Tendercare Snappi Instruction manual

Other manuals for Snappi

2

This manual suits for next models

1

Table of contents

Other Tendercare Wheelchair manuals

Tendercare

Tendercare GAS STRUT TILT and FOLD Wheelchair Instruction manual

Tendercare

Tendercare TILT and FOLD Instruction manual

Tendercare

Tendercare Extra Small Fold-a-Way Spring User manual

Tendercare

Tendercare Gas Strut Model v4 User manual

Tendercare

Tendercare Mini Tilt Wheelchair Instruction manual

Tendercare

Tendercare Snugseat Snappi User manual

Tendercare

Tendercare Extra Small Fold-a-Way Spring Instruction manual

Tendercare

Tendercare MINI TILT Instruction manual

Tendercare

Tendercare Snappi User manual

Tendercare

Tendercare New Aluminium Mini Tilt Wheelchair User manual

Popular Wheelchair manuals by other brands

Vermeiren

Vermeiren RAPIDO instruction manual

Invacare

Invacare MK5 EX Service manual

Invacare

Invacare 9000 jymni Series Owner's operator and maintenance manual

Cobi Rehab

Cobi Rehab H2O user manual

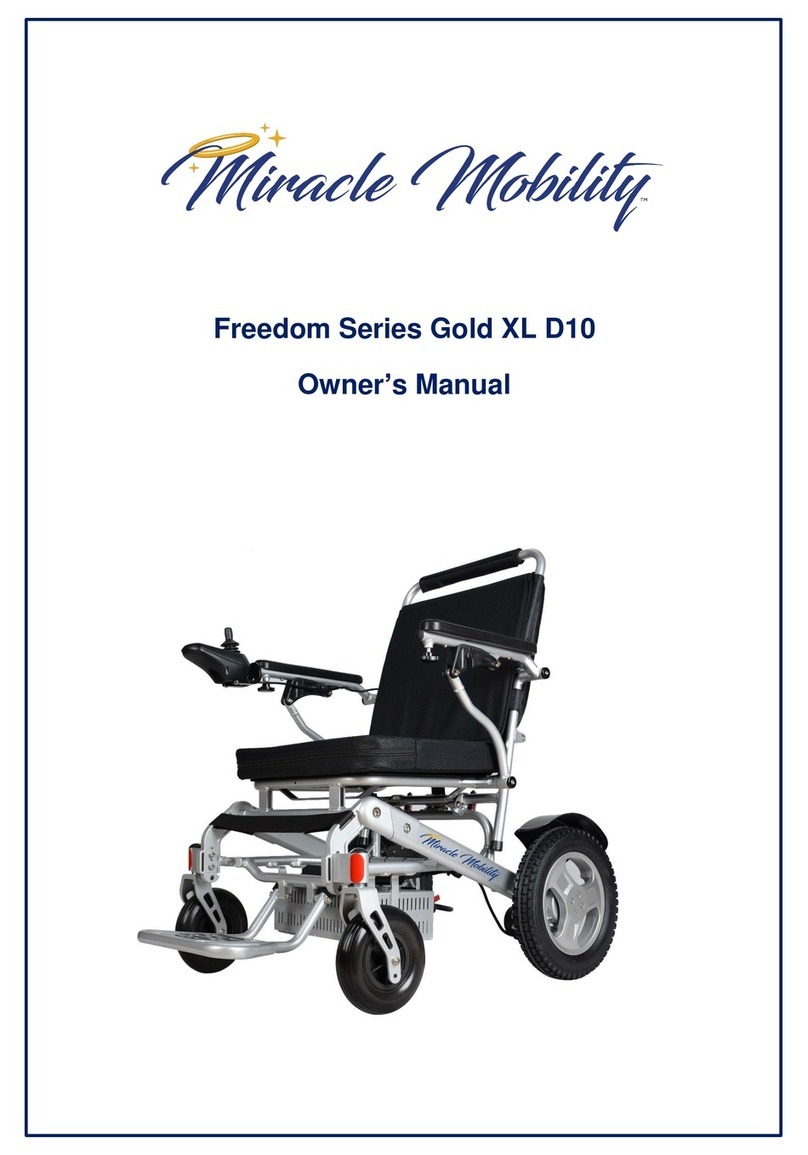

Miracle Mobility

Miracle Mobility Freedom Series owner's manual

Otto Bock

Otto Bock Discovery Instructions for use