Tempco TEC-9100 User manual

1

Instructions for TPC Power Through Control Console

SPECIFICATIONS

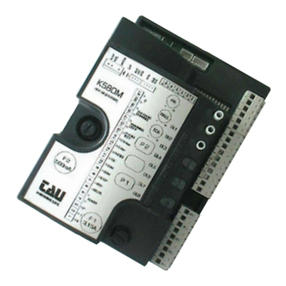

Temperature Controller: Model TEC-9100, 1/16 DIN Dual Display with PID Auto-tuning

Sensor Input: Type “J” or type “K” thermocouple dependent on model ordered

(Alternative inputs available for special order)

Power Cord/voltage Input: 120VAC or 240VAC (dependent on model ordered)

Heater Output: 12A max for 1-zone consoles

6A max per zone for 2-zone consoles

4A max per zone for 3-zone consoles

3A max per zone for 4-zone consoles

Output Device: Solid State Relay

Main Power Switch: Located on front panel

Fuse Main Power: See replacement parts list (located on back panel)

Fuse Control Power: See replacement parts list (located on back panel)

WARNINGS

1. Air vents located on top and bottom of console must not be blocked! To prevent an

overheating condition the internal components must remain as close to room

temperature (75ºF / 24ºC) as possible.

2. Dangerous voltage capable of causing injury or death is present within this console.

Power to all equipment must be disconnected before installation or beginning any

troubleshooting procedures. Heater output wiring and component replacement must

be made by qualified personnel only.

3. To minimize the possibility of fire or shock, do not expose this console to rain or

excessive moisture.

4. Do not use this console in areas where hazardous conditions exist such as excessive

shock, vibration, dirt, corrosive gases, oil or where explosive gases or vapors are

present.

WIRING (For safety, disconnect all power sources prior to wiring)

1. Attach the leads from your type thermocouple to the mini-plug provided. Take care to

note the correct polarity. The red lead is (-) negative.

2. The heater output current is sourced directly through the line cord. The rear console

output receptacle and mating Hubbell plug provides live controlled power for direct

connection to your heater(s). Connect one lead from your heater to one prong of the

Hubbell plug (not ground). Connect the other lead from your heater to the other prong.

Connect heater ground (if applicable) to the ground connection (G) on the plug.

© Copyright 2020. All Rights Reserved. Rev. 3/20 D1304.01

2

OPERATION

1. Verify the power switch is in the off position. Plug your heater & thermocouple into the rear

connectors. Plug the provided line cord from the console into a standard outlet. Switch on

the console.

2. Set your desired temperature setpoint by using the up and down arrow buttons on the

TEC-9100 temperature controller.

3. Refer to the following pages for complete operation and auto-tuning of the TEC-9100

temperature controller.

SPARE/REPLACEMENT PARTS

Tempco Description

Part Number

EHD-124-148 Fuse, rated 15 Amps/ 250V, ¼" x 1¼", fast acting, BUSS ABC-15-R.

Used for main and heater power.

EHD-124-276 (for 1, 2, and 3-zone units) Fuse (1), rated 1 Amp/ 250V, ¼" x 1¼", fast acting,

BUSS ABC-1-R. Used for TEC-9100 Controller.

EHD-124-290 (for 4-zone units) Fuse (1), rated 1.5 Amp/ 250V, ¼" x 1¼", slow acting,

BUSS ABC-1.5-R. Used for TEC-9100 Controller.).

EHD-124-300 (for 2-zone units) Fuses (2), rated 8 amps, 250V, ¼" x 1¼", fast acting, BUSS ABC-8-R.

EHD-124-279 (for 3-zone units) Fuses (3), rated 5A, 250V, ¼"x 1¼", fast acting, BUSS ABC-5-R.

EHD-124-282 (for 4-zone units) Fuses (4), rated 4 amps, 250V, ¼" x 1¼", fast acting, BUSS ABC-4-R.

EHD-102-113 (for 120V units) Power output plug (1 per zone), Hubbell HBL4720C, 15A 125V Twist-Lock.

EHD-102-121 (for 240V units) Power output plug (1 per zone), Hubbell HBL4570C, 15A 250V Twist-Lock.

(Type of plug dependent on console model ordered)

TCA-101-104 Type “K” thermocouple mini plug (1 per zone), yellow

TCA-101-105 Type “J” thermocouple mini plug (1 per zone), black

TCA-101-136 Type “CU” mini-plug, white (for 2-wire RTD)

NOTE: For all fuses, use listed BUSS part numbers or equivaliant.

3

1–1 General

Tempco’s TEC-x100 Series Fuzzy Logic plus PID

microprocessor-based controllers incorporate two bright easy to

read 4-digit LED displays, indicating process value and set point

value. The process value (PV) display is always the top digital

display. The setpoint (SV) display is always the bottom display.

Fuzzy Logic technology enables a process to reach a

predetermined set point in the shortest time with a minimum of

overshoot during power-up or external load disturbance.

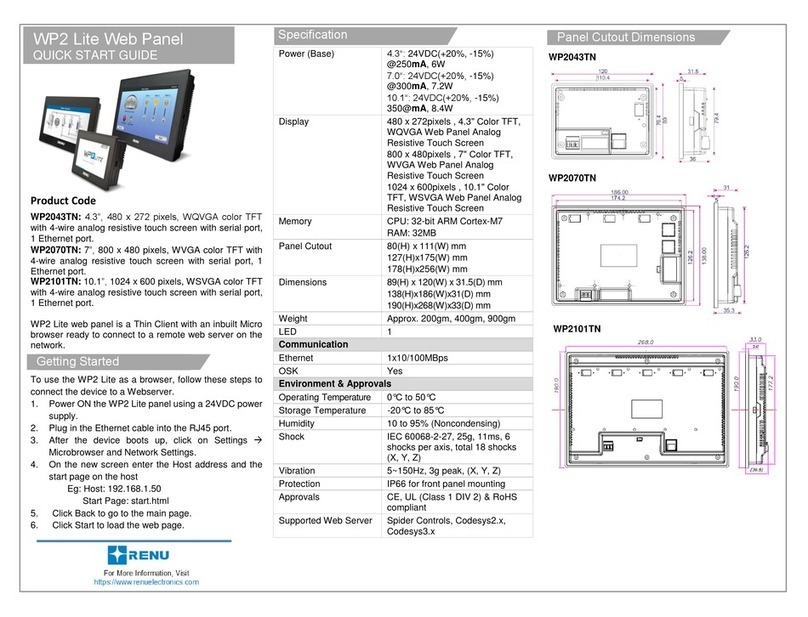

TEC-9100 is a 1/16 DIN size panel mount controller. TEC-7100

is a 72×72 DIN size panel mount controller. TEC-8100 is a 1/8

DIN size panel mount controller and TEC-4100 is a 1/4 DIN size

panel mount controller. These units are powered by 11–26 or 90–

250 VDC/VAC 50/60 Hz supply, incorporating a 2 amp control

relay output as standard. The second output can be used as a

cooling control or an alarm. Both outputs can select triac, 5V

logic output, linear current, or linear voltage to drive an external

device. There are six types of alarm plus a dwell timer that can

be configured for the third output. The units are fully

programmable for PT100 RTD and thermocouple types J, K, T,

E, B, R, S, N, and L with no need to modify the unit. The input

signal is digitized by using an 18-bit A to D converter. Its fast

sampling rate allows the unit to control fast processes.

Digital communications RS-485 or RS-232 (excluding TEC-

7100) are available as an additional option. These options allow

the units to be integrated with supervisory control systems and

software.

A programming port is available for automatic configuration,

calibration, and testing without the need to access the keys on the

front panel.

By using proprietary Fuzzy modified PID technology, the control

loop will minimize overshoot and undershoot in a short time. The

following diagram is a comparison of results with and without

Fuzzy technology.

High accuracy

This series is manufactured with custom

designed ASIC (Application Specific

Integrated Circuit) technology which

contains an 18-bit A to D converter for

high resolution measurement (true 0.1°F

resolution for thermocouple and PT100)

and a 15-bit D to A converter for linear

current or voltage control output. The

ASIC technology provides improved

operating performance, low cost,

enhanced reliability and higher density.

Fast sampling rate

The sampling rate of the input A to D

converter is 5 times/second. The fast

sampling rate allows this series to control

fast processes.

Fuzzy control

The function of Fuzzy control is to adjust

PID parameters from time to time in order

to make manipulation of the output value

more flexible and adaptive to various

processes. The result is to enable a process

to reach a predetermined set point in the

shortest time, with the minimum of

overshoot and undershoot during power-

up or external load disturbance.

Digital communication

The units are equipped with an optional

RS-485 or RS-232 interface cards to

provide digital communication. By using

twisted pair wires, up to 247 units can be

connected together via RS-485 interface

to a host computer.

Programming port

A programming port can be used to

connect the unit to a PC for quick

configuration. It also can be connected to

an ATE system for automatic testing and

calibration.

Auto-tune

The auto-tune function allows the user to

simplify initial setup for a new system. An

advanced algorithm is used to obtain an

optimal set of control parameters for the

process, and it can be applied either as the

process is warming up (cold start) or

when the process is in a steady state

(warm start).

Lockout protection

Depending on security requirements, one

of four lockout levels can be selected to

prevent the unit from being changed

without permission.

Bumpless transfer

Bumpless transfer allows the controller to

continue to control if the sensor breaks by

using its previous value. Hence, the

process can be controlled temporarily as

if the sensor is normal.

Soft-start ramp

The ramping function is performed during

power up as well as any time the set point

is changed. It can be ramping up or

ramping down. The process value will

reach the set point at a predetermined

constant rate.

Digital filter

A first order low pass filter with a

programmable time constant is used to

improve the stability of the process value.

This is particularly useful in certain

applications where the process value is

too unstable to be read.

SEL function

The units have the flexibility to allow the

user to select those parameters which are

most significant to him and put these

parameters in the front of the display

sequence. Up to eight parameters can be

selected to allow the user to build his own

display sequence.

Figure 1.1 Fuzzy Control Advantage

Chapter 1 Overview

4

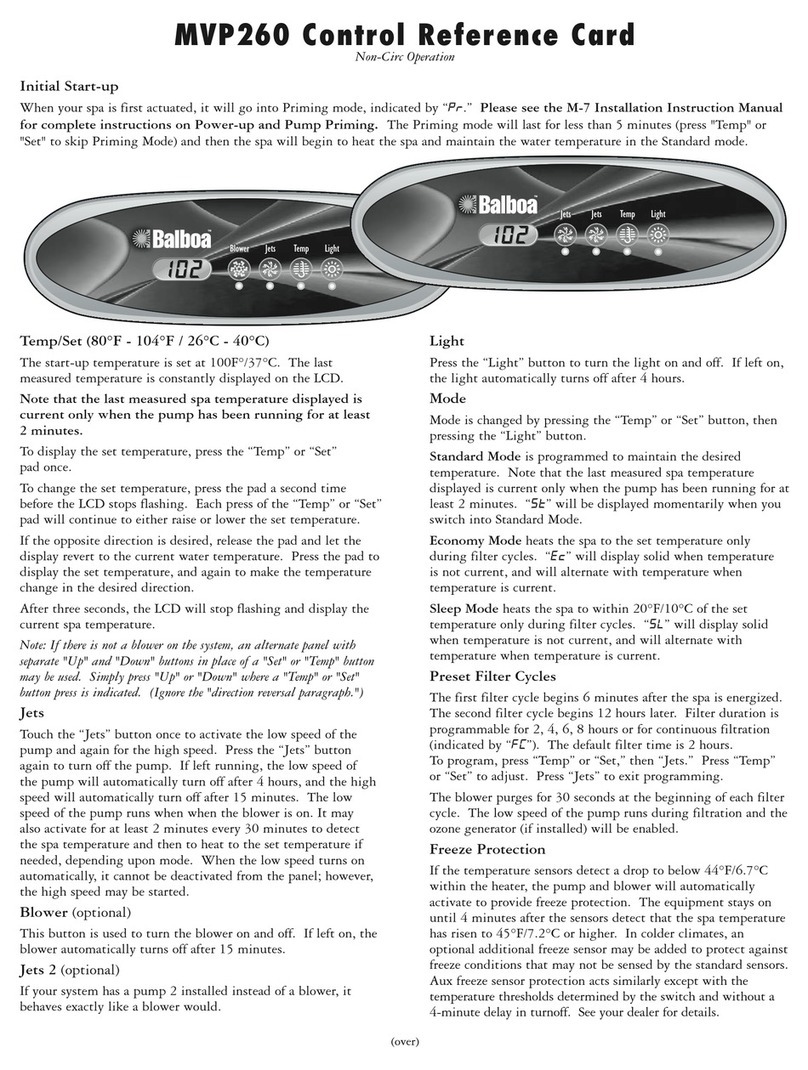

1–4 Keys and Displays

KEYPAD OPERATION

SCROLL KEY:

This key is used to select a parameter to be viewed or adjusted.

UP KEY:

This key is used to increase the value of the selected parameter.

DOWN KEY:

This key is used to decrease the value of the selected parameter.

RESET KEY:

This key is used to:

1. Revert the display to show the process value.

2. Reset the latching alarm, once the alarm condition is removed.

3. Stop the manual control mode, auto-tuning mode, and

calibration mode.

4. Clear the message of communication error and auto-tuning

error.

5. Restart the dwell timer when the dwell timer has timed out.

6. Enter the manual control menu when in failure mode.

ENTER KEY: Press for 5 seconds or longer.

Press for 5 seconds to:

1. Enter setup menu. The display shows .

2. Enter manual control mode—when manual control mode

is selected.

3. Enter auto-tuning mode—when auto-tuning mode is

selected.

4. Perform calibration to a selected parameter during the

calibration procedure.

Press for 6.2 seconds to select manual control mode.

Press for 7.4 seconds to select auto-tuning mode.

Press for 8.6 seconds to select calibration mode.

R

TEMPCO

Table 1.1 Display Form of Characters

Display program code of the product for

2.5 seconds.

The left diagram shows program number

6 for TEC-9100 with version 12.

The program no. for TEC-7100 is 13, for

TEC-8100 is 11 and for TEC-4100 is 12.

5

1–5 Menu Overview

6

Parameter Descriptions (TEC-9100 Temperature Controller)

Controller Parameter Descriptions that are not applicable are not shown in the above table.

NOTE:

It is strongly recommended that a process should

incorporate a LIMIT CONTROL such as the

TEC-910 which will shut down the equipment at

a preset process condition in order to preclude

possible damage to products or system.

Information in this user's manual is subject to change

without notice.

7

Chapter 3 Programming

Press for 5 seconds and release to enter the setup menu. Press

to select the desired parameter. The upper display indicates

the parameter symbol, and the lower display indicates the selected

value of the parameter.

3–1 Lockout

There are four security levels that can be selected using the

LOCK parameter.

If NONE is selected for LOCK, then no parameter is locked.

If SET is selected for LOCK, then all setup data are locked.

If USER is selected for LOCK, then all setup data as well as

user data (refer to section 1-5) except the set point are

locked to prevent them from being changed.

If ALL is selected for LOCK, then all parameters are locked to

prevent them from being changed.

3–2 Signal Input

INPT: Selects the sensor type or signal type for signal input.

Range: (thermocouple) J-TC, K-TC, T-TC, E-TC, B-TC,

R-TC, S-TC, N-TC, L-TC

(RTD) PT.DN, PT.JS

(Linear) 4–20mA, 0–20mA, 0–60mV, 0–1VDC,

0–5VDC, 1–5VDC, 0–10VDC

UNIT: Selects the process unit

Range: °C, °F, PU (process unit). If the unit is set for

neither °C nor °F, then it defaults to PU.

DP: Selects the resolution of process value.

Range: (For T/C and RTD) NO.DP, 1-DP

SL = Setpoint Low Stop SH = Setpoint High Stop

8

PV Shift

In certain applications it is desirable to shift the controller

display value (PV) from its actual value. This can easily

be accomplished by using the PV shift function.

The SHIF function will alter PV only.

Example: A process is equipped with a heater, a sensor,

and a subject to be warmed up. Due to the design and

position of the components in the system, the sensor

could not be placed any closer to the part. Thermal

gradient (differing temperatures) is common and

necessary to an extent in any thermal system for heat to

be transferred from one point to another. If the difference

between the sensor and the subject is 35°C, and the

desired temperature at the subject to be heated is 200°C,

the temperature at the sensor should be 235°C. You

should enter -35°C to subtract 35°C from the actual

process display. This in turn will cause the controller to

energize the load and bring the process display up to the

set point value.

Figure 3.7 PV Shift Application

3–9 Digital Filter

In certain applications, the process value is too unstable

to be read due possibly to electrical noise. A

programmable low-pass filter incorporated in the

controller is used to improve this. It is a first-order filter

with the time constant specified by the FILT parameter.

The default value of FILT is set at 0.5 seconds before

shipping. Adjust FILT to change the time constant from

0 to 60 seconds. 0 seconds means no filter is applied to

the input signal. The filter is characterized by the

following diagram:

Note

The filter is available only for PV, and is performed for

the displayed value only. The controller is designed to

use unfiltered signal for control even if the filter is

applied. A lagged (filtered) signal, if used for control,

may produce an unstable process.

The controller will enter failure mode if one

of the following conditions occurs:

1. SBER occurs due to input sensor break

or input current below 1mA if 4–20 mA

is selected or input voltage below 0.25V

if 1–5V is selected.

2. ADER occurs due to the A-D converter

of the controller failing.

Output 1 and output 2 will perform the

failure transfer function as the controller

enters failure mode.

Output 1 failure transfer, if activated, will

perform:

1. If output 1 is configured as proportional

control (PB≠ 0), and BPLS is selected

for O1FT, then output 1 will perform

bumpless transfer. Thereafter, the

previous averaging value of MV1 will

be used for controlling output 1.

2. If output 1 is configured as proportional

control (PB≠ 0), and a value of 0 to

100.0% is set for O1FT, then output 1

will perform failure transfer. Thereafter,

the value of O1FT will be used for

controlling output 1.

3. If output 1 is configured as ON-OFF

control (PB=0), then output 1 will be

driven OFF if OFF is set for O1FT and

will be driven ON if ON is set for O1FT.

Output 2 failure transfer, if activated, will

perform:

1. If OUT2 is configured as COOL, and

BPLS is selected for O1FT, then output

2 will perform bumpless transfer.

Thereafter, the previous averaging value

of MV2 will be used for controlling

output 2.

2. If OUT2 is configured as COOL, and a

value of 0 to 100.0% is set for O2FT,

then output 2 will perform failure

transfer. Thereafter, the value of O1FT

will be used for controlling output 2.

3. If OUT2 is configured as alarm

function, and O2FT is set to OFF, then

output 2 will go off. Otherwise, output

2 will go on if O2FT is set to ON.

Alarm failure transfer is activated as the

controller enters failure mode. Thereafter,

the alarm will transfer to the ON or OFF

state preset by ALFT.

3–10 Failure Transfer

Figure 3.8 Filter Characteristics

9

Auto-tuning

The auto-tuning process is performed near the set point. The process

will oscillate around the set point during the tuning process. Set the

set point at a lower value if overshooting beyond the normal process

value is likely to cause damage.

Auto-tuning is applied in cases of:

• Initial setup for a new process

• The set point is changed substantially from the previous

auto-tuning value

• The control result is unsatisfactory

Operation:

1. The system has been installed normally.

2. Set the correct values for the setup menu of the unit, but don’t

set a zero value for PB and TI, or the auto-tuning program will

be disabled. The LOCK parameter should be set at NONE.

3. Set the set point to a normal operating value, or a lower value if

overshooting beyond the normal process value is likely to cause

damage.

4. Press and hold until appears on the display.

5. Then press again for at least 5 seconds. The AT indicator will

begin to flash and the auto-tuning procedure begins.

NOTE: The ramping function, if used, will be disabled when

auto-tuning is taking place.

Auto-tuning mode is disabled as soon as either failure mode or

manual control mode is entered.

Procedures:

Auto-tuning can be applied either as the process is warming up

(cold start), or when the process has been in a steady state (warm

start). After the auto-tuning procedures are completed, the AT

indicator will cease to flash and the unit will revert to PID control

using its new PID values. The PID values obtained are stored in

the nonvolatile memory.

Auto-Tuning Error

If auto-tuning fails an ATER message will appear on the upper

display in the following cases:

• If PB exceeds 9000 (9000 PU, 900.0°F or 500.0°C),

• if TI exceeds 1000 seconds,

• if the set point is changed during the auto-tuning procedure.

Solutions to

1. Try auto-tuning once again.

2. Don’t change the set point value during the auto-tuning procedure.

3. Don’t set a zero value for PB and TI.

4. Use manual tuning instead of auto-tuning (see section 3-12).

5. Touch RESET key to reset message.

Manual Tuning

In certain applications auto-tuning may be inadequate for the

control requirements. You can try manual tuning for these

applications.

If the control performance using auto-tuning is still unsatisfactory,

the following rules can be applied for further adjustment of PID

values:

Figure 3.9 shows the effects of PID

adjustment on process response.

Figure 3.9 Effects of PID Adjustment

Table 3.2 PID Adjustment Guide

10

Table A.1 Error Codes and Corrective Actions

11

WARRANTY

Tempco Electric Heater Corporation is pleased to offer

suggestions on the use of its products. However, Tempco makes

no warranties or representations of any sort regarding the fitness

for use, or the application of its products by the Purchaser. The

selection, application, or use of Tempco products is the

Purchaser's responsibility. No claims will be allowed for any

damages or losses, whether direct, indirect, incidental, special, or

consequential. Specifications are subject to change without

notice. In addition, Tempco reserves the right to make changes–

without notification to the Purchaser–to materials or processing

that do not affect compliance with any applicable specification.

TEC Temperature Controllers are warranted to be free from

defects in material and workmanship for two (2) years after

delivery to the first purchaser for use. Tempco's sole

responsibility under this warranty, at Tempco's option, is limited

to replacement or repair, free of charge, or refund of purchase

price within the warranty period specified. This warranty does

not apply to damage resulting from transportation, alteration,

misuse, or abuse.

RETURNS

No product returns can be accepted without a completed Return

Material Authorization (RMA) form.

TECHNICAL SUPPORT

Technical questions and troubleshooting help is available from

Tempco. When calling or writing please give as much

background information on the application or process as possible.

Phone: 630-350-2252

800-323-6859

607 N. Central Avenue Wood Dale, IL 60191-1452 USA

P: 630-350-2252 Toll Free: 800-323-6859

www.tempco.com

Band Heaters

Cast-In Heaters

Radiant Heaters

Flexible Heaters

Process Heaters

Temperature Control

Cartridge Heaters

Coil & Cable Heaters

Strip Heaters

Tubular Heaters

Instrumentation

Temperature Sensors

HEAT THINGS UP!HEAT THINGS UP!

With Thousands of Design Variations

We Make Everything You Need.

Custom Manufacturer Since 1972

ELECTRIC HEATING ELEMENTS • TEMPERATURE CONTROLS • SENSORS • PROCESS HEATING SYSTEMS

© Copyright 2020. All Rights Reserved

Other manuals for TEC-9100

1

Table of contents