Tendercare Extra Small Fold-a-Way Spring Instruction manual

Tendercare Ltd

Fold-A-Way Spring Workshop Manual

Document. 045-02v1Foldaway Spring workshop manual.doc.

Authority. Quality Controller

Authorised. J Adams

Sept 05

WORKSHOP MANUAL

Extra Small Fold-a-Way Spring

Small Fold-a-Way Spring

Large Fold-a-Way Spring

Extra Large Fold-a-Way Spring

Please read these instructions carefully

Before attempting to maintain the pushchair

In case of difficulty contact: -

Tendercare Ltd

PO Box 3091, Littlehampton, BN16 2WF

Tel (01903) 726161

Fax (01903) 734083

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 2

Sept 05

FOLD-A-WAY SPRING PUSHCHAIR

Frame

Lock

Footrest

Brake

Pedal

Seat Tilt

Lock

Harness

Mounting

Slots

“L”

Shaped

Pad

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 3

Sept 05

Item Description Page

1 Your Fold-A-Way Spring Workshop Manual……………………..…………….. 4

2 Transit Packaging…….………………………..……….……….…………………. 4

3 Tools & Torque Settings………………………………….…….…………………..

5

4 Preparing for use and operation……...………………………….………………...

6

4.1 Unfolding and assembling the pushchair…………….………….….…………… 6

4.1.1 Unfolding the frame…..……..………………….…….……………… 6

4.1.2 Folding the backrest…………..……………….……..………………. 6

4.1.3 Upholstery, seat straps and 5-point harness…..……………..……….. 6

4.1.4 Five Point harness checks….…………………………..…………….. 6

4.1.5 Seat Pads………………………………………………..……………. 7

4.1.6 Footrest………………………………………………….…………… 7

4.2 Options……………………………………………………………..……………. 7

4.3 Tilt in Space………………………………………………………..……………. 8

4.4 Brakes………………………………………………………………...………….. 8

4.5 Front Wheels – (Castors)…………………………………………..……………. 8

5 Cleaning………...……………………………………………..…………..…………

8

5.1 Frame…………………………………………………….….…………………… 8

5.2 Patterned cover………………...……………………….….………….…………. 8

5.3 Patterned “L” shaped pad cover……………………...…..…………..………….. 9

5.4 Five point harness……………………………………….….……….…………… 9

6 Maintenance………………………………………………………………………... 9

6.1 Routine maintenance……………………………………….……….…………… 9

6.2 Six monthly maintenance……………………………………..…….……..…….. 9

7 Repairs...……………………………………………………………………………. 10

7.1 Rear wheels..……………………………………………………….….………… 10

7.2 Castor assemblies…………………………………………….……….….……… 10

7.3 Replacing Gas Struts………………………………………………….…………. 11

7.4 Brake Rod……………………………………………………………….……….. 12

7.5 Upholstery cover/ components and 5-point harness…….……………..………… 12

Table Fold-A-Way Spring Dimensions…………………………………...……………… 13

Sketch General Assembly Fold-A-Way Spring…………………………...….……………

14

Table Parts list Extra Small & Small Fold-A-Way Spring………………...……………

15

Table Parts list Large Fold-A-Way Spring……………………………………………….

16

Table Parts list Extra Large Fold-A-Way Spring………………………………………..

17

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 4

Sept 05

1. Your Fold-a-Way Spring Workshop Manual

The purpose of this manual is to help you get the best from your pushchair. It does this by

telling you how to complete those maintenance and repair tasks that can be carried out by a

competent person. The manual also tells you when you should contact the manufacturer who

is: -

Tendercare Ltd

PO Box 3091, Littlehampton, BN16 2WF

Tel (01903) 726161 Fax (01903) 734083

Important: - This manual must be read and used in conjunction with the User

Manual.

The pushchair is available in four sizes, extra small, small, large and extra large. This manual

applies to all four sizes of the pushchair. The recommended maximum user weight includes

the occupant, carrying tray and any other items carried.

All sizes and weights are given as a guide. Tendercare Ltd reserves the right to amend

specifications at any time as part of their product development programme.

SEAT SIZESIZE MAX USER

WEIGHT WIDTH DEPTH HEIGHT

Extra Small 45kg 280 220 520

Small 45 kg 320 270 550

Large 45 kg 320 320 610

Extra large 45 kg 370 365 660

Important: - The maximum occupant weight includes the occupant and all accessories.

2. Transit Packaging

Warning: - The transit carton is quite bulky so moving and unpacking must be done with

care. Observe all lifting and handling regulations.

The Fold-a-Way Spring is delivered in a cardboard carton of approximate weight between

14kg - 20kg and size 640 mm wide x 245 mm deep x 1140 mm high.

1) Stand the carton upright making sure it is supported and cannot fall over. Open the

carton carefully. Remove any packages or packing, which could obstruct the removal of

the pushchair.

2) Using the correct lifting procedure, lay the carton on its wide side and carefully remove

the Fold-a-Way Spring frame.

3) Remove any other packages, which are still in the carton.

4) Check that you have the following items: -

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 5

Sept 05

Item Component Number Yes No

1.

Fold-a-Way Buggy 1

2.

Footrest & Chrome support bar 1

3.

Upholstery 1

4.

Upholstery support boards with 2 Velcro strips on the

front for attachment of foam pads. Size dependent

on model.

Head support board and foam pad. 1

Back support board and foam pad. 1

Seat support board and foam pad. 1

5.

Small “L” Shaped Pads 13mm thick complete with

fabric cover 2

6.

Large “L” Shaped Pads 25mm thick complete with

fabric cover 2

7.

5 point harness 1

8.

User Manual 1

If any items are damaged or missing please contact Tendercare,

Preferably by fax 01903-734083 within 36 hours of delivery.

5) Remove the upholstery from the plastic bag and any protective

bubble wrap from the frame. Take particular note to remove the

foam pads from the backrest folding mechanism. See picture

opposite.

6) After unpacking and checking you have all components and that

they are in good condition, carefully dispose of the packaging at

your local recycling centre.

3. Tools and Torque Settings

The following tools are required to dismantle, reassemble and repair the pushchair: -

Spanners and sockets: - 7, 8, 10, 13, 17 and 19 mm.

Hexagon Keys: - 2.5, 3, 4, and 5mm.

Torque Wrench: - range 0 to 60 Nm.

Torque Settings

Spanner Size – (mm)

Torque (Nm)

7 8

8 10

10 15

13 25

17 50

19 55

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 6

Sept 05

4. Preparing for use and operation

Warning. When opening or folding the pushchair, ensure that you hold the frame so that

you avoid any danger of catching your fingers in moving parts.

The following pre-delivery procedures should be carried out to check that the pushchair has

not suffered damage during transit and that all features operate satisfactorily. Refer to the

user manual for detailed instructions on performing each action.

4.1 Unfolding and assembling the pushchair

4.1.1 Unfold the frame: - Follow the instructions in section 4.1.1 of the User manual.

Check that: - All items are working properly. That the frame linkages move freely and

that the safety catches operate properly.

4.1.2 Folding Backrest: - Follow the instructions in section 4.1.2 of the User manual.

Check that all linkages move freely and that the plungers slide in and out of their

sockets with ease, if necessary apply a smear of ‘3in1’ oil to the plungers. Make sure

that the backrest locks / unlocks positively.

Important: Always lift the backrest fully upwards before folding to avoid damage to the

socket.

4.1.3 Upholstery and 5-Point harness: - Follow the instructions in section 4.2 of the user

manual.

1) Check that the upholstery has been assembled and fits properly pay particular to the

seat boards. Check that all the seat boards have been inserted correctly and that the

foam pads are facing the user.

2) It is important that the 5-point harness is installed exactly as detailed in the user

manual. Care over the checking of this item must be taken to ensure the correct and

safe operation of the Fold-a-Way pushchair.

4.1.4 Five Point harness assembly checks

1) Check that the harness is fitted the correct way up i.e. with the strap length adjusters

over the hips and that the straps have not been twisted during the threading process.

2) Check that the straps have been pulled tight and that there is no slack. Check that the

black buckles have been threaded correctly through the cover, seat boards and foam

pads and that they sit flat against the seat cover. See photograph below.

Black Buckle flat

against seat cover

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 7

Sept 05

3) Check that there are no signs of cuts, nicks or fraying in the webbing or stitching.

4) Check that the length adjustment mechanism and release button on the 5-point harness

works correctly.

4.1.5 Seat Pads: - Follow the instructions in section 4.6 of the user manual.

Check that the foam pads are in the correct covers and that they attach to the outer

seat cover properly.

4.1.6 Footrest: - Follow the instructions in section 4.7 of the user manual.

Make sure the footrest has been fitted properly and that both the footrest height and

seat straps have been adjusted to meet the user’s needs.

4.2 Options: - This only applies if any optional items have been supplied with the pushchair.

Make sure that all extras supplied such as Rainhood, Play tray, Shopping basket

and Carrying tray fit onto the buggy and are properly secured.

Pommel: - Follow the instructions in section 4.8.1 of the user manual.

1) Check the pommel fits and has been adjusted to suit the user.

The pommel is mounted on an adjustable steel frame so that the height and depth can

be adjusted using thumbscrews.

1) To adjust depth, loosen the thumbscrew under the seat

and move the pommel in or out to the desired position

and then retighten the screw.

2) To adjust height, loosen the thumbscrew on the front of

the pommel support tube. Move the pommel to the

desired height then retighten the screw.

Looking under the front of the seat, remove the thumbscrew

shown in the picture opposite. Insert the slotted bar of the

pommel into the mounting slot then insert and tighten the

thumbscrew

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 8

Sept 05

4.3 Tilt in Space: - Follow the instructions in section 4.9 of the user manual.

Check that the tilting and seat locking system operates properly throughout its range of

adjustment.

Important – Always support the front of the seat when operating the gas spring release

lever. If the front of the seat is not supported, the seat may move very swiftly

and could cause distress to the operator

4.4 Brakes: - Follow the instructions in section 4.10 of the user manual.

1. Test operation of the brake and make sure the brake assembly

is secure and operates properly. When the brakes are ON the

rear wheels should be locked. If they do not lock either the

wheel is worn or the brake rod is bent. Either or both these

items should be replaced. See sections 7.1 and 7.4 below.

2. To put the brakes on press the pedal down and backwards with

the sole of your foot until it locks into place.

3. To release the brake, place your toe under the lever and lift up.

4.5 Front Wheels – (Castors)

1) Make sure the castor assembly is secure and operates properly. If the castor assembly is

damaged it must be replaced as a complete unit. See Section 7.2 below.

5. Cleaning

Make sure the pushchair is clean and well presented. If there is any dirt it should be cleaned

off as follows: -

5.1 Frame

1) To clean the frame, wipe with a damp cloth and dry thoroughly.

2) For more stubborn stains wipe with a damp cloth and warm water in which a little

mild soap has been dissolved. Dry thoroughly.

3) Never use furniture polish or any spirit to clean the frame.

5.2 Patterned cover

1) Remove the cover from the pushchair. Remove the harness and support boards from

the cover. Wash as per the instructions on the cover (40°C Synthetic Wash).

2) Dry cover thoroughly before re-assembly. Do not tumble dry.

ON

OFF

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 9

Sept 05

5.3 Patterned “L” shaped pad cover

1) Remove foam pads,

2) Wash as per the instructions on the cover (40°C Synthetic Wash).

3) Dry covers thoroughly before re-assembly. Do not tumble dry.

4) The foam pads can wiped with a damp cloth but must be dried thoroughly.

5.4 Five point harness

1) Remove harness from pushchair.

2) Wipe with a damp cloth and dry very thoroughly. Do not tumble dry.

3) Do Not immerse in water or wash in a machine.

6. Maintenance

Should a problem be found when carrying out the regular checks, it should be immediately

reported to the issuing authority or Tendercare Ltd.

6.1 Routine maintenance

The users family or attendants can easily carry out the following routine tasks. No tools are

required. These regular checks are designed to ensure the efficient and safe operation of the

pushchair. If a fault is found stop using the pushchair until it has been corrected. Advice can

be obtained from Tendercare Ltd. See the front cover or page 3 for contact details.

1) Always wipe the pushchair dry. Never put it away damp.

2) Check that the two-footrest retaining thumbscrews are in place and are hand tight

(daily).

3) Check that the pommel-retaining thumbscrew is in place and is hand tight (daily).

4) Check operation of the brake, folding and reclining mechanisms (weekly).

5) Check condition of harness, stitching and buckle (weekly).

6) Clean frame when necessary (we suggest at least once a week).

If you find any faults refer to you’re issuing authority or Tendercare Ltd.

6.2 Six-monthly maintenance

Someone who is a competent tradesman or repairer should only carry out this work. If a fault

is found stop using the pushchair until it has been corrected. Advice can be obtained from

Tendercare Ltd. See the front cover or page 3 for contact details.

1) Fold and open the pushchair. Check that all movements through the folding range are

free. Examine frame for any damage. Check operation of the seat recline mechanism.

2) Examine the upholstery, harness and foot straps for wear.

3) Examine nuts, bolts, pivots, sliders and frame plugs for tightness and general condition.

4) Check that the two-footrest retaining thumbscrews are in place and are hand tight.

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 10

Sept 05

Axle Bol

t

Washer

Wheel

M8 Nyloc Nut

Washer

Wheel

Mounting Hole

5) Check that the pommel-retaining thumbscrew is in place and is hand tight.

6) Examine brake / rear wheel assembly for wear, damage and correct operation.

7) Check both castors and rear wheels for free rotation, security and accumulation of fluff

and grit. Remove with a dry lint free cloth. Note that the bearings are maintenance free

and should not be lubricated.

8) Examine tyres for sharp objects, cuts or splits.

For all other repairs refer to your issuing authority or Tendercare Ltd.

7.0 Repairs

Only an authorised repairer should carry out the following repairs.

1) Repairs: - for all repairs contact your issuing Authority.

2) Major repairs: - for all major repairs e.g. bent or damaged frame. The pushchair should

be returned to the factory. Contact Tendercare Ltd, Customer Services on telephone

01903-726161.

3) Factory replacement components should be used in all repairs. These are available from

Tendercare Ltd.

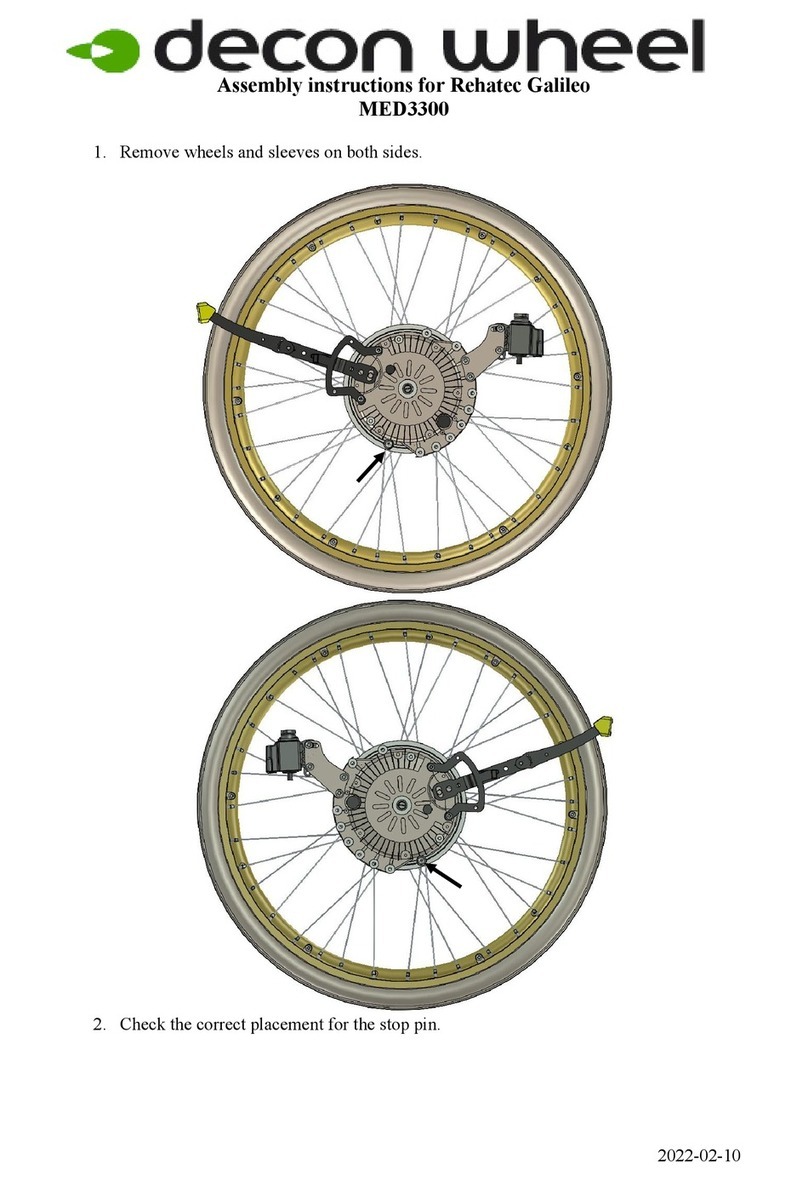

7.1 Rear wheels: - Replace complete assembly as follows if damaged or worn.

1) Make sure the brake is off before attempting to

remove the rear wheels.

2) Note the position of the various washers before

removal.

3) Using a 5mm Hexagon Key and 13mm Spanner

undo the axle nut and remove the wheel from

the buggy frame (see picture opposite).

4) To replace the wheel reverse the

above procedure using a new M8

Nyloc Nut. Make sure the washers

are in the correct position see sketch

opposite. Finally tighten the nut to

25Nm.

13mm

Spanner

5mm

Hex Key

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 11

Sept 05

7.2 Castor Assemblies: - Replace as follows if damaged or worn.

1. Always replace castors as a complete

assembly. Never change the wheels alone.

2. Unscrew the retaining nut (see picture

opposite) using a 19mm spanner and remove

the assembly from the frame.

3. To replace the castor assembly apply a drop of

Loctite thread locking compound grade 241 to

the thread of the castor stem then screw the

stem into the frame. Tighten the retaining nut

to 55 Nm

7.3 Replacing the Gas Struts

The pushchair is fitted with two gas struts one either side of the seat. A release lever located

at the rear of the backrest operates the struts.

WARNING: - The gas struts are pressurised devices and therefore, are potentially

dangerous if mishandled. Do not attempt to dismantle or repair them.

They must always be replaced as a complete unit.

Removal

1) Extend the gas struts to their maximum length by holding onto the front of the seat

frame with one hand then operate the release lever with the other hand and slowly

allow the gas struts to extend to their full length.

2) Loosen the locking nut on the gas strut

at the operating lever end using a

17mm spanner. See picture “A”.

3) Remove the screw holding the gas

strut to the inner frame using a 4mm

Hexagon key and 10mm spanner. See

picture “B” Note the position of the

nylon spacer and plain washer.

4) Unscrew and remove the gas strut

from the release lever assembly.

Retaining Nut

BA

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 12

Sept 05

Re-assembly

1) Screw a new lock nut onto the new gas strut. See photo “A” above.

2) Screw the gas strut into the operating lever assembly until the operating lever is just

touching the pin that extends from the end of the gas strut.

3) Tighten the lock nut against the release operating lever housing.

4) Mount the gas strut onto the inner frame using a new M6 hexagon head screw and

Nyloc nut. Make sure the nylon spacer and plain washer are fitted and that the screw

thread extends through the nut and that the nut is on the inside of the frame. See photo

“B” above.

5) Test operation of the strut as per section 4.3 above.

7.4 Brake Rod: - Removal and replacement.

Removal

1) Put the brake in the ON position to gain

access to all the fixing screws.

2) Remove the four fixing screws using a

2.5mm hexagon key and 7mm socket.

3) Remove the two locking plates, one

either side of the pushchair. Carefully

turn the brake to the off position and

remove the brake-operating rod by

dropping it downwards.

Replacement

1) Fit a new rod making sure that the spring is properly located on both the frame and brake

rod. (See picture above).

2) Put the brake into the ON position. Refit the two locking plates making sure that slot

opening is towards the top of the pushchair and that the lip is under the rod mounting

plate.

3) Refasten with new screws and Nyloc nuts making sure that the screw threads pass

through the Nyloc nuts. (See picture above).

4) Check operation of brake as per section 4.4 above.

7.5 Upholstery Cover / Components and 5-point harness

These are non-repairable items. If they are damaged or worn they should be replaced. For

details on how to do this, follow instructions in section 4.2 of the User Manual.

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 13

Sept 05

Important Points

1) Do not reuse Nyloc nuts. Always replace with a new Nyloc nut.

2) Always use Loctite thread locking compound Grade 241.

3) Always use recommended components and parts available from Tendercare Ltd.

4) Do not modify or repair the frame

Fold-A-Way Spring DIMENSIONS

B

A

C

Sizes for Guidance Only

Please refer to latest manufacturer specifications for sizes

MODEL

DIMENSION A DIMENSION B DIMENSION C

Assembled Dimensions

XTRA SMALL

960 485 1010

SMALL

960 515 1010

LARGE

960 515 1010

XTRA LARGE

960 645 1010

Folded Dimensions

XTRA SMALL

230 485 1040

SMALL

230 515 1040

LARGE

230 515 1090

XTRA LARGE

230 645 1070

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 14

Sept 05

General Assembly

Fold-A-Way Spring

1

7

8

9

10

13

14

15

17

18

20 23 24

12

26

25

5

6

4

11

26

16

21

22

19

23

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 15

Sept 05

Parts List

Extra Small Fold-A-Way Spring

Ref No Part No Description Quantity Req.

1.

MS7MA Handlebar (Extra Small) 1

2.

MS5MA Front Wheel Frame (Extra Small) 1

3.

MS11MA Rear Wheel Frame (Extra Small) 1

4.

MS1MA Seat Frame Cradle (Extra Small) 1

5.

MS2M Seat Frame Goal Post (Extra Small) 1

6.

XX3 Seat Frame Connector 2

7.

MS4M Front to Rear frame Con Strip 2

8.

TS6077 Spring Release Pins 2

9.

TS6261 Leaf Spring 2

10.

TS6075 Black End Caps ” 4

11.

TS6258 Castors 2

12.

TS6357 Rear Wheels 2

13.

TS6225 Handle Bar Grips 2

14.

TF6401 Gas Strut 2

15.

MXS13M Gas Strut Trigger Assembly Double 2

16.

TS6070 Thumbscrews 3

17.

TS6230 Sliders Nylon 2

18.

TS6264 Wheel Bolts M8 x 80mm (Stainless Steel) 2

19.

TS6035 Footrest Moulding 1

20.

TS6454 Footrest Back Plate 1

21.

TS6040 Footrest Rod 1

22.

TS6590 Ankle Straps 2

23.

TS6079 Rod Clamp Bracket 1

24.

TS6257 Brake Pedal Cover 2

25.

TS6350 Footrest Casting 1

26.

TS6069 Thumbscrew Pommel 1

27.

TF6408 Compression Spring 2

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 16

Sept 05

Parts List

Small & Large Fold-A-Way Spring

Ref No. Part No. Description. Quantity Req.

1MS7M Handlebar (Small & Large) 1

2MS5M Front Wheel Frame (Small & Large) 1

3MS11M Rear Wheel Frame (Small & Large) 1

4MS1M Seat Frame Cradle (Small & Large) 1

MS4M Seat Frame Goal Post (Large) 1

5MS2 Seat Frame Goal Post (Small) 1

6XX3 Seat Frame Connector (Small & Large) 2

7MS4M Front to Rear frame Con Strip 2

8TS6077 Release Pins 2

9TS6261 Leaf Spring 2

10 TS6075 Black End Caps " 4

11 TS6258 Castors 2

12 TS6257 Rear Wheels 2

13 TS6225 Handle Bar Grips 2

14 TF6401 Gas Strut 1

15 MS13M

Gas Strut Trigger Assembly Double (Small &

Large) 2

16 TS6070 Thumbscrews 3

17 TS6230 Sliders Nylon 2

18 TS6264 Wheel Bolts M8 x 80mm (Stainless Steel) 2

19 TS6135 Footrest Moulding Junior 1

20 TS6454 Footrest Back Plate 1

21 TS6140 Footrest Rod Junior 1

22 TS6590 Ankle Straps 2

23 TS6079 Rod Clamp Bracket 1

24 TS6257 Brake Pedal Cover 2

25 TS6350 Footrest Casting 1

26 TS6069 Thumbscrews – Pommel 1

27 TF6408 Compression Springs 2

Tendercare Ltd

Fold-A-Way Spring - Workshop Manual

Document No 045-02v1Foldaway Spring

workshop manual.doc

Authority. Quality Controller

Authorised. J Adams

Page 17

Sept 05

Parts List

Extra Large Fold-A-Way Spring

Ref No. Part No. Description Quantity Req.

1MX7M Handlebar (Extra Large) 1

2MX5M Front Wheel Frame (Extra Large) 1

3MX11M Rear Wheel Frame (Extra Large) 1

4MX1M Seat Frame Cradle (Extra Large) 1

5MX2M Seat Frame Goal Post (Extra Large) 1

6XX3 Seat Frame Connector 2

7MX4M Front to Rear frame Con Strip (Extra Large) 2

8TS6077 Release Pins 2

9TS6261 Leaf Springs 2

10 TS6075 Black End Caps " 4

11 TS6258 Castors 2

12 TS6357 Rear Wheels 2

13 TS6225 Handle Bar Grips 2

14 TF6401 Gas Strut 1

15 MX13M Gas Strut Trigger Assembly Double Ex L 2

16 TS6070 Thumbscrews 3

17 TS6230 Sliders Nylon 2

18 TS6264 Wheel Bolts M8 x 80mm (Stainless Steel) 2

19 TS6135 Footrest Moulding Junior 1

20 TS6454 Footrest Back Plate Large 1

21 TS6540 Footrest Rod Senior 1

22 TS6590 Ankle Straps 2

23 TS6079 Rod Clamp Bracket 1

24 TS6257 Brake Pedal Cover 2

25 TS6350 Footrest Casting 1

26 TS6069 Thumbscrews – Pommel 1

27 TF6405 Compression Springs 2

Other manuals for Extra Small Fold-a-Way Spring

1

This manual suits for next models

3

Table of contents

Other Tendercare Wheelchair manuals

Tendercare

Tendercare Snappi User manual

Tendercare

Tendercare MINI TILT Instruction manual

Tendercare

Tendercare MINI TILT User manual

Tendercare

Tendercare Extra Small Fold-a-Way Spring User manual

Tendercare

Tendercare GAS STRUT TILT and FOLD Wheelchair Instruction manual

Tendercare

Tendercare Snugseat Snappi User manual

Tendercare

Tendercare Snappi Instruction manual

Tendercare

Tendercare Gas Strut Model v4 User manual

Tendercare

Tendercare Mini Tilt Wheelchair User manual

Tendercare

Tendercare New Aluminium Mini Tilt Wheelchair User manual