Tenney BTS User manual

)

i

PAGE 2

Q

800

574

2748

323

770

0634

:

Please Note: This Manual is for reference purposes only and not Specific to this

Chamber. Each Chamber may vary depending on Age, Options, Controller, and

Individual Configuration

r· )

)

PAGE 3

TENNEY ENVIRONMENTAL

SAFETY

WARNINGS

.-

I

1.

PLEASE READTHE ENTIRE TENNEY INSTRUCTIONMANUALAS WELL AS THE

VENDOR MANUALS AND CUT-SHEETS PROVIDED, BEFORE OPERATINGTHlS

CHAMBER1 FAILURETOADHERE TO THE SAFETYWARNINGS, OR TO FOLLOW

THE PROPER OPERATING PROCEDURESLISTED THROUGHOUT THE MANUALS

AND INFORMATION PROVIDED, COULD CAUSEDAMAGE TO YOUR EQUIPMENT,

PERSONALINJURY, OR DEATH.

2.

A MAINPOWER DISCONNECTIS NOT PROVIDEDWlTH YOUR CHAMBER. ITIS

HIGHLY SUGGESTED THAT A DISCONNECTSWITCH ONA SEPARATEBRANCH

CIRCUIT BEINSTALLEDAS THE POWER SOURCE TOYOUR CHAMBER, IN

ACCORDANCE WlTH ALL NATIONALAND LOCAL ELECTRICAL CODES. IFYOUR

CHAMBER IS EQUIPPEDWlTH A POWER CORD AND PLUG, YOU MUST UTILIZEA

RECEPTACLEWlTH THE APPROPRIATE RATINGWHICH ISON A BRANCHCIRCUIT

OF ITSOWN. OPENING THE BRANCHCIRCUIT BREAKER INTHE TEST CHAMBER

DOES

NOT REMOVEALL POWER FROMTHE CHAMBER.

3.

ELECTRICALENCLOSURES, GAUGE BOXES, CONDITIONINGCOMPARTMENT,

etc.,

CONTAIN EXPOSED ELECTRICAL CONNECTIONS. DISCONNECTALL ELECTRICAL

POWER FROM THE FACILITYAT ITS SOURCE BEFORE SERVICINGOR CLEANING.

4.

DO NOTATTEMPT ANY SERVICE OR ADJUSTMENT TO ANY ELECTRICALOR

,---

MECHANICALCOMPONENTS DURING OPERATION.

)

5.

KEEP PANELS INPLACEPROPERLYWHEN THE CHAMBER IS INOPERATION.

6.

THlS ISNOTAN EXPLOSIONPROOFCHAMBER

-

THEAIR CONDITIONINGSECTION

CONTAINS LOW MASS, OPENWIRE HEATINGELEMENTS. DUE TO THlS LOW MASS,

THE HEATERELEMENTSCANREADILY ATTAIN TEMPERATURES SUFFICIENTLY

HlGHTO IGNITEGAS VAPORS. DO NOT INSTALLTESTARTICLES THAT MAY

RELEASE EXPLOSIVEOR FLAMMABLEVAPORS INTHE CHAMBER.

7. REFRIGERANTS UNDER HlGHPRESSUREARE USED. SERVICEOF THE

REFRIGERATIONSYSTEM MUST ONLY BECARRIEDOUT BYA QUALIFIED

REFRIGERATIONMECHANIC.

8.

HUMANEXPOSURETO TEMPERATURE EXTREMES CANCAUSE INJURY. TAKE

APPROPRIATE PRECAUTIONS BEFORE OPENINGCHAMBER DOORSAND UPON

HANDLING TEST SPECIMENS.

TENNEY ENVIRONMENTAL

INSTALLATIONINSTRUCTIONS

READ THE FOLLOWINGCOMPLETELYBEFOREATTEMPTINGTO INSTALLOR

OPERATE THE EQUIPMENT.

IMPORTANT!

--

FOR ALL MODELS EXCEPTBTS. BTC. T6S. T6C

CAUTION: TO SAFELY SECURETHE REFRIGERATIONSYSTEM COMPRESSORS AND

PIPING DURING SHIPPING, WOODEN BLOCKS HAVE BEENINSTALLEDUNDERNEATH

THE COMPRESSORS. THESE BLOCKS MUST

BE

REMOVEDBEFORE OPERATION!

SERIOUSDAMAGEMAY RESULT IFNOT REMOVED1

ON COMPRESSORS WlTH SPRiNG$lOaNTS ONLY, YOU MUSTLOOSENTHE

COMPRESSOR HOLD DOWN NUTS JUST ENOUGHTO REMOVE THE BLOCKS. DO NOT

LOOSENNUT BEYOND TOP OF BOLT.

ON COMPRESSORSWlTH

RUBEER~OUNTS

ONLY, JUST SIMPLY SLIDETHE WOODEN

BLOCK OUT. DO NOT LOOSENANY NUTS.

DELIVERY: Inspectequipment and shipping crate immediatelyuponreceipt. If any damage is

apparent, please contact the transportationcompany immediately. Retain all shippingmaterials

for inspection. Any claims for damage muststart at the receivingpoint. Check packingslip

carefully and make sure allmaterials have been receivedas indicatedon the packingticket.

Unless othewise noted, YOUR ORDER HAS BEENSHIPPED COMPLETE.

CAUTION!

Benchtopandreach-inchambers shouldbe handledand transported inan

upright position. Itmustnot becarriedon its back, front, orany side.

lmpo?tanfi Doto the vibration incurredduring shipping and handling, it is possiblethat

mechanicalconnections such as water fittings may become loose. For chambers with a water

cooled refrigerationsystem, check all water fittings to make sure they are t~ght.

GENERAL INFORMATION: Your equipment has beenfully operated, tested. and balancedin

our plant priorto shipment.Make sure the chamber is leveledwhenset up. Many times control

panels are removed to facilitate shipment. Replacementusually involves repositioningpanels

on the equipment mechanicallyand reconnectionOf numberedwires to matchingnumbered

terminalblocks. The chamber should be installedin an area where there is goodair ventilation,

especially if anair-cooledcondenser isused. Allow a minimumof

12

inches between any wall

and chamber side.

AIR SUPPLY CONNECTION(S): Your chamber may haveone or more air supply connections

which may includecompressed air, purged air, or other. Please check your chamber

specifications for completedetails. Make sure all air supplies are clean and that all connections

are secure.

GN,

I

LN,

I

CO, CONNECTION(S): Your chambermay requirea supply of GN,, LN,, or CO,.

Please check your chamberspecificationsfor completedetails. Makesure all connections are

secure.

TENNEY ENVIRONMENTAL

WATER SUPPLY CONNECTION(S): Ifthe chamber utilizes a water-cooled refrigeration

/-.

!

condenser,connect the supply to the Water-In connectionat the rear of the chamber. Connect

the Water-Out connectionto

an

opendrain.

POWER CONNECTION: WARNING1

--

BEFORE MAKING

THE

POWER SUPPLY

CONNECTION TO YOUR CHAMBER YOU MUST DO THE FOLLOWING:

1.

Verify the power supplyvoltage rating establishedfor yourchamber. The voltage

rating isfound onthe serial tag onthe side of the chamber.

Pleasenotethe ratedvalue here:

2.

Measureand recordthevoltage source you intendtosupply your chamberwith.

Pleasenotethe measuredvalue here:

3. Go to the section entitled "Line Voltage" inthis manual. Verify that the power supply

voltage source you measured and recordedis withintheminimum and maximum

allowable operating voltages for your chamber rating. Ifit is notwithin this operating

range, do notmake the power connectionl Otherwise, erratic operation and damage

may occurto your chamber which may void your warranty. Callthe Tenney Service

Departmentwith any questions.

A

main power disconnect is not providedwith your chamber. Itis highlysuggested that a

disconnect switch on a separate branchcircuit be installed as the powersource to your

chamber, in accordance with all nationaland local electricalcodes. Make sure equipmentis

.-

properly grounded in accordance with all codes. Forunits providedwith a cord andplug,

)

simply connect to a receptaclewhich hasthe appropriatepower supply on a branchcircuit of

itsown. Otherwise,connect incomingpower supply to the main inputconnectionsprovided.

Most units have a main line block connectionwhich is labeled for the correct service.

Unitswith three phase motors must becheckedto insureproper motor rotation.

A

redarrow is

locatedonthe motorhousing to show properrotation. If it is opposite,simply reverse two of the

linefeeds to obtainproperoperation. Failureto check motorrotationmay result in DAMAGE

TO THE EQUIPMENTdue to opposite airflowor no airflow. If the equipment hasmore than

one motor,they haveall beenproperly phased at the factory.

Beforeenergizingany equipment give ita visual inspectionfor loosecomponents,

electrical connections, fittings, etc. Shutall operating switchestothe "off" position

beforeenergizing.

Pleasehavetrained personnelstart and check out theequipment before itsfirst cycle.

TENNEY ENVIRONMENTAL

-

LINE VOLTAGE

I

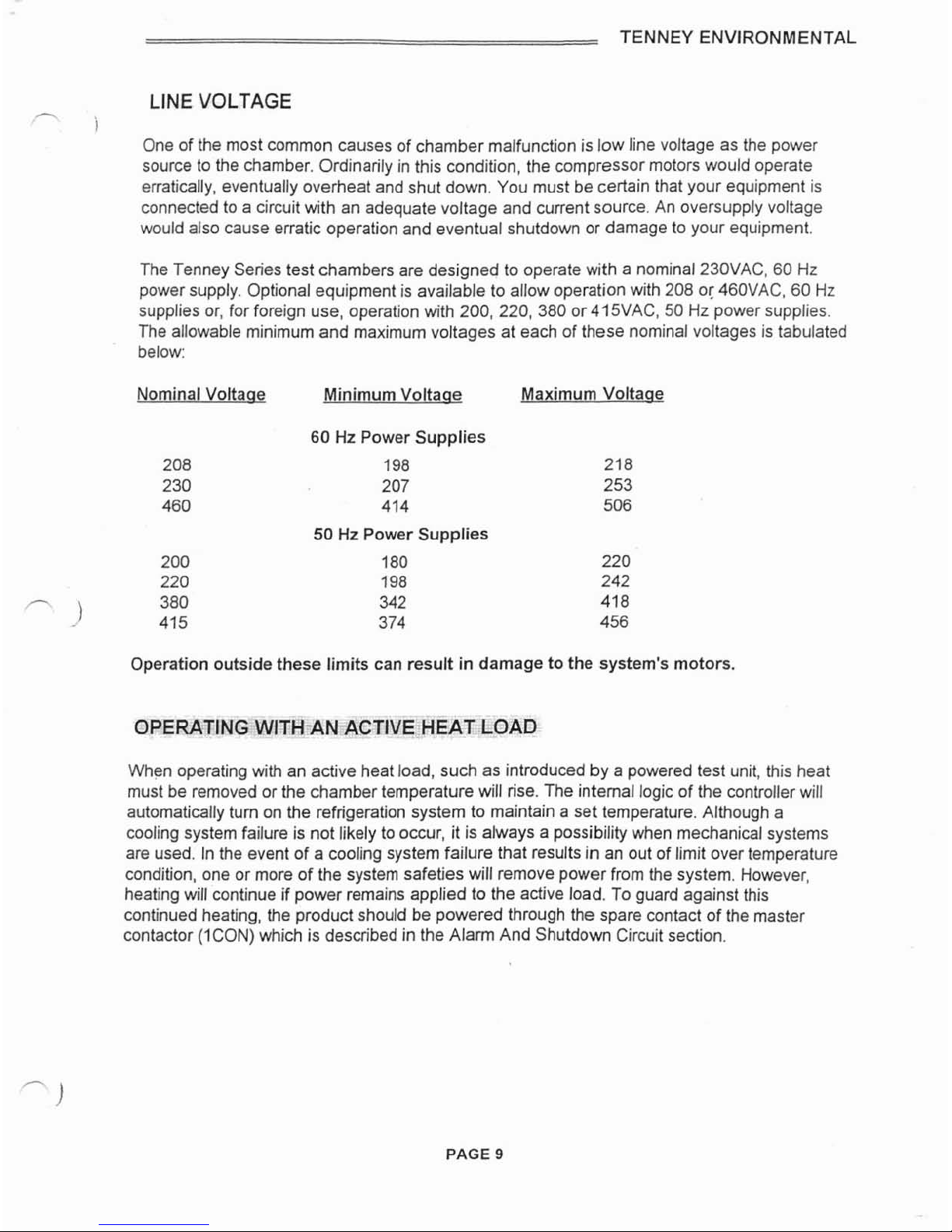

One of the most common causes of chamber malfunctionis low linevoltage as the power

source to the chamber.Ordinarily inthis condition, the compressormotorswouldoperate

erratically, eventually overheat and shut down. You must becertainthat your equipment is

connectedto a circuit with an adequate voltage and currentsource. An oversupplyvoltage

would also cause erratic operationand eventualshutdown or damage to your equipment.

The Tenney Series test chambers are designedto operate with a nominal230VAC, 60

Hz

power supply. Optionalequipment is availableto allow operationwith208 or460VAC, 60

Hz

supplies or, for foreign use, operation with 200, 220, 380 or415VAC. 50

Hz

powersupplies.

The allowable minimum and maximumvoltages at eachof these nominalvoltages is tabulated

below:

NominalVoltaae Minimum Voltaae MaximumVoltaae

60

Hz

Power Supplies

198 218

207 253

414 506

50

Hz

Power Supplies

180 220

198 242

342

418

374 456

Operation outsidethese limits can result

in

damage tothe system's motors.

OPERATINGWITH-AN

ACTIVE

HEAT LOAD

When operatingwith an active heatload, such as introducedby a powered test unit, this heat

must be removedor the chambertemperaturewill rise. The internallogic of the controllerwill

automaticallyturn on the refrigerationsystemto maintaina set temperature.Althougha

cooling systemfailure is not likelyto occur, it is always a possibilitywhen mechanicalsystems

are used. Inthe event of a coolingsystem failure that results

in

an out of limit over temperature

condition, one or moreof the system safeties will removepower from the system. However,

heating

will

continue if power remains appliedto the active load. To guardagainst this

continuedheating, the productshould bepoweredthrough the spare contact of the master

contactor (ICON)which is describedinthe Alarm And ShutdownCircuit section.

PAGE

9

TENNEY ENVIRONMENTAL

-

TEMPERATURE CONTROL

-

WATLOW

942

CONTROLLER

1

Temperature conditions are attainedand controlledby a Watlow 942 microprocessorbased

controller. Temperaturemeasurementsare made utilizing a 100ohm platinumRTD sensor.

This controllerfeatures dual outputs, auto-tuningcontrolwith 24 step programcapability and

easy fixed set point operation.

Heatingof the chamberisaccomplishedwith the time proportioned(PID) Output ICI-01 of the

controller, which turns on a triac inthe heater circuit supplying powerto the heaterelements.

Coolingof the chamberis accomplishedwith ONIOFF Output ICI-02of the controller,which

energizes a contactorsupplying powerto the refrigerationcircuitry.

IMPORTANTI

Output 1CI-02isset up for ONIOFF controlandthe PIDvalue is set to zero

Do not change the PIDvalue for channeltwo under any circumstance!

--

Corn~ressorTurn-On

Loaic

Indeterminingwhen to turn the refrigerationsystem on or off, the controller'slogicwill compare

the following signals and setpoints.

1.

Actual Chamber Temperature

2.

SetpointTemperature

3.

Hysteresis

4.

Deadband

-

)

Hysteresis

(HYS)

anddeadband

(db)

are parameters entered at thefactory. Hysteresisis the

temperaturechange necessaryto changethe output from full ON to full

OFF

andis detailedin

the Setup Menusection inthe Watlow 942 Manual. Deadband is the span inwhich Output ICI-

02will remainON belowthe controller's low setpoint, and isdetailed inthe Operation Menu

sectionof the Watlow Manual.

HYSand

db

are entered

in

degrees

C.

Deadbandis always enteredas a

(-)

minus.The logic is

as follows:

Measuredtemperature rises above setpoint: Refrigerationturn-on equals

hysteresisminusdeadband.

Measuredtemperature falls below setpoint: Turn-on is always above setpoint.

Tum-off is always below setpoint: Turn-on is always above setpoint.

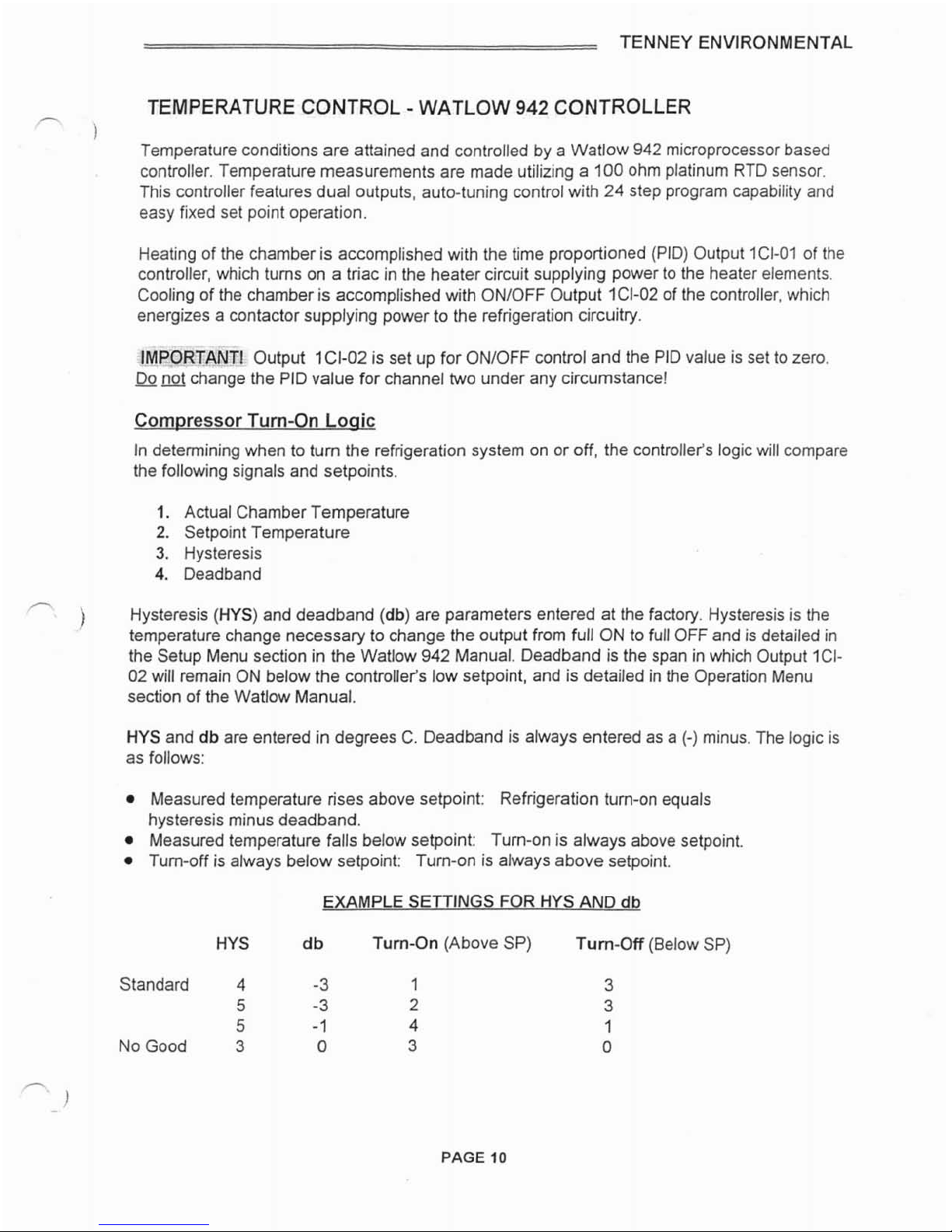

EXAMPLE

SETTINGS FOR HYSAND

db

HYS

db

Turn-On (AboveSP) Turn-OR (Below SP)

Standard 4

-3

1

5

-3

2

5

-

1

4

NoGood

3 0

3

TENNEY ENVIRONMENTAL

r--

Chambers are shipped with

HYS

=

4,

and db

=

-

3,

as shown onthe top line in the above

examples. It

is

unlikely a changeto these settings will be required. Fortunately, these settings

are not subject to "coldstart" default, andwill remainvalid afler a power interruption.They are

held in EEROM, not battery-backed RAM.

The pre-programmedconfigurationof the Watlow

942

is

documentedin the Test Report.

Pleaserefer to this and the Watlow 942 user's manual for completeoperationaldetails. These

are found in the SupplementalInstructionsSection.

Controller Versions

The Watlow 942 Controlleris provided infour versions with the following nomenclature:

1.

The basic 24-step rampingcontrol: 942A-3KDO-AE00

2.

Basic plus two events: 942A-3KD2-AE00

3.

Basic plus communications: 942A-3KDO-BE00

4.

Basic plus events andcommunications: 942A-3KD2-BE00

The nomenclatureis printedonthe back of the controllerand can be seen when the chamber's

controlpanel

is

opened.

NOTE: The communicationsarrangementis isolated RS232lRS423, RS422, EIA-485, or IEEE.

Each event output is through a mechanicalrelay having contacts rated

6

Amps,

120

or

240

VAC.

TENNEY ENVIRONMENTAL

-

ALARM AND SHUTDOWN CIRCUIT

1

A

comprehensive alarm and shutdowncircuit may be provided for multiple protectionagainst

product overtundertemperature and chamber over temperature. The sensor utilized for

temperature measurementand the Heat Limiter Fuse are normallyplaced at the plenum in the

downstream airflow. This is the most responsivearea of the chamber.

Chamber Over Temperature Protection: The following device is used,

1.

HeatLimiter (HL)

-

-

TemperatureActuated Fuse (Standard)

Product OverIUnderTemperature Protection: The following optional device may be used.

With this option, a

100

ohm platinum RTD

IS

utilizedfor temperature measurement.

1.

Watlow

93

Controller

-

-

TempGard IV Feature

-

HighlLowLimits (Optional)

WARNING! When Master Contactor ICONis deenergized duetoANY alarm condition

described below, power is only

removed

from the conditioning control circuitry. The

instrumentationandalarm circuitry will still be energizedl

For any questions concerningtheoperationof any of the controllers described below, please

reference the appropriate user manual locatedinthe SupplementalInstructionsSection.

CIRCUITOPERATIONS<

'

~)

NormalConditions:

When chambertemperatureiswithin the selectedsetpoints the switch (green) ON light is

illuminatedandthe Master Contactor ICONisenergized. The contacts of ICONprovide

powerto the conditioning control circuitry. (Withthe optionalalarnlbuzzer1silence switch or

TempGard IV feature, the NORMALlight 2LT will illuminate. When either of these optional

features are used, the main controlswitch will not be equipped with any integrallights.)

Note:

A

spare set of ICONcontactsare providedfor the customer'sclosure. It is

recommendedthat these contacts, wired to terminal blocks

#14

&

#15,

be usedto energize an

active heat load if utilized.

Ovened HeatLimiter:

When a predeterminedhightemperature limit isreachedandthe Heat Limiter Fuse (which

looks likea regularfuse) opens. Master Contactor ICONwill deeneraize alona with the

conditioningcontrol circhitj. The switch OVERTEMP lightwill illuminateand the switch ON

lightwill extinguish. (Withthe optional alarm buzzer

I

silence switch feature, boththe red

chamber

OVERTEMP

light

~LT

and redALARM light

4LT

will immediately illuminate, bealarm

buzzerwill sound, and the NORMALlightwill extinguish.)When the Heat Limiter Fuse opens,

it bereplaced.

WARNINGI

Whenreplacing the Heat Limiter Fuse, make sure all power

IS

completely

disconnectedfrom the chamber. Open the closest main power disconnect and pull the plug (if

,-

1

provided) from the outlet.

TENNEY ENVIRONMENTAL

-

TempGard IVAlarm

-

-

O~tional:

1

When a presettemperature limit isreachedwithin the Watlow 93 TempGard IV, the TGlV

alarm contacts open to deenergizeMaster Contactor ICON,which removes powerfrom the

conditioningcontrolcircuitry. The NORMAL light is nowextinguished,the redALARM light

4LT

illuminates, and the alarm buzzer sounds. The red Chamber OVERTEMPlight 3LTwill

illuminatewhen the alarm conditionclears

and

the TernpGard IValarm is clearedas detailedin

the Watlow 93 manual.

Note: The alarm buzzerwith silence switch is an optional feature for all chambers. This alarm

circuitry comes standardwith the Watlow 93 TempGardIVfeature. The TempGard IV

configurationis shown inthe "Watlow 93 TempGard IVConfigurationAnd Use" section.

Svstem Reset For

Alann

Buuer

I

Silence SwitchorTemoGardIVOption

-

-

Important!

After an out of limit condition hasbeen corrected, the conditioningcontrolcircuits must be

restarted by momentarily pressingthe RESET button IPB. You must rememberto clear the

Watlow

93

alarm message.

A

1.5

second timer ITC,is included

in

the reset circuit to providefor automatic start when

power is applied to the chamber. This avoidsthe needto press the resetbutton each time that

power is removedand reapplied.

Alarm Buuer

&

Silence Switch

- -

O~tional:

With this option the silenceswitch disables the alarm buzzerwhile correctiveaction is taken.

,-

When 1SSis activated, the white Silence light

5LT

will be illuminated. If the alarm buzzerwas

)

disabled and the system was successfullyreset with IPB,the alarm buzzer will now sound to

alert the operator to place the silence switch 1SS

in

it's normal (down) position.

Heatingof the chamber is accomplishedwith the time proportionedoutput 1CI-01of the

Watlow

942

Controller,which turns ontriac ITRCto supply powerto the heaterelements.

These elements are open air lowmass nichrome wires, which havelow thermal lag and

provide rapidresponseto the controller's demands.The heater elements are isolatedfrom the

workspace to preventdirect radiationto the product. Please referencethe electrical schematic

for your particularchamber's heaterbank ratings.

TENNEY ENVIRONMENTAL

SINGLE STAGE REFRIGERATION SYSTEM DESCRIPTION

-.

1

The basic single stagesystemconsists of a compressor, anoil separator (exceptfor Models

BTS,T6S,

T27,

&

T65), either an air cooledorwater cooled condenser, an evaporatorcoil

(locatedinthe chamber conditioningsection)which is providedwith a capillary (tube)type

expansion device, anda suctionlineaccumulatorto guard againstliquidrefrigerantreturnto

the compressor.

Refrigerantflow is fromthe compressoras a hot compressed gas throughthe oil separatorto

the condenser. Here the refrigerantcools andcondenses to liquidform and flows through the

capillary tube to the evaporatorcooling coil inthe chamber conditioningsection. Warm

chamber air is circulated throughthe coolingcoil andheat exchange occurs as the liquid

refrigerantboils, vaporizes, and absorbs heat. The vaporized refrigerant returnsto the

compressorthrough the suction lineaccumulator

SLA.

The cycle

is

repeated.

Forall unitsexcept Model

BTS,

a

thermostat is mountedonthe suction returnline near the

compressorto monitorthe temperature of the retumgas flow. When a predeterminedhigh

temperature is reached,the thermostat will energize an artificialloadingsolenoid, which will

injectrefrigerantthrough a capillarytube into the suction side ofthe system. This action will

maintain a positivecoolrefrigerantflow to the compressor, preventingoverheatingof the

compressor and the dischargegas.

,-.

The basic cascade system consists of a low stage compressor, a high stage compressor, an

'8

)

evaporatorcoil, anda cascade condenser.

The low stage system includes an oil separator(for models with compressor motors greater

than

IH.P.),

a cascadecondenser,an expansion tank, and an evaporator coil (locatedinthe

chamber conditioningsection) which is providedwith a capillary (tube) type expansion device

The high stage system includes an air cooledorwater cooled condenser, a capillarytube

which feeds the cascade condenser, and

a

suction line accumulatorto guard against liquid

refrigerantretum to the compressor.

The functionof the cascade condenserisfor the highstage refrigerantto cooland condense

the low stage refrigerant. This permits greaterSystem efficiency and allows lower chamber

temperatures to be reachedthan what can beattainedwith a single stage system. The low

stage liquidrefrigerantfrom the cascade condenser is metered through

a

capillarytube to the

evaporatorcoil. Heat exchangetakes place hereas the liquidrefrigerant convertsto a gas and

then returnsto the lowstage compressor.

A

thennostat is mountedon the suction returnlinenearthe low stage compressor to monitor

the temperatureof the return gas flow. When a predetermined hightemperature is reached,

the thermostatwill energizethe Artificial Loading solenoid 14SOL,whichwill inject refrigerant

intothe suction side of the system.

It

will first enter the expansiontank where the added

volume permitsthe charging of additional refrigerantwithout increasingthe standby or

charging pressurebeyondworkable limits. Refrigerantgas is then sucked out of the expansion

,-

tank and meteredthrough

a

capillarytube to the suction side of the low stage compressor.

.

~

)

This actionwill maintain a positive cool refrigerant flow to the compressor, preventkg

TENNEY ENVIRONMENTAL

overheatingof the compressor and the discharge gas.

-

)

A high pressurecut-in sensor monitors the pressureinsidethe lowstage compressor

and will activate the Load Limit Switch 4PS when the low stage discharge pressurereaches

280 PSIG. This will energizethe Artificial Loading solenoid 14SOLwhich will inject refrigerant

intothe suction side of the systemas describedabove. Switch 4PS preventsthe compressor

from cycling on and off in responseto signals from the high pressurecut-out switch. 4PS will

openwhen pressurefalls to 240 PSIG.

Formore detailedinformationon acascadesystem, please referencethe section entitled

"Servicing Cascade RefrigerationSystems".

REFRIGERAT~N

SYSTEM

SAFETY

DEVICES

The refrigeration system is providedwith several safety devices that stop the compressor(s)

from ~nningif conditions exceed preset limits. In a cascade systemboth the low stage and the

highstage includethese safety devices. With a low limit conditionthe

HI-LO

PressureCutout

Switch 1PS (and 2PS for cascade)will continueto automaticallyreset untilsufficientpressure

develops. With a highlimit conditionyou must manuallv reset IPS(or2PS). If the compressor

continues to trip off have the system checked by

a

qualifiedrefrigerationsystem mechanic.

The possiblecauses of a highor low limitcutout are as follows: NOTE:

The

HI-LO Pressure

Cutout Switch does not apply to the Models BTS. BTC.T6S, andT6C.

HighPressure Cutout

(1

PS, 2PS)

-

-

Opens if a preset compressor dischargepressure

'-

.)

is exceeded. Probable cause for high stage cut-out is insufficientcoolingwater (water

cooledsystems) or restrictedair flow (air cooledsystems). Probable cause for low stage

cutout is a malfunction of the high stage system. IPSRPS are typically set at

300

PSIG.

Low PressureCutout

(1

PS, 2PS)

-

-

Opens if the compressorsuction pressurefalls

below a presetvalue. Probablecauses are a loss of refrigerant(eitherstage) or restricted

air flow across the evaporator (low stage).

1

PSl2PSare typically set at

6

inchesof vacuum.

MotorOverload

-

-

Opens ifthe motorwindings exceed a preset temperature. Probable

causes are insufficientflow across the motor dueto a refrigerantlossor a failure of the

liquidinjectionvalve providedfor suction gas cooling. The motoroverloadis installed

directly in the motorwindings and will automaticallyreset andrestart the compressorafter

the motorhas cooled.

TENNEY ENVIRONMENTAL

WATLOW

93

-

TEMPGARD

IV

CONFIGURATION

&

USE

(Optional)

-

I

As an option, your chamber may include the TempGard IV feature with the Watlow

93

Controller. The circuitoperation description is explained inthe AlarmAnd Shutdown Circuit

section of this manual. This configuration section serves as a briefreferenceguide. For

completedetails ofthe Watlow

93

Controller, please reference the user manual.

When properly configured, the lower display of the control will be blank and the upper display

will show the actual temperature as measured by the control's RTDsensor, when conditions

arewithin the alarm settings. If an out of limitcondition occurs, the lower displaywill flash "HI"

or

"LO"

depending on the particular fault.

IMPORTANT: ForAll Models

-

When the alarm has cleared you must press the

RESET pushbutton

1

PB.

To configure the controlto perform as described above, power it upand select the setup menu

by pressingthe UPIDownarrow keys simultaneously. Pressing the

"M"

key then allows you to

scrollthrough the set up parameters.

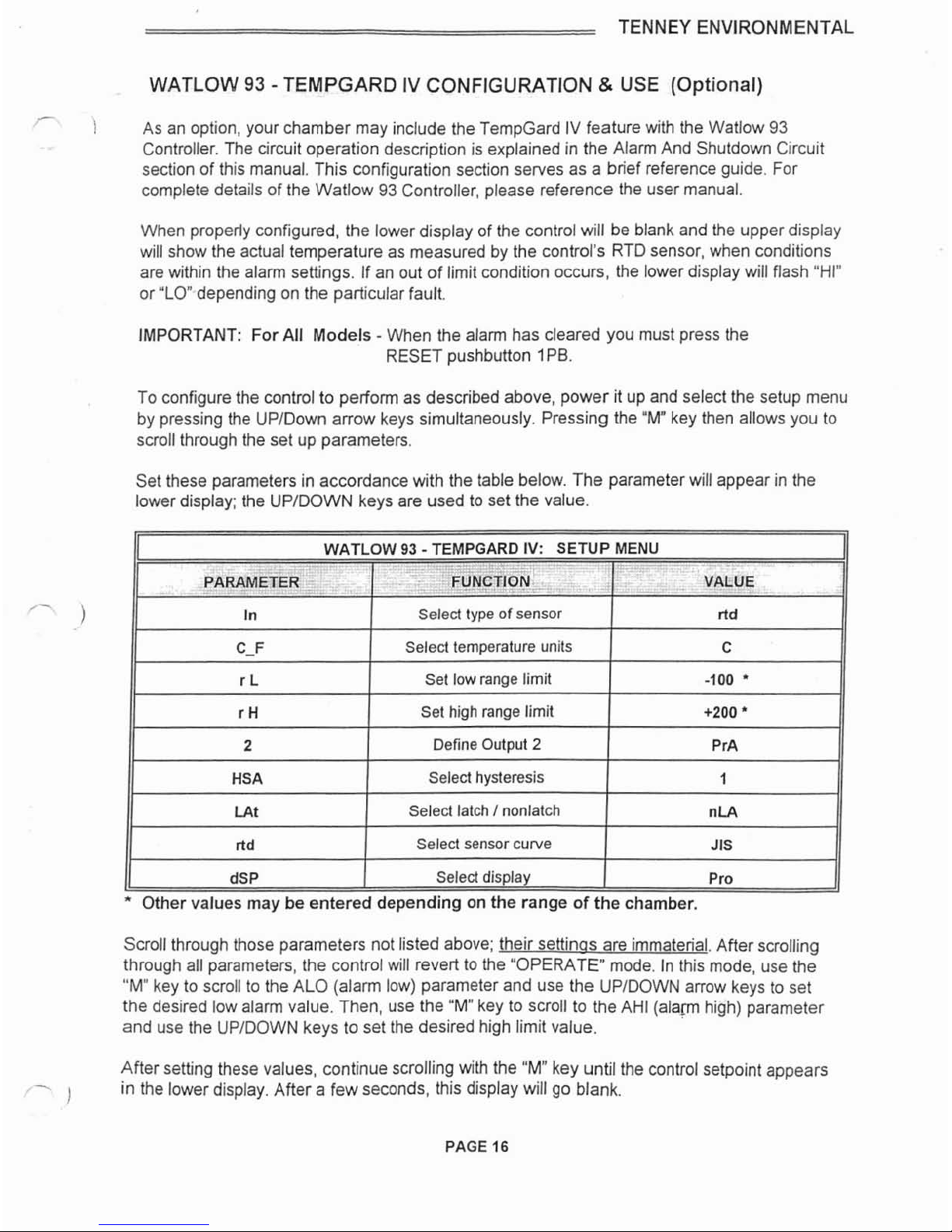

Set these parametersin accordance with the table below. The parameterwill appear inthe

lower display; the UPIDOWN keys are usedto set the value.

WATLOW

93

-

TEMPGARD IV: ENU

-.--.-I

PARAMETER

,

-

In

11

r

H

1

Set high range limit

1

+200

11

c-F

r

L

11

2

1

DefineOutput

2

I

PrA

11

FUNCTION

II

Select

type

of

sensor

11

HSA

I

Select hysteresis

1

1

11

VALUE

ltd

Selecttemperature units

Set low range limit

C

-100

'

dSP

I

Select display

I

Pro

Other values

may

beentereddepending on the range of thechamber.

LAt

ltd

Scrollthrough those parameters not listedabove; their settinos are immaterial.After scrolling

through all parameters,the controlwill revert to the "OPERATE" mode. Inthis mode, use the

"M"

keyto scroll to theALO (alarm low) parameter and use the UPIDOWNarrow keys to set

the desired low alarm value. Then, use the

"Mu

key to scroll to the AH1 (alamhigh) parameter

and usethe UPIDOWNkeys to set the desired high limit value.

After setting these values, continue scrolling with the

"M"

keyuntilthe controlsetpoint appears

-

1

inthe lower display. After a few seconds, this displaywill go blank.

Select latch

I

nonlatch

Select sensor curve

--

nLA

JIS

TENNEY ENVIRONMENTAL

BOOST HEAT (Optional)

-

)

As an option, your chambermaybe equippedwith the boost heat feature which includes extra

heaters to provide rapidincreasesin temperature. The boost heat will automaticallytum on ifa

preset time delay relaytimes out, indicatingthat the desired temperature has not been

achieved.

As output 1CI-01of the controllerenergizes the main heater bank, ICI-01will at the same time

energizea time delay relay.When this relay times out it

will

energize a mercury relay, which

providespower to the boost heaters.A mechanicalcontactor is also providedwhich has it's

contactswired intothe power supply line to the boost heaters. This contactor is providedto

deenergizethe heaters in the event of an over temperature condition.

BOOSTCOOLING (Optional)

USING LIQUIDNITROGEN or

CARBON

DIOXIDE

As an option, your chambermaybe equipped with a boost cooling system which is activated

byan event output from the Watlow 942 Controller. Cooling is achievedby injectingeither LN,

or

CO,,

depending on the optionpurchased, into the chamberthrough a solenoid valve. To

activate the system the event must beturned on as explained inthe Watlow

942

Controller

manual.

Event No.

1

is generally used for this function. However,a referencetable definingthe function

of each event is affixed to the controlpanelof each chamber. Please check this table before

1

operatingthe chamber.

Once enabledthrough the event, the cooling will turn on if a demand for coolingexists for a

presettime period.

A

timer connectedto the time proportioned output of the controller"times

our' and energizes the cooling solenoid valve if the output is 100percent "ON"indicatinga

needfor additional cooling.

When the desiredtemperatureis attained andthe controllerheat output begins to turn on, the

boostcoolingfunctionwill cease.

LN, systems are providedwith a manuallyset flow adjustingvalve providedto allow for

adjusting the flowto avoid incompleteevaporationat valying

LN,

supply pressures.A setting

of

4

tums open generally provides good perfomlance at asupplypressure of 20 to

25

PSIG.

This valve may be readjusted as necessaryto accommodatethe supply pressureat the end

use point.

TENNEY ENVIRONMENTAL

PURGEAIR SYSTEM

(Optional)

-

USING COMPRESSED AIR

or

NITROGEN

i

As an option, your chamber may be equippedwith a dry air or GN, purge system which is

activatedby an event output from the Watlow

942

Controller. To use the system, the event

must be turned on as explained in the Watlow

942

manual. EventNo.

2

is generally used for

this function.However,a referencetable defining the function of each event is affixed to the

controlpanelof each chamber. Please check this table before operatingthe chamber.

A

metering valve and flowmeter is supplied as part of thesystem to establishthe design purge

flow. The valve should

be

adjusteduntilthe indicatedflow isabout 300 cubic feet per hour.

The

GN,

purge system is primarilyutilizedto provideaninert atmospherewhich minimizes the

buildupof moistureand preventscondensationonthe product undertest. Eliminatingthe

oxygeninthe chamber air helps prevent corrosion of the product under test.

A drier is providedfor compressedair purgesystems. This system requires

a

supply of

relativelyoil free compressed air at a minimum pressure of 80 PSIG. This air is dried by a twin

tower heatless, self regeneratingdryer and is introduced intothe chamber through

a

solenoid

valve.

As anoption, your chamber may be providedwith either a circularor strip type chart recorder

'

)

to recordtemperature versus time. This recorder istypically a one pen type which also digitally

displays the processvalue.

A

100ohm platinum RTD is used for temperature measurement

and is normallyplacedin the plenum of the chamber.

The recorderconfigurationis documentedinthe Test Report, which is locatedinthe

Supplemental Instructions Section. For complete details on the operation of the recorder,

pleasereferencethe recorder's user's manualwhich is locatedin the same section.

PAGE

18

TENNEY ENVIRONMENTAL

DATA

COMMUNICATIONS (Optional)

7

1

As an option, your chamber may includedata communications withthe maincontrolletsserial

port. When employed, either a Data Communications manual or a Computer Interfacemanual

will be includedinthe Supplementallnstmctions Section.As a reference,the availabledata

types are listedand briefly described below. Please contact

a

Tenney Sales Engineerfor more

informalion.

RS232C

I

RS423A: Both interfaces are compatibleand use

3

wires: a singletransmitwire;

a

single receivewire; and

a

commonline. The maximum wire length

is

50 feet. Only a single

chambermay be connected to your computer. Data signals are measured as plus and minus

12volts to commonwith RS232C, and plus and minus 5v71ts to common with RS423A.

RS422A: This interfaceuses

5

wires: a transmit pair; a receivepair;anda common line. Up

to ten chambersmay be connected to your computer on a multi-drop network up to 4,000 feet

long. Data signals in each pair are measuredas a plus or minus5 volt differential.

EIA-485: This interface usesonly

2

wires. Both wires are usedfor transmittingandreceiving

data, and therefore, only one device may talk at a time. Up to

10

chambers may beconnected

to your computer on a multi-dropnetwork up to 4,000 feet long. Data signals are measured as

a plus or minus

5

volt differential.An EIA-485 card must be installedfor signalconversion.

IEEE-488: This is a parallel multi-dropinterface with several controland data lines. Each

device connected must be setto a uniqueaddress. Datafrom other test devices may also be

collected.Since the controllers we use only have serial communications, an IEEE-488to serial

'

)

converter card isinstalledinthe chamber. Maximumcable lengthisapproximately

33

feet for

all devices.

TENNEY ENVIRONMENTAL

LinkTenn

SOFTWARE

(Optional)

-

)

Welcome to anotherunique optionalfeature developedbyTenney Environmental.

LinkTenn software isdesignedto operate on a remotecomputer system and provide complete

control of Tenney Environmentaltest chambers.This is accomplished by communicating

through a RS232lRS422interfacewith the VersaTenn Ill or Watlow 942, 945, and 988

Controllers. Up to ten chambers may be controlledfrom one computerwith RS422 interface.

LinkTennsoftware isprovidedboth in a DOS format and in a Windows format on

3%

inch

diskettes. Inthe DOS format, "LinkTenn

II"

software is designedto work with the VersaTenn

Ill

Controller, and"LinkTenn942"software is designedto work with the Watlow 942 Controller. In

the Windows format. "LinkTenn For Windows" software is designedto work with the

VersaTenn

Ill

and the Watlow 942, 945, and988 Controllers.

The hardwareand software requirements to run LinkTennsoftware inbothformats are listed

below.

DOS

Format: LinkTenn

II

&

LinkTenn

942

1.

Any DOS basedcomputer

2.

256K

of

RAM

memory

3.

CGA graphics card

4.

DOS

2.0 or higher

5. RS232 computerinterfacefor single chamber control

6.

RS422 computerinterfacefor multiplechamber control

7.

With IEEE-488communications, a NationalInstruments PC2A or compatible card

1

Windows Format: LinkTennForWindows

1.

Computerwith 486 processor or higher

2. Eight Megof harddrive memory

3.

Eight Megof

RAM

memory

4. Windows

3.X

operatingsystem or higher

5. RS232 computerinterfacefor single chamber control

6.

RS422computerinterfacefor multiplechambercontrol

7.

Currently not availableto work with IEEE-488communications

A sample menudisplay screenentitled "ProgramControl"from the LinkTenn For Windows

program,

is

providedin the SupplementalInstructions Section. This screen shows some of the

uniquefeatures incorporatedintothe programalongwith sample setpoints.

When LinkTennsoftware is providedineitherformat, a correspondingLinkTennUser's Manual

will be providedinthe SupplementalInstructionsSection.

TENNEY ENVIRONMENTAL

CHAMBER OPERATION

/.

)

To operate the chamber, turnonthe power source to the chamber and close all chamber

circuit breakers.The display of the Watlow

942

should now be illuminated. Enterthe desired

temperature programor manualsetpoints as explainedin the Watlow

942

user'smanual.

Closethe Power On switch 1SS.The green ON light should be illuminated.

If your chamberincludesthe optional Watlow

93

Controllerwith TempGard IV feature, set this

controller's highnow temperaturelimits at this time. Referto the "AlarmAnd Shutdown Circuit"

descriptionand the "TempGard IV ConfigurationAnd Use Instructions"for further details.

Forthose chambers which includeany otheroptions, please referto the appropriate "optional"

manualsectionsfor

a

detailedoperationdescription.

IMPORTANTNOTE1 For complete programmingand/oroperating instructions on any of the

controllers, electrical

I

mechanicalcomponents, or optional equipment, you must referto their

operatingmanuals includedwith your Tenney Environmentalmanual.

TENNEY ENVIRONMENTAL

PREVENTIVE

MAINTENANCE

GUIDE

-.

)

Frequencyof preventivemaintenance operations depends upon how the facility is used and

uponother circumstances. Because of this, a hard and fast schedule of maintenance

operations is difficultto present. Indeed, an inflexible schedule might be suitable for one user,

but completely inadequate for another. Therefore, the preventivemeasuresgiven here are

offered as a guide, allowingyou to arrange your own program.

We suggest that you maintaina preventive maintenance log. Inthis log you will record

operating notes, pressures,temperatures, and electric readings.The log is valuable becauseit

will help maintenance and servicepeople bydocumenting long term trends and by showing

parameterlevelswhen the chamber is operating properly.

Sincethe refrigeration system issealed andthe instruments are solidstate, little maintenance

is requiredon the temperature chamber. However,the following preventivemaintenance steps

are suggested.

ALL INTERLOCKSAND SAFETYFEATURES SHOULD

BE

TESTED

PERIODICALLYFOR PROPER OPERATION.

1.

Periodically inspectthe refrigerationsystem condensercoil for dust or dirt accumulation

that would impede the flow of air.

A

dirty condenserwill driveup head pressure. If

necessary,clean with

a

brushor vacuumcleaner. Frequencyof cleaning depends upon

the air quality at the chamber. (Air Cooled)

r

-

j

2.

Makesure the condenserwater supply isadequate and is flowing unimpeded to its drain

Inadequateflow will drive up head pressure. (Watercooled)

3.

lnspect the door gasket, making sure the door seals tightly. Replace gasket if significant

wear is evident.

4.

Ifthe door does notsealwell, adjust the door latch. If adjustmentof the latchdoes not

make the door close tightly, replace the gasket.

5.

Only afterdisconnecting all powerto the chamber, inspect andcleanthe condenserfan

and the conditioner fan. Make sure they spin freely and that the conditionerfan is tight on

its shaft.

6.

Only after disconnectingall powerto the chamber,inspect insidethe machinery

compartment; look for looseelectrical connections,frayedwires, and loosecomponents.

7.

Only after disconnectingall power to the chamber, inspect the electric heater insidethe

conditioner; look for sagging elements, brokeninsulatorsor other defects. lnspect the

heat limiter (if supplied), makingsure that its contacts are bright and clean.

TENNEY ENVIRONMENTAL

8.

Ifyour chamber has the optional TempGard IV, do the following:

a) HighSetpoint: Dial a temperaturewell belowactualworkspace temperature.

The instrumentmust transfer to alarm state, disabling protectedcircuits.

b)

LowSetpoint: Diala temperaturewell aboveactual workspace temperature. The

instrument must transfer to alarmstate, disablingprotectedcircuits.

c)

Test the alarm buzzer, makingsure it isoperable

d)

Ifcustomer's contactclosure is usedto energize an externally powered heat source,

make sure that the contact closure removes powerwhen TempGard IV is inthe alarm

state.

IMPORTANTNOTE: Forcomplete preventative maintenanceinstructions or equipment

maintenance instructions on any

of

the instruments,electrical

or

mechanicalcomponents,or

electrical

/

mechanicalmachinery and motors, you must refer to their operating manuals

includedwith your Tenney Environmentalmanual. The smaller manuals andvendor cut-sheets

are located inthe SupplementalInstructionsSection. Any large manuals that could not fit into

this 3-ring bluebinderare sent alongside of it.

NOTES:

The refrigerationsystem is permanently sealed and a periodic oilchange is NOT

I

-

required.

'

.

Ifa loss of cooling performanceis noted, immediatelycheck the condenser for

restrictedair or water flow.

All motors are permanentlylubricated; therefore, greasingor oiling is not required.

This manual suits for next models

7

Table of contents

Other Tenney Test Equipment manuals

Popular Test Equipment manuals by other brands

Big Joe

Big Joe E30 Series manual

One-Tool

One-Tool OTB620 product manual

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 8031 CE instruction manual

EGAmaster

EGAmaster Egatronik 51249 operating instructions

WHALETEQ

WHALETEQ AECG100 user manual

Amprobe

Amprobe RS-3 PRO CAT IV Analog user manual