Tendercare GAS STRUT TILT and FOLD Wheelchair Instruction manual

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 1 of 18

W

WO

OR

RK

KS

SH

HO

OP

P

M

MA

AN

NU

UA

AL

L

F

Fo

or

r

T

TI

IL

LT

T

a

an

nd

d

F

FO

OL

LD

D

W

WH

HE

EE

EL

LC

CH

HA

AI

IR

R

G

Ga

as

s

S

St

tr

ru

ut

t

M

Mo

od

de

el

l

Please read these instructions carefully

before attempting to maintain the wheelchair

Warnin

The cartons are heavy

Moving and unpacking must be performed with care

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 2 of 18

Headrest

Push

Handle

Tipping

Lever

Seat Tilt

Lock

Brake

Lever

Footrest

Armrest

T

TE

EN

ND

DE

ER

RC

CA

AR

RE

E

TILT & FOLD WHEELCHAIR

Backrest

Lock

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 3 of 18

CONTENTS

ITEM

DESCRIPTION PAGE

1 Your Tilt & Fold Wheelchair Manual……………………….……... 4

2 Transit Packaging…………………………………………………... 4

3

Tools and Torque Settings………………………………………

…..

5

4

Preparing for Use……………………………………………….…...

5

4.1 Unfolding the Wheelchair……………………………………… 5

4.2 Fitting Footrest…………………………………………….…… 7

4.3 Fitting and Removing Headrest………………………………… 8

4.4 Tilt in Space Mechanism……………………………………….. 8

4.5 Tyres and Brakes……………………………………………….. 9

5

Cleaning……………………………………………………………..

9

6

Maintenance…………………………………………………………

9

6.1 Routine Maintenance…………………………………………… 9

6.2 Six Monthly Maintenance Procedure……………………….…. 10

7 Repairs………………………………………………………….…… 10

7.1 Front Castors …………………………………………………... 10

7.2 Rear Wheels…………………………………………………….

1

1

7.3 Brake Adjustment………………………………………….……

11

7.4 Replacing Armpads……………………………………………..

11

7.5 Replacing Seat Upholstery………………………………

……...

11

7.6 Replacing Backrest Upholstery………………………….……... 12

7.7 Replacing Gas Struts…………………………………………… 13

8 Important Points…………………………………………………….. 16

9 Dimensions and Weights……………………………………….…… 16

10

Parts List……………………………………………………………..

1

8

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 4 of 18

1. Your Tilt & Fold Wheelchair Manual

The purpose of this manual is to help you get the best from your wheelchair. It does this by

telling you how to complete those maintenance tasks that can be carried out by a competent

person. The manual also tells you when you should contact the manufacturer who is: -

Tendercare Ltd

PO Box 3091, Littlehampton, BN16 2WF

Tel (01903) 726161 Fax (01903) 734083

2. Transit Packaging

Warning the transit carton is heavy, moving and unpacking must be done with care.

Observe all lifting and handling regulations.

1) The wheelchair is supplied in a cardboard carton of approximate size and weight 800 mm

wide x 350 mm deep x 870 mm high. Weight of carton 28 kg

2) Stand the Carton upright making sure it is supported and cannot fall over. Open the

carton and remove any packages or packing, which could obstruct the removal of the

frame.

3) When you have removed the contents and checked you have all the items listed below you

should dispose of the packaging at your local recycling centre.

4) Check that you have the following items: -

Item Component Number Yes No

1

Tilt and Fold wheelchair

1

2 Armrests 2

3 Push handles 2

4

Thumb Screws

(for push handles)

4

5

Footrests

2

6 Headrest support rods 2

7 Fabric headrest support. 1

8

Headrest cushion

1

9 User Manual 1

Check all items for damage to paintwork, alignment, welds etc.

If any items are damaged or missing please contact Tendercare, preferably by fax 01903-

734083 within 36 hours of delivery.

The general assembly of the Tilt & Fold wheelchair is illustrated on page 2.

A parts list is given on page 13.

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 5 of 18

3. Tools and Torque Settings

The following tools are required to dismantle and reassemble the wheelchair: -

Spanners and sockets: - 7mm, 8mm, 10mm, 13mm, 19mm, 22mm, 24mm,

3

/

16

Whitworth.

Hexagon Keys: - 2.5mm, 3mm and 4mm.

Torque Wrench: - range 0 to 60 Nm.

Screwdrivers: - Phillips and Flat Blade.

Torque settings: -

Spanner Size Torque Nm

7 mm

8

8mm

10

10mm 15

13mm 25

17mm

30

19mm 45

22mm 50

24mm

54

3

/

16

Whitworth

(Footplate angle adjustment)

8

4. Preparing for use

The wheelchair is supplied ready for use. The following pre-delivery procedures should be

carried to check that the wheelchair has not suffered damage during transit and that all

features operate satisfactorily.

Warning: - When opening or folding the wheelchair, ensure that you hold the frame so

that you avoid any danger of catching your fingers in moving parts.

4.1 Unfolding and folding: - make sure all items below are working properly

With the wheelchair standing upright.

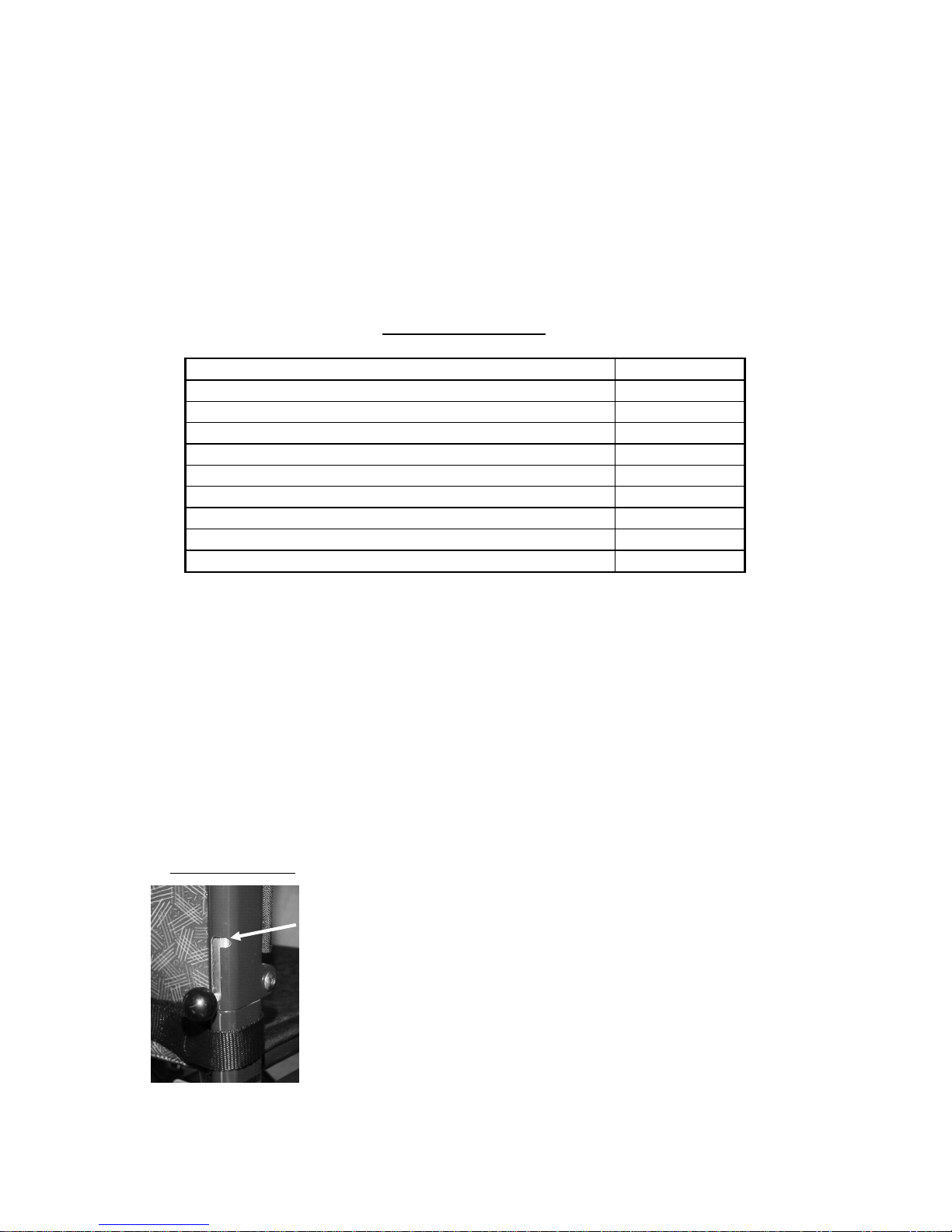

1. Backrest supports: - Make sure the locks operate positively and freely

Standing behind the wheelchair lift the backrest locking pins using the

ball shaped handgrips at the bottom of the backrest tubes. Turn them

so that they lock into the groove arrowed opposite

Lift backrest supports vertical.

Lock the supports in position by moving the finger grips out of the

arrowed groove (see photo) and making sure they have moved to the

bottom of the slot in the backrest tube.

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 6 of 18

2. Push handles: - Check adjustment and security.

The push handles are fitted to the wheelchair prior to delivery. Make sure that they are in

place and that two thumbscrews are fitted to each push handle.

To adjust the height of the push handles unscrew (turn anti clockwise) the two thumbscrews

at either side and near the top of the backrest. Lift or lower the push handles to the height

required then retighten (turn clockwise) the thumbscrews.

To prevent the push handles moving in use these screws must be tight. Check tightness daily.

To make it easier for some people to push the wheelchair when the backrest is in its lowest

position the push handles can be reversed so that the handgrips are pointing forwards. Simply

unscrew the thumbscrews, turn the push handles so they are pointing forwards and refit the

thumbscrews. Take care not to get the screws cross threaded when refitting them. Note; -

when the handgrips are in this position the headrest cannot be used.

3. Unfolding the seat: - Check operation of folding mechanism

Standing in front of the wheelchair place palms of hands on each side of the seat then press

down to open the wheelchair. Take care to hold your fingers towards the centre of the seat to

avoid catching them on the wheelchair frame.

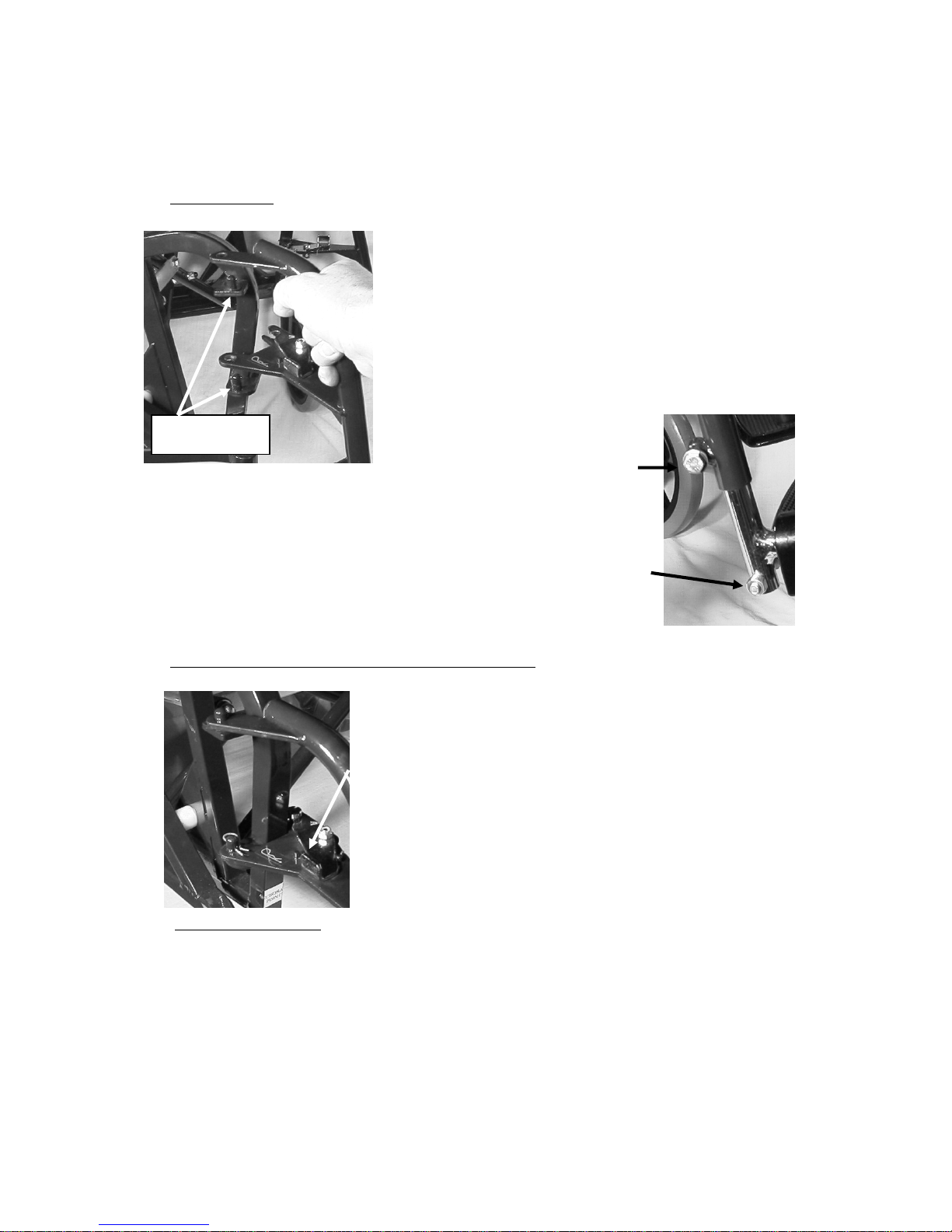

4. Backrest spreader bar: - check operation

Standing behind wheelchair lift the chrome “spreader” bar,

which is on the right hand backrest support, upwards and

place its slotted end onto the peg on the left hand backrest

support (arrowed). It may be necessary to push the backrest

supports apart when doing this.

5. Armrests: - Check fitting

Standing at the side of the wheelchair place each armrest into

the holes in the wheelchair frame. (See photo). Make sure they

are pressed into the wheelchair frame properly.

Make sure that the tube supporting the armpad extends to the

rear of the wheelchair.

To fold the wheelchair, reverse the above.

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 7 of 18

4.2 Fitting and removing footrests

1) Fit the footrest: - check operation

To fit the right hand footrest, stand in front of the

wheelchair. Remove the spring clip from the lower hinge

pin on the side of the wheelchair. Making sure the footplate

is facing in towards the centre of the wheelchair place the

footrest onto the hinge pins. (See Photo opposite). Replace

the spring clip. Swing the footrest towards the centre of the

wheelchair until it locks in place.

Repeat for the right hand footrest.

Adjust the height of the footrest by

loosening the nut on the support tube

using a 10 mm spanner. Move the footrest to the desired height then

retighten the clamp nut. (See picture opposite).

The angle of the footplate can be adjusted by loosening the lock nut,

which is at the bottom of the footplate support tube. Screw in or out the

footplate stop; until the desired angle is obtained then retighten the lock

nut.

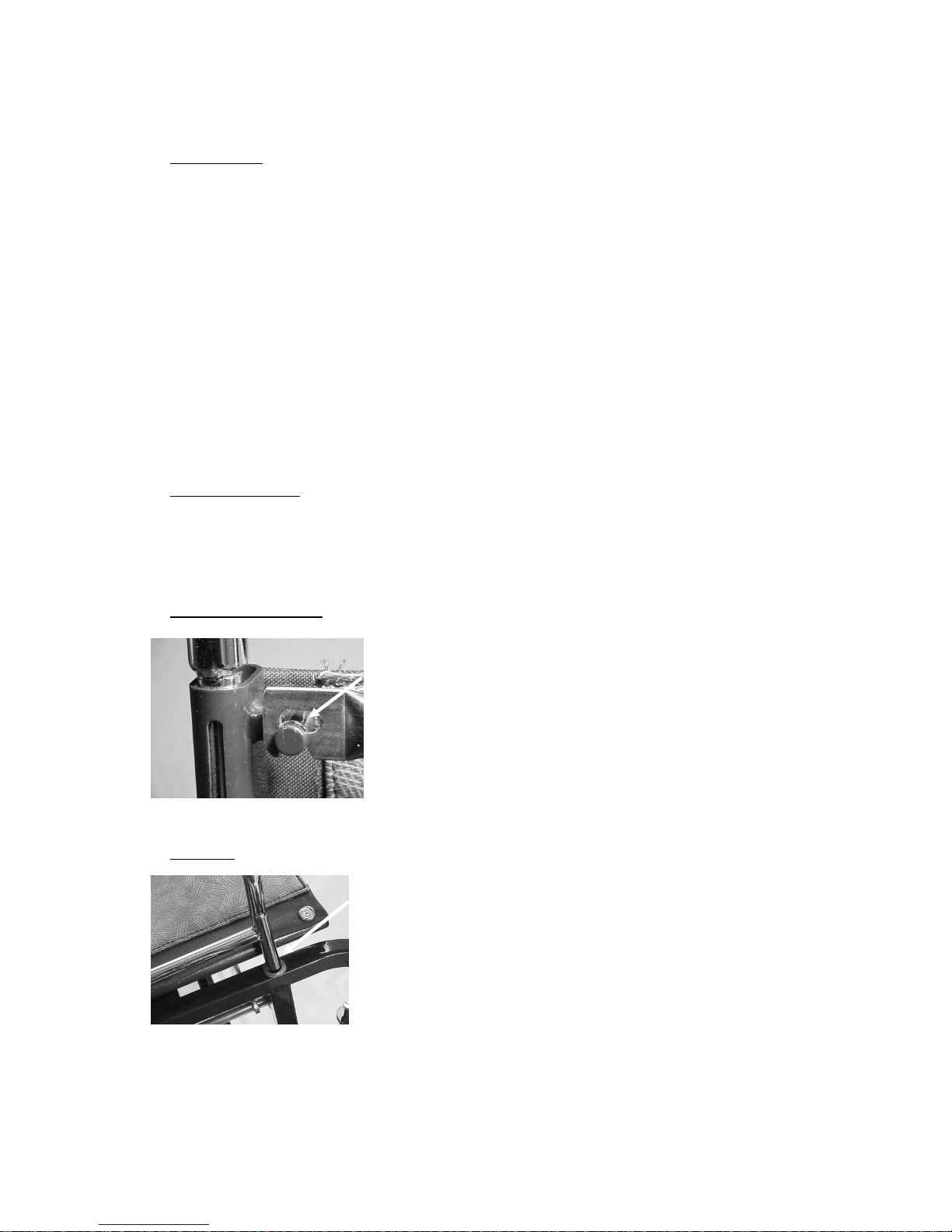

2) To fold footrests back against the wheelchair frame.

Lift up the footplate so that it is vertical then push on the silver

catch on the footrest. The Footrest will then swing back. (See

picture opposite).

To return the footrest ready for use simply swing the footrest

forwards, the catch will lock automatically, and lower the

footplate.

3) To remove footrests.

Remove the spring clip from the lower hinge pin. Swing the footrest to the side and holding

the curved part of the support tube lift upwards.

Note: - The spring clip prevents the footrests being lost. However, if the user needs to

regularly remove the footrests the spring clip can be discarded.

Hinge Pins

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 8 of 18

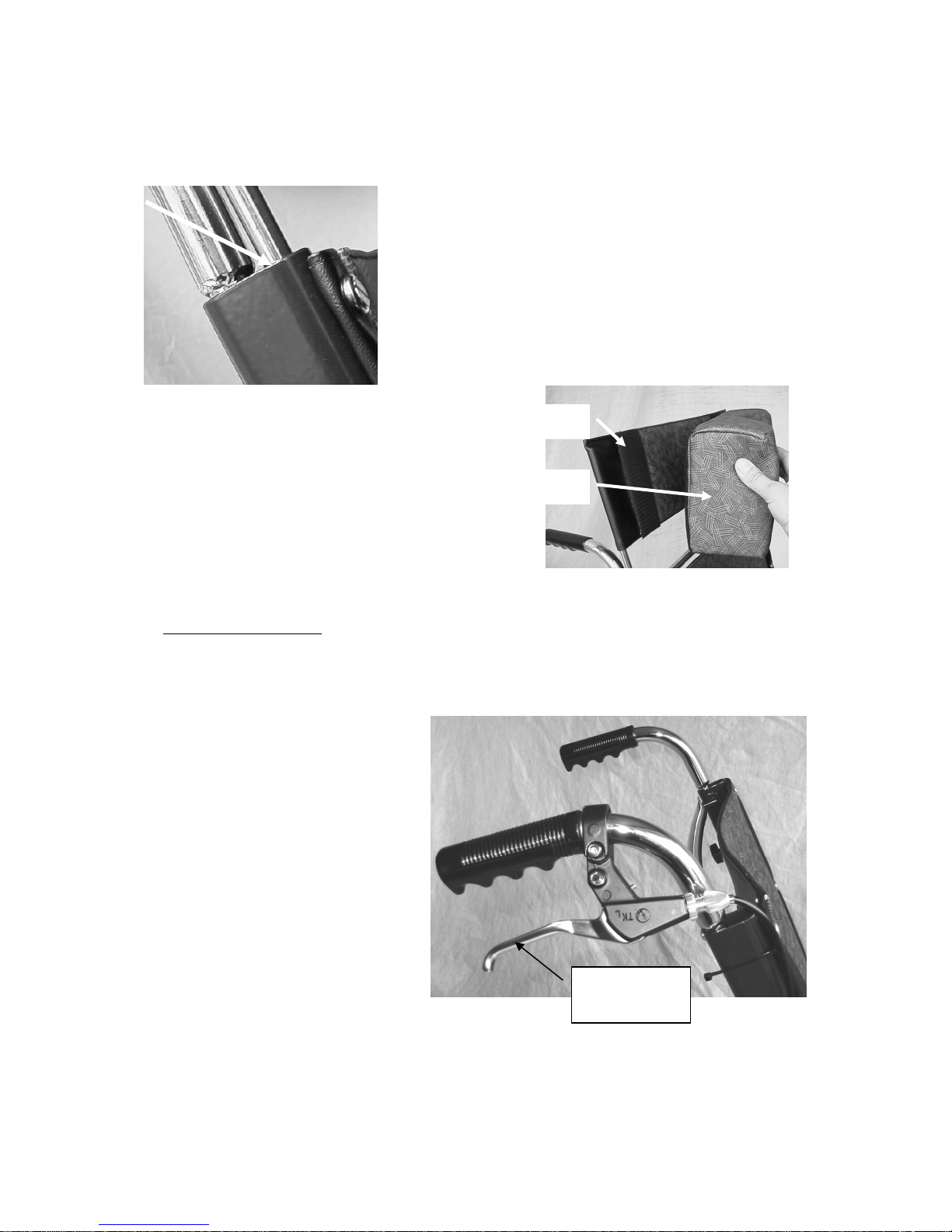

4.3 Fitting and Removing Headrest: - check operation

Place the headrest support tubes into the top of the

backrest tubes just in front of the push handles (see photo

opposite).

Fit the headrest upholstery (A) over the two support

rods.

Attach the headrest cushion (B) using the Velcro

strips.

Reverse the above to remove the headrest

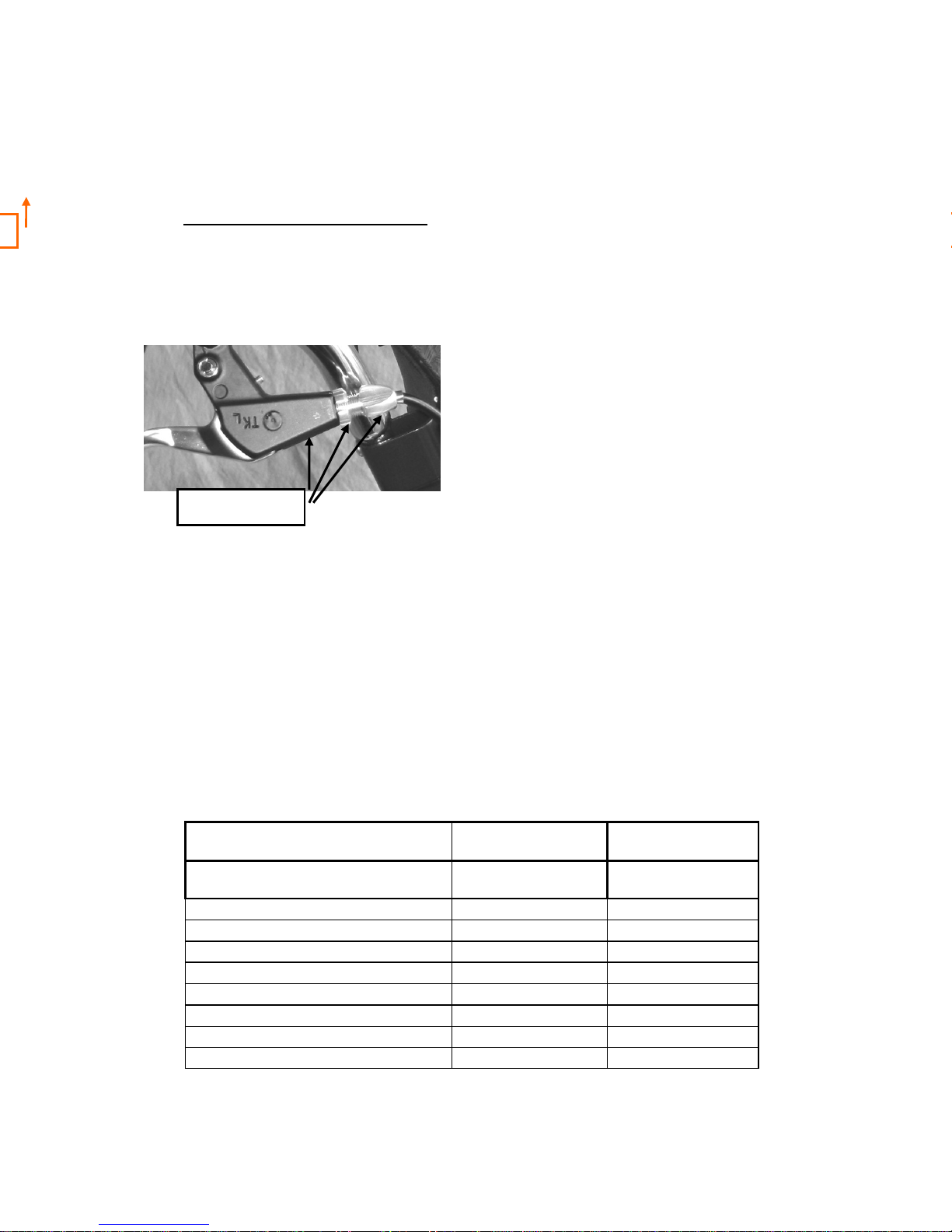

4.4 Tilt in Space

1) Check Tilt mechanism: - Move the seat through its full range of adjustment.

The angle of the seat and backrest can be adjusted to any angle between the upright and fully

reclined position.

To recline the seat, put the brakes on

and stand behind the wheelchair.

Holding both push handles squeeze

the operating lever (see photo

opposite) and push down evenly on

both handles. Release the lever when

the seat is at the desired angle.

To bring the seat upright put the

brakes on and stand behind the

wheelchair. Holding both push

handles squeeze the operating lever

(see photo opposite) and lift evenly on

both handles. Release the lever when

the seat is at the desired angle.

Important: - Always hold and move both push handles together when adjusting the

seat angle.

A

B

OPERATING

LEVER

Tendercare Ltd

Tilt and Fold Workshop Manual - Gas Strut Model

Tilt & Fold Gas Strut Workshop Manual Issue: D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 9 of 18

4.5 Tyres and Brakes

The tyres do not require any attention other than being cleaned with a damp cloth when dirty.

Test Brake operation by moving both levers forward as far as they will go. The wheels should

now be locked. If the wheels move the brakes need adjusting. Adjust them as instructed in

section 7.3 below.

To avoid making flat sections on the tyre never leave the brakes on for long periods i.e.

overnight or during storage.

5. Cleaning

Make sure the wheelchair is clean and well presented. If there is any dirt it should be cleaned

off using a damp cloth and then dried thoroughly.

For more stubborn stains wipe with a damp cloth using a mild solution of warm water and

soap.

Never use furniture polishes or spirit to clean the frame.

The Fabric parts of the Wheelchair are made from Ambla fabric. Ambla is resistant to most

mild acids, alkalis, drinks and household stains. Clean with a damp soapy cloth and rinse well

with clean water. A soft brush can be used for heavy soiling. Do not use solvents, bleaches,

abrasives, synthetic detergents, wax polishes or aerosol sprays.

6. Maintenance

Should a problem be found when carrying out the regular checks, it should be immediately

reported to the issuing authority or repairer.

6.1 Routine maintenance

The user or their family can easily carry out the following tasks. No tools are required.

1) Always wipe the wheelchair dry. Never put it away damp.

2) Check all four push handle retaining knobs is in place and are hand tight (daily).

3) Check brake operation (weekly).

4) Check operation of Tilt and Fold mechanism (weekly).

5) Clean frame when necessary (we suggest at least once a week).

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 10 of 18

6.2 Recommended maintenance procedure - 6 monthly

Someone who is a competent tradesman or repairer should only carry out this work. If a

major problem is found do not allow the wheelchair to be used until it has been corrected.

1) Fold and open the wheelchair. Check that all movements through the folding range are

free. Examine frame for any damage.

2) Examine upholstery for wear and arrange for replacement if necessary.

3) Examine nuts, bolts, pivots, sliders and frame plugs for tightness and general condition.

4) Examine push handle retaining knobs and check they are hand tight.

5) Examine heel loops for damage or excessive wear and that the retaining nuts are tight.

6) Examine brake assemblies for wear, damage and adjustment.

7) Examine Tilt and Fold mechanism and check operation of reclining mechanism.

8) Examine front castors and rear wheels for free rotation and security.

7. Repairs

An authorised repairer should only carry out the following repairs.

Repairs: - for all repairs contact your issuing Authority or Tendercare Ltd.

Major repairs: - for all major repairs e.g. bent or damaged frame. The equipment should be

returned to the factory. Contact Tendercare Ltd Customer Services on telephone 01903-

726161.

Factory replacement components should be used in all repairs, these are available from

Tendercare.

7.1 Front castors: - Replace the complete assembly if damaged or worn.

1) Using a 24mm spanner unscrew the hexagon nut at the top of the castor swivel until the

castor is removed.

2) Before fitting new castor apply LOCTITE thread locking compound grade 241 to the

thread on the castor stem. Screw the stem into the wheelchair mounting and tighten to

54Nm.

3) When fitted the castor should rotate under its own weight. If it does not rotate the castor

forks a number of times to ease the mechanism.

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 11 of 18

7.2 Rear Wheels: - Replace if damaged or worn.

1) Unscrew the axle retaining nut using 19mm spanners. Remove the washers and pull the

wheel assembly from the wheelchair. Important – Always fit new steel locking washer

and nut.

2) Place the spacer taken from the old wheel onto the axle of the wheel. Insert axle into the

wheelchair-mounting hole then fit a new 12mm friction washer onto the axle. Apply

LOCTITE thread locking compound grade 241 to the axle thread and secure with a M12

nut. Tighten to 45Nm. When fitted make sure the wheel rotates freely and the brakes

operate properly.

7.3 Brake adjustment

1) The tyres are made from a solid material and do not require any attention other than being

cleaned with a damp cloth when dirty.

2) Test brakes by moving both levers forward as far as they will

go. The wheels should now be locked. If the wheels move the

brakes need adjusting.

3) Adjust the brakes by loosening the nut (arrowed) locking the

brake pad in place, then turn the pad so that it is near to, but

not touching, the tyre. Retighten the locking nut.

4) Always adjust both brakes at the same time and recheck that

the brakes work properly.

Note: Don’t leave the brakes ON for a long period. If you do a flat

section may appear on the tyre. When not using the wheelchair i.e.

overnight or during storage make sure the brakes are OFF.

7.4 Replacing armpads

1) Remove armrest from the wheelchair and turn upside down.

2) Using a screwdriver remove the armpad retaining screws. Remove the armpad.

3) Hold a new armpad against the support making sure that the large overhang is towards the

outside of the armrest.

4) Insert the fixing screws and tighten.

7.5 Replacing seat upholstery

1) Partially fold the wheelchair seat to take the pressure off the upholstery.

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 12 of 18

2) Using a screwdriver remove the eight retaining screws and washers (four each side of the

upholstery).

3) Remove the two reinforcing strips from the loops on each side of the upholstery and fit

these strips into the new upholstery.

4) Measure the distance across the wheelchair seat rails between the centres of the fixing

holes.

5) Take 3mm off of the above measurement and use this measurement to align the insert

reinforcing straps on top of the Cordura sections of the seat canvas. Ensure you measure

from the centre of the pre-drilled holes on the reinforcing straps. At this stage do NOT

insert the reinforcing straps into the seat canvas.

6) Once the reinforcing straps are correctly aligned on top of the canvas drill through the

reinforcing strap holes and through the canvas below. There will be an overhang of

Cordura either side of the holes.

7) Insert the reinforcing straps into the seat canvas and refit to the wheelchair using the eight

screws and washers. Make sure the screws are properly tightened.

7.6 Replacing backrest upholstery

1) Partially fold the wheelchair to take the pressure off the upholstery.

2) Unfasten the Velcro loops, one each side at the bottom of the backrest upholstery.

3) Using a screwdriver remove the eight retaining screws and washers (four each side of the

upholstery).

4) Remove the two reinforcing straps from the loops on each side of the upholstery .

5) Measure the distance across the wheelchair backrest tubes between the centres of the fixing

holes.

6) Take 3mm off of the above measurement and use this measurement to align the insert

reinforcing straps on top of the Cordura sections of the back canvas. Ensure you measure

from the centre of the pre-drilled holes on the reinforcing straps. At this stage do NOT

insert the reinforcing straps into the back canvas.

7) Once the reinforcing straps are correctly aligned on top of the canvas drill through the

reinforcing strap holes and through the canvas below. There will be an overhang of

Cordura either side of the holes.

8) Insert the reinforcing straps into the back canvas and refit to the wheelchair using the eight

screws and washers. Make sure the screws are properly tightened.

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 13 of 18

9) Pass the Velcro loops around the bottom of the backrest tubes and refasten on the back of

the upholstery.

7.7 Replacing the gas struts.

The wheelchair is fitted with two gas struts one either side of the seat between the inner and

outer frame. A single lever located on the push handle and a cable linkage operates both gas

struts.

WARNING: - The gas struts are pressurised devices and therefore, are potentially

dangerous if mishandled. Do not attempt to dismantle or repair them. They

must always be replaced as a complete unit.

Important: - When removing or replacing the gas struts take care not to accidentally

operate the release lever in order to prevent the strut extending to its full

length. When fully open the gas strut length is longer than the fixing

centres and it is difficult to close them by hand.

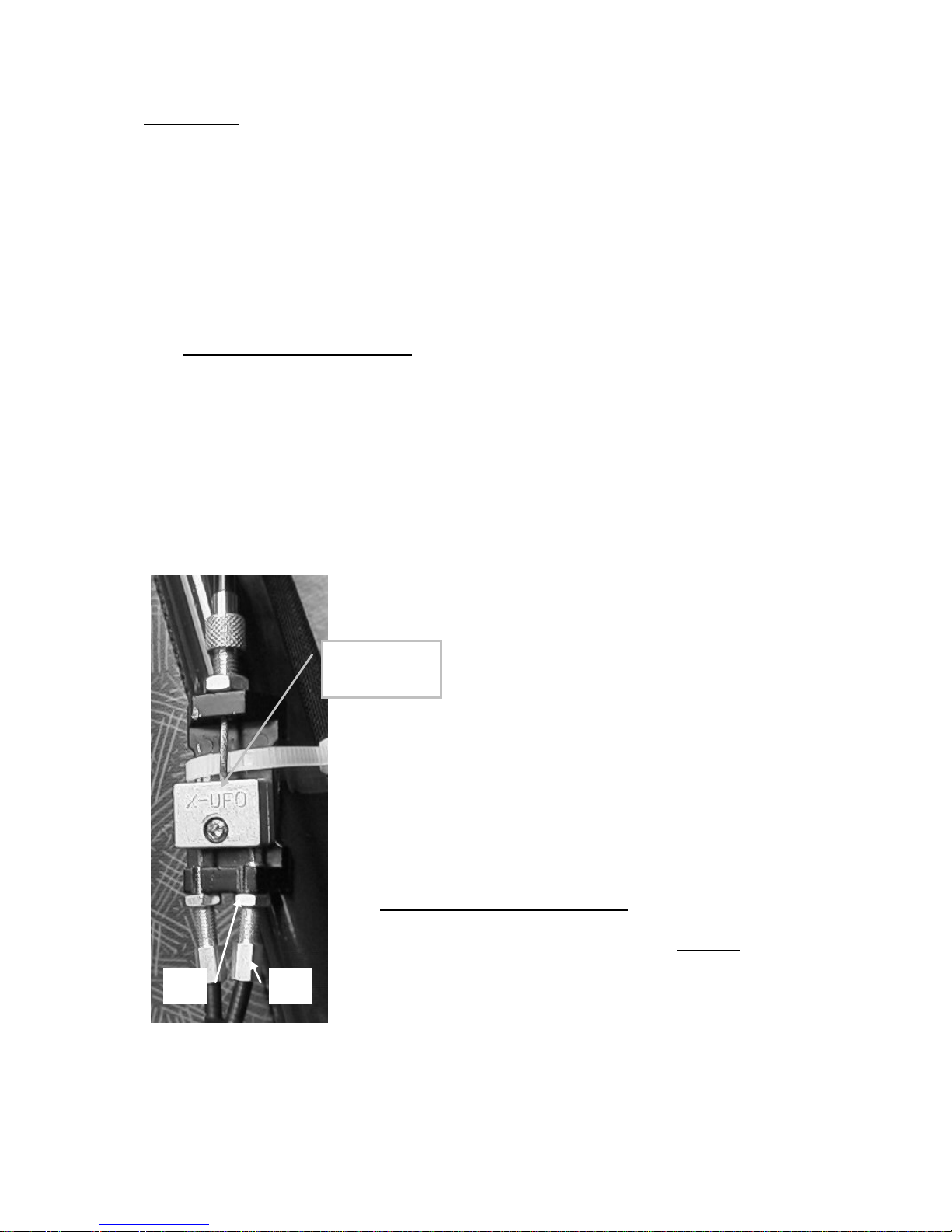

7.7.1 Removal

1) Recline the seat to its mid position (See section 4.4).

2) Remove the operating cable from the strut by lifting it off the locating lug and fork. (see

pictures below).

3) Remove the lower mounting components using 13mm

and17mm spanners. Make sure you take note of the

position of the components as you remove them.

LIFT OFF CABLE

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 14 of 18

8mm Bolt

Outer Frame Nylon

Spacer Metal Guide

Inner Frame

Large Lock Nut

Gas Strut Plain Washer

M8 Nyloc Nut

LOWER MOUNTING COMPONENTS

4) Remove the upper mounting bolt using

10mm spanner and 4mm Hexagon Key.

Make sure you take note of the position of

the components as you remove them.

Remove the gas strut from the wheelchair.

5) Loosen the locknut holding the operating

catch assembly to the shaft of the gas strut

using a 13mm spanner. Unscrew the

operating catch. (see picture opposite).

7.7.2

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 15 of 18

Re-assembly

1) Screw lock nut onto the new gas strut.

2) Screw the gas strut onto the operating lever assembly until the operating lever is almost

but not quite touching the operating pin that extends from the gas strut.

3) Tighten the lock nut against the release operating lever housing.

4) Mount the gas strut following the removal instructions in reverse order.

7.7.3 Adjusting the operating cables

1) The assembly consists of the hand lever on the push handle, one cable leading to an

equaliser block mounted on the backrest tube and two cables leading to the two gas

struts.

2) After fitting a new gas strut always test the operation of the strut as per section 4.4 above

and if necessary adjust the operating cables.

3) The cables to individual gas struts should be adjusted first and the final adjustment made

to the single cable leading to the hand lever.

4) The cables should be adjusted so all slack is

taken up between the gas strut operating lever on

the end of the gas strut and the operating pin that

extends from the gas strut. It is important to

make sure the operating lever is just touching the

gas strut pin but not depressing it.

5) Adjust the lower cables as follows. Loosen the lock nut “A”

then turn the cable end piece “B” clockwise to loosen the

cable and anti clockwise to tighten the cable.

6) Adjust the upper cable so that all slack is taken up and the gas

strut operating lever begins to move as soon as the lever on

the push handle is squeezed.

7.7.4 Replacing lower operating cables

1) Remove cable from the gas strut. See 7.7.1 Removal above.

2) Loosen Locknut “A” (See picture opposite) and unscrew the

cable end from the equaliser bracket.

A B

EQUALIZER

BLOCK

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 16 of 18

3) Using a 2.5mm Hexagon key remove the cover from the equaliser block and remove the

cable.

4) To fit the new cable, reverse the procedure.

7.7.5 Replacing upper operating cable

1. Loosen Locknut and unscrew the cable end from the equaliser bracket.

2. Using a 2.5mm Hexagon key remove the cover from the equaliser block and remove the

cable.

3. Loosen locknut on hand lever and align slots

in the locknut and cable socket with the slot in

the handle.

4. Pull cable though slot and disconnect from the

handle.

5. To fit the new cable, reverse the procedure.

Important: - Always check the adjustment of cables after replacing them.

8. Important Points

1) Do not reuse Nyloc nuts. Always replace with a new Nyloc nut.

2) Always use Loctite thread locking compound Grade 241.

3) Always use recommended components and parts available from Tendercare Ltd.

4) Do not modify or repair the frame

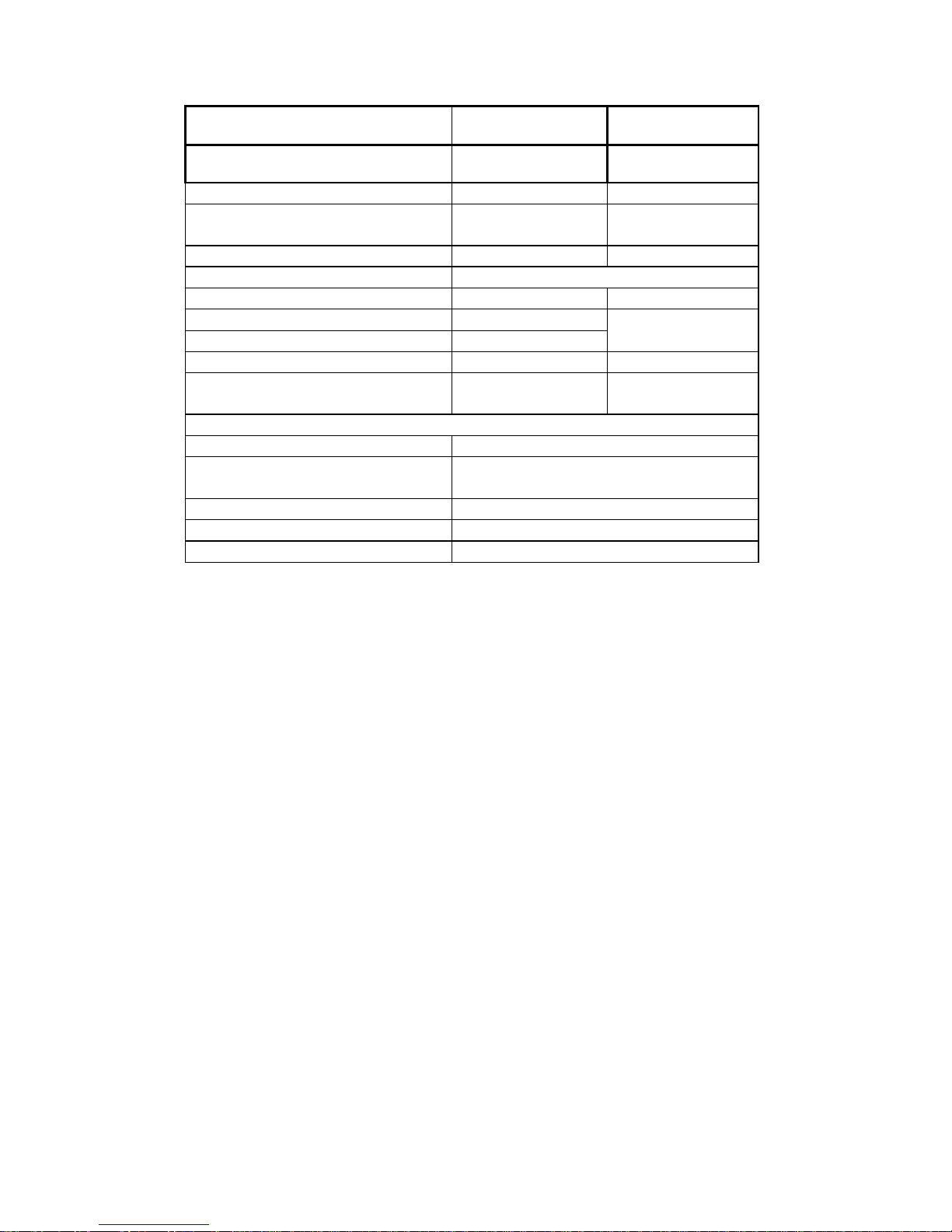

9. Dimensions and Weights

SEAT SIZE 380 mm (15 inch)

430 mm (17 inch)

Item mm mm

Overall Length 1100 1100

Overall width (inc. wheels) 630 690

Overall

height

1030

1030

Length folded

(ex Footrests)

900

900

Width folded 360 360

Height folded 735 735

Seat width

380

430

Seat depth 410 430

ALIGN SLOTS

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 17 of 18

SEAT SIZE 380 mm (15 inch)

430 mm (17 inch)

Item mm mm

Backrest height (above seat) 560 560

Standard armrest height (above

seat) 240 240

Seat to footrest 370 / 450 450/370

Seat angle from horizontal

10° to 27°

Rear Wheel Diameter 305 305

Castor wheel diameter 200 200

640

Track rear

620

Track front 555 575

Wheel base castors trailing (rear

wheel in forward position) 540 540

Weights

kg

Total weight excluding all

detachable items 20

Footrests (both) 2.0

Armrests (both) 1.8

Headrest Assembly

1.2

Tendercare Ltd

Tilt and Fold Workshop Manual – Gas Strut Model

Tilt & Fold Workshop Manual Gas Strut Model Issue D

Authority: Quality Controller Date: September 2010

Authorised by J Adams

Page 18 of 18

10. Parts List

GENERAL ASSEMBLY PARTS LIST

Ref No. Description Qty Part No.

SIDES; HANDED FROM REAR OF WHEELCHAIR

1

Push Handles & Thumbscrews (inclu

ding grips)

2

TTF009

2

Backrest Spreader Bar

1

TTF011

3Backrest Locking Pin (Complete) 2 TTF0088

4Curved Handle 3843/M - M5x20mm 4 TTF090

5Brake Assembly – L/H 1 TTF018

6Brake Assembly – R/H 1 TTF019

7Castors – Front 200mm 2 TTF020

8Wheels – 315mm 2 TTF021

9

Square Insert 20mmx20mm E Cap

2

TS6081

10

Blanking Cap 9mmx13x6.4

2

TS6082

11

Gas Spring 3803ZV

2

TT7400

12 Release head (784575) 2 TT7401

13 Release Head Lever (783234) 2 TT7402

14 M10 Lock Nut (012491) 2 TT7403

15 Complete Cable Mechanism 1 TT7300

16 Pair Outrigged Armrests - 250mm 1 TTF035

17

Brass Armrest Bushes

2

TTF054

18

Pair Height Adjustable Footrest

-

complete

1

TTF037

19

L/H Footplate

-

7 1/2"

1

TTF04

1

20 R/H Footplate -7 1/2" 1 TTF041A

21 Adult Heel Loop 8 1/2" - Black 2 TTF043

22 Seat Canvas Set – inc. H/Rest (17” model) 1 TT6021

23 Seat Canvas Set – inc. H/Rest (152 model) 1 TT6121

24 Insert Bars (Seat Canvas) for 17x17” model 2 TTF032

25 Insert Bars (Seat Canvas) for 15x16” model 2 TT6359

26 Back Canvas Insert Bars 2 TTF033

27

Headrest Rods

2

TTF034

28

Armrest Pads

2

TTF001

Table of contents

Other Tendercare Wheelchair manuals

Tendercare

Tendercare MINI TILT Instruction manual

Tendercare

Tendercare Mobility Nursery Snugseat Spring User manual

Tendercare

Tendercare Snappi User manual

Tendercare

Tendercare Extra Small Fold-a-Way Spring User manual

Tendercare

Tendercare MINI TILT User manual

Tendercare

Tendercare Snappi Instruction manual

Tendercare

Tendercare Mini Tilt Wheelchair Instruction manual

Tendercare

Tendercare Snugseat Snappi User manual

Tendercare

Tendercare Mini Tilt Wheelchair User manual

Tendercare

Tendercare New Aluminium Mini Tilt Wheelchair User manual