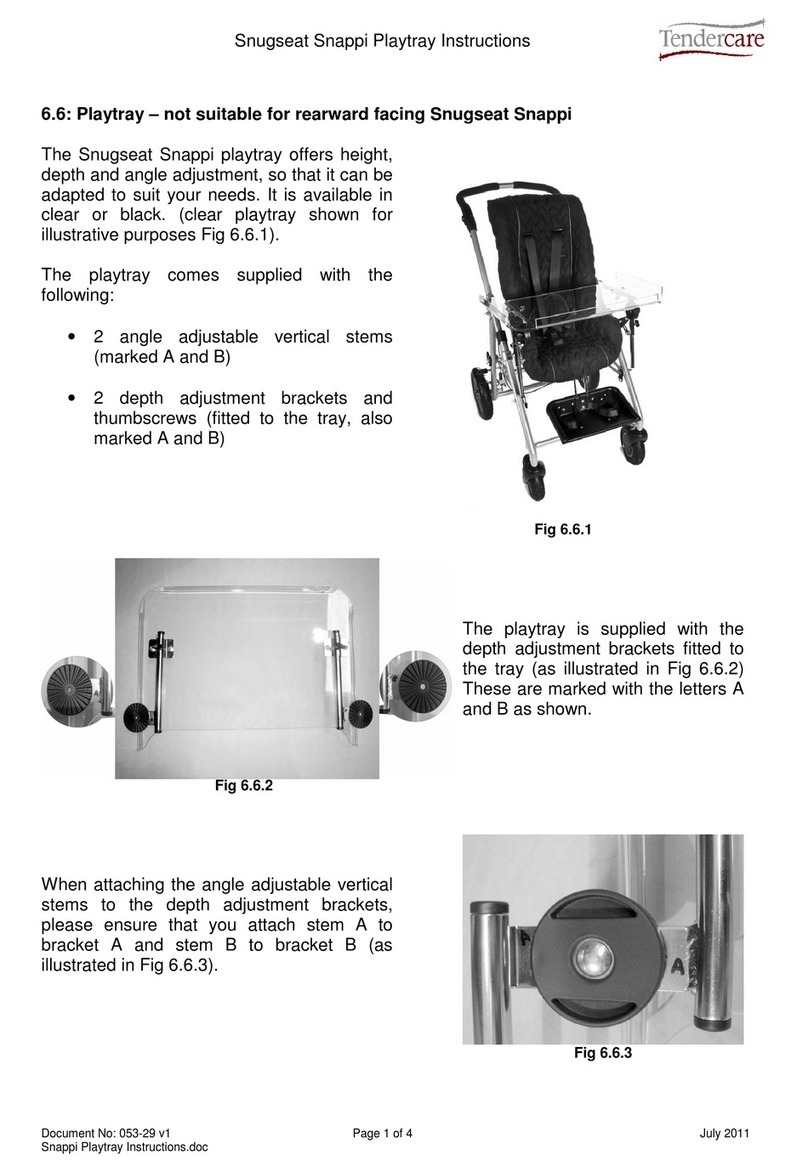

Tendercare Snazzi Instruction manual

Other manuals for Snazzi

1

Table of contents

Other Tendercare Stroller manuals

Tendercare

Tendercare Nursery Snugseat Spring User manual

Tendercare

Tendercare Snugseat Snappi User manual

Tendercare

Tendercare Snappi Pushchair User manual

Tendercare

Tendercare Swirl Instruction manual

Tendercare

Tendercare Cloud Instruction manual

Tendercare

Tendercare Snappi Pushchair Instruction manual

Tendercare

Tendercare Snappi User manual

Tendercare

Tendercare Snapi Pushchair User manual

Tendercare

Tendercare Swirl User manual

Tendercare

Tendercare Snugseat Snappi User manual

Popular Stroller manuals by other brands

Baby Jogger

Baby Jogger City Tour Lux user manual

Baby Trend

Baby Trend TJ83 instruction manual

MaxiCosi

MaxiCosi Zelia3 Instructions for use

Steelcraft

Steelcraft AX101 series instruction manual

Baby Trend

Baby Trend Navigator DJ86 B Series instruction manual

Baby Trend

Baby Trend EZ Ride Plus TS44 D Series instruction manual

Baby Trend

Baby Trend Expedition 2-in-1 Stroller Wagon PLUS WG01 A... instruction manual

Baby Jogger

Baby Jogger VUE Assembly instructions

MaxiCosi

MaxiCosi Board manual

VALCOBABY

VALCOBABY VEEBEE CO-RIDER Assembly instructions

MaxiCosi

MaxiCosi MURA PLUS instructions

Baby Trend

Baby Trend SERENGETTI 1956CT instruction manual