Tendercare Swirl Instruction manual

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 1 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Swirl ®

WHEELBASE AND INTERFACE

WORKSHOP MANUAL

IMPORTANT

Please read these instructions carefully before attempting any repairs to the

wheelbase / interface. Repairs should only be carried out by a repairer as

approved by either Tendercare Ltd or the NHS.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 2 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Fig 0.1 Swirl Wheelbase Front View

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 3 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Fig 0.2 Swirl Wheelbase Rear View

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 4 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Fig 0.3 Wheelbase Folded

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 5 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Fig 0.4 Seat Interface

Fig 0.5 Interface Fitted To Frame

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 6 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Fig 0.7 Swirl with Snug Seat, Forward Facing

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 7 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Fig 0.8 Swirl with Snug Seat, Rearward Facing

Fig 0.9 Swirl with Modular Seat, Rearward Facing

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 8 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

CONTENTS

Item

Description

Page

1

Your Snappi Wheelbase and Interface Workshop Manual

9 –10

2

Transit Packaging

11

3

Tools & Torque Settings

12

4

Preparing for use and operation

12

4.1 Unfolding the frame

12

4.2 Pin Brakes

12

4.3 Tilt In Space

13

4.4 The Interface

13

4.5 Rotation mechanism

13

5

Fitting Special Seat

14 –15

6

Final Checks

15

7

Maintenance

15

7.1 Routine maintenance

15

7.2 Six monthly maintenance

16

8

Repairs

17

8.1 Rear wheels

18

8.2 Castor assembly

19

8.3 Pin Brake Assembly

20 –23

8.4 The Interface

24 –25

8.5 Push Handle Adjustors

26 –27

8.6 Change the Locking Lever

28 –33

9

Cleaning

34

10

Parts Lists

34

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 9 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

1: Your Swirl Wheelbase / Interface Workshop Manual

The purpose of this manual is to help you get the best from your wheelbase & interface. It

does this by telling you how to complete those maintenance and repair tasks that can be

carried out by a competent person. The manual also tells you when you should contact the

manufacturer who is:

Tendercare Ltd.

PO BOX 3091, Littlehampton, BN16 2WF

Tel: (01903) 726161 Fax: (01903) 734083

Email: [email protected]

Web: www.tendercareltd.com

IMPORTANT:

This manual must be read and used in conjunction with the user manual.

The Wheelbase is made of a strong and lightweight aluminium alloy, minimising weight

and providing a very rugged frame. The wheelbase provides tilt in space and rotation

facilities and has 2 fixed rear wheels and 2 castor wheels at the front for easy steering.

The Interface provides a very lightweight, easy to operate, quick release system that can

be fitted to a wide range of special seating systems. Please note the interface requires

additional framework to fit to a seat, and has been designed to take 19mm (3/4”)

aluminium or mild steel tube.

The interface can be quickly fitted and released from the wheelbase, which can be folded

for transport. The Swirl has been successfully impact tested as a wheelbase and interface,

with the Snappi, Snug and Modular seating systems. When fitting 3rd party seating

systems to the Swirl, the manufacturer of the system must carry out a risk assessment

before use.

These instructions apply to all sizes.

Interfacing Options:

Seat / Interface

Version

Max Carry

Weight (Kg)*

Maximum Seat Width

(mm)

Maximum Footrest

Width (mm)

Size 1

50

430

320

IMPORTANT:

❖Maximum width; maximum space available for seating systems being fitted into

frame.

❖*Maximum carry weight is defined as the user weight, weight of the seating

system, plus any accessories / equipment which may be fitted or carried on the

chassis. Warning: Never exceed the maximum stated carry weight.

Frame Weight: 13.4kg

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 10 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

Swirl Wheelbase Open Dimensions (mm):

A

B

C

985

583

984

Swirl Wheelbase Folded Dimensions (mm):

A

B

C

622

583

546

All sizes and weights are given as a guide. Tendercare ltd reserves the right to amend

specifications at any time as part of their product development programme.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 11 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

2: Transit Packaging

The Swirl wheelbase and interface are delivered together in a cardboard carton. This

measures 740mm wide x 650mm deep x 510mm high and weighs approximately 16.5Kg.

WARNING:

The transit carton is quite bulky so moving and unpacking must be done with care.

Observe all lifting and handling regulations.

Stand the carton upright making sure it is supported and cannot fall over. Open the carton

and remove any packages or packing materials, which could obstruct the removal of the

wheelbase. Remove the wheelbase.

The carton should contain the following items:

Item

Component

QTY.

Yes

No

1

Swirl Wheelbase

1

2

Interface (if ordered)

1

3

User Manual

1

IMPORTANT:

❖The interface will be supplied fitted to the frame. These can easily be separated by releasing

the interface catch once the frame has been removed from its packaging. Please refer to

section 4.4 of the user manual for more information on working with the interface.

❖If any items are damaged or missing, then please contact Tendercare, preferably by email at

delivery.

After unpacking and checking that you have all the components and that they are in good

condition dispose of the packaging at your local recycling centre. Alternatively retain and

reuse.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 12 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

3: Tools and Torque Settings

The following tools are required to dismantle, reassemble and repair the Wheelbase /

Interface:

Spanners and sockets: 10mm, 13mm and 19mm

Hexagon Keys: 4mm, 5mm and 6mm

Torque Wrench: Range 0 to 50 Nm

Torque Settings If Not Specified

Spanner Size (mm)

Torque (Nm)

10

15

13

25

19

50

4: Preparing for use and operation

WARNING:

When opening or folding the wheelbase, ensure that you hold the frame so that you

avoid any danger of catching your fingers in moving parts.

The following pre-delivery procedures should be carried out to check that the wheelbase

and interface has not suffered damage during transit and that all features operate

satisfactorily. Refer to the user manual for detailed instructions on performing each action.

4.1 Unfolding the Frame

Unfold and assemble the frame: Follow the instructions in section 4.1 of the user manual

Checks:

•Make sure all joints move freely

•Make sure the frame lock bar latches correctly

•Ensure the handles move freely and lock securely

•Check that the push handle adjustors work

•Ensure that all fixings are secure and that the frame has not been bent or otherwise

damaged during transit.

4.2 Brakes

Test the brakes: Follow the instructions in section 4.2 of the user manual

Checks:

•Make sure the brakes work correctly

•Check that the fixing bolts are secure

WARNING:

The break mechanism is spring loaded so care must be taken when operating it.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 13 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

4.3 Tilt in Space

Test the tilt in space mechanism: Follow the instructions on section 4.3 of the user

manual.

Checks:

•Make sure that the tilt lever is free to move.

•Check that the centre section tilts correctly and locks throughout its adjustment

range.

•Check that the 4 bolts that mount the centre section into the frame are secure.

IMPORTANT:

❖Always ensure any harness provided for the child is used and correctly adjusted before

reclining or returning the seat to a more upright position.

❖Always support the seat when tilting, as the gas springs can be quick to operate. If the seat is

not supported, is may move swiftly and could cause the occupant distress.

4.4 The Interface

Test the operation of the interface: Follow the instructions on section 4.4 of the user

manual to attach and remove the interface.

Checks:

1. Make sure that the interface frame has not been bent or damaged during transit

2. Check that the spring clips move freely and snap back to their closed position when

the lever is released

3. Make sure the interface latches down and locks securely to the frame

4. Check that the secondary latch mechanism functions correctly

5. Check that the interface releases correctly and that there is not excessive friction on

the lever when releasing it from the frame

IMPORTANT:

❖The interface is spring loaded, so ensure your fingers are clear of the clips before fitting.

4.5 Rotation System

Test the operation of the rotation mechanism: Follow the instructions on section 4.5 of the

user manual ‘switching from forward to rearward facing’.

Checks:

1. Make sure the handles release easily and are free to move when lowered

2. Ensure the rotation release catch lifts easily and fully releases

3. Ensure the mid-section is free throughout the full rotation

4. Check that the rotation locks securely once the mid-section has been rotated 180

degrees.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 14 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

