Tempest Typhoon 54.100 User manual

Typhoon User Manual 1

User Manual

Typhoon

Revision 02.1

December 2020

© Tempest Lighting, Inc.

Typhoon User Manual 2

Table of Contents

Introduction ................................................................................................................................................................................................ 5

IMPORTANT: Safety Advisories.............................................................................................................................................................. 5

Installation................................................................................................................................................................................................... 6

Dimensions and Rigging Points.............................................................................................................................................................. 6

Air Clearance....................................................................................................................................................................................... 7

Snow Clearance .................................................................................................................................................................................. 7

Mounting Bolts and Accessories............................................................................................................................................................ 7

Rigging Options –Grab Handles ........................................................................................................................................................ 8

Rigging Options –Unistrut Kit............................................................................................................................................................ 8

Rigging Options –Truss Kit................................................................................................................................................................. 8

Rigging Options –Stacking Kit............................................................................................................................................................ 9

Rigging Options –Drop Arms............................................................................................................................................................. 9

Mounting the Projector............................................................................................................................................................................10

Using Typhoon enclosures in Portrait mode...........................................................................................................................................11

Check your Projector............................................................................................................................................................................11

Outdoor Use in Portrait Mode.............................................................................................................................................................11

Rotate Fan and Connector Panel..................................................................................................................................................... 11

Connecting the Enclosure ........................................................................................................................................................................12

Power Inlet Connector .....................................................................................................................................................................12

Signal Connectors and Cables.......................................................................................................................................................... 12

Rubber Connector Flap .................................................................................................................................................................... 12

Remote Monitoring Connections ........................................................................................................................................................13

Remote Monitoring Options............................................................................................................................................................ 13

Remote Monitoring Connectors...................................................................................................................................................... 13

Digital Enclosure Control.......................................................................................................................................................................... 14

Schematic.............................................................................................................................................................................................. 14

DEC4 Main Functions ...........................................................................................................................................................................15

Firmware Revision............................................................................................................................................................................15

Factory Settings –Data Modes............................................................................................................................................................ 15

Hardware Indicators & Fuses...............................................................................................................................................................16

............................................................................................................................................................................................................... 16

Operating Modes..................................................................................................................................................................................17

RDM Only Monitor (Factory Default) ..............................................................................................................................................17

RDM+DMX Control...........................................................................................................................................................................17

RDM+DMX Service ........................................................................................................................................................................... 17

DEC4 Control Parameters .................................................................................................................................................................... 18

Control Interface ..............................................................................................................................................................................19

User Interface LCD Display...............................................................................................................................................................20

Typhoon User Manual 3

Control Interface Operation ............................................................................................................................................................20

Control Menu........................................................................................................................................................................................ 21

Set Data Options...............................................................................................................................................................................21

Set Temp Units ................................................................................................................................................................................. 22

Set Temp Ranges ..............................................................................................................................................................................22

Set Max Humidity .............................................................................................................................................................................22

Set Lamp On Point............................................................................................................................................................................22

Reset Lamp Hours.............................................................................................................................................................................22

Set Fan Function...............................................................................................................................................................................23

Status Display.................................................................................................................................................................................... 23

Safe Mode............................................................................................................................................................................................. 24

Safe Mode –What to do:................................................................................................................................................................. 24

DEC4 Firmware Updates .......................................................................................................................................................................... 26

Indirect Firmware Updates ..................................................................................................................................................................26

Requirements ................................................................................................................................................................................... 26

Installation Procedure......................................................................................................................................................................26

Routine Maintenance............................................................................................................................................................................... 31

Clean Port Glass................................................................................................................................................................................ 31

Check Filter ....................................................................................................................................................................................... 31

Check Temperature/Humidity Sensor.............................................................................................................................................32

For After Sales Support ....................................................................................................................................................................32

Troubleshooting........................................................................................................................................................................................33

Warranty ...................................................................................................................................................................................................35

Appendix –TEMP Protocol.......................................................................................................................................................................36

Physical Layer........................................................................................................................................................................................36

Developer’s Guide ................................................................................................................................................................................ 36

Typhoon User Manual 4

CERTIFICATE AND DECLARATION OF CONFORMITY

FOR CE MARKING

Tempest Lighting, Inc.

11845 Wicks Street, Sun Valley, CA 91352, USA

t: +1 818 787 8984 f: +1 818 252 7101 e: info@tempest.biz

www.tempest.biz

Tempest Lighting, Inc. declares that their

Projector Enclosure Series 54.xxx.xx

complies with the Essential Requirements of the following EU Directives:

Low Voltage Directive 2006/95/EC Test Report G4.51.LVD

Electromagnetic Compatibility Directive 2004/108/EC Test Report G4.51.EMC

and further conforms with the following EU Harmonized Standards:

EN 60065 : 2002 Test Report 60065.G4.51.01

EN 60529:2001-2002 Test Report 60529.G4.51.02

EN 61000-6-3:2007+A1:2011 Test Report 61000.G4.51.03

EN61000-6-1:2007 Test Report 61000.G4.51.03

EN55015:2006+A2:2009 Test Report 61000.G4.51.03

Dated: 1st July 2016

Position of signatory: President

Name of Signatory: Tim Burnham

Signed below:

on behalf of Tempest Lighting, Inc.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typhoon User Manual 5

Introduction

Thank you for purchasing a Tempest enclosure! We have worked hard to provide you with the very best

product available for its purpose, and we shall continue to do everything possible to ensure that it works well

for you for many years to come.

Please read this manual before starting work!

In the event of difficulty, please contact your Tempest reseller or Tempest direct:

+1 818 787 8984

We will do everything we can to help you get the very best results from your Tempest enclosure.

IMPORTANT: Safety Advisories

•All installation and rigging work done must where applicable be designed and built in accordance

with norms and standards of the local authority having jurisdiction of the installation site. It is the

responsibility of the installer to obtain such approvals as may be required to achieve full

compliance.

•All electrical work must be carried out by a suitably licensed electrical contractor in full compliance

with local electrical standards.

•Lifting: some enclosures and the equipment inside them may be heavy. Use properly rated lifting

equipment where appropriate and never attempt to carry out work with fewer than the number of

workers needed to lift safely.

•It is the responsibility of the installer to ensure that all local building, safety and electrical codes are

strictly adhered to in the installation of this enclosure. Tempest Lighting, Inc., its employees and

agents are in no way responsible for damage arising from failure to follow either the instructions in

this manual or building, safety and electrical codes prevailing at the installation location.

•Do not attempt to install or operate the enclosure before fully reading and understanding this

manual

•Never allow anyone who has not read this manual to open the enclosure or perform maintenance

on the projector within.

•Never leave the enclosure unattended when open.

•Always make sure all bolts and latches are tight and safety locks are in place after performing any

form of maintenance on the unit.

•Do not open any electrical boxes until power has been shut off to all supply lines to the enclosure

(including the one powering the projector).

•Do not open the enclosure in wet weather.

Typhoon User Manual 6

Installation

Dimensions and Rigging Points

*Enclosure weight, no options or accessories

Typhoon A in A mm B in B mm C in Cmm D in D mm E in E mm F in F mm W lb * W kg *

54.100 34 864 30 762 15 381 32 813 26 660 13 330 85 39

54.150 42 1067 32 813 18 445 40 1016 28 711 16 394 106 48

54.210 51 1295 32 813 22 559 49 1245 28 711 20 508 177 80

54.250 51 1295 37 940 24 610 49 1245 33 838 22 559 223 101

54.305 51 1295 34 864 24 610 49 1245 30 762 22 559 205 93

54.310 59 1499 34 864 25 635 57 1448 30 762 23 584 247 112

54.320 67 1702 37 940 25 635 65 1651 33 838 23 584 305 139

Rigging Points:

Six M12-1.75 x 40mm threaded

holes top and bottom, left and

right sides.

Note: M12x40 stainless steel bolts

Supplied.

Note: Typhoon 100 –four rigging

points top, left and right sides, six

on base.

A

B

C

D

E

F

Typhoon User Manual 7

Air Clearance

Observe the minimum clearances shown around your

enclosure

Snow Clearance

In areas where snow is likely, make sure the base of the

enclosure is at least 24” [60cm] above highest potential snow

drift level.

Mounting Bolts and Accessories

Note: In most cases Typhoon enclosures will be installed with

the rigging options shown below.

All the rigging kits are installed using these mounting bolts.

•Each Enclosure must be mounted with SIX points (4 for

Typhoon 100).

•All mountings must be made using the M12 threaded

holes on the enclosure.

•Use an 8mm hex key to secure the M12 socket cap

screws provided.

•Tempest recommends the use of stainless steel

mounting hardware.

•Make sure the air inlet has at least 75mm/3in clearance.

IMPORTANT SAFETY NOTICE

Installer must ensure that all mounting points are secure and

conform to local safety regulations. Tempest Lighting Inc.

accepts no responsibility for damage or injury arising from

inappropriate or unsafe installation.

60cm/24in

8mm

M12-1.75 bolts

Use 8mm hex key

Sealing Washer –

important for outdoor use

Typhoon User Manual 8

Rigging Options –Grab Handles

Grab handles make it much easier to carry and install the

enclosure at the job site.

Handles install to the base of the enclosure for landscape

operation, using the M12 bolts provided. For portrait, attach

the handles to the side rigging points.

Grab handles may be used in conjunction with any of the

available Typhoon rigging accessories.

54.GH.100 Typhoon 100 Pair of Grab Handles

54.GH.150 Typhoon 150 Pair of Grab Handles

54.GH.210 Typhoon 210 Pair of Grab Handles

54.GH.250 Typhoon 250 Pair of Grab Handles

54.GH.310 Typhoon 310 Pair of Grab Handles

54.GH.320 Typhoon 320 Pair of Grab Handles

Rigging Options –Unistrut Kit

If mounting positions for the corner bolts are not convenient,

use the Unistrut Kit to add two Unistrut rails and Unistrut

spring nuts.

Using the spring nuts provided, the enclosure may now be

attached at any point along the Unistrut rails.

54.UR.100 Typhoon 100 Pair of Unistrut Rails

54.UR.150 Typhoon 150 Pair of Unistrut Rails

54.UR.210 Typhoon 210 Pair of Unistrut Rails

54.UR.250 Typhoon 250 Pair of Unistrut Rails

54.UR.310 Typhoon 310 Pair of Unistrut Rails

54.UR.320 Typhoon 320 Pair of Unistrut Rails

Rigging Options –Truss Kit

Use the Truss Hanger kit to hang any Typhoon enclosure from

a truss up to 24in/600mm.

54.TR.100 Truss Kit, Typhoon 100

54.TR.150 Truss Kit, Typhoon 150

54.TR.210 Truss Kit, Typhoon 210

54.TR.250 Truss Kit, Typhoon 250

54.TR.310 Truss Kit, Typhoon 310

54.TR.320 Truss Kit, Typhoon 320

Unistrut Rails may

be mounted above

or below

Max Ø2in [50]

Typhoon User Manual 9

Rigging Options –Stacking Kit

Typhoon may be stacked up to three units high, using the

51.SK stacking Kit. You will need the total number of Typhoons

to be stacked, minus one stacking kit(s).

Note: Typhoons must be of the same model to stack in this

way.

51.SK Stacking Kit (set of four, for one enclosure)

Rigging Options –Drop Arms

Use a pair of drop arms to rig a stack of Typhoons at different

tilt angles, up to 45°.

The drop arms install to the stacking kit legs using the stacking

kit clevis pins.

Important: Stacking kit legs must be installed facing forwards

for use with drop arms.

Note: Drop Arms require the use of a 51.SK Stacking Kit.

54.DA Pair of Typhoon Drop Arms

Attach male stacking leg

to base of top enclosure

with M12 Bolt supplied

Attach female stacking

leg to top of lower

enclosure with M12 Bolt

supplied

Join enclosures together

with clevis pins supplied

Typhoon User Manual 10

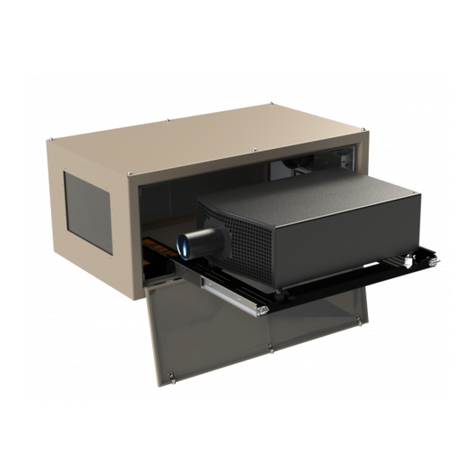

Mounting the Projector

Typhoon enclosures come with a projector mounting plate, customized for each projector type to be used.

The projector mounts to the plate using either the ceiling mount threaded holes in the projector plate, or by removing the

projector feet and replacing with appropriate screws (usually M10 or M12). This varies depending on the projector type.

1. Remove the projector tray from the Typhoon enclosure

2. Remove projector feet

3. Mount projector to plate, using the mounting holes and

screws provided (this will differ by projector type)

IMPORTANT:

Use either all four projector feet sockets or all available

ceiling mount threaded holes, especially for portrait

operation.

NOTE:

You may transport the projector inside the Typhoon

enclosure, provided the enclosure is suitably protected in a

road case or other vibration-absorbing method.

NOTE: You may specify multiple projector types when

ordering, and Tempest will provide mounting holes for each

type specified, based on projector manufacturer drawings.

4. Mount the projector/tray assembly in the enclosure

5. Adjust position front-back –it is usually best to have the

lens front close to the port glass, both for projection and

for air circulation.

6. Fix tray to projector beams, using the M8 screws

provided. For larger projectors, use at least three screws

on each side, especially for portrait operation.

Typhoon User Manual 11

Using Typhoon enclosures in Portrait mode

Typhoon enclosures may be used in either landscape or

portrait mode.

Check your Projector

Many projectors may be used in portrait mode, but some

may not –check with your projector manufacturer.

For those projectors that may be used in portrait mode, the

manufacturer may specify a particular orientation –feet left,

or feet right. Be sure to follow projector manufacturer’s

recommendations.

Outdoor Use in Portrait Mode

When using Typhoon projectors outdoors in portrait mode,

the following steps must be taken:

Rotate Fan and Connector Panel

1. Remove the 12 M4 nuts holding the fan assembly and

Connector panel

2. Rotate the fan assembly connector panel and rubber

connector panel flap 90 degrees COUNTERCLOCKWISE

(looking from inside the enclosure)

3. Replace all nuts.

IMPORTANT: For outdoor use in portrait mode, the enclosure

MUST be used with the inlet grille DOWN, as shown here.

For outdoor use in

portrait mode, you MUST

rig with the inlet grille

down, as shown here

Fan Louver, rotated for

portrait operation

Connector panel and

rubber flap, rotated for

portrait operation

Typhoon User Manual 12

Connecting the Enclosure

Typhoon enclosures for rental and staging are equipped with the power and signal connectors specified by each user, to suit

the user’s existing flexible power and signal cabling systems.

All power and signal connectors are located on the back door:

Rubber Connector flap

DEC4 User Interface

Signal feedthrough connectors (max 9 Neutrik plus 2 x

DVI, to user specification)

Power inlet connector (connector type to user

specification)

Power Inlet Connector

The inlet connector is supplied to customer specification. Types and electrical standards vary.

Signal Connectors and Cables

Signal connectors are bulkhead feedthrough types.

Use short cables inside the enclosure (not supplied) to connect from the feedthroughs to the projector.

Rubber Connector Flap

The rubber flap is intended to protect connectors from rain on outdoor jobs. It may be helpful to wrap it around the cable

bundle and secure with a zip tie or similar.

