oventrop Hydromat DP DN 25 Manual

Other oventrop Controllers manuals

oventrop

oventrop Hydromat DTR Series User manual

oventrop

oventrop Unibox E RTL User manual

oventrop

oventrop NR 24 User manual

oventrop

oventrop Aktor M ST L User manual

oventrop

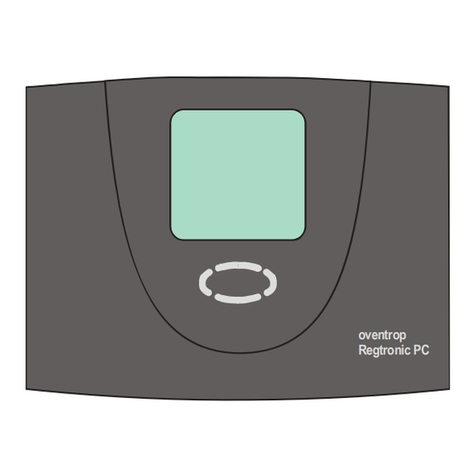

oventrop REGTRONIC PC User manual

oventrop

oventrop Hydromat DFC Operating instructions

oventrop

oventrop Hydromat DTR User manual

oventrop

oventrop Unibox RTL User manual

oventrop

oventrop Aktor M ST L Modbus User manual

oventrop

oventrop R-Tronic User manual

oventrop

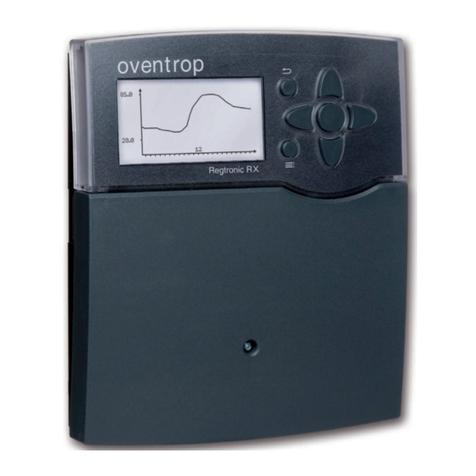

oventrop Regtronic RX User manual

oventrop

oventrop Regtronic RM Operating instructions

oventrop

oventrop Regtronic BS/2-B User manual

oventrop

oventrop Aktor M ST User manual

oventrop

oventrop ENOCEAN R-Tronic RT B User manual

oventrop

oventrop R-Tronic RT B User manual

oventrop

oventrop OV-5 Owner's manual

oventrop

oventrop Regtronic KM IP User manual

oventrop

oventrop Aktor M Manual

oventrop

oventrop Regtronic RH HT Operating instructions

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions