Temperzone UC8 Troubleshooting Guide

Contents

1. Cautions........................................................................................................................................... 3

2. Recommended service tool set ........................................................................................................ 3

3. Recommended set of spare parts ..................................................................................................... 3

4. Items to check first........................................................................................................................... 3

5. Controller start-up procedure........................................................................................................... 4

6. Viewing system information ........................................................................................................... 5

7. Controller test mode ........................................................................................................................ 6

8. Commissioning mode...................................................................................................................... 7

9. Timer durations................................................................................................................................ 7

10. Troubleshooting procedure.............................................................................................................. 8

11. Fault messages............................................................................................................................... 10

12. Fault codes..................................................................................................................................... 13

13. Inverter fault codes........................................................................................................................ 16

14. Fault codes shown on a room thermostat ...................................................................................... 17

TZT-100 room thermostat fault codes ................................................................................. 17

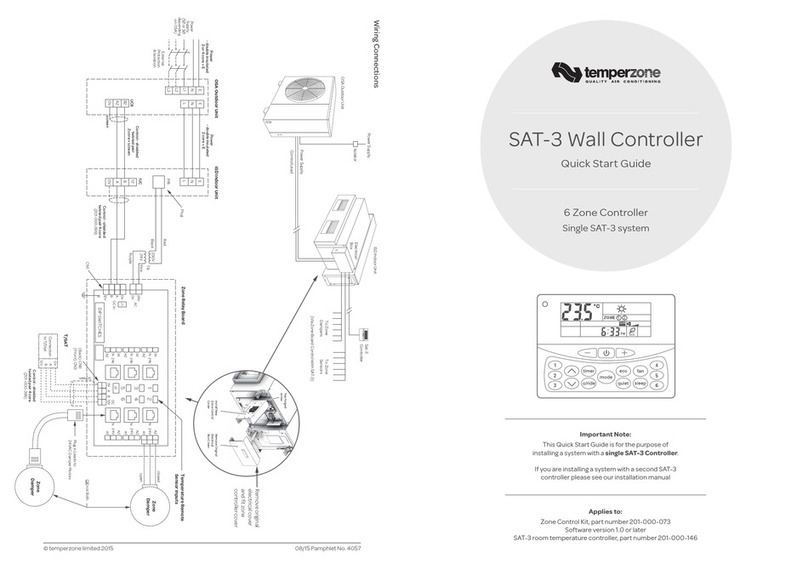

SAT-3 room thermostat fault codes..................................................................................... 17

SAT-3 internal fault codes ................................................................................................... 17

SAT-3 + Zone controller fault codes ................................................................................... 17

SAT-3 + UC8 fault codes..................................................................................................... 18

15. Protection function details............................................................................................................. 19

High pressure protection (HP).............................................................................................. 19

Low pressure protection (LP)............................................................................................... 19

Indoor coil frost protection................................................................................................... 19

High temperature protection................................................................................................. 19

High suction line / evaporating temperature protection....................................................... 20

Low discharge side superheat protection............................................................................. 20

High discharge side superheat protection............................................................................. 20

Freeze protection.................................................................................................................. 20

Reverse cycle valve fault protection .................................................................................... 21

Overload protection.............................................................................................................. 21

High compression ratio protection....................................................................................... 21

Low compression ratio protection........................................................................................ 22

16. Lock-out......................................................................................................................................... 22

17. Unit log.......................................................................................................................................... 23