol~

44

V/BR

19 SR/V

45

VIS

3

23

C';i,';";

46

VIal

21

BLiV

41

VlO

4

24

QI'I

48

VlG

23

GIV

49

VlBR

(

3)

I5

25

ZONE

o

ll!)'

26

W/SL

I

Bt/W

27

WIO

6

26

(")

Uo

28

WIt:)

:3

G/w

29

W/BR

721 (G"3 )

8

28

JI2

9

29

10

30

I

31

32

33

34

9391

(4)

38

39

40

J4

9391

(7)

J7

00

.....J>

I'V

to

W

r'->

page

19

2)

PIN

SPARE

TO

36

rh~nli"~m

(page

2

page

Table of contents

Popular Security System manuals by other brands

RS

RS 566-780 instruction manual

Esse-ti

Esse-ti Helpy GSM quick guide

aquilar

aquilar AquiTron AT-RAP-230 Installation & operation instructions

AMC

AMC SR136 manual

Whelen Engineering Company

Whelen Engineering Company B6LED Series installation guide

DMP Electronics

DMP Electronics 135 Series installation guide

M-system

M-system AS4V instruction manual

AJAX

AJAX MotionProtect quick start guide

Honeywell Home

Honeywell Home SMART HOME SECURITY quick start guide

Bosch

Bosch Security Escort SE2005 Installation, operating and maintenance guide

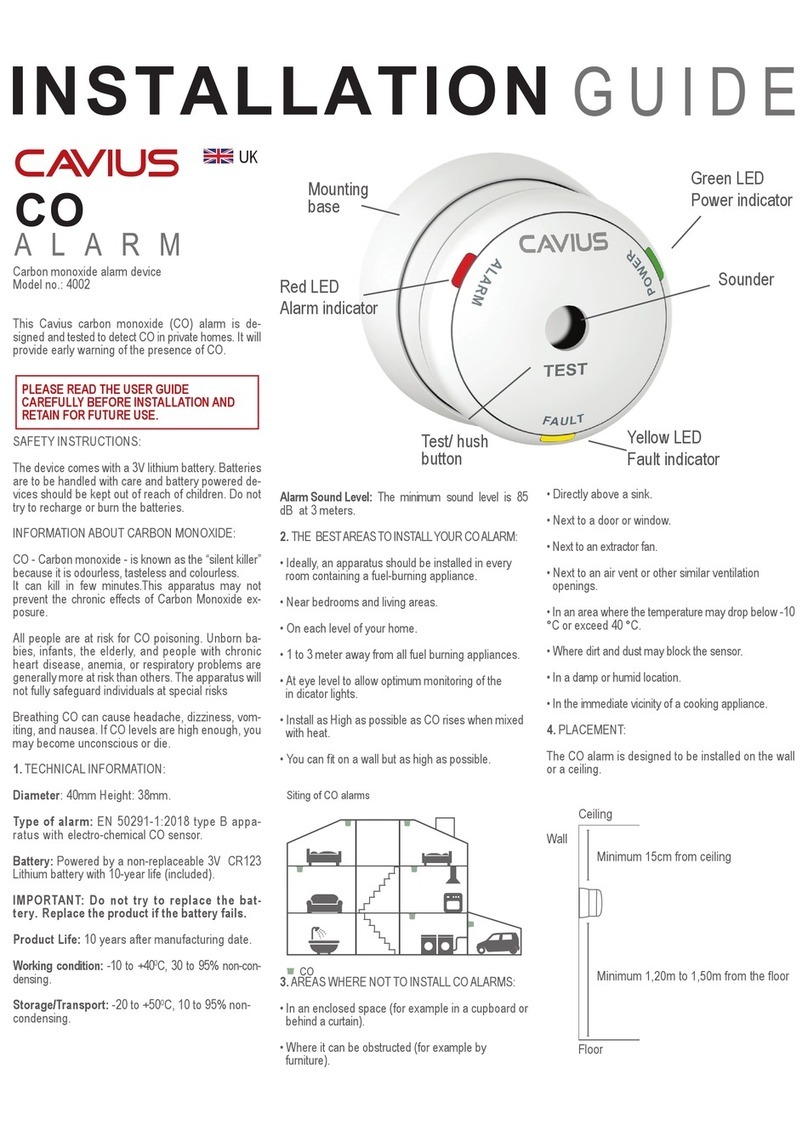

Cavius

Cavius CO ALRM installation guide

HIK VISION

HIK VISION DS-PD1-EB-WS2 manual