Tepack M4K-10 Operating instructions

ENGLISH INSTRUCTIONS FOR REPAIR

MECHANICAL TOOL SOR STEEL STRAPPING

M4K-10 (MK4-10)

INSTRUCTIONS FOR REPAIR

2011

Content

1. Introduction...........................................................................................3

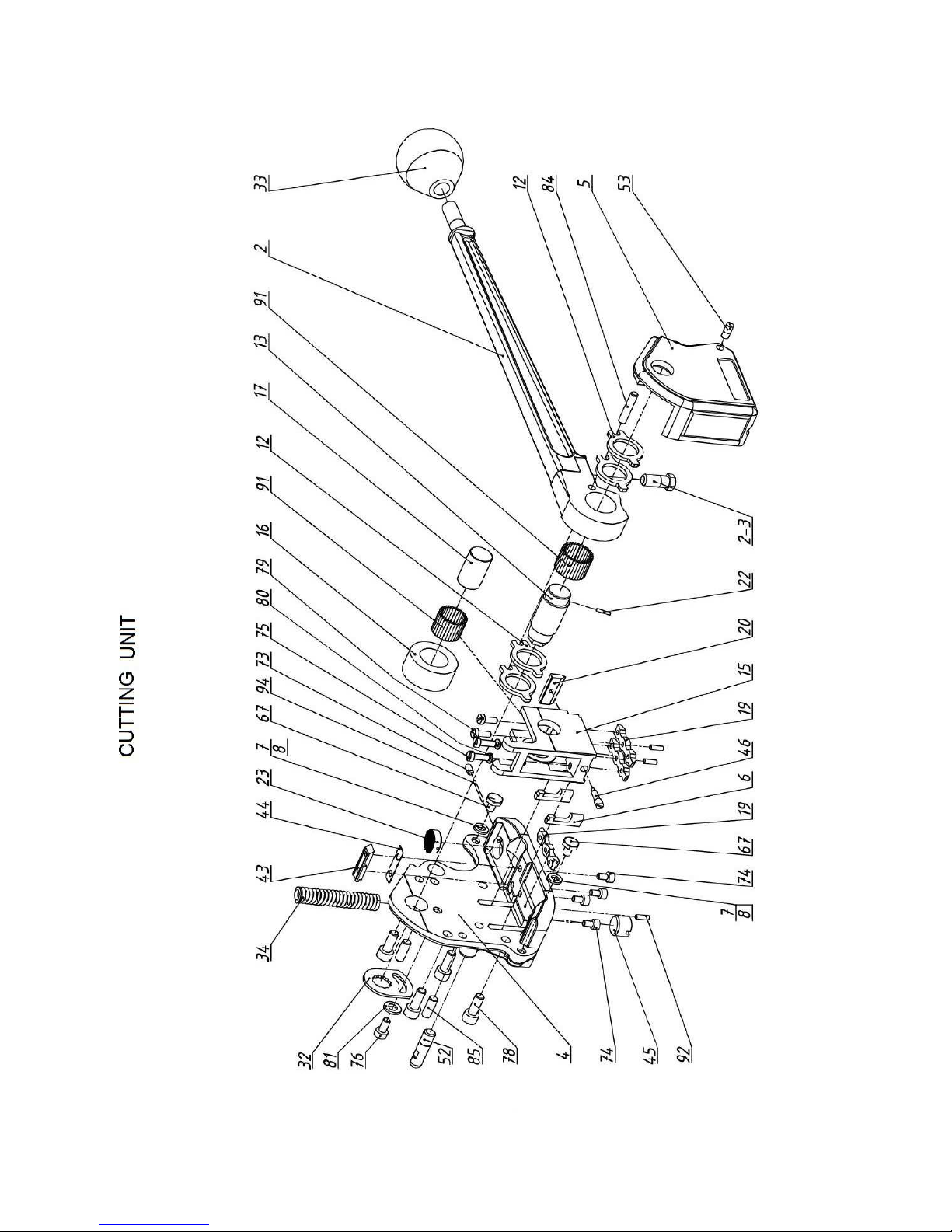

Scheme of tension unit..........................................................................4

Scheme of cutting unit..........................................................................5

Table......................................................................................................6

2. Disassembly of tool...............................................................................7

2.1. Removal of parts with direct access.................................................7

2.2. Separation of tension and cutting units............................................11

2.3. Disassembly of tension unit.............................................................13

2.4. Disassembly of cutting unit.............................................................17

3. Assembly of tool...................................................................................21

3.1. Assembly of cutting unit..................................................................21

3.2. Assembly of tension unit.................................................................22

3.3. Connecting of tension and cutting units...........................................22

3.4. Installation of details with direct access..........................................23

2

1. Introduction

1.1. This instruction defines the order of disassembly and assembly of the tool M4K-10

(MK4-10), during which some spare part can be changed.

1.2. Numbers of spare parts and their location are shown in schemes of tension and

cutting units, from which the tool consists.

1.3. Full list of spare parts of tool and paragraphs of instruction, where it is shown how

to change needed spare part, are shown in table.

If paragraph is not shown in table, it means that replacement of part can be made

using only schemes of tension and cutting units.

1.4. After disassembly and assembly of tool it is needed to perform regulating of it in

accordance with operating instructions.

3

4

5

Table

Name of spare part Pos. No. No. of points in instruction

Tension handle 1 2.3.4, 2.3.6, 2.3.7

Sealer handle 2 2.2, 2.4.1…2.4.3

Feedwheel support handle 3 2.2, 2.3.1…2.3.3, 2.3.9, 2.3.10

Frame 4 2.2, 2.4.1…2.4.2, 2.4.4, 2.4.5

Side cover 5 2.2, 2.4.1

Strap lifter 6 2.2, 2.4.1, 2.4.2, 2.4.4, 2.4.5

Washer 7 2.1.5

Washer 8 2.1.5

Washer 12 2.2, 2.4.1…2.4.3

Excentric shaft 13 2.2, 2.4.1…2.4.3

Die holder 15 2.2, 2.4.1, 2.4.2, 2.4.4, 2.4.6, 2.4.7

Cam follower 16 2.2, 2.4.1, 2.4.2, 2.4.4, 2.4.6

Die holder shaft 17 2.2, 2.4.1, 2.4.2, 2.4.4, 2.4.6

Die 19 2.2, 2.4.1, 2.4.2, 2.4.4, 2.4.7, 2.4.8

Cutter blade 20 2.1.9

Feedwheel support shaft 21 2.2.4

Roll pin 22 2.2, 2.4.1…2.4.3

Clutch plug 23 2.1.10

Feedwheel 24 2.2, 2.3.1…2.3.3

Feedwheel shaft 25 2.2, 2.3.1…2.3.4, 2.3.6, 2.3.8

Tension pawl 26 2.3.5

Spring 27 2.3.5, 2.3.7

Tension pawl 28 2.3.7

Ratchet wheel 29 2.3.4, 2.3.6

Support plate 31 2.3.4, 2.3.5, 2.3.6

Adjustment plate 32 2.1.1

Knob 33 2.1.2

Spring 34 2.2.3

Tension pawl 35 2.3.5

Screw 36 2.3.7

Screw 37 2.3.5

Washer 38 2.3.1, 2.3.4

Screw М6х30 39 2.1.7

Pin 40 2.3.1, 2.3.4

Washer 42 2.3.1

Bush 43 2.1.8

Plate 44 2.1.8

Stopper 45 2.2.2

Screw 46 2.1.9

Guide arm 47 2.2, 2.3.10, 2.3.11

Screw 49 2.2, 2.3.10, 2.3.11

Strap guide 51 2.1.3

Strap guide 52 2.1.4

Screw 53 2.2.1

Screw 55 2.3.10

Screw 65 2.3.11

6

Continuation of the table

Screw 67 2.1.5

Screw М4х10 72 2.2.4

Screw М4х6 73 -

Screw М4х8 74 -

Screw М4х12 75 -

Screw М5х10 76 -

Screw М6х16 78 -

Screw М4х10 79 -

Washer 6 82 -

Roll pin 5х25 84 2.2, 2.4.1…2.4.3

Roll pin 6х16 85 2.2, 2.4.1

Small bearing 87 2.2, 2.3.1…2.3.3, 2.3.9

Large bearing 88 2.2, 2.3.1…2.3.4, 2.3.6, 2.3.8

Support roller 2х15,8 91 2.2, 2.4.1…2.4.6

Roll pin 3х9,8 92 -

Retaining wire diam. 1.4 94 2.1.10

2. Disassembly of the tool

Disassembly of the tool provides removal of parts, to which you have direct access (see

point 2.1), separation of tension and cutting units(p. 2.2) and further disassembly of each

unit (p. 2.3, 2.4).

