Tenney T6S User manual

P

U

For

Quality

efurbished

-Warranteed

est

quipment

Contact

us

at

800-574-2748

323-770-0634

Web

Site:

www.

.com

ote:

anual

For

eference

nly

-

ctual

hamber

ay

ary

Depending

on

odel

Year,

ptions,

ontrollers,

and

ndividual

onfiguration

PAGE 1

TENNEY ENVIRONMENTAL

INTRODUCTION

)

Congratulations on purchasinga Tenney Environmentaltest chamber. We truly hopethat

every aspect of design and qualitywill measure up to your stricteststandards. Your chamber

has beendesigned to operatewiththe reliabilityyou expect for the demands you impose on

your productand researchtesting.

Your environmentaltest chamber incorporates manydifferent engineeringtechnologies.

Tenney Engineershavedesignedeven the mostcomplex chambers to operate in away that

the customercan competently understand,configure, and maintain.Anytime you have a

question, you can phone, fax, or E-mailour dedicatedservice staff. Their diverse experience

and knowledgewill get you the answersyou need. We have put the PartsAnd Service

Inquiries sectioninthe front of the manualfor your convenience.

Like our test chambers, this manualhas been designedwith the customer inmind. Section

General aives a brief overviewof the chamber s~ecifications.while the remaininosections

detailthedifferent functionsandoperating cond/tionsand procedures. Inthe re$ of the

manualvou'll findthe Su~~lementalInstructionsSection filled with a varietv of information.As

applicable to the chamber: this section includesseparatevendor user manualsand cut-sheets,

expandedinstructionand informationsections, drawings, tables, data sheets, the test

inspectionreport, and the warranty. Itis extremely importantthat you readthe entire manual

and all of the informationcontained therein beforeoperatingyour equipment.

You must adhere to the wamings and safety procedureslisted throughout this manualas well

as to those listed in the vendor user manuals and cut-sheets. Failuretofollowthe wamings,

)

safety proceduresand properoperating procedures listed throughout the manuals

couldresult indamaged equipment, personal injury, ordeath.

YOUR POWER SUPPLYLINEVOLTAGE MAY BETOO LOWOR TOO HIGHTO

PROPERLYAND SAFELYOPERATEYOUR CHAMBER.

BEFOREMAKINGTHE POWER SUPPLY CONNECTIONTO YOUR CHAMBER,

YOU MUSTFOLLOWTHE SPECIFIC DIRECTIONSSTATED UNDER

"POWER CONNECTION" IN THE INSTALLATIONINSTRUCTIONSSECTION.

FAILINGTO PERFORMTHE DIRECTIONS STATED MAY VOID YOUR WARRANTY!!

PAGE

2

TENNEY

ENVlRVNMtN

I

AL

GENERAL DESCRIPTION

\

The Tenney ModelsT27, T65, Models BTS, BTC, and Models T6S. T6C throughT30S, T30C

series test chambers are designedto provide a temperature controlledenvironment.

Temperatureconditionsare attainedby recirculatingchamber air through a refrigeratedcooling

coil and open air nichromewire heaterelements.Air circulation is generated by a propeller

type fan directly driven by an externally mountedmotor.Non-CFCrefrigerantsare used in the

refrigeration systems of all Tenney chambers.

The suffix

'S'

inthe chamber modelnumberindicatesthat the chamber is equippedwith a

singlestage refrigerationsystem, incorporatingone compressor. The temperature controlled

rangefor these chambers is -40to +ZOO degrees Centigrade, a.3degrees Centigrade. The

exceptionto this standard rangeare the ModelsBTSand T6S, which have a low range of -34

degrees Centigrade.

The ModelsT27 andT65 also incorporate a single stage refrigerationsystem, but havea

smallertemperature operating rangethanthose mentioned above.This rangeis from -20 to

+I00degrees Centigrade,f0.21i0.3 degrees.

The suffix

'C'

inthe chambermodelnumberindicatesthatthe chamberis equippedwith a

cascade refrigerationsystem, incorporating two compressors. Thetemperaturecontrolled

rangefor these chambers is from -73 to +ZOO degreesCentigrade,i0.3 degrees Centigrade.

The exceptionto this standard range are the Models BTC and T6C, which have a low rangeof

-70 degrees Centigrade.

)

Temperature conditions are attained andcontrolledbya Watlow 942 microprocessorbased

controller, utilizing an RTDfor temperaturemeasurement.This controller provides24 step

programmingwith dual outputs inthe time-proportionedand ONIOFFmodes. It also may be

usedas a non-ramping manualcontroller.As options, you may have auxiliary event outputs

and RS232lRS423, RS422, EIA-485, or IEEEdata communicationswith the Watlow 942.

Your Tenney chamber may include many other uniqueoptions such as; TempGardIV feature

with the Watlow93 Controller for redundantproductoverlunder temperature protection, boost

coolingusing CO, or

LN,,

boostheating, purgeair system using compressedair or

GN,,

a two

channelchart recorder, and LinkTenn software that permitsyour computerto control up to 10

chambers.

As you can see, the Tenney Environmentaltest chamberis a diversifiedtool designedto

encompass a wide range of operatingconditions andfunctions. If you come upon any

questions as you continueonthrough the manual, pleasefeel free to contact our Service

Department.

PAGE

3

TENNEY ENVlRONMtN

IAL

SAFETY

WARNINGS

1

1.

PLEASE READ THE ENTIRE TENNEY INSTRUCTIONMANUALAS WELLAS THE

VENDOR MANUALSAND CUT-SHEETS PROVIDED, BEFORE OPERATING THlS

CHAMBER! FAILURE TOADHERE TO THE SAFETY WARNINGS, OR TO FOLLOW

THE PROPEROPERATING PROCEDURESLISTED THROUGHOUTTHE MANUALS

AND INFORMATIONPROVIDED, COULD CAUSEDAMAGETO YOUR EQUIPMENT,

PERSONALINJURY, OR DEATH.

2.

A MAIN POWER DISCONNECTIS NOT PROVIDED WlTH YOUR CHAMBER. ITIS

HIGHLYSUGGESTEDTHAT A DISCONNECTSWITCH ONA SEPARATEBRANCH

CIRCUITBEINSTALLEDAS THE POWER SOURCE TOYOUR CHAMBER, IN

ACCORDANCEWlTH ALL NATIONALAND LOCAL ELECTRICALCODES. IFYOUR

CHAMBER IS EQUIPPEDWlTHA POWER CORDAND PLUG, YOU MUST UTILIZEA

RECEPTACLEWlTH THEAPPROPRIATE RATINGWHICH ISON A BRANCHCIRCUIT

OF ITS OWN. OPENING THE BRANCHCIRCUIT BREAKER INTHE TEST CHAMBER

DOESNOT REMOVEALL POWER FROMTHE CHAMBER.

3.

ELECTRICAL ENCLOSURES, GAUGE BOXES, CONDITIONINGCOMPARTMENT,

etc.,

CONTAIN EXPOSEDELECTRICAL CONNECTIONS. DISCONNECTALL ELECTRICAL

POWER FROMTHE FACILITYAT ITSSOURCE BEFORESERVICING OR CLEANING.

4.

DO NOT ATTEMPT ANY SERVICEOR ADJUSTMENT TOANY ELECTRICALOR

MECHANICALCOMPONENTSDURINGOPERATION.

)

5.

KEEP PANELSINPLACEPROPERLYWHEN THE CHAMBER ISINOPERATION.

6.

THlS ISNOTAN EXPLOSION PROOFCHAMBER

--

THEAIR CONDITIONING SECTION

CONTAINS LOW MASS, OPENWIRE HEATINGELEMENTS. DUE TO THlS LOW MASS,

THE HEATER ELEMENTSCANREADILYATTAIN TEMPERATURESSUFFICIENTLY

HlGHTO IGNITEGAS VAPORS. DO NOT INSTALL TEST ARTICLESTHAT MAY

RELEASE EXPLOSIVE OR FLAMMABLEVAPORS IN THE CHAMBER.

7.

REFRIGERANTSUNDER HlGHPRESSUREARE USED. SERVICE OFTHE

REFRIGERATIONSYSTEM MUSTONLY BECARRIED OUT BYA QUALIFIED

REFRIGERATIONMECHANIC.

8.

HUMAN EXPOSURETO TEMPERATURE EXTREMES CANCAUSE INJURY. TAKE

APPROPRIATE PRECAUTIONSBEFOREOPENING CHAMBER DOORSAND UPON

HANDLING TEST SPECIMENS.

PAGE

4

TENNEY ENVIRONMENTAL

INSTALLATIONINSTRUCTIONS

I

READ THE FOLLOWINGCOMPLETELYBEFOREATTEMPTING TO INSTALLOR

OPERATE THE EQUIPMENT.

IMPORTANT!

-

-

FOR ALL MODELSEXCEPT BTS. BTC. T6S. T6C

CAUTION: TO SAFELYSECURE THE REFRIGERATIONSYSTEM COMPRESSORSAND

PIPINGDURING SHIPPING, WOODEN BLOCKS HAVEBEENINSTALLEDUNDERNEATH

THE

COMPRESSORS.

THESE

BLOCKS

MUST

BE

REMOVED

BEFORE

OPERATION!

SERIOUS DAMAGE MAY RESULTIFNOT REMOVED1

ON

COMPRESSORS

WITH

SPR~G

~~~OUNTSONLY,

YOU

MUSTLOOSEN

THE

COMPRESSOR HOLDDOWNNUTSJUST ENOUGHTO REMOVETHE BLOCKS. DO NOT

LOOSEN NUT BEYOND TOP OF BOLT.

ON COMPRESSORS WITH RUBEER'MOUNTSONLY, JUST SIMPLYSLIDETHE WOODEN

BLOCK OUT. DO NOT LOOSENANY NUTS.

DELIVERY: Inspectequipmentandshipping crate immediately upon receipt. If any damage

is

apparent, please contact the transportation company immediately. Retainall shippingmaterials

for inspection. Any claims for damage must start at the receivingpoint. Check packingslip

carefully andmakesure all materials have been receivedas indicatedon the packingticket.

1

Unless otherwise noted,YOUR ORDER HAS BEEN SHIPPEDCOMPLETE.

CAUTION1 Benchtopandreach-in chambers shouldbe handledand transported in an

upnght position.It

must not be caniedon its back,front, or any side.

Importint1 Doto the vibration incurred during shippingand handl~ng,itispossiblethat

mechan~calconnections such as water fittings may become loose. For chambers w~thawater

cooledrefrigerationsystem, check allwater fittings to make sure they are tight.

GENERAL INFORMATION: Your equipmenthas beenfully operated, tested, and balancedin

our plant priorto shipment. Make sure the chamber is leveledwhen set up. Many times control

panelsare removed to facilitate shipment. Replacementusually involves repositioningpanels

on the equipment mechanicallyand reconnectionof numberedwires to matching numbered

terminal blocks. The chamber should be installed in an area where there isgoodair ventilation,

especially if an air-cooledcondenseris used. Allow a minimum of

12

inches betweenany wall

and chamberside.

AIR SUPPLYCONNECTION(S): Your chamber may haveone or more air supply connections

which may includecompressedair, purged air, or other. Pleasecheck your chamber

specifications for completedetails.Make sure all air supplies are clean andthat all connections

are secure.

GN,

I

LN,

I

CO, CONNECTION(S): Your chamber may requirea supply of GN,, LN,, or CO,.

1

Please check your chamber specificationsfor complete details. Make sure all connectionsare

secure.

TENNEY ENVIRONMENTAL

WATER SUPPLY CONNECTION(S): Ifthe chamber utilizes a water-cooled refrigeration

)

condenser, connect the supply to the Water-In connection at the rear of the chamber. Connect

the Water-Out connectionto an open drain.

POWER CONNECTION: WARNING1

-

-

BEFORE MAKING THE POWER SUPPLY

CONNECTIONTO YOUR CHAMBER YOU MUST DO THE FOLLOWING:

1.

Verifythe power supply voltage ratingestablishedfor your chamber. The voltage

rating isfound onthe serial tag onthe side ofthe chamber.

Please notethe ratedvalue here:

2.

Measure and recordthe voltage source you intendtosupply your chamber with.

Please notethe measuredvalue here:

3.

Gotothe sectionentitled "Line Voltage" inthis manual. Verify thatthe power supply

voltage source you measured and recorded iswithintheminimum andmaximum

allowable operating voltages for your chamber rating.

If

it

is notwithin this operating

range, do not makethe powerconnection1 Otherwise, erratic operationand damage

may occurtoyour chamber which may void your warranty. Callthe Tenney Service

Departmentwith any questions.

A

main power disconnectis not providedwith your chamber.

It

is highly suggestedthat a

disconnectswitch ona separate branchcircuit be installedas the powersource to your

chamber, in accordance with all nationaland localelectrical codes. Make sure equipment is

properlygrounded inaccordancewith all codes. For units providedwith a cordand plug,

)

simply connect to a receptaclewhich has the appropriate power supply on a branchcircuitof

its own. Otherwise, connect incoming power supply to the main input connections provided.

Most unitshave a mainline block connection which is labeledfor the correct service.

Units with three phase motors must be checked to insure propermotor rotation.

A

redarrow is

locatedonthe motor housingto show properrotation. If itisopposite, simply reverse two of the

linefeeds to obtainproperoperation. Failureto check motorrotationmay result in DAMAGE

TO

THE

EQUIPMENTdueto opposite airflow or no aifflow. If the equipment has more than

one motor,they haveall beenproperlyphasedat the factory.

Beforeenergizingany equipment give

it

a visualinspectionforloose components,

electrical connections, fittings, etc. Shut all operating switches tothe "off' position

beforeenergizing.

Please havetrained personnelstart andcheck outtheequipment before itsfirst cycle.

PAGE

8

TENNEY ENVIRONMENTAL

LINEVOLTAGE

One of the most common causes of chamber malfunction is lowlinevoltage as the power

sourceto the chamber. Ordinarilyinthis condition, the compressormotors would operate

erratically, eventuallyoverheatandshut down. You must becertainthat your equipment is

connectedto a circuitwith an adequate voltage and current source. An oversupply voltage

would also cause erratic operation and eventual shutdown or damage to your equipment.

The Tenney Seriestest chambers are designed to operate with a nominal

230VAC, 60

Hz

power supply. Optionalequipment is available to allow operation with

208

or

460VAC, 60

Hz

supplies or, for foreign use, operationwith

200, 220, 380

or

415VAC, 50

Hz powersupplies.

The allowableminimumand maximum voltages at each of these nominalvoltages is tabulated

below:

NominalVoltaae Minimum Voltaae Maximum Voltaae

60

Hz

Power Supplies

208 198

218

230 207 253

460 414 506

50

Hz

Power Supplies

200 180 220

220 198 242

f

380 342 418

415 374 456

Operationoutsidethese limits can result indamage

to

the system's motors.

OPERATING

WITH

AN

ACTIVE

HEAT

LOAD

When operatingwith an active heat load, such as introduced

by

a poweredtest unit, this heat

must be removedor the chamber temperature will rise. The internallogicof the controllerwill

automatically turn onthe refrigerationsystem to maintain a set temperature. Although a

coolingsystemfailure is notlikely to occur, it is alwaysa possibilitywhen mechanicalsystems

are used. Inthe event of a coolingsystemfailure that resultsinan out of limitover temperature

condition, one or more of the system safetieswill removepowerfrom the system. However,

heatingwill continue if power remainsapplied to the active load. To guardagainst this

continued heating. the productshould be poweredthrough the spare contact of the master

contactor (ICON) which is describedinthe Alarm And Shutdown Circuit section.

PAGE

9

TENNEY ENVIRONMENTAL

TEMPERATURE CONTROL

-

WATLOW

942

CONTROLLER

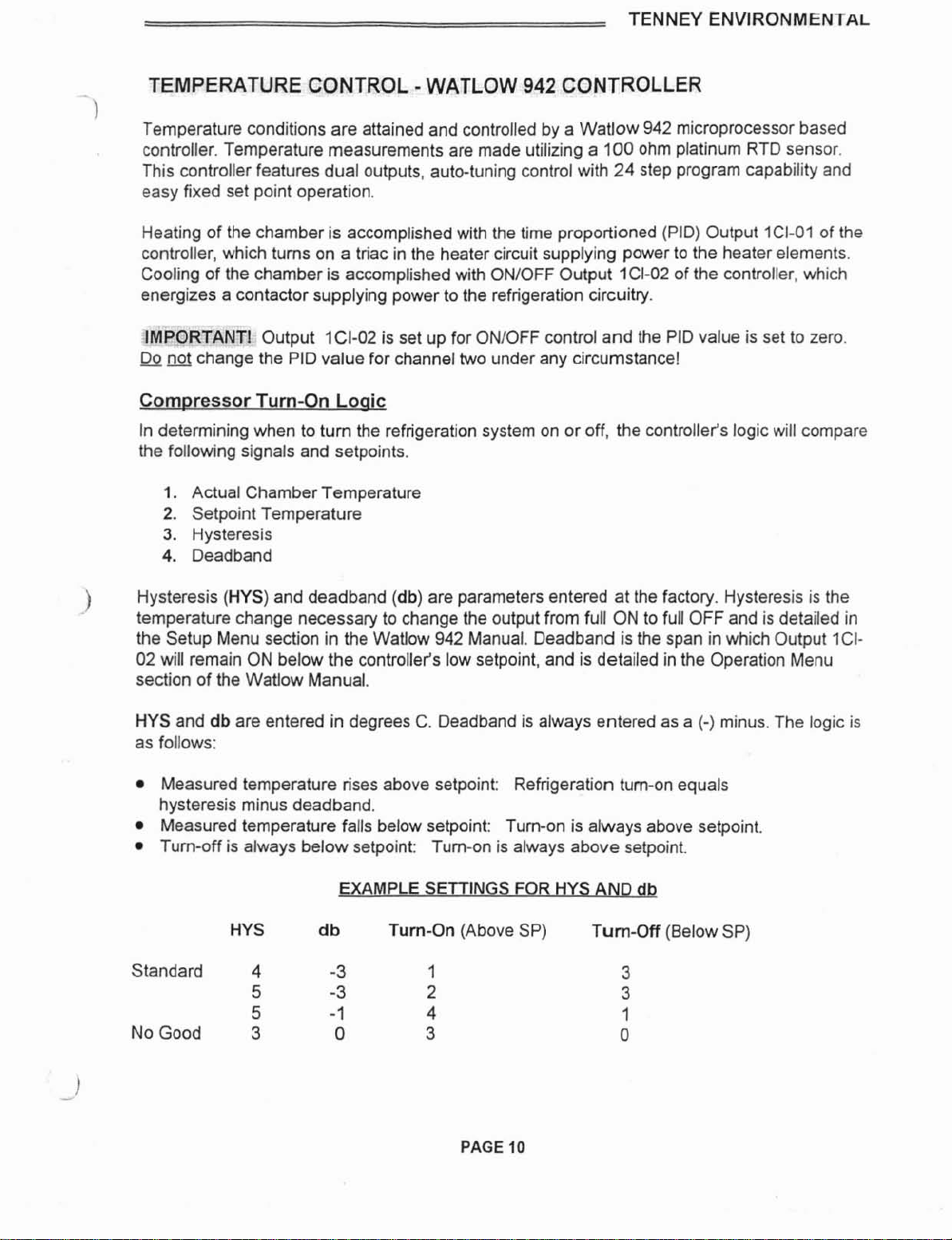

Temperature conditions are attainedandcontrolled by a Watlow 942 microprocessor based

controller. Temperaturemeasurementsare made utilizing a 100ohm platinumRTD sensor.

This controllerfeatures dual outputs, auto-tuning controlwith 24step programcapability and

easy fixed set point operation.

Heatingof the chamberis accomplishedwith the time proportioned(PID) Output ICI-01of the

controller, which turns on a triac in the heater circuit supplying powerto the heater elements.

Coolingof the chamberisaccomplishedwith ONIOFFOutput ICI-02of the controller, which

energizesa contactor supplying powerto the refrigerationcircuitry.

IMPORTANT! Output ICI-02is set upfor ONIOFF control and the PIDvalue is set to zero

Do not changethe PIDvalue for channeltwo under any circumstance!

--

Corn~ressorTurn-On

Loaic

Indeterminingwhen to turn the refrigerationsystem on or off, the controller's logic will compare

the following signals and setpoints.

1.

Actual ChamberTemperature

2.

SetpointTemperature

3.

Hysteresis

4. Deadband

)

Hysteresis(HYS)and deadband (db) areparametersentered at the factory. Hysteresisis the

temperaturechange necessaryto change the outputfrom full

ON

to full OFFand

is

detailed in

the Setup Menu section inthe Watlow 942 Manual. Deadbandisthe span inwhichOutput ICI-

02 will remain ON below the controller's low setpoint, and isdetailed inthe Operation Menu

section of the Watlow Manual.

HYS and db are entered in degrees

C.

Deadbandis always enteredas a

(-)

minus.The logic

is

as follows:

Measuredtemperature rises above setpoint: Refrigerationturn-on equals

hysteresisminus deadband.

Measuredtemperature falls belowsetpoint: Turn-on is always above setpoint.

Turn-off is always below setpoint: Turn-on is always above setpoint.

EXAMPLE SETTINGS

FOR

HYSAND db

HYS

d

b Turn-On (Above SP) Turn-Off (BelowSP)

Standard 4

-3

1

5

-3

2

5

-1

4

No Good

3

0

3

PAGE

10

TENNEY

ENVIRONMENTAL

Chambers are shippedwith

HYS

=

4, and

db

=

-

3, asshown onthe top line inthe above

)

examples. It is unlikelya change to these settings will be required. Fortunately,these settings

are not subject to "coldstardefault, andwill remainvalid afler a powerinterruption. They are

held in EEROM, not battery-backedRAM.

The pre-programmedconfigurationof theWatlow 942

is

documentedin the Test Report.

Pleasereferto this andthe Watlow 942 usetsmanualfor complete operationaldetails. These

are found inthe Supplemental InstructionsSection.

ControllerVersions

The Watlow 942 Controller is providedinfour versionswith the following nomenclature:

1.

The basic24-step ramping control: 942A-3KDOAE00

2.

Basic plustwo events: 942A-3KD2-AE00

3.

Basicpluscommunications: 942A-3KDO-BE00

4.

Basic plus events and communications: 942A-3KD2-BE00

The nomenclatureisprintedon the backof the controller and can be seen when the chamber's

control panel isopened.

NOTE: The communications arrangementis isolated RS232lRS423,RS422, EIA-485,or IEEE.

Eachevent output is through a mechanicalrelay havingcontactsrated

6

Amps, 120or 240

VAC.

PAGE

I1

TENNEY ENVIRONMENTAL

ALARM

AND

SHUTDOWN

CIRCUIT

I

A comprehensivealarmandshutdown circuit may be providedfor multiple protection against

productoverlundertemperature and chamber overtemperature.The sensor utilizedfor

temperaturemeasurementand the Heat Limiter Fuseare normally placedat the plenum inthe

downstream airflow. This isthe most responsive area of the chamber.

Chamber Over Temoerature Protection; The following device is used.

1.

Heat Limiter

(HL)

--

TemperatureActuatedFuse (Standard)

ProductOverIUnderTernaerature Protection: The following optionaldevice may be used.

With this option, a

100

ohm platinum RTD is utilizedfor temperature measurement.

1.

Watlow

93

Controller

-

-

TempGard IV Feature

-

HighlLow Limits (Optional)

WARNING1 When Master Contactor ICONisdeenergized due toANY alarm condition

described below, power isonly removedfrom the conditioning controlcircuitry. The

instrumentationand alarm circuitry will still beenergized!

Forany questions concerningthe operationof any of the controllers describedbelow, please

referencethe appropriateuser manual locatedinthe SupplementalInstructionsSection.

CIRCUITOPERATIONS:

)

NormalConditions:

When chamber temperature

is

withinthe selectedsetpoints

the

switch (green)

ON

light is

illuminatedandthe MasterContactor ICONis energized. The contacts of ICONprovide

powerto the conditioningcontrolcircuitry. (Withthe optional alarmbuzzer

I

silence switch or

TempGard IVfeature, the NORMALlight

2LT

will illuminate. When either of these optional

features are used, the maincontrol switchwill not

be

equipped with any integrallights.)

Note:

A

spare set of ICONcontacts are providedfor the customer's closure. Itis

recommendedthat these contacts,wired to terminal blocks#I4

&

#15, be usedto energizean

active heat load if utilized.

Oaened Heat Limiter:

When a predeterminedhigh temperature limit is reachedand the Heat LimiterFuse (which

looks like a regularfuse) opens, Master Contactor ICONwill deenergizealongwith the

conditioningcontrolcircuitry.The switchOVERTEMP lightwill illuminateand the switch

ON

lightwill extinguish. (With the optionalalarm buzzer1silence switch feature, boththe red

ChamberOVERTEMPlight 3LTand redALARM light4LT will immediately illuminate, the alarm

buzzerwill sound, andthe NORMAL lightwill extinguish.) Whenthe Heat LimiterFuse opens,

it

bereplaced.

-

--

WARNING1 When replacingthe Heat Limiter Fuse, make sure all power is completely

disconnectedfrom the chamber. Open the closest main power disconnect and pullthe plug (if

provided)from the outlet.

PAGE

12

TemoGard IV Alarm

-

-

Ootional:

1

When a presettemperaturelimit is reachedwithin the Watlow 93 TempGard IV, the TGlV

alarm contacts open to deenergize MasterContactor ICON,which removespowerfrom the

conditioningcontrolcircuitry. The NORMAL light is now extinguished, the red

ALARM

light 4LT

illuminates,and the alarm buzzersounds.The redChamberOVERTEMP light 3LTwill

illuminatewhen the alarmcondition clears

and

the TempGard IValarm is clearedas detailedin

the Watlow 93 manual.

Note: The alarm buuerwithsilenceswitch isan optionalfeature for allchambers. This alarm

circuitry comes standardwith the Watlow

93

TempGard IV feature. The TempGardIV

configuration is shown in the "Watlow 93 TempGard IV ConfigurationAnd Use" section.

Svstem Reset ForAlarm Buuer

I

Silence Switch

or

Tem~GardIVO~tion

-

-

lm~ortant!

After an out of limit conditionhas been corrected, the conditioningcontrol circuits must be

restartedby momentarily pressingthe RESET button

IPB.

You must rememberto clear the

Watlow 93 alarm message.

A 1.5second timer ITC,

is

indudedin the resetcircuitto provide for automatic startwhen

poweris appliedto the chamber. This avoids the need to press the reset buttoneach time that

poweris removedand reapplied.

Alarm Buzzer

8,

Silence Switch

-

-

Ootional:

With this option the silenceswitch disables the alarm buuerwhile correctiveaction is taken.

When 1SSis activated, thewhite Silence light 5LTwill be illuminated. If the alarm buuerwas

)

disabled and the system was successfullyresetwith IPB, the alarm buzzer will nowsound to

alert the operatorto place the silence switch 1SSin it's normal(down) position.

Heatingof the chamber is accomplishedwith the time proportionedoutput ICI-01of the

Watlow

942

Controller,which tums on triac ITRCto supplypowerto the heaterelements.

These elements are open air low mass nichrome wires, which havelowthermal lagand

provide rapid responseto the controller's demands. The heater elements are isolatedfrom the

workspaceto prevent direct radiationto the product. Pleasereferencethe electricalschematic

for your particularchamber's heaterbank ratings.

PAGE

13

SINGLE STAGE REFRIGERATION SYSTEM DESCRIPTION

)

The basic single stagesystem consists of a compressor, anoilseparator (exceptfor Models

BTS.

T6S. T27, & T65). eitheran air cooled or water cooled condenser, an evaporator coil

(located

in

the chambd; conditioningsection) which is provided with a capillary (iube) type

expansiondevice, and a suction lineaccumulatorto guard against liquid refrigerantreturnto

the compressor.

Refrigerantflow is from the compressor as a hot compressed gas through the oil separatorto

the condenser. Herethe refrigerantcools and condensesto liquidform and flows through the

capillary tube to the evaporatorcooling coil inthe chamberconditioningsection. Warm

chamber air iscirculated through the cooling coil and heat exchange occurs as the liquid

refrigerantboils, vaporizes, and absorbs heat. The vaporized refrigerantreturnsto the

compressorthrough the suction lineaccumulator SLA. The cycle is repeated.

Forall units except ModelBTS, a thermostatis mountedon the suction retum line near the

compressorto monitorthe temperatureof the returngas flow. When a predeterminedhigh

temperature is reached, the thermostatwill energizean artificial loadingsolenoid, which will

injectrefrigerant through a capillary tube intothe suction side of the system. This actionwill

maintain a positivecool refrigerantflow to the compressor, preventingoverheatingof the

compressorand the discharge gas.

The basiccascadesystem consists of a low stage compressor. a high stage compressor, an

,

evaporator coil, anda cascade condenser.

The lowstage system includes an oil separator(for models with compressor motorsgreater

than

1

H.P.), a cascadecondenser, an expansiontank, and an evaporator coil (locatedinthe

chamber conditioningsection) which is providedwith a capillary (tube)type expansiondevice.

The high stage system includesan air cooled or water cooled condenser, a capillarytube

which feeds the cascade condenser, and a suction line accumulatorto guard against liquid

refrigerantreturnto the compressor.

Thefunctionof the cascadecondenserisfor the high stage refrigerantto cool and condense

the lowstage refrigerant. This permits greater system efficiency and allows lowerchamber

temperatures to be reachedthanwhat can beattainedwith a single stage system. The low

stage liquidrefrigerantfrom the cascadecondenser is metered through a capillary tube to the

evaporatorcoil. Heatexchange takes place here as the liquid refrigerantconverts to a gas and

then returnsto the low stage compressor.

A

thermostat is mountedon the suction return line near the low stage compressorto monitor

the temperature of the return gas flow. When a predeterminedhigh temperatureis reached,

the thermostatwill energizethe Artificial Loadingsolenoid 14SOL,which will injectrefrigerant

intothe suction side of the system. Itwill first enterthe expansiontank where the added

volume permitsthe chargingof additionalrefrigerantwithout increasingthe standby or

charging pressure beyondworkable limits. Refrigerantgas isthen suckedout of the expansion

tank and meteredthrough

a

capillarytube to the suction side of the low stage compressor.

)

This actionwill maintain a positivecool refrigerantflow to the compressor, preventing

..

overheatingof the compressor and the dischargegas.

A

high pressurecut-in sensor monitorsthe pressureinsidethe low stage compressor

andwill activatethe Load LimitSwitch4PS when the low stage dischargepressurereaches

280 PSIG.This will energizethe Artificial Loadingsolenoid 14SOLwhichwill inject refrigerant

into the suction side of the system as described above. Switch 4PS preventsthe compressor

from cyclingon and off inresponse to signals from the high pressurecut-out switch. 4PS will

open when pressurefalls to 240 PSIG.

For moredetailed informationon a cascade system, please referencethe sectionentitled

"ServicingCascade RefrigerationSystems".

The refrigerationsystem is providedwith several safety devices that stop the compressor(s)

from runningif conditionsexceedpreset limits. Ina cascadesystem boththe low stage and the

high stage includethese safety devices. With a low limit conditionthe HI-LO Pressure Cutout

Switch 1PS (and 2PS for cascade)will continue to automaticallyreset until sufficient pressure

develops. With a highlimit condition you must manuallv reset

1

PS (or2PS). If the compressor

continuesto trip off havethe system checked by a qualifiedrefrigerationsystem mechanic.

The possiblecauses of a high or low limit cutout are as follows:

NOTE:

The HI-LO Pressure

Cutout Switch does notapply to the Models BTS, BTC, T6S, andT6C.

HighPressure Cutout (IPS, ZPS)

-

-

Opens if a preset compressordischargepressure

is exceeded. Probablecausefor highstage cut-out is insufficientcoolingwater (water

cooled systems) or restrictedair flow (air cooledsystems). Probablecause for low stage

cutout is a malfunctionof the high stage system. 1PSRPSare typically set at 300 PSIG.

Low Pressure Cutout (IPS, 2PS)

-

-

Opens if the compressorsuction pressurefalls

below a preset value. Probablecausesare a loss of refrigerant(either stage) or restricted

air flow acrossthe evaporator(low stage). 1PSRPSare typically set at 6 inches of vacuum.

Motor Overload

- -

Opensifthe motorwindings exceed a preset temperature. Probable

causes are insufficientflow across the motor due to a refrigerant loss or a failure of the

liquidinjectionvalve providedfor suctiongas cooling. The motor overload is installed

directly inthe motorwindings and will automaticallyreset and restartthe compressorafter

the motorhas cooled.

PAGE

15

WATLOW

93

-

TEMPGARD IV CONFIGURATION

&

USE

(Optional)

As an option, your chamber may include the TempGard IV feature with the Watlow

93

Controller. The circuit operationdescription is explained

in

the Alarm And Shutdown Circuit

section of this manual. This configuration sectionserves as a brief referenceguide. For

complete details of the Watlow

93

Controller, please reference the user manual.

When properly configured,the lower display of the controlwill beblank and the upper display

will show the actualtemperature as measuredby the control's RTDsensor, when conditions

are within the alarm settings. If an out of limit conditionoccurs, the lowerdisplay will flash "HI"

or

"LO

depending on the particularfault.

IMPORTANT:

For

All Models

-

When the alarm hascleared you mustpressthe

RESET pushbutton

1

PB.

To configurethe control to performas describedabove, power it up and select the setup menu

by pressingthe UPlDown arrow keys simultaneously. Pressingthe

"M"

key then allows you to

scrollthrough the set up parameters.

Setthese parametersin accordancewith the table below. The parameterwill appear inthe

lower display; the UPIDOWN keysare usedto set the value.

11

rL

1

Set low range limit

1

-100

11

)

11

r

H

I

Set high range limit

1

+ZOO

*

11

WATLOW

93

-

TEMPGARD

IV:

SETUP MENU

II

rtd

I

Select sensor curve

I

JIS

II

PARAMETER

In

c-F

2

HSA

LAt

Scrollthroughthose parametersnot listed above; their settinas are immaterial.After scrolling

throughall parameters, the controlwill revert to the "OPERATE"mode. Inthis mode, usethe

"M

key to scroll to the ALO (alarmlow) parameter and use the UPIDOWNarrow keys to set

the desiredlow alarm value. Then, use the

"M"

key to scroll to theAH1 (alarmhigh) parameter

anduse the UPIDOWN keys to set the desired high limitvalue.

FUNCTION

Select

type

of sensor

Select temperature units

DefineOutput

2

Select hysteresis

Select latch

I

nonlatch

dSP

Aftersettingthese values, continue scrollingwith the

"M"

key untilthe controlsetpointappears

J

inthe lower display. After a few seconds, this display will go blank.

E

rtd

C

--

--

PrA

I

nLA

Other values maybeentered depending onthe range

of

the chamber.

Select display

~-

Pro

BOOST HEAT (Optional)

)

As anoption,your chamber may be equippedwith the boost heatfeature which includes extra

heaters to provide rapid increasesintemperature. The boost heatwill automaticallyturn on if a

preset time delay relay times out, indicatingthat the desired temperature has not been

achieved.

As output ICI-01of the controller energizes the mainheater bank, ICI-01will at the same time

energize a time delay relay. When this relaytimes out itwill energizea mercury relay,which

provides powerto the boost heaters.

A

mechanical contactorisalso providedwhich has it's

contactswired into the power supply line to the boost heaters. This contactoris providedto

deenergizethe heaters in the event of an over temperature condition.

BOOST COOLING (Optional)

USING LIQUID NITROGEN

or

CARBON DIOXIDE

As an option, your chamber may be equippedwith a boost coolingsystem which is activated

by anevent output from the Watlow 942 Controller. Cooling is achieved by injectingeither LN,

or CO,, dependingon the option purchased, intothe chamber through a solenoid valve. To

activatethe system the event must be turned on as explained inthe Watlow

942

Controller

manual.

Event No.

1

is generally used for this function. However, a referencetable defining the function

of each event is affixed to the control panelof each chamber. Pleasecheck this table before

)

operatingthe chamber.

Onceenabledthrough the event, the coolingwill turn on if

a

demandfor cooling existsfor a

preset time period.

A

timer connectedto the time proportioned outputof the controller "times

out" and energizesthe cooling solenoid valve if the output is 100percent "ON" indicatinga

needfor additionalcooling.

When the desired temperature is attained andthe controller heat output begins to turn on, the

boostcoolingfunction will cease.

LN, systemsare provided with a manually set flow adjustingvalve providedto allow for

adjustingthe flow to avoid incomplete evaporation at varying LN, supply pressures.

A

setting

of 4 turns open generally provides good performanceat a supply pressureof 20 to 25 PSIG.

This valve may be readjustedas necessaryto accommodatethe supply pressureat the end

usepoint.

PAGE

17

PURGEAIR SYSTEM (Optional)

USING COMPRESSEDAIR or NITROGEN

As an option, your chambermay beequippedwith a dry air or

GN,

purge system which is

activatedby an event output from the Watlow

942

Controller. To usethe system, the event

must be turned on as explained inthe Watlow

942

manual. EventNo.

2

is generally used for

this function. However,a referencetable definingthe function of each event is affixed to the

controlpanelof each chamber. Pleasecheck this table before operatingthe chamber.

A meteringvalve and flowmeter is suppliedas part of the system to establishthe design purge

flow. Thevalve should be adjusteduntilthe indicatedflow is about

300

cubic feet per hour.

The

GN,

purge system isprimarilyutilizedto providean inert atmospherewhich minimizesthe

buildupof moistureand prevents condensationon the product undertest. Eliminatingthe

oxygen inthe chamberair helps preventcorrosionof the productundertest.

A drierisprovidedfor compressed air purgesystems. This systemrequires a supply of

relatively oil free compressed air at a minimumpressureof

80

PSIG. This air isdriedby a bin

tower heatless, self regeneratingdryer and is introducedinto the chamber through a solenoid

valve.

CHART

RECORDER

(optional)

As an option, your chamber may beprovidedwith either a circularor strip type chart recorder

)

to recordtemperature versus time. This recorderistypically a one pentype which also digitally

displays the processvalue. A

100

ohm platinumRTD is used for temperature measurement

and is nomlally placedinthe plenum of the chamber.

The recorderconfigurationis documented inthe Test Report, which is locatedin the

Supplementallnst~ctionsSection. For completedetails on the operationof the recorder

pleasereferencethe recorder's user's manualwhich is located in the same section.

DATA COMMUNICATIONS (Optional)

)

As an option, your chamber may include data communicationswith the maincontroller's serial

port. when employed, either a bata Communications manualor a Computer Interfacemanual

will be included in the Supplemental InstructionsSection. As a reference, the availabledata

types are listedand brieflydescribed below. Pleasecontact a Tenney Sales Engineerfor more

information.

RS232C

I

RS423A: Both interfacesare compatibleand use 3 wires: a single transmit wire; a

single receive wire; and a commonline. The maximumwire length is 50 feet. Only a single

chamber may be connectedto your computer. Data signals are measuredas plus and minus

12 volts to commonwith RS232C, and plus and minus 5 vylts to common with RS423A.

RS422A: This interfaceuses 5 wires: a transmit pair; a receive pair; and a commonline. Up

to tenchambersmay be connectedto your computeron a multi-dropnetworkup to 4,000 feet

long. Datasignals ineach pair are measured as a plus or minus 5 volt differential.

EIA-485: This interface uses only 2 wires. Bothwires are usedfor transmittingand receiving

data, andtherefore, only one device may talk at a time. Up to 10chambers may be connected

to your computer on a multi-dropnetworkupto 4,000 feet long. Data signals are measuredas

a

plus or minus 5 volt differential.An EIA-485 card must beinstalledfor signal conversion.

IEEE-488: This is a parallel multi-dropinterfacewith several control and data lines. Each

device connectedmust be set to a uniqueaddress. Data from othertest devices may also be

collected. Sincethe controllerswe use only have serialcommunications, an IEEE-488to serial

)

converter cardis installed in the chamber. Maximum cable lengthis approximately

33

feet for

all devices.

PAGE

19

LinkTenn SOFTWARE (Optional)

)

Welcome to anotheruniqueoptionalfeature developed by Tenney Environmental.

LinkTennsoftware is designedto operate on a remote computer system and provide complete

control of Tenney Environmentaltest chambers. This is accomplishedby communicating

through a RS232lRS422interfacewith the VersaTenn

Ill

or Watlow 942, 945, and 988

Controllers.Upto ten chambers may be controlledfrom one computerwith RS422 interface.

LinkTennsoftware isprovidedboth in a DOSformat and in a Windows format on

3%

inch

diskettes. Inthe DOSformat, "LinkTennII" software is designed to work with the VersaTenn Ill

Controller, and "LinkTenn 942" software is designedto work with the Watlow 942 Controller. In

the Windows format, "LinkTennForWindows"software is designed to work with the

VersaTenn

Ill

andthe Watlow 942. 945, and 988 Controllers.

The hardwareand software requirementsto run LinkTennsoftware in bothformats are listed

below.

DOS

Format: LinkTenn

II

&

LinkTenn942

1.

Any DOS basedcomputer

2. 256K of RAMmemory

3. CGA graphics card

4. DOS2.0 or higher

5.

RS232computer interfacefor singlechamber control

6.

RS422computer interfacefor multiplechamber control

7.

With IEEE-488communications, a National InstrumentsPC2A or compatiblecard

)

Windows

Format:

LinkTenn ForWindows

1.

Computerwith 486 processor or higher

2. Eight Megof harddrive memory

3. Eight Megof RAM memory

4. Windows 3.X operating system or higher

5. RS232computer interfacefor single chamber control

6. RS422computer interface for multiplechamber control

7.

Currently notavailableto work with IEEE-488communications

A sample menu display screen entitled"ProgramControl"from the LinkTennFor Windows

program, is provided in the SupplementalInstructionsSection. This screen shows some of the

uniquefeatures incorporatedintothe programalongwith sample setpoints.

When LinkTennsoftware is providedineitherformat, a correspondingLinkTennUser'sManual

will be providedinthe SupplementalInstructionsSection.

I

CNNCY ENVlKUNNlClV

IHL

CHAMBER

OPERATION

)

To operatethe chamber, turn onthe powersource to the chamber and close all chamber

circuit breakers.The display of the Watlow 942 should now be illuminated. Enterthe desired

temperature programor manualsetpoints as explained inthe Watlow 942 user's manual.

Closethe Power On switch ISS. The greenON light should beilluminated.

If your chamber includes the optionalWatlow 93 Controllerwith TempGard IV feature, set this

controller'shighllow temperature limits at this time. Referto the "AlarmAnd Shutdown Circuit"

descriptionandthe "TempGardIV ConfigurationAnd Use Instructions"for further details.

Forthose chamberswhich includeany other options, please referto the appropriate "optional"

manualsectionsfor a detailed operationdescription.

IMPORTANT

NOTE1

For complete programmingandlor operating instructionson any of the

controllers, electrical

I

mechanicalcomponents, or optional equipment, you must referto their

operatingmanuals includedwith your Tenney Environmentalmanual.

PAGE

21

This manual suits for next models

12

Table of contents

Other Tenney Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started