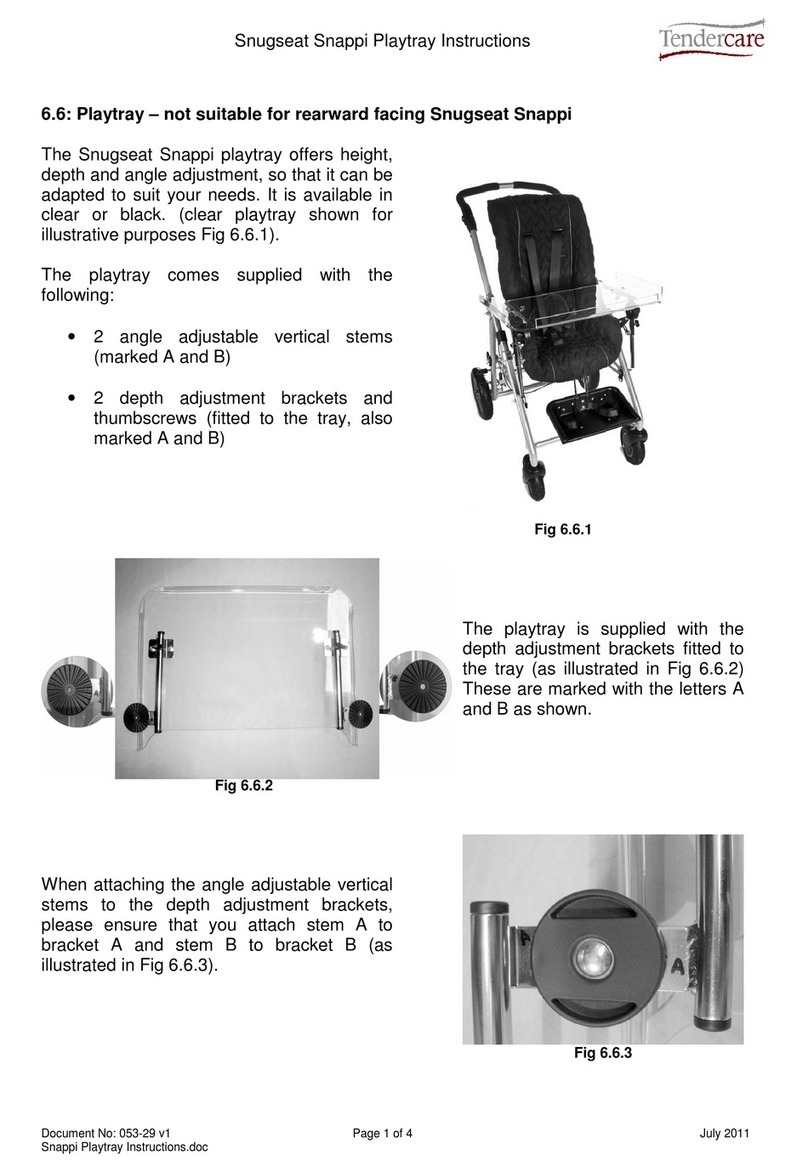

5: Fitting a Special Seat

The interface is designed to bolt onto the base of a special seating system using the 4

base fixing points.

The interface should always be fitted with a suitable framework and includes 4 tube

mounting brackets that fit 19mm or ¾” aluminium or mild steel tube.

We recommend using ¾” x 10 SWG (or 19 x 3mm metric) aluminium tube in grade 6063

T6 for the frame mounting. Alternatively 16 SWG (1.6mm) mild steel tubing can be used.

Due to the wide range of different special seating systems, Tendercare do not supply

fixing brackets for these items. Please refer to the special seat manufacturers instructions.

An example set up using the interface is shown below:

Fig 5.0.1

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 15 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

IMPORTANT:

❖The Swirl has been successfully impact tested as a wheelbase and interface with the Snappi

seating system. When fitting third party seating systems to the Swirl, the manufacturer of the

system must carry out a risk assessment before use.

❖When fitting a third party seat stability may be affected. A test is necessary to confirm that

the static stability is satisfactory. A stability test to meet the requirements of EN.ISO7176

must be completed by the commissioning wheelchair service. This test must be passed

before handover of the system.

6: Final checks

1. Check that the special seat is firmly attached to the interface and framework.

2. Check that all harnesses are secure and adjusted properly.

3. Check that the interface is located and locked correctly in the wheelbase.

7: Maintenance

Should a problem be found when carrying out the regular checks, it should be immediately

reported to the issuing authority or Tendercare Ltd.

7.1 Routine maintenance

The user’s family can easily carry out the following tasks. No tools are required.

1. Always wipe the wheelbase and seat frame dry. Never put them away damp.

2. Check all nuts, bolts, and hand wheels are tight (daily)

3. Check operation of the brake, folding, rotation and reclining mechanisms (weekly).

4. Clean frame when necessary (we suggest at least once a week).

5. If your pushchair is fitted with pneumatic tyres, regularly check the condition of the

tyre. Ensure tyres are inflated to 36 psi (if too low use a suitable hand or foot pump,

do not use an air-line or mechanical inflator, and do not over inflate the tyre). In the

event of a puncture, you will need to purchase a set of tyre levers and a puncture

repair kit form a reputable bicycle shop. Always follow the instructions given in the

puncture repair kit.

If you find any faults refer to your issuing authority or Tendercare Ltd.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 16 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

7.2 Six-monthly maintenance

Only someone who is a competent tradesman or repairer should carry out this work. If a

major fault is found stop using the wheelbase until it has been corrected.

1. Fold and open the wheelbase. Check that all movements through the folding

range are free. Examine frame for any damage.

2. Check operation of the wheelbase tilt in space mechanism.

3. Examine nuts, bolts, pivots and frame plugs for tightness and general condition.

4. Examine brake assembly for wear, damage and correct operation.

5. Examine tyres for sharp objects, cuts or splits.

6. Examine castor and wheel bearings for excessive wear.

7. Check castors and rear wheels for free rotation, security and accumulation of fluff

and grit. Remove any fluff and grit with a dry lint free cloth.