2.1. Removal of parts with direct access.

2.1.1. With the help of hex key S = 4mm unscrew the screw 76, remove washer 82 and

adjustment plate 32 (pic. 2.1.1, 2.1.2).

Pic. 2.1.1 Pic. 2.1.2

7

2.1.2. Unscrew knobs 33 (pic. 2.1.3).

Pic. 2.1.3

2.1.3. With the help of hex key S = 4mm unscrew the screw 76 and remove strap guide

51 (pic. 2.1.4, 2.1.5).

Pic. 2.1.4 Pic. 2.1.5

2.1.4. Unscrew with the help of wrench S = 6mm strap guide 52 (pic. 2.1.6, 2.1.7).

Pic. 2.1.6 Pic. 2.1.7

8

2.1.5. Unscrew with the help of socket wrench S = 10mm front and rear strap guides 67

(pic. 2.1.8, 2.1.9) with washers 7, 8.

Pic. 2.1.8 Pic. 2.1.9

2.1.6. Unscrew with the help of hex key S = 2mm screw 73 (pic. 2.1.10).

Pic. 2.1.10

2.1.7. With the help of hex key S = 3mm unscrew the screw 39 (pic. 2.1.11, 2.1.12).

Pic. 2.1.11 Pic. 2.1.12

9

2.1.8. With the help of hex key S = 3mm unscrew screws 74, remove bush 43 and plates

44 (if available) (pic. 2.1.13, 2.1.14).

Pic. 2.1.13 Pic. 2.1.14

2.1.9. Turn sealer handle from yourself against the stop and with the help of hex key S =

2,5mm unscrew the screw 46 (pic. 2.1.15, 2.1.16). Return sealer handle to its original

position and with the help of tweezers remove cutter blade 20 (pic. 2.1.17).

Pic. 2.1.15 Pic. 2.1.16

Pic. 2.1.17

10

2.1.10. With the help of hex key S = 2mm unscrew the screw 73 from frame 4, remove

using tweezers retail wire 94 and remove clutch plug 23 (pic. 2.1.18 - 2.1.20).

Pic. 2.1.18 Pic. 2.1.19

Pic. 2.1.20

2.2. Separation of tension and cutting units.

2.2.1. Unscrew the screw 53 (pic. 2.2.1, 2.2.2).

pic. 2.2.1 pic. 2.2.2

11

2.2.2. Unscrew stopper 45 from the foot of frame 4 (pic. 2.2.3).

Pic. 2.2.3

2.2.3. Remove spring 34 (pic. 2.2.4).

Pic. 2.2.4

2.2.4. Unscrew with the help of hex key S = 2mm screw 72 and with the help of tapping

(ø10mm, length 120mm) knock out feedwheel support shaft 21 (pic. 2.2.5 - 2.2.7).

Pic. 2.2.5 Pic. 2.2.6

12

Pic. 2.2.7

2.2.5. Disconnect tension unit from cutter unit (pic. 2.2.8).

Pic. 2.2.8

2.3. Disassembly of tension unit.

2.3.1. Knock out using tapping (ø2,5mm, length 100mm) pin 40, remove washer 38 and

washer 42 (pic. 2.3.1, 2.3.2).

Pic. 2.3.1 Pic. 2.3.2

13

2.3.2. With the help of tapping (ø10mm) knock out feedwheel shaft 25 (pic. 2.3.3).

Pic. 2.3.3

2.3.3. Remove feed wheel 24 and remove handle 3 (pic. 2.3.4).

Pic. 2.3.4.

2.3.4. Knock out pin 40 and remove washer 38 (pic. 2.3.5).

Pic. 2.3.5.

14

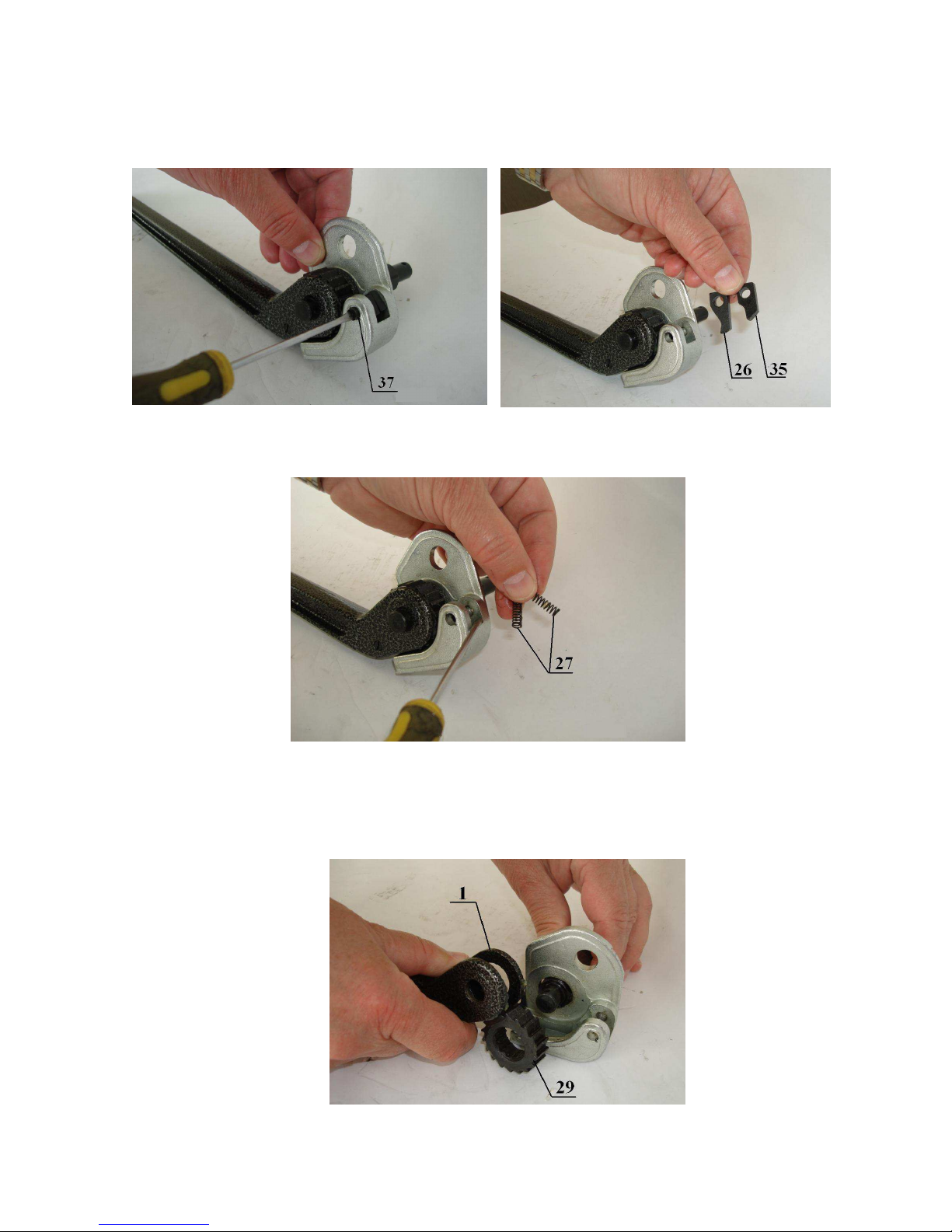

2.3.5. Unscrew tension pawl shaft 37 and remove tension pawls 26, 35 with 2 springs 27

from support plate 31 (pic. 2.3.6-2.3.8).

Pic. 2.3.6. Pic. 2.3.7.

Pic. 2.3.8.

2.3.6. Disconnect tension handle 1 with ratchet wheel 29 from support plate 31 remove

support plate from feedwheel shaft 25 (pic. 2.3.9).

Pic. 2.3.9.

15

2.3.7. Unscrew the screw 36 from handle 1 and remove tension pawl 28 and spring 27

(pic. 2.3.10, 2.3.11).

Pic. 2.3.10. Pic. 2.3.11.

2.3.8. Remove bearing 88 from feedwheel shaft 25 (pic. 2.3.12).

Pic. 2.3.12.

2.3.9. With the help of tapping (ø16mm) knock out bearing 87 from handle 3 (pic.

2.3.13, 2.3.14).

Pic. 2.3.13. Pic. 2.3.14.

16

2.3.10. Unscrew the screw 55 and remove guide arm 47 from handle 3 (pic. 2.3.15,

2.3.16).

Pic. 2.3.15. Pic. 2.3.16.

2.3.11. