TEM Opera Plus Series User manual

Codice

TM050E_10

Quality Management System

Tipo

Operation Manual

Rev.N° 10

0

del

19/03

/2019

Titolo

A07

EXXXX

–

1 Unit Transmitters

Eco line

A07EXXXX

Prefix

One Unit Transmitters

A07E

XXXX

Watt

0011

10

0021

20

0031

30

0051

50

0101

100

0201

200

0251

250

0301

300

0401

400

0501

500

Operation Manual

© 2014 - 2027 Copyright by:

Telecomunicazioni Elettroniche Milano Srl

Via Copernico, 11

20082 Milano, Italy

All rights reserved.

All specifications, characteristics and circuit descriptions set forth in this manual are subject to change

withoutnotice.

TEM A07EXXXX – 1 Unit Transmitters Page 2

1Revision Index

Revision

date

Description

Re

vision Autor

0

04/11

/2014

Original draft

Antonio Fiordelisi

01

03/02/2015

Rev.Cap 3.3

–

3.4

-

4.9

Antonio Fiordelisi

02

09/02/2015

Capter 4.11

page 18 & Rev.Pages 19

-

20

Antonio Fiordelisi

03

25/02

/2015

Rev page 21

-

34

-

35

Antonio Fiordelisi

04

02/03/

2015

Pag 08

Antonio Fiordelisi

05

22/05/2015

Pag 15

-

16

-

24

Antonio Fiordelisi

06

21/11/2016

Pag

14

-

15

-

16

-

25

-

36

Antonio Fiordelisi

07

02/06/2017

Pag 16

-

17

-

18

-

84

-

85

-

86

-

87

-

88

Antonio Fiordelisi

08

01/02/2018

Pag 21

Antonio Fiordelisi

09

25/02/2019

Pag 2

-

1

8

-

84

-

85

-

86

-

87

-

91

-

92

-

93

-

116

-

121

Antonio Fiordelisi

10

19/03/2019

Pag

1

-

19

-

2

0

Antonio Fiordelisi

TEM A07EXXXX – 1 Unit Transmitters Page 3

2Contents

1 RevisionIndex...................................................................................................................................... 2

2 Contents.............................................................................................................................................. 3

3 SAFETY INSTRUCTIONS........................................................................................................................ 5

3.1 Introduction................................................................................................................................. 5

3.2 Safety suggestion......................................................................................................................... 7

3.3 General safety recommendations................................................................................................. 8

3.4 Goodpractices ............................................................................................................................. 9

3.5 Procedure for establishthe absence of voltage............................................................................10

3.5.1 Procedure for determination of the absence of voltage.......................................................10

3.6 First aid in case of electrical shock...............................................................................................11

3.7 Emergency resuscitation technique.............................................................................................11

3.7.1 Treatmentforburns ............................................................................................................12

3.8 Electricsafety precautions...........................................................................................................12

3.9 Electrostaticprecautions.............................................................................................................12

3.10 Waste electrical and electronicequipment (WEEE)......................................................................13

4 ELECTRICAL SPECIFICATION................................................................................................................14

4.1 FREQUENCY-POWER..................................................................................................................14

4.3 MODULATION CAPABILITY...........................................................................................................15

4.4 CHARACTERISTICS IN MPX...........................................................................................................15

4.5 CHARACTERISTICS IN MONO........................................................................................................15

4.6 CHARACTERISTICS IN STEREO ......................................................................................................16

4.7 SCA-ExtRDS CHARACTERISTICS..................................................................................................16

4.8 REMOTE CONTROL......................................................................................................................16

4.9 POWERSUPPLYAND TEMPERATURERANGE...............................................................................17

4.10 MECHANICALSPECIFICATION......................................................................................................17

4.11 INTERNAL MAIN MODULES..........................................................................................................18

4.12 OPTIONS......................................................................................................................................18

5 Dichiarazione di Conformità UE...........................................................................................................19

6 EU Declaration of Conformity (DoC) ...................................................................................................20

7.0 AUX I/O Rear Panel Interface DB15-DB09 Connector Description .....................................................21

7 GENERAL DESCRIPTION......................................................................................................................22

7.1 Mainfeatures..............................................................................................................................22

8 INSTALLATION.....................................................................................................................................23

TEM A07EXXXX – 1 Unit Transmitters Page 4

8.1 Unpacking and inspection...........................................................................................................23

8.2 Installation..................................................................................................................................23

8.3 Power supply...............................................................................................................................23

8.4 Groundloops...............................................................................................................................23

8.5 Rear Panel Description................................................................................................................24

8.6 AudioInputsConnectorsDescription...........................................................................................25

8.7 Audio Alarm Detector & Automatic Audio Changeover Description.............................................25

8.8 Transmitterpowerup..................................................................................................................26

8.9 Front Panel Description...............................................................................................................26

8.10 Transmittersettings(referredA07E0501model).........................................................................27

9 DIAGRAMSANDPARTLIST..................................................................................................................40

TEM A07EXXXX – 1 Unit Transmitters Page 5

3SAFETY INSTRUCTIONS

3.1 Introduction

T.E.M. has always managed to improve the safety standard if its transmitting and receiving equipment. All

produced systems are tested in compliance with international rules.

Obviously this is not sufficient to avoid any accident during the installation and the use of our equipment in

compliance with EN60215 rule, the radio transmitters and the auxiliary equipment must be used by

qualified technical staff only and T.E.M. declines any responsibility for damages caused by an improper use

or improper setting up performed by inexperienced staff, not qualified or operating with instruments or

tools notin compliance with safety set of rules.

WARNING

CURRENT AND VOLTAGE WORKING IN THIS EQUIPMENT ARE DANGEROUS. THE STAFF

MUST ALWAYS OBSERVE THE SAFETY RULES, INSTRUCTIONS AND NORMS CONTAINED

HEREIN.

THE INSTRUCTIONS CONTAINED IN THIS MANUAL MUST BE READ BEFORE SWITCHING ON

OR SETTING THE TRANSMITTER

ANY TRANSMITTER SERVICING, REPAIRING OR CHECKING OPERATION REQUIRING THE

OPENING OF THE TOP OR BOTTOM COVER, MUST BE PERFORMED AFTER THE MAINS

SUPPLY DISCONNECTION WITHOUT REMOVING THE EARTH CONNECTION WHICH THE

EFFICIENCY MUST BE VERIFIED: THE CABLE MUST BE IN GOOD CONDITIONS AND WELL

CONNECTED.

STAFF OPERATING UPON THE TRANSMITTER SYSTEM MUST NOT BE TIRED: AFTER HEAVY

WORKS OR CARRYING HEAVY MACHINES BY HAND, IT IS NECESSARY TO RESPECT A PERIOD

OF REST BEFORE WORKING WITH SYSTEMS WHICH COULD HAVE DANGEROUS ELECTRIC

VOLTAGE IF THEY ARE NOT DISCONNECTED.

SEVERAL SYMBOLS, INSIDE THE TYPICAL TRIANGLE SHOWING DANGER, HAVE BEEN

PRINTED ON SEVERAL TRANSMITTER PARTS. ATTENTION SHOULD BE PAID, BECAUSE THERE

COULD BE THE DANGER DUE TO HOT SURFACES, ELECTRIC VOLTAGE HIGHER THAN 50VOLT

OR OTHER SPECIFIED DANGERS.

Certain devices (for example the RF final circuits mosfets) contain Beryllium Oxide BeO; these components

must not be broken, crashed or heated. This oxide passes through the common systems of filtering,

including the respiratory apparatus. The prolonged inhalation at high degrees causes poisoning with

respiratory apparatus paralysis, till death.

TEM A07EXXXX – 1 Unit Transmitters Page 6

WARNING

ALL THE MODULES CONTAINING BeO ARE MARKED WITH THE TRIANGULAR WARNING SYMBOL

INDICATING THE NOTICE:

WARNING ! TOXIC HAZARD

THESE DEVICES CONTAIN BERYLLIUM OXIDE

OBSERVE SAFETY INSTRUCTIONS !

The staff in charge, besides being technically qualified, must have a practice of the first aid in case of

emergency or accident (reanimation, heart massage, mouth to mouth respiration, etc.).

Before going on with the operations to be performed, it is necessary to know the position of the general

electric switch and the one of the extinguishers, which are to be used very quickly if necessary.

TEM A07EXXXX – 1 Unit Transmitters Page 7

3.2 Safety suggestion

Regardless of how well electrical equipment is designed, personnel can be exposed to dangerous electrical shock

when protective covers are removed for maintenance or other activities.

Therefore, it is incumbent in the user to see that all safety regulations are consistently observed and that each

individual assigned to the equipment has a clear understanding of the first aid related to electrical shocks (see

next pages).

In addition these safety practices must be followed:

Do not attempt to adjust unprotected circuit controls or to dress leads with power on.

Always avoid placing parts of the body in series between ground and circuit points.

To avoid burns, do not touch heavily loaded or overheated components without precautions.

Remember that some semiconductor cases and solid-state circuits carry high voltages.

Do not assume that all danger of electrical shock is removed when the power is off.

Charged capacitors can retain dangerous voltages for a long time after power is turned off.