Spare flaps are provided with each enclosure and are available from Tempest:

54.CF Typhoon Rubber Connector Flap

Typhoon User Manual 13

Remote Monitoring Connections

Remote Monitoring Options

Tempest G4 enclosures optionally support three types of

remote monitoring:

1. Direct via Ethernet, using Tempest TEMP protocol.

Requires 51.EN Ethernet board

2. Grouped via RS485, using RDM

Requires one 51.485 RS485 board per enclosure

3. Grouped via RS485, using an Ethernet bridge and

Tempest TEMP protocol

Requires one 51.485 RS485 board per enclosure

Remote Monitoring Connectors

When Remote monitoring is required, the following signal

connectors must be specified. These connectors must be

included in the maximum allowance of 9 Neutrik signal

connectors, and they will be supplied ready wired to the

enclosure comms boards:

RS485 IN Neutrik XLR5M

RS485 OUT Neutrik XLR5F

Ethernet Neutrik NE8FD EtherCon

Note: Tempest System Manager and web-based monitoring will be available early 2017

51.EN Ethernet Board

51.485 RS485 Board

51.485 RS485 Board

51.485 RS485 Board

51.485 RS485

51.EN Ethernet Board

RS485 Daisy Chain

(use CAT5 Cable)

Ethernet LAN

Ethernet LAN

Local PC

Local PC

Remote PC

Smartphone

Tempest System

Manager

Typhoon User Manual 14

Digital Enclosure Control

DEC4TM –that’s Digital Enclosure Control, fourth

Generation –is the brain of your Tempest enclosure. It will

maintain the internal environment in a comfortable

temperature and humidity range, and prevent

condensation –the real killer of outdoor equipment. DEC4

monitors internal and external temperature, humidity and

lamp current at all times, and uses this information to

control the enclosure’s lamp relay, fan(s) and heater(s). It

can report back over an RS485 network, using the RDM

protocol (Remote Device Management), or connect to

your TCP/IP network for remote monitoring amd

management using Tempest’s TEMP protocol.

Schematic

Typical DEC4

configuration, with

Motherboard, fan

control board and

RS485 comms board

Typhoon User Manual 15

DEC4 Main Functions

Firmware Revision

This manual covers DEC4 Firmware revision 2.03.000 and higher.

To check the Firmware revision, on the User Interface menu, go to Status Display/Firmware.

1. Sense current to projector (lamp on/off)

2. Record lamp hours

3. Monitor temperature and relative humidity

inside Enclosure

4. Monitor temperature outside enclosure

5. Maintain internal temperature at safe operating

level

6. Maintain relative humidity within safe limits to

prevent condensation

7. Isolate projector in case of unsafe temperature

8. Report status over RS485, RDM, TCP/IP

9. Maintain positive pressure (optional) 24/7 to

prevent ingress of salt air and other

contaminants through the exhaust path

10. Circulates air internally to prevent hot and cold

spots when projector is idle

DEC4 constantly monitors the following parameters:

•Projector/Luminaire current

•Line Voltage

•External Temperature

•Internal Temperature

•Internal Relative Humidity

DEC 3.3’s patented GoldilocksTM algorithm uses a combination

of sensors, heaters and fans to maintain a safe operating

temperature and a safe relative humidity level that will not

allow condensation to take place.

As air is heated it is able to support more moisture without

condensing, so Goldilocks uses heat to raise the air temperature

inside the enclosure in the event that relative humidity

approaches dewpoint.

Factory Settings –Data Modes

In most applications, DEC4 will operate correctly with its

factory default settings, in Basic operating mode.

You do not need to do anything. Please skip to the next

section.

•Standard default temperature and humidity settings

•DMX, RDM and Remote Monitoring disabled

•Best for standalone operation

If your needs are more complex, read on.

Typhoon User Manual 16

Hardware Indicators & Fuses

External Temperature Sensor is

connected and functioning (custom

applications only)

Main Temperature & Humidity

Sensor is connected and

functioning (All Enclosures)

Auxiliary Temperature &

Humidity Sensor is connected

and functioning (custom

applications only)

Fan Board is connected and

functioning correctly (blinking)

Optional Ethernet Board is

connected and functioning

RS 485 Comms Board is

connected and functioning

correctly (blinking)

RS485 (DMX/RDM) Data

Packets:

Green: Transmit

Red: Receive

Heater Fuse –10A

slow-blow

Daughter Board

Power Fuse –4A

slow-blow

Fan Fuse –2A

slow-blow

DEC4 Serial Number. Please quote

in all technical support enquiries.

Typhoon User Manual 17

Operating Modes

RDM Only Monitor (Factory Default)

•Supports RDM monitoring over RS485 if present

•Supports TEMP monitoring if present

•RDM Status Reporting over RS485

•RDM Configuration –settings may be changed remotely or

at the enclosure user interface.

