Tennant 8300 Training manual

Other Tennant Scrubber manuals

Tennant

Tennant T17 Series Training manual

Tennant

Tennant T3 User manual

Tennant

Tennant T391 User manual

Tennant

Tennant CS16 User manual

Tennant

Tennant 7300 Training manual

Tennant

Tennant T600e User manual

Tennant

Tennant CS5 User manual

Tennant

Tennant T3 User manual

Tennant

Tennant Litter Hawk User manual

Tennant

Tennant EZ Rider User manual

Tennant

Tennant 7200 User manual

Tennant

Tennant 9021147 User manual

Tennant

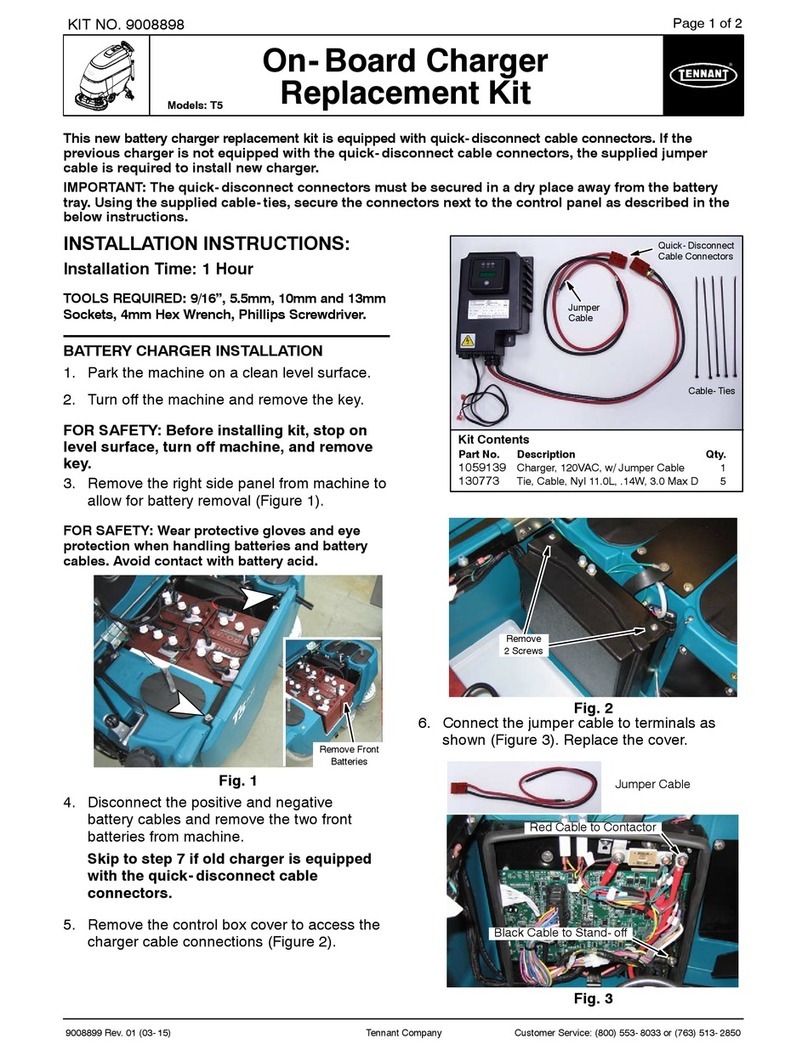

Tennant T5 User manual

Tennant

Tennant ec- H2O 5680 User manual

Tennant

Tennant 8300 User manual

Tennant

Tennant T1 Li User manual

Tennant

Tennant LPTB03175 User manual

Tennant

Tennant SpeedGleam 7 User manual

Tennant

Tennant 5300 User manual

Tennant

Tennant 7100 User manual

Popular Scrubber manuals by other brands

Numatic

Numatic TTB 4045/100 Original instructions

U.S. Products

U.S. Products PEX 500-C-TICK Information & operating instructions

Mclennan

Mclennan C510 Operator's manual

Columbus

Columbus ARA 66 BM 100 operating manual

Numatic

Numatic TTV 678G / 300T Owner's instructions

American-Lincoln

American-Lincoln 505-945 Instructions for use