8. Check the Interface fits securely into the frame, and that it is not worn or damaged.

9. Check the interface clips to ensure they can rotate freely and that the springs

return the clips to the closed position when released.

10. Check the handle folding mechanism for wear, damage and correct operation.

11. Check the rotation mechanism, ensure it locks securely and rotates freely when

released.

For all other repairs refer to your issuing authority or Tendercare Ltd.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 17 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

8: Repairs

Only an authorised repairer should carry out the following repairs.

1. Repairs: For all repairs contact your issuing authority

2. Major repairs: For all major repairs e.g. bent or damaged frame, the wheelbase /

interface should be returned to the factory. Contact Tendercare ltd, customer

3. Factory replacement components should be used in all repairs. These are available

from Tendercare. Please refer to the parts lists at the end of this manual (section

10) for details of replacement parts.

Important points when performing a repair:

1. Do not reuse Nylock nuts, always replace with a new nut

2. Always use Loctite thread locking compound grade 241 or 243 on all threads when

reassembling any part of the system.

3. Always use the recommended component parts available from Tendercare Ltd.

4. Do not attempt to correct bent framework or perform any modifications to welded

parts. If any main framework sections are bent or damaged please return the

product to the factory.

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 18 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

8.1: Rear Wheels

Replace if damaged or worn. To change the rear wheel:

Fig 8.1.1

•Remove the wheel cap using a small

screwdriver (see fig 8.1.1 left)

•Using a 19mm spanner, undo the

axle bolt and remove the wheel from

the frame (see fig 8.1.2 below)

•Place the M12 bolt through the rear

wheel, apply a pea-sized amount of

loctite 243 to the bolt thread, and

thread into the threaded hole in the

frame.

•Tighten to 35Nm with a torque

wrench

•Finally push fit the wheel cap over

the bolt head.

Fig 8.1.2

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 19 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

8.2: Front Castors

Replace if damaged or worn. To change the front castor:

Fig 8.2.1

•Remove the wheel by unscrewing

the M8 socket cap bolt using a 5mm

hexagon key (see Fig 8.2.1, left).

•Next remove the castor housing and

front tie down by undoing the main

M12 bolt using a 19mm spanner as

shown in Fig 8.2.2 (below).

•To fit the new castor, first ensure the

wheel is removed from its housing.

•Place the M12 front castor bolt

through the castor housing and the

tie down bracket, making sure to

keep the loop of the tie down bracket

facing the front of the frame. Apply

some Loctite to the thread on the

M12 bolt (see fig 8.2.3 below).

Fig 8.2.2

Fig 8.2.3

•Tighten the M12 bolt to 35Nm with a

torque wrench. This should secure

the castor hosing and front tie down

bracket.

•Screw the new wheel into the castor

housing using a 5mm hexagon key

and tighten firmly (no other tool is

required to fit the wheel as the castor

housing includes a captured nylock

nut).

Swirl Wheelbase and Interface Workshop Manual

Document No: 056-02 v3 Page 20 of 34 June 2018

Swirl Wheelbase and Interface Workshop Manual.doc Patent No. GB2552197

8.3: Pin Brake Assembly

Replace the brake bar if it is bent or damaged. The springs, actuators and guide bushes

can also be replaced if warn.

IMPORTANT

❖The brake system uses two compression springs. Care must be taken when working on the

brake mechanism. The following instructions are the recommended method to safely

dismantle the brake assembly. If you are not confident to work on this assembly please

return your frame to the Tendercare factory.

To remove the pin brake. First set to the

brake to the ON position (for instructions

how to do this please refer to the user

manual).

Then, remove the rear wheels (see section

8.1).

Fig 8.3.1

Fig 8.3.2

As the brake is set to ‘on’ the ends of the

lock pins will be accessible. Use a pair of

grips to pull one of the pins out against the

spring to reveal the 2mm ‘assembly’ hole in

the brake pin (see Fig 8.3.2, left).

Push a 2mm pin through the assembly hole

(pins will be provided with replacement

brake parts).

This will hold the brake pins in the fully

extended position.

Fig 8.3.3

Other manuals for Swirl

1

Table of contents

Other Tendercare Stroller manuals

Tendercare

Tendercare Snappi Pushchair User manual

Tendercare

Tendercare Snugseat Snappi User manual

Tendercare

Tendercare Snappi Pushchair Instruction manual

Tendercare

Tendercare Snazzi User manual

Tendercare

Tendercare Nursery Snugseat Spring User manual

Tendercare

Tendercare Snappi Seat User manual

Tendercare

Tendercare Snazzi Instruction manual

Tendercare

Tendercare Cloud Instruction manual

Tendercare

Tendercare Snugseat Snappi User manual

Tendercare

Tendercare Snazzi Pushchair User manual