•No DMX control

RDM+DMX Control

•Enclosure functions as a 1-channel DMX device, with

remote control of the lamp relay

oDMX level > 75% enables normal relay operation

(normally ON)

oDMX level < 25% disables normal relay operation

(relay turns OFF)

oThis allows you to force a hard reset of the lamp

relay in the event of a projector malfunction

•RDM Status Reporting over RS485

•RDM Configuration –settings may be changed remotely or

at the enclosure user interface.

•Control mode is recommended for show control

applications, but can be risky in live show operation, since

the DMX slot used for the enclosure MUST be kept high to

prevent the lamp relay from opening.

RDM+DMX Service

For trained service personnel only

•Normal operation is suspended and the enclosure

functions as a 3-channel DMX device:

oLamp Relay (Slot 1)

oFans (Slot 2)

oHeater (Slot 3)

•RDM Status Reporting over RS485

•RDM Configuration –settings may be changed remotely or

at the enclosure user interface.

•Service mode is ONLY for troubleshooting –DO NOT use

Service mode for normal operation.

Typhoon User Manual 18

DEC4 Control Parameters

Temperature and Humidity Ranges

Notes:

1 In moving light enclosures the temperature sensor is located in the exhaust airflow. Temperatures

shown may be higher than those around the projector.

2 We recommend using the factory default settings for several weeks or months before making any

changes. In most cases they will not be necessary.

Trip Temp

(55-70˚C, Default 60 ˚C)

Upper Temp

(35-50˚C, Default 40 ˚C)

Trend Temp

(Dynamic)

IdealTemp (Dynamic, based

on Relative Humidity)

LowerTemp

(0-10˚C, Default 0 ˚C)

Cooling Fan(s)

Heater(s)

Relative Humidity

(50-90%,

Default 80%)

Low

High

Typhoon User Manual 19

Control Interface

LED Indicators

Heater

ON (Green)

Heater is ON, to maintain lower temperature level or to prevent

condensation

ON (Amber)

Enclosure is temporarily outside the Goldilocks zone, and DEC is working to

restore it

Fan

ON (Green)

Lamp is ON, or Temperature is HIGH and fan is cooling enclosure. Short burst

when lamp off indicates fan moving air to stabilize temp/humidity.

NOTE: Fan LED will not light if no fan is detected

Lamp On

ON (Green)

Current sensing shows lamp is ON

Lamp hour counter is running

OFF

Current sensing shows lamp is OFF

Lamp hour counter is not running

Lamp Relay

ON (Green)

Lamp relay is closed (normal)

Projector power receptacle is energized

ON (Red)

Lamp relay is open due to over-temperature event. Projector power

receptacle is isolated.

Temp

FLASHING

(Green)

Temperature is below lower temp setting

ON (Green)

Temperature is in normal range

ON (Amber)

Humidity is above target limit

ON (Red)

Temperature is above top setting

FLASHING (Red)

Temperature is above Trip level

Projector power is isolated

Data

OFF

Data not used in present Mode. OR DEC4 is in RDM + DMX Control Mode and

no valid data packet has been detected.

ON (GREEN)

Good data packet received.

ON (RED)

RDM + DMX Control Mode: Data Fail. A previously good data signal has failed.

Typhoon User Manual 20

User Interface LCD Display

The display on the Control display provides additional status

information, depending on the operating mode:

RDM Only Monitor Mode

RDM+DMX Control Mode

RDM+DMX Service Mode

Control Interface Operation

The Control Interface is normally LOCKED.

•To UNLOCK, hold ESC and OK together for 5 seconds.

•You are now in the CONTROL MENU

•Use to scroll up and down the menu.

•Press OK to enter a menu item

•Use to set the item parameter, or to scroll to the

next menu level.

•Use ESC to go BACK, or OK to confirm settings ().

•To exit and LOCK, hold ESC for 5 seconds.

Menu will time out and the display will lock after ten

minutes.

(Alternating DMX Display requires a DMX

signal to be present)

This manual suits for next models

6

Table of contents

Other Tempest Enclosure manuals