MemoTrans

3

Table of Contents

1 Basic Safety Instructions.............................................................................................................. 5

1.1 Personnel Requirements.................................................................................................................................... 5

1.2 Intended Use.......................................................................................................................................................... 5

1.3 Symbols and Markings on the Product ........................................................................................................ 5

1.4 Occupational Safety ............................................................................................................................................ 5

1.5 Operational Safety ............................................................................................................................................... 6

2 Product Description ..................................................................................................................... 7

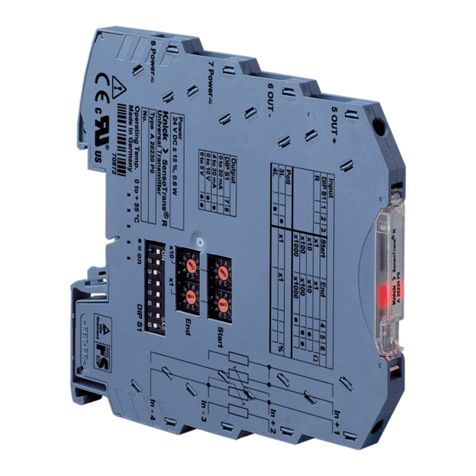

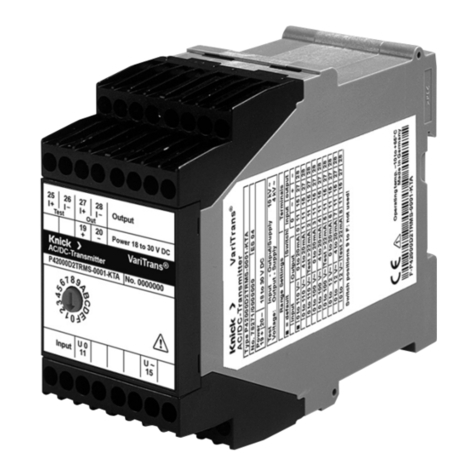

2.1 Product Design...................................................................................................................................................... 7

3 Incoming Acceptance and Product Identification ..................................................................... 8

3.1 Incoming Acceptance......................................................................................................................................... 8

3.2 Product Identification......................................................................................................................................... 8

3.3 Package Contents................................................................................................................................................. 8

3.4 Certificates and Approvals................................................................................................................................ 8

4 Installation.................................................................................................................................... 9

4.1 Dimensions............................................................................................................................................................. 9

5 Electrical Connection ................................................................................................................... 10

5.1 Connection ............................................................................................................................................................. 10

5.2 Post-Connection Check...................................................................................................................................... 10

6 Operating Options ....................................................................................................................... 11

6.1 Overview of Operating Options...................................................................................................................... 11

6.2 Structure and Function of the Operating Menu ....................................................................................... 11

7 System Integration ....................................................................................................................... 12

7.1 Integrating the Compact Transmitter into the System........................................................................... 12

8 Commissioning............................................................................................................................. 13

8.1 Preparatory Steps................................................................................................................................................. 13

8.2 Function Check...................................................................................................................................................... 13

8.3 Date and Time........................................................................................................................................................ 15

8.4 Configuring the Measuring Device................................................................................................................ 15

8.5 Configuration Management............................................................................................................................. 22

9 Operation ...................................................................................................................................... 23

9.1 Reading Measured Values ................................................................................................................................. 23

9.2 Adapting the Measuring Device to the Process Conditions................................................................. 24

10 Calibration .................................................................................................................................... 25

10.1 pH Sensor ................................................................................................................................................................ 25

10.2 ORP Sensor.............................................................................................................................................................. 25

10.3 Combo Sensor (pH/ORP) ................................................................................................................................... 25

10.4 Conductivity Sensor ............................................................................................................................................ 25

10.5 Oxygen Sensor ...................................................................................................................................................... 25