IB 9015101 (07- 2016)2

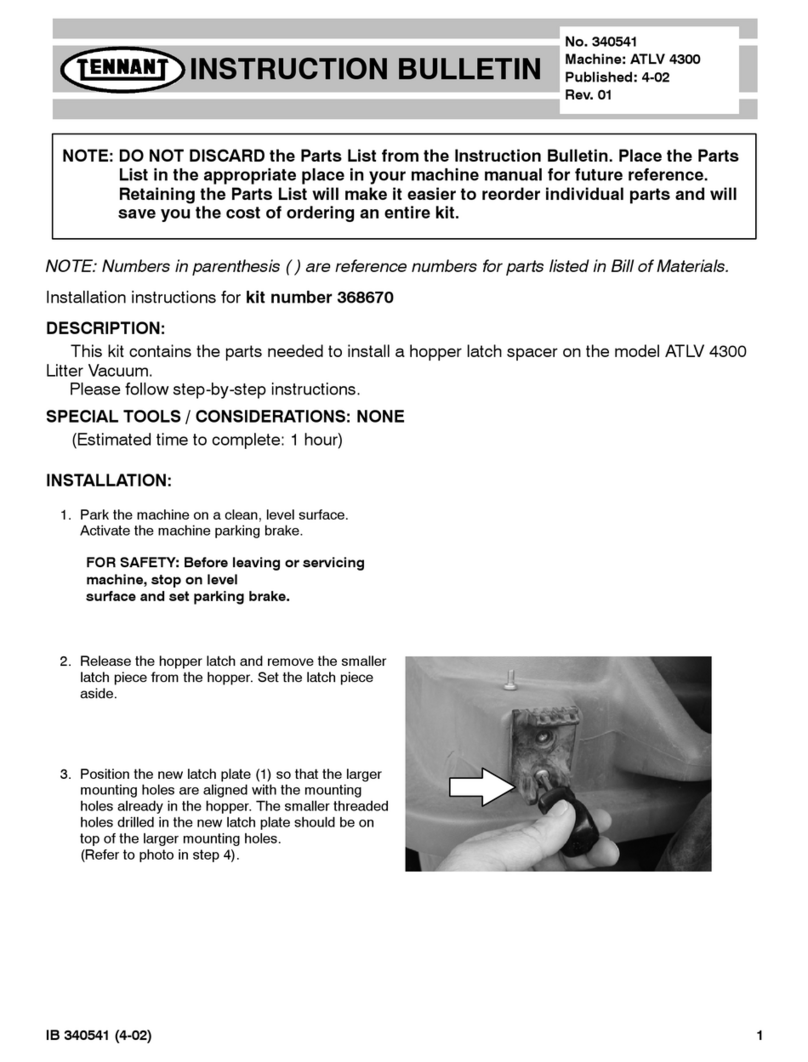

2. Carefully remove the electrical enclosure

cover from the electrical enclosure and

position the electrical enclosure cover out of

the way. Do Not break or damage wires / wire

connections when removing the electrical

enclosure cover from the electrical enclosure.

(Fig.1/Fig.2)

FIG. 2

3. Disconnect all main wire harness connectors

from the existing scrub circuit board. Discard

all P2 / GND and P1 / B+ mounting hardware.

(Fig. 3)

4. Remove both M4 pan screws and nylon

washers securing the scrub circuit board to

the electrical enclosure. Set the M4 pan

screws and nylon washers aside. (Fig. 3)

5. Remove the scrub circuit board from the

plastic stand- offs in the electrical enclosure.

Discard the scrub circuit board. (Fig. 3)

6. Replace broken plastic stand- offs with new

plastic stand- offs (2). (Fig. 3)

7. Ensure the B+ and GND (ground) terminals

are tight on the new scrub circuit board (1).

(Fig. 3)

8. Place the scrub circuit board (1) onto the

plastic stand- offs (3) and use the two M4 pan

screws and nylon washers to secure the

scrub circuit board to the electrical enclosure.

(Fig. 3).

9. Reconnect all harness connections to the

scrub circuit board (1). (Fig. 3)

10. Use one M6 hex nut (8), one flat washer (6)

and one lock washer (7) to connect the P2 /

GND cable to the scrub circuit board (1). Hold

the circuit board stand- off with an open ended

wrench while tightening the M6 hex nut.

Torque the M6 hex nut to 36 in. lbs. (4.0 Nm).

Do Not over tighten hardware. (Fig. 3)

11. Use one M5 hex nut (5), one flat washer (6)

and one lock washer (4) to connect the P1 /

B+ cable to the scrub circuit board (1). Hold

the circuit board stand- off with an open ended

wrench while tightening the M6 hex nut.

Torque the M5 hex nut to 30 in. lbs. (3.4 Nm).

Do Not over tighten hardware. (Fig. 3)

12. Reinstall the electrical enclosure cover onto

the electrical enclosure. (Fig. 1)

13. Reconnect the battery cable to the machine.

14. Close the right shroud.

15. Start and test the machine. Operate all

machine functions to ensure all modes /

systems are functional. If there is a Pickup

Module CAN alert, confirm CB1 (circuit

breaker 1) is not tripped. Press the CB1

button to reset the circuit breaker if it is

tripped.