These capacitors should be discharged trough a suitable resistor before any circuit points are touched.

Don't take chances. Be fully trained.

TEMItalia equipment should be operated and maintained by fully qualified personnel.

Do not service alone and do not perform internal adjustments of this unit unless another person capable

of rendering first aid and resuscitation is present.

Some components used in the construction of this equipment contain Beryllium Oxide (BeO).

This substance is harmless as it is, but becomes highly dangerous if it is ground to powder.

Special procedures of disposal must be observed in case of failure of these devices.

NOTE: This section is not intended to contain a complete statement of all safety precautions which should be

observed by personnel in using this electronic equipment or others.

TEM shall not be responsible for injury or damage resulted from improper procedures or from using it by

improperly trained or inexperienced personnel.

TEM A07EXXXX – 1 Unit Transmitters Page 8

3.3 General safety recommendations

When connecting the equipment to the power , please follow these importantrecommendations:

This product is intended to operate from a power source that will not apply more than 10% of the voltage

specified on the rear panel between the supply conductors or between either supply conductor and

ground.

A protective-ground connection by way of the grounding conductor in the power cord is essential for safe

operation.

This equipment is grounded through the grounding conductor of the power cord.

To avoid electrical shock, plug the power cord into a properly wired socket before connecting to the product input

or output terminals.

Upon loss of the protective-ground connection, all accessible conductive parts (including parts that may

appear to be insulating) can render an electric shock.

To avoid fire hazard,use only the fuse of correct type, voltage rating, and current rating.

Refer for use replacement to qualified service personnel.

To avoid explosion, do not operate this equipment in an explosive atmosphere.

To avoid personal injury, do not remove the product covers or panels.

Do not operate the product without the covers and panels properly installed.

TEM A07EXXXX – 1 Unit Transmitters Page 9

3.4 Good practices

In maintaining the equipment covered in this manual, please keep in mind the following, standard good practices:

At regular intervals, the condition of the equipment and the correct functioning of protective and safety

devices shall be checked by a skilled person approved by the appropriate authority for this duty.

Functional checks shall be carried out on interlocking systems of doors, mechanical interlocks, isolating switches,

earthing switches, parallel resistances and protective devices against over-voltages and over-currents.

The above checks shall also be carried out after the protective and safety devices have operated under fault

conditions.

The safety devices shall not be altered or disconnected except for replacement, nor shall the safety circuit be

modified without specific approval of the appropriate authority in each case.

When connecting any instrument (wattmeter, spectrum analyzer, etc.) to a high frequency output, use

the appropriate attenuator or dummy load to protect the final amplifiers and the instrumentinput.

When inserting or removing printed circuit boards (PCBs), cable connectors, or fuses, always turn off

power to the affected portion of the equipment.

After power is removed, allow sufficient time for the power supplies to bleed down before reinserting PCBs.

When troubleshooting, remember that FETs and other metal-oxide semiconductor (MOS) devices may

appear defective because of leakage between traces or componentleads on the printed circuit board.

Clean the printed circuit board and recheck the MOS device before assuming it is defective.

When replacing MOS devices, follow standard practices to avoid damage caused by static charges and

soldering.

When removing components from PCBs (particularly ICs), use care to avoid damaging PCB traces.

TEM A07EXXXX – 1 Unit Transmitters Page 10

3.5 Procedure for establish the absence of voltage

Follow these simple steps for establish the absence of voltage:

Before starting work onthe equipment, it shall be isolated from the mains supply.

This disconnection shall always be checked by visual inspection.

Further precautions shall be taken to ensure that the mains supply cannotbe restored whilst work is being carried

out.

After the mains supply has been disconnected, all other lines such as control, interlocking and modulation lines

shall be disconnected if they carry dangerous voltages.

Moreover, the antenna or the antenna transmission line shall be disconnected from the antenna terminal device

to prevent the introduction of dangerous voltages due to antenna pick-up.

When disconnection of the antenna or antenna transmission line is not possible, other suitable precautions shall

be taken, for example, earthing, when necessary at several places, to esablish absence of voltage.

These earthing connections shall be very short compared with the wave-lenght.

Capacitors which are connected to a circuir isolated from its supply shall be discharged and have their

terminals permanently short-circuited and the casing earthed during the whole period of the work.

The electrical charge retained by electrical machinerywhen stopped may, in certain cases, besufficient to

cause a severe shock.

This shall be taken into accountwhen making connections to an apparently "dead" machine.

Therefore all machinery shall be discharged and earthed using an adequately insulated lead for this purpose.

The discharge operation shall be repeated several times.

Before any maintenance work is carried out on automatic or remote controlled equipment, the remote

swithching circuits shall be made inoperative.

3.5.1 Procedure for determination of the absence of voltage

After the equipment has been isolated according to the standard EN60215, the absence of voltage shall be

determined at the work place.

This may be done by the use of voltage indicators, measuring instruments, glow discharge lamps for indicating

radio-frequency voltage or other suitable means.

TEM A07EXXXX – 1 Unit Transmitters Page 11

DO NOT TOUCH VICTIM OR HIS CLOTHING BEFORE

POWER IS DISCONNECTED OR YOU CAN ALSO BECOME

A SHOCK VICTIM

3.6 First aid in case of electrical shock

If someone seems unable to free himself while receiving an electric shock, turn power off before rendering aid.

A muscular spasm or unconsciousness can make a victim unable to free himself from the electrical power.

If power cannot be turned off immediately, very carefully loop a length of dry non-conducting material (such as a

rope, insulating material, orclothing) around the victim and pull him free of the power.

Carefully avoid touching him or his clothing until free of power.

3.7 Emergency resuscitation technique

Step 1

Check the victim for unresponsiveness. If there is no response, immediately call for medical

assistance,andthen return to the person.

Step 2

Position the person flat on their back. Kneel by their side and place one hand on the forehead

and the other under the chin. Tilt the head back and lift the chin until teeth almost touch. Look

and listen for breathing.

Step 3

If not breathing normally, pinch the nose and cover the mouth with yours. Give two full breaths.

The person's chest will rise if you are giving enough air.

Step 4

Put the fingertips of your hand on the Adam's apple, slide them into the groove next to the

windpipe. Feel for a pulse. If you can notfeel a pulse or are unsure, move on to the next step.

TEM A07EXXXX – 1 Unit Transmitters Page 12

Step 5

Position your hands in the center of the chest between the nipples. Place one hand on top of the

other.

Step 6

Push down firmly two inches. Push on chest 15 times.

CONTINUE WITH TWO BREATHS AND 15 PUMPS UNTIL HELP ARRIVES.

3.7.1 Treatment for burns

Continue treat victim for electrical shock.

Check for points of entry and exit of current.

Cover burned surface with a clean dressing.

Remove all clothing from the injured area, but cut around any clothing that adheres to the skin and leave

it in place.

Keep the patientcovered, except the injured part, since there is a tendency to chill.

Splint all fractures.

(Violent muscle contractions caused by the electricity may result in fractures.)

Never permit burned surfaces to be in contact with each other, such as: areas between the fingers or

toes, the ears and the side of the head, the undersurface of the arm and the chest wall, the folds of the

groin, and similar places.

Transport to a medical facility

3.8 Electric safety precautions

All the parts making up the equipment have got danger identification tags (with a yellow background) to highlight

the parts dangerous for the operator that has access to the system.

Presence of hazardous energy levels

A hazardous energy level is defined as a stored energy level of 20 J or more, or

an available continuous power level of 240 VA or more, at a potential of 2 V or

more.

3.9 Electrostatic precautions

Before removing or replacing any PCB assembly within the equipment, make sure that all precautions comply

with ESD protections (ESD = Electro Static Discharge).

Make sure thatelectrostatic discharge protections are reset after maintenance and/or measurement operations.

TEM A07EXXXX – 1 Unit Transmitters Page 13

This ATTENTION tag is used for the majority of electronic devices that are

sensitive to electrostatic discharges.

If electronic parts have to be touched during installation or repair, please observe the following precautions.

Operators must be equipped with anti-static protection devices such as:

Elastic wrist band. To be fixed on the operator’s wrist.

Flexible cord. To be connected to the elastic wrist band and the special

plug on the shelf highlighted with the ESD warning label.

3.10 Waste electrical and electronic equipment (WEEE)

The purpose of the DIRECTIVE 2002/96/EC OF THE EUROPEAN PARLIAMENT

AND OF THE COUNCIL of 27 January 2003 on waste electrical and electronic

equipment ( WEEE ) is, as first priority, the prevention of waste electrical and

electronic equipment and, in addition, the reuse, recycling and other forms of

recovery of suchwastes so as to reduce the disposal of waste.

To do this, remember to collect separately all the electronic material.

TEM A07EXXXX – 1 Unit Transmitters Page 14

4ELECTRICAL SPECIFICATION

4.1 FREQUENCY - POWER

Frequency range-------------------------------------------------------------------------------------87.5 to 108.0MHz

Frequency setting------------------------------------------------------------------------------------------10 KHz steps

Internal setting mode--------------------------------------------------------------------------------------------by keys

External setting mode-------------------------- byOptional remote control ( GSM-TCP/IP-RS232-RS485 )

Frequency stability---------------------------------------------------------------------------------------- ±500Hz/year

Frequency generation--------------------------------------------------------------------------------- PLL synthesizer

Modulation type----------------------------------------------------------------direct VCO frequency modulation

Nominal frequency deviation --------------------------------------------------------------------------------- ±75KHz

RF output power ---------------------------------------------------0 to 10-20-50-100-200-250-300-400-500W

Power resolution setting ------------------------------------------------------------------------------------------1-5W

Power control stability------------------------------------------------------------------------------------------ < 0.2dB

Reverse output power control limit ----------------------------------------------------------------------- 1 to 30W

Harmonics emission---------------------------------------------------------------------------------------------<-70dBc

Spurious emission------------------------------------------------------------------------------------------------<-95dBc

Carrier reduction power ( carrier enable off )-------------------------------------------------------------->70dBc

TEM A07EXXXX – 1 Unit Transmitters Page 15

4.3 MODULATION CAPABILITY

MONO (left or right)------------------------------------------------------------------------------------30Hz to 15KHz

STEREO (by internal stereo generator OPT)------------------------------------------------------30Hz to 53KHz

MPX1 & MPX2 (opt) COMPOSITE (MONO or STEREO +RDS+ SCA)--------------------------30Hz to 75KHz

AES-EBU up to 192KHz or IP Audio (opt) ----------------------------------------------------------30Hz to 53KHz

SCA (opt) -------------------------------------------------------------------------------------------------30Hz to 100KHz

RDS Ext----------------------------------------------------------------------------------------------------30Hz to 100KHz

RDS Int (by internal RDS generator OPT) --------------------------------------------------------------------57KHz

4.4 CHARACTERISTICS IN MPX

Signal input --------------------------------------------------------------------------------------------MPX Unbalanced

Input impedance ---------------------------------------------------------------------------------------- 600or 10k

Input level-----------------------------------------------------0/+6/+12/dBm or Variable input level capability

Audio frequency response ( 50Hz to 57KHz) ---------------------------------------------------------------±0.5dB

Total HarmonicDistortion THD -------------------------------------------------------------------------------<0.02%

Signal to noise referred at deviation of 75KHz-------------------------------------------------------------->80dB

4.5 CHARACTERISTICS IN MONO

Signal input -------------------------------------------------------------------------------------------------Left or Right

Inputimpedance --------------------------------------------------------------------------600(balanced) or 10k

Unbalance rejection----------------------------------------------------------------------------------------------->40dB

Input level-----------------------------------------------------0/+6/+12/dBm or Variable input level capability

Pre-emphasis------------------------------------------------------------------------------------ std.50s ( opt 75uS )

Audio frequency response ( 50Hz to 15KHz) ---------------------------------------------------------------±0.5dB

Total HarmonicDistortion THD -------------------------------------------------------------------------------<0.02%

Signal to noise referred at deviation of 75KHz-------------------------------------------------------------->82dB

TEM A07EXXXX – 1 Unit Transmitters Page 16

4.6 CHARACTERISTICS IN STEREO

Signal inputs--------------------------------------------------------------------------------------------------Left &Right

Inputimpedance --------------------------------------------------------------------------600(balanced) or 10k

Unbalance rejection----------------------------------------------------------------------------------------------->40dB

Input level-----------------------------------------------------0/+6/+12/dBm or Variable input level capability

Pre-emphasis-------------------------------------------------------------------------------------std.50s ( opt 75uS )

Audio frequency response (30Hz to 15KHz)---------------------------------------------------------------<0.25dB

Cross-talk between left and right channel------------------------------------------------------------------->50dB

Total HarmonicDistortion THD -------------------------------------------------------------------------------- <0.1%

Signal to noise referred at deviation of 75KHz-------------------------------------------------------------->77dB

Suppression of 38KHz--------------------------------------------------------------------------------------------->70dB

Spurious suppression outside band ----------------------------------------------.in according to ETS 300-384

Pilot reference for RDS encoder (19 KHz out)-----------------------------------------------------------------1Vpp

4.7 SCA-Ext RDS CHARACTERISTICS

Input (SCA1) --------------------------------------------------------------------------------------------BNC unbalanced

Inputimpedance ----------------------------------------------------------------------------------------------------10K

Frequency response (50KHz to 100KHz)--------------------------------------------------------------------- ±0.2dB

Modulation capability------------------------------------------------------------------------------------------0 to 10%

4.8 REMOTE CONTROL

AUX I/O on DB15 TC-TS rear panel connector Interface---------------------------------------------------------

LAN on front panel ( OPT)-----------------------------------------------------TCP-IP Web-Server/SNMP/SMTP

RS485 on rear panel-------------------------------------------------------------------------------------------------------

Internal GSM Modem (OPT)----------------------------------------------------------------------------------------SMS

TEM A07EXXXX – 1 Unit Transmitters Page 17

4.9 POWER SUPPLY AND TEMPERATURE RANGE

Nominal Operating AC Mains Voltage --------------------------------------------------------------230VAC ±10%

AC Mains protection fuses ----------------------------------------------------------------------------2xT 8 AL 250V

50W Model Line Power-------------------------------------------------------<120VA @ 50W RF Output Power

100W Model Line Power --------------------------------------------------- <175VA @ 100W RF Output Power

300W Model Line Power --------------------------------------------------- <450VA @ 300W RF Output Power

500W Model Line Power --------------------------------------------------- <710VA @ 500W RF Output Power

Nominal temperature range------------------------------------------------------------------------------ -5° to 45°C

Operating temperature range -------------------------------------------------------------------------- -10° to 50°C

Storage temperature range------------------------------------------------------------------------------ -40° to 50°C

4.10 MECHANICAL SPECIFICATION

1 unit rack 19” ---------------------------------------------------------------------------------------485x44.4x545mm

10-20-50W model Weight -------------------------------------------------------------------------------------- <6.0Kg

100W model Weight --------------------------------------------------------------------------------------------- <7.5Kg

300W model Weight --------------------------------------------------------------------------------------------- <8.0Kg

500W model Weight --------------------------------------------------------------------------------------------- <8.0Kg

TEM A07EXXXX – 1 Unit Transmitters Page 18

4.11 INTERNAL MAIN MODULES

Exciter module------------------------------------------------------------------------------------------------13M7EXC1

Audio Connection Board Module ------------------------------------------------------------------------13M31640

FrontPanel Interface Module ---------------------------------------------------------------------------13M31800

RF 100-200-250 Module Amplifier-------------------------------------------------------------------- 13M3188B-C

RF 300-400-500W Module Amplifier------------------------------------------------------------------ 13M72387B

Power Supply Module for 500W Model-----------------------------------------------------13MPWRSP100048

Service Power Supply Module ----------------------------------------------------------------------13MPWRS7524

Current Meter Sensor Module ( only for 500W model) --------------------------------------------13M31810

Universal Current Meter Sensor Module (for all 1 Unit Rack TX models)----------------------13M32110

4.12 OPTIONS

Option A-----: Internal Stereo generator Module -----------------------------------------------------44C01180

Option B :--------Internal RDS Encoder--------------------------------------------------------------13M7MINIRDS

OptionC :------AES-EBU Digital Input Interface----------------------------------------------------13MAESEBU0

Option D : --- Automatic Frequency Deviation Control Card------------- -------------------------13M5804A

Option E :-------GSM by SMS Remote Control---------------------------------------------------------13KGSM05

Option F :----- TCP-IP Web Server/SNMP/SMTP Remote Control Card--------------------------13KTCPIP2

Option G : -- GSM & TCP-IP Web Server/SNMP/SMTP Remote Control Card------------------13KTCPIP3

TEM A07EXXXX – 1 Unit Transmitters Page 19

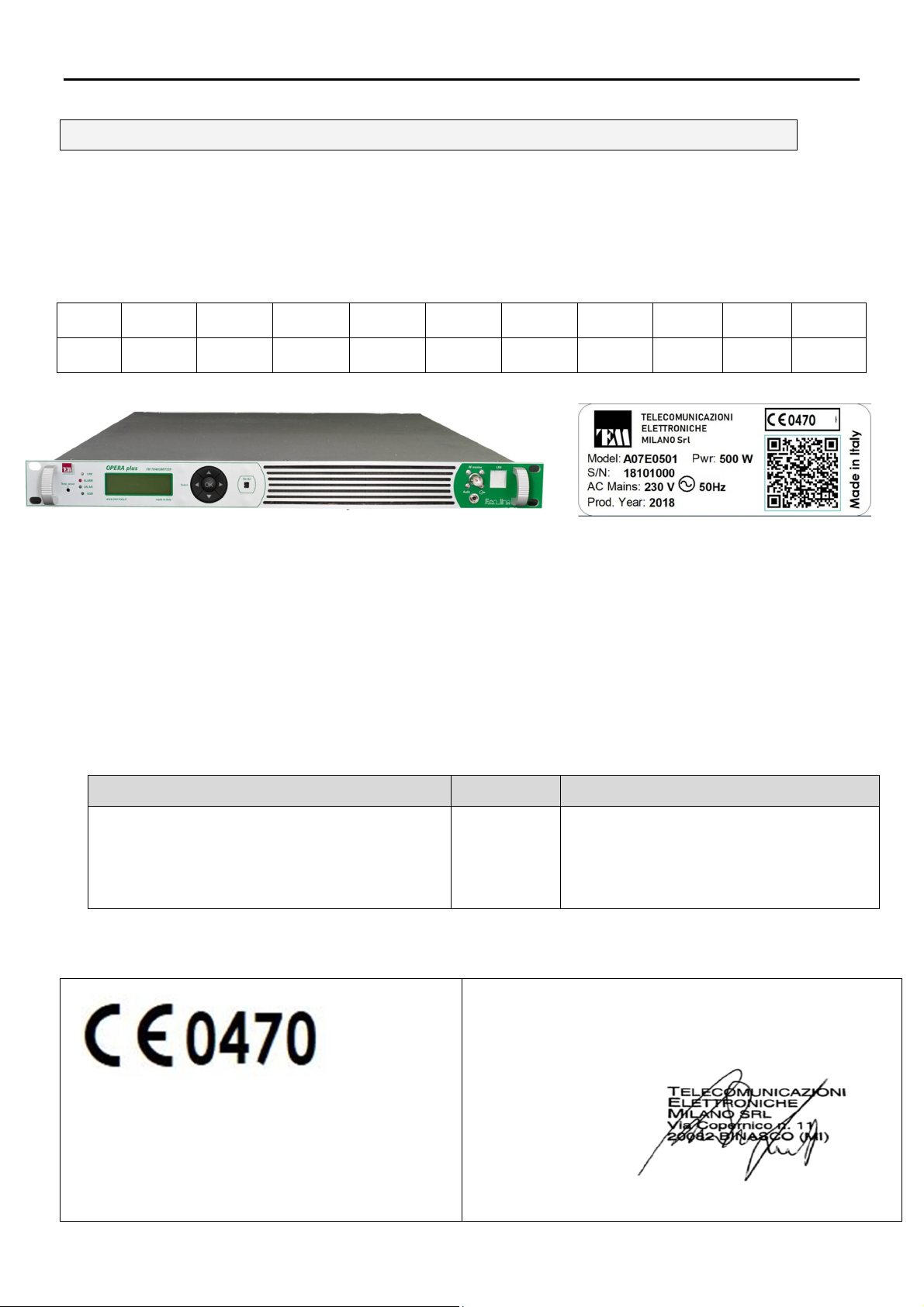

5Dichiarazione di Conformità UE

La presente dichiarazione di conformità è rilasciata sotto l'esclusiva responsabilità del fabbricante:

Produttore: Telecomunicazioni Elettroniche Milano Srl - Via Copernico, 11 - 20082 Binasco (MI)

Apparecchio radio Marca: TEM Trasmettitore VHF FM Modello A07E0501 – PotenzaRF 500W N°serie: VediEtichetta

applicata

Configurabile nei seguenti tagli di potenza da Software coni relativi codici

Codici A07E0501 A07E0401 A07E0301 A07E0251 A07E0201 A07E0101 A07E0051 A07E031 A070021 A07E0011

Potenza 500 W 400 W 300 W 250 W 200 W 100 W 50 W 30 W 20 W 10 W

Versione software: L.27.XX

“La potenza di uscita di ogni singolo apparato è certificata dalla presenza di uno dei suddetti codici sull’etichetta

apposta sull'apparato stesso e sulla presente Dichiarazione di Conformità.”

L'oggetto della dichiarazione è conforme alla pertinente normativa di armonizzazione dell'Unione:

Direttiva 2014/53/UE

Norma applicata Data Emesso da

EN 302 018 V2.1.1

EN 301 489-1 V1.9.2

EN 301 489-11 V1.3.1

EN 60215 Ed.1989 +A1:1992+A2:1994

29/11/18

26/11/14

26/11/14

04/02/15

TEM28/11/18

NEMKO N° 273431TRFEMC

NEMKO N° 273431TRFEMC

NEMKO N° 273431TRFSAF

Firmato a nome e per conto di (Signed for and on behalf of):

Luogo(Place): Binasco

Data (Date):29/11/18

Posizione (Position): Amministratore

Nome (Name): Antonio Fiordelisi

Firma (Signature):

L’immagine

rappresenta il modello A07E0501

TEM A07EXXXX – 1 Unit Transmitters Page 20

6EU Declaration of Conformity (DoC)

We,as producer,Telecomunicazioni Elettroniche Milano Srl - Via Copernico, 11 - 20082 Binasco (MI)

Declare that the DoC is issued under our sole responsibilityand belongs to the following product:

Radio Equipment Brand: TEM:Transmitter VHF FM ModelA07E0501 – RF Power 500W S/N: See Applied Label

RF power Sectable as by Software with following code

Code A07E0501 A07E0401 A07E0301 A07E0251 A07E0201 A07E0101 A07E0051 A07E031 A070021 A07E0011

Power 500 W 400 W 300 W 250 W 200 W 100 W 50 W 30 W 20 W 10 W

Firmware L.27.XX

"The output power of each individual is certified by the presence of one of the aforementioned codes on the label

affixed to the apparatus itself and to this Declaration of Conformity. "

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

Directive 2014/53/UE RED

Standard Date From

EN 302 018 V2.1.1

EN 301 489-1 V1.9.2

EN 301 489-11 V1.3.1

EN 60215 Ed.1989 +A1:1992+A2:1994

29/11/18

26/11/14

26/11/14

04/02/15

TEM28/11/18

NEMKO N° 273431TRFEMC

NEMKO N° 273431TRFEMC

NEMKO N° 273431TRFSAF

Firmato a nome e per conto di (Signed for and on behalf of):

Luogo(Place): Binasco

Data (Date):29/11/18

Posizione (Position): Amministratore

Nome (Name): Antonio Fiordelisi

Firma (Signature):

The

Picture represent the A07E0501

Labe

l

This manual suits for next models

10

Table of contents

Popular Transmitter manuals by other brands

BWI Eagle

BWI Eagle AIR-EAGLE XLT 44-10100-120I-AC Product information bulletin

Conexx

Conexx Smart Transmitter user guide

Distech Controls

Distech Controls HS-RT Series Hardware installation guide

Evikon

Evikon PluraSens E2658-NH3-E user manual

Drivecon

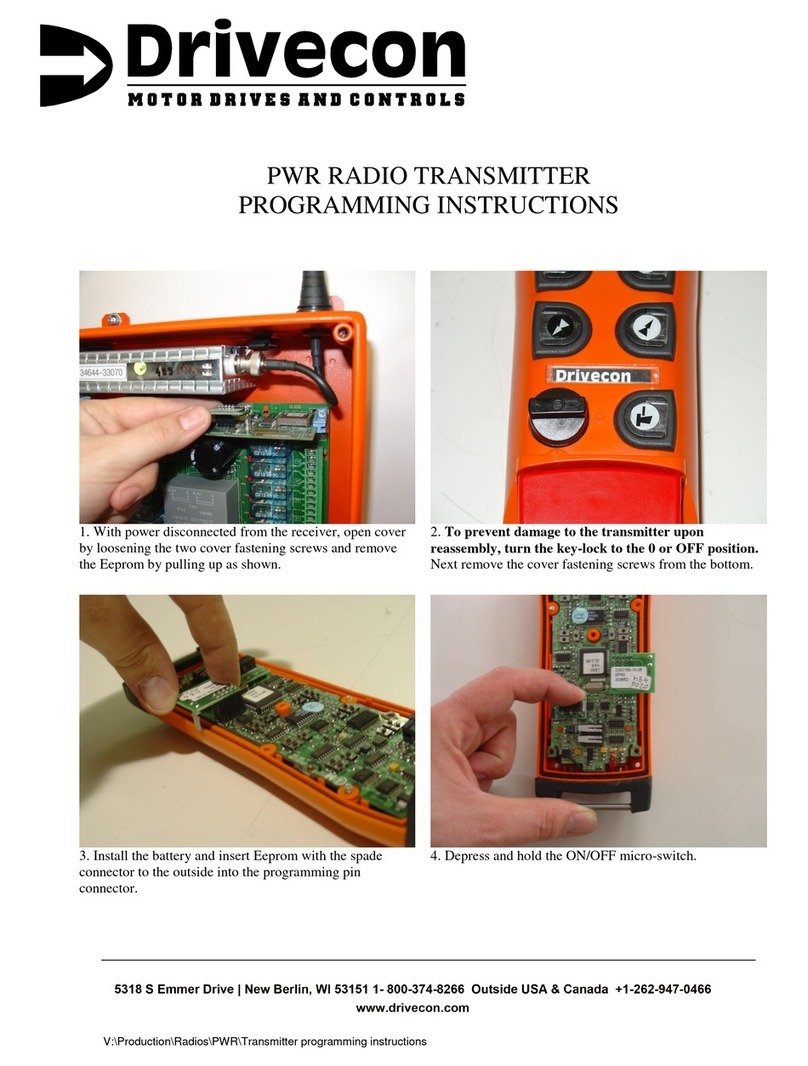

Drivecon PWR Programming instructions

Erone

Erone SETR2641AM1 quick start guide