158PE12767

ITEM PT. NO. DESC. QUAN.

DR.: SRB 4/42006 INTERMATIC INCORPORATED

CHKD.: TJS 4/4/2006

SCALE: FULL NAME: INST SHT - DOOR, PE45300

APPROVED MATL.: SEE MATERIAL SPECIFICATIONS

2REV ART TOREF NOTE 6 WAS 5 SRB 4/27/2006 2-TD 4/27/2006 FINISH: BLACK PRINTING INK

1RELEASED TO ELEC. DATA HEAT TREAT:

LET. REVISION SIGN. MODEL SUPERSEDES: FRACTIONS + .010 . DECIMALS AS SPECIFIED - ANGLES + 1/2˚

ALL DIMENSIONS MUST BE MET BEFORE PLATING.

DIM :

TOL

NOTES:

1. ALL PRINTING TO BE AS PER INTERMATIC

APPROVED ARTWORK, AND TO BE

CENTRALLY LOCATED ON LABEL.

D29

8.25”

6.5”

1/8 R. (4) OPTIONAL

MATERIAL SPECIFICATIONS:

1. WHITE VINYL WITH PERMANENT PRESSURE SENSITIVE

ADHESIVE BACKING. (.005” THICK)

SEE B/M FOR ALL PART NUMBERS & QUANTITIES

MODEL: PE45300

I

IN

NR

RA

AI

IN

NP

PR

RO

OO

OF

F(

(T

TY

YP

PE

E3

3R

R)

)E

EN

NC

CL

LO

OS

SU

UR

RE

EF

FO

OR

RI

IN

ND

DO

OO

OR

R/

/O

OU

UT

TD

DO

OO

OR

RU

US

SE

E.

.

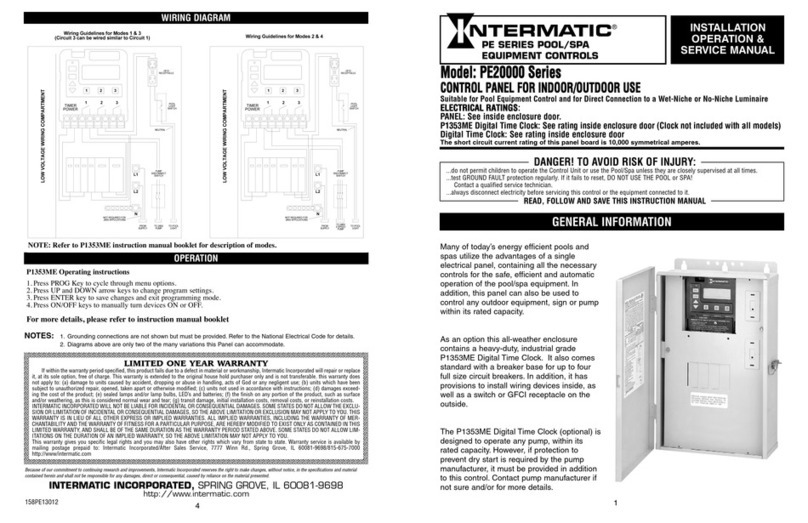

SUITABLE FOR SWIMMING POOL/SPA APPLICATIONS AND FOR DIRECT CONNECTION TO A WET-NICHE OR NO NICHE LUMINAIRE.

125 amp. US/120 amp CANADA (If used as residential Distribution/Control equipment, not more

than 6 disconnects can be provided.)

120/240 volt or 120/208 volt single phase (three wire) AC

The short circuit rating of this panel is 10000 symmetrical amperes.

IMPORTANT: This control panel must be installed according to the National Electrical Code (including article 680)

or Canadian Electrical Code (including section 68) and local code requirements. This installation is subject to the approval

by the local inspection authority. The main lugs and neutral main are suitable for No.14 to 2 AWG COPPER conductors.Use

No.14 to 6 AWG COPPER conductors for branch circuit wiring. Follow gauge selection table and corresponding terminal

screw tightening torque requirements below. Install interchangeable circuit breakers with an interrupting current rating of

10000 symmetrical amperes, or higher. All circuit breakers in this control panel shall be of the same manufacturer and type.

See list of suitable types below. Follow manufacturers instructions for installing and testing of ground fault circuit breakers

(GFCB) and interrupters (GFCI). Install only LISTED receptacle(s) and/or wiring device(s) inside the enclosure. A LISTED

wiring device may be installed in the rectangular side knockout provided. When panel is outdoors, a LISTED rainproof

cover must be installed over the wiring device in the side knockout. If this enclosure is used for direct conduit connection

to a wet-niche or no niche luminaire, one of the connection kits listed below in Note 6 must be used. This control should

not be connected to any equipment which would cause bodily injury or property damage should it be activated unexpectedly.

After wiring, install front panel over wiring compartment and close unused breaker openings with filler plates.

KEEP DOOR CLOSED AT ALL TIMES.

CCLLAASSSSCCTTLLDDIISSTTRRIIBBUUTTIIOONN//CCOONNTTRROOLL

PPAANNEELLWWIITTHH33--CCIIRRCCUUIITTDDIIGGIITTAALLCCOONNTTRROOLL

INTERMATIC INCORPORATED

SPRING GROVE, ILLINOIS 60081-9698 158PE12767

3-CIRCUIT DIGITAL CONTROL RATINGS:

CLOCK SOURCE VOLTAGE: 120/240VAC, 50/60 Hz.

POWER CONSUMPTION: 6.0 Watts Max.

CONTACT CONFIGURATION: SPST - each circuit.

CONTACT RATINGS -EACH CIRCUIT (P1353ME)

- 17A Resistive - 120/240V AC

-17 Full Load A, 80 Lock Rotor A - 120/240V AC

-5A Tungsten, or Ballast 120/240V AC

- Aux Switch: 2A, 24V AC

EVENTS PER CIRCUIT: 3 On/Off Events Per Circuit

MEMORYRETENTION:

• 40 Year retention for all programmed settings.

• 8-hour time retention.

VALVE / PUMP SWITCH MECHANISM (P4243ME) RATINGS:

CIRCUITS #1 & #2:

17A Resistive 120-240V, 10 ATungsten-120V,

1.5 HP- 120V, 3 HP - 240V, 60 Hz; Double Pole Single Throw (DPST)

VALVE ACTUATOR SUPPLY: 24V - 40VAMAX.

SUITABLE LISTED BREAKERS

CIRCUIT BREAKER FILLER

MANUFACTURER SINGLE DOUBLE TWIN QUAD GFCB PLATE

CUTLER-HAMMER BR BR BRD BRD GFCB BRFP

MURRY MP-T MP-T MH-T MH-T MP-GT LX100FP

SIEMENS QP QP QT QT QPF QF3

SQUARE D HOM HOM HOMT HOMT HOM HOMFP

THOMAS & BETTS TB TB TBBD TBBQ GFB FP-1C-TB

aTORQUE CIRCUIT BREAKER LUGS TO VALUES SPECIFIED ON CIRCUIT BREAKERS

b45 AMP FOR CANADA.

c120 AMP FOR CANADA.

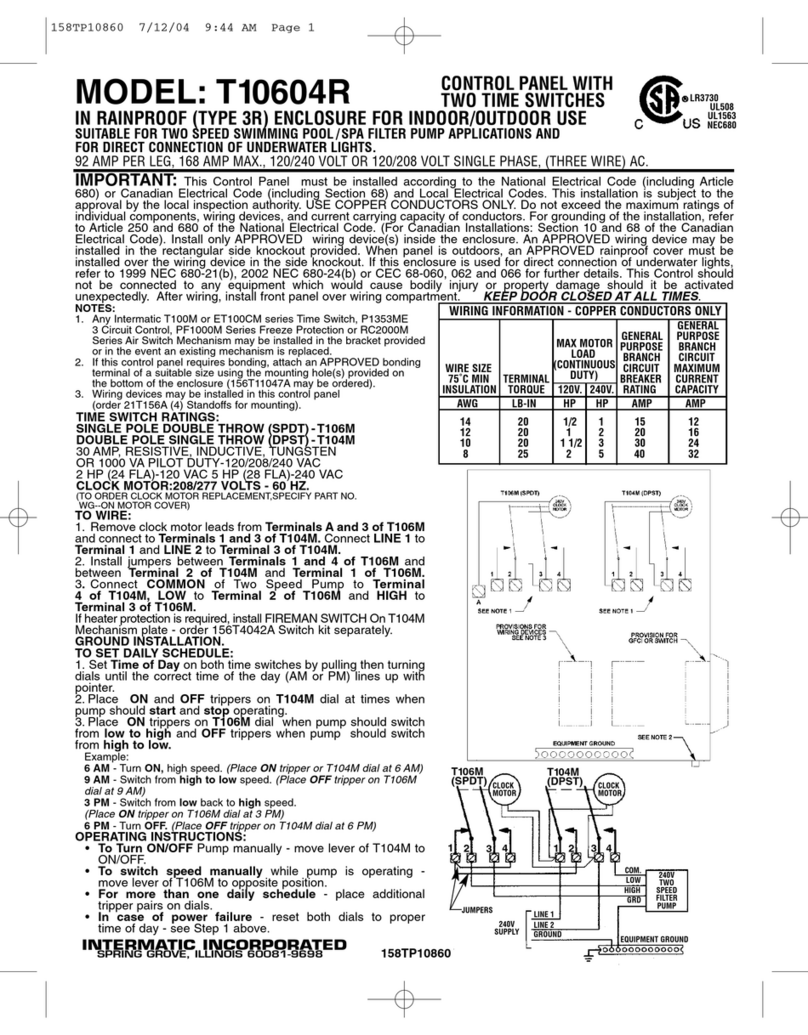

WIRING INFORMATION - COPPER CONDUCTORS ONLY

TERMINAL TORQUEaGENERAL

GENERAL PURPOSE

MAX MOTOR PURPOSE BRANCH

SUPPLY LINE AND LOAD BRANCH CIRCUIT

WIRE SIZE CIRCUIT NEUTRAL NEUTRAL (CONTINUOUS CIRCUIT MAXIMUM

75˚C MIN BREAKER MAIN AND DUTY) BREAKER CURRENT

INSULATION RATING LUGS GROUND 120V. 240V. RATING CAPACITY

AWG AMP LB-IN LB-IN HP HP AMP AMP

14 15 35 20 1/2 1 15 12

12 20 35 20 1 2 20 16

10 30 35 20 1 1/2 3 30 24

850

b40 25 2 5 40 32

665 45 35 --- --- 60 44

4 85 45 35 --- --- --- ---

2115 50 --- --- --- --- ---

2 (90˚C) 125c50 --- --- --- ---

LR3730

UL508

UL1563

NOTES:

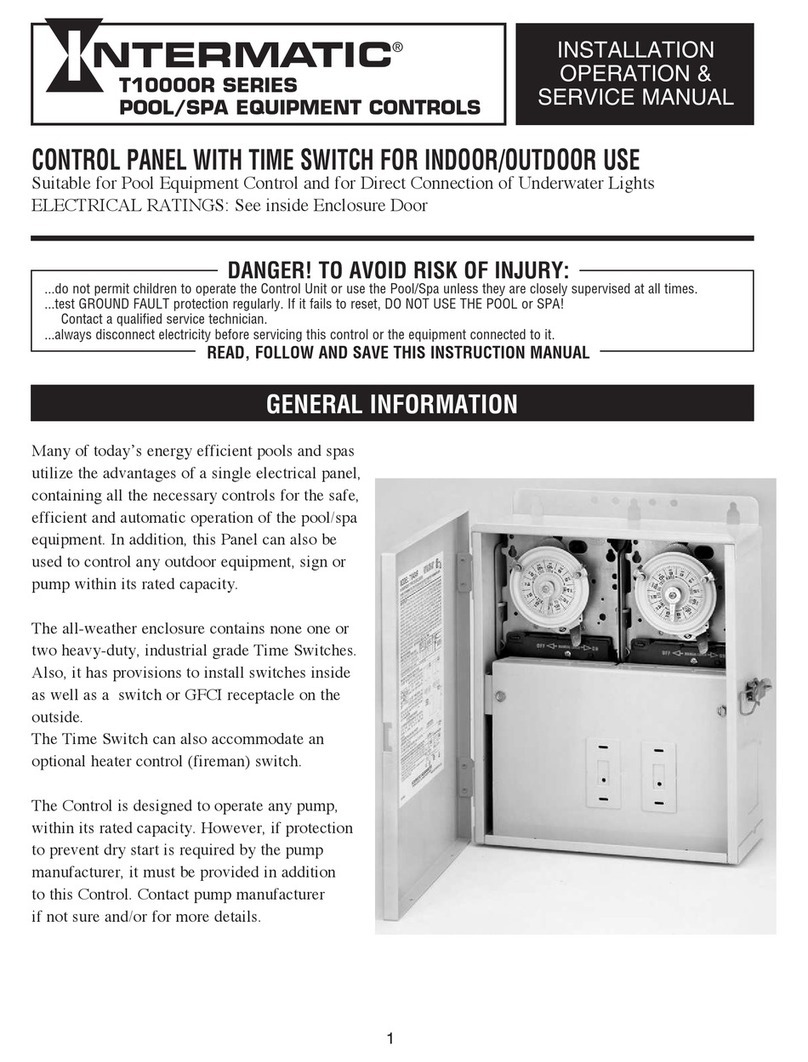

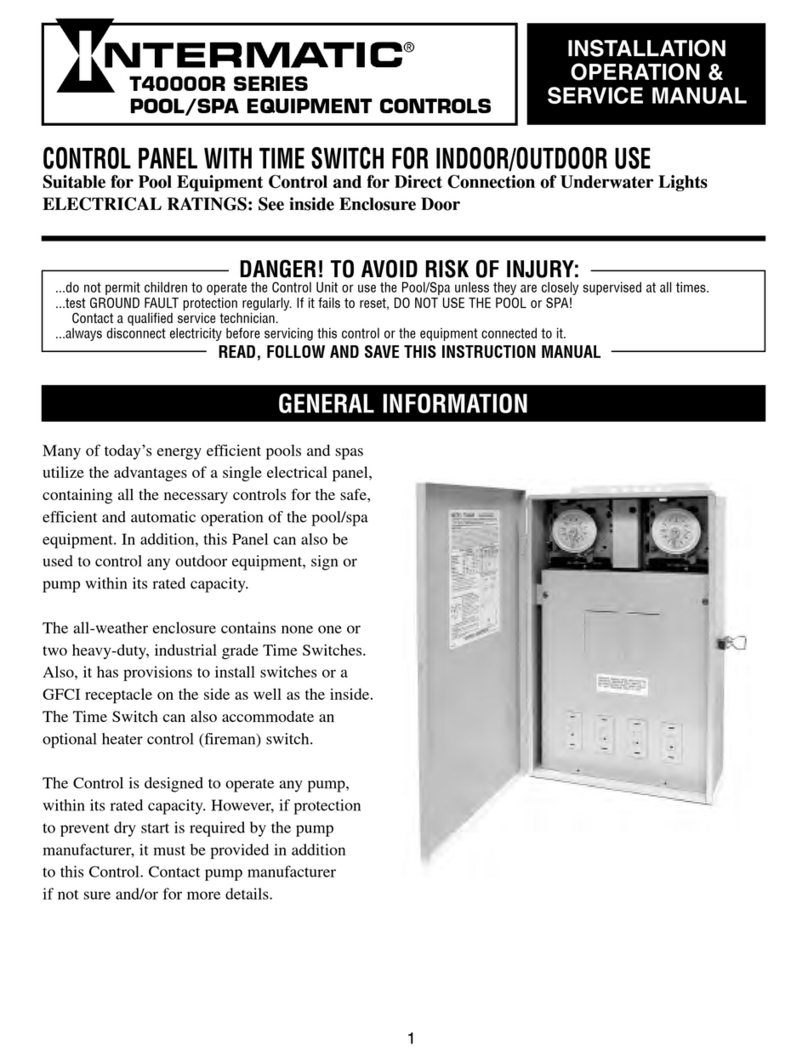

1. Any Intermatic T100M Series Time Switch, P1353ME mechanism, or

P4243ME mechanism may be installed in the bracket(s) provided or in

the event an existing mechanism(s) is replaced.

2. An additional ground bar may be installed in this control panel

(order 130T1318A).

3. If this control panel requires bonding, attach a LISTED bonding

terminal of a suitable size using the mounting hole(s) provided on the

bottom of the enclosure (156T11047A may be ordered).

4. When a circuit breaker is backfed, 22T904A Breaker Hold-Down Kit must

be used.

5. Wiring devices may be installed in this control panel (order 21T156A

(4) stand-offs for mounting).

6. The following kits are available to connect under water luminaires to this

enclosure: 1/2” non-metallic - order 156PA13713A

3/4” non-metallic - order 156PA13714A

1” non-metallic - order 156PA13715A

1/2” metallic - order 156PA14336A

7. Optional opening for Intermatic control device.