IB 340763 (11-2005) 1

No. 340763

Machine: 6100/6100E/

7100/EZ Rider/7080

Published: 11-2005

Rev. 01

INSTRUCTION BULLETIN

NOTE: DO NOT DISCARD the Parts List from the Instruction Bulletin. Place the

Parts List in the appropriate place in the machine manual for future

reference. Retaining the Parts List will make it easier to reorder

individual parts and will save the cost of ordering an entire kit.

NOTE:Numbers in parenthesis ( ) are reference numbers for parts listed in Bill of Materials.

Installation instructions for kit number 377411

SYNOPSIS / PROBLEM:

This kit contains the parts needed to replace the brake linkage on 6100, 7100, and EZ Rider

machines.

Please follow step-by-step instructions.

SPECIAL TOOLS / CONSIDERATIONS: Floor jack or chain hoist

(Estimated time to complete: 2 hours)

PREPARATION:

1. Park the machine on a clean level surface.

2. Turn off machine, remove key, and set

parking brake.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, turn off machine, and remove key.

3. Disconnect the battery cables from the

batteries.

WARNING: Always disconnect battery

cables from machine before working on

electrical components.

4. Block the rear wheels of the machine.

FOR SAFETY: When servicing machine, block

machine tires before jacking up machine.

5. Use a jack to raise the front end of the

machine. Refer to Operators Manual for more

information about safely jacking up the

machine.

FOR SAFETY: When servicing machine, use a

hoist or jack that will support the weight of

the machine.

FOR SAFETY: When servicing machine, jack

machine up at designated locations only.

Support the machine with jack stands.

INSTALLATION:

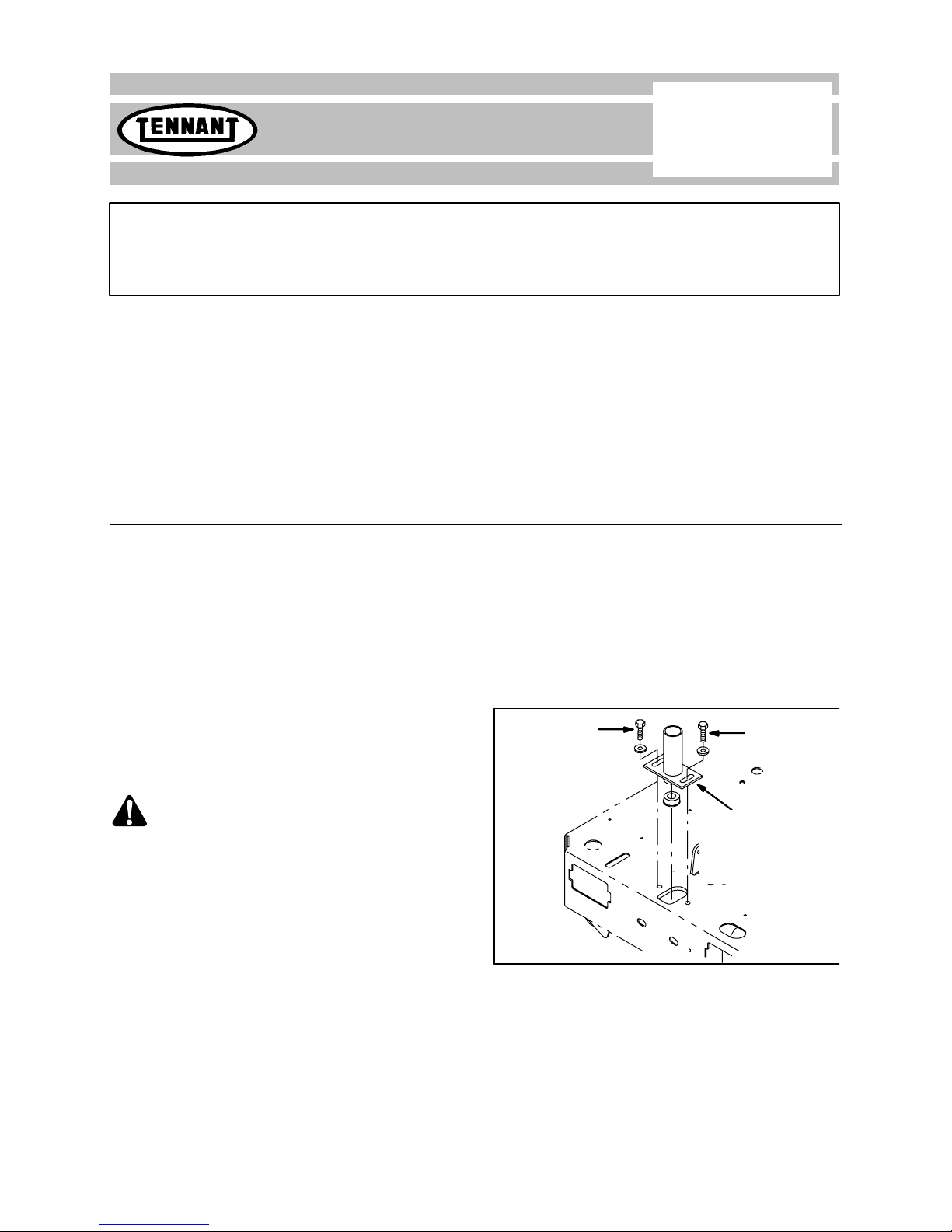

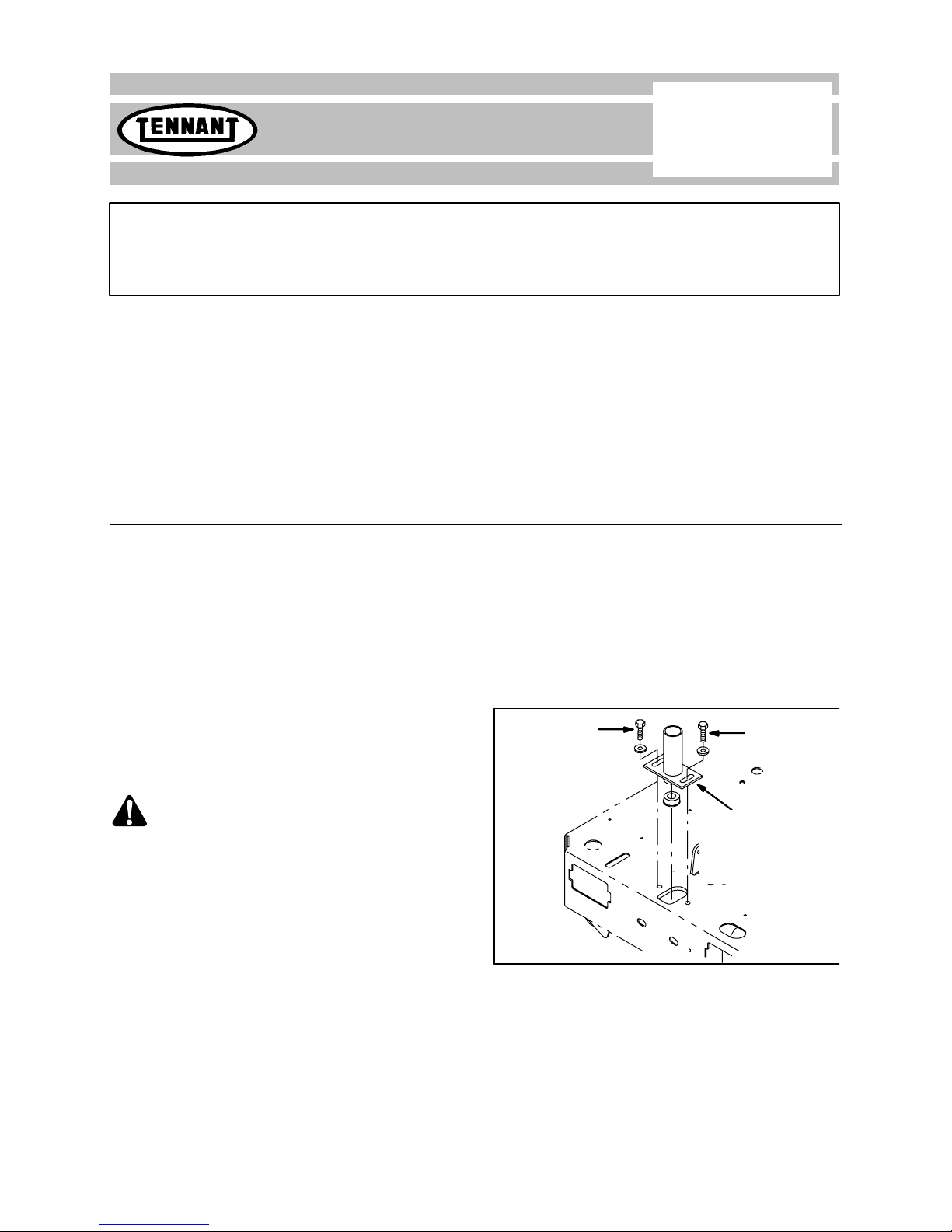

1. Loosen both hex screws securing the steering

assembly housing to the machine frame.

Refer to Fig. 1.

Loosen Loosen

Slide entire

assembly

towardsrear

of machine

FIG. 1

2. Slide the steering assembly housing toward

the rear of the machine to loosen the steering

chain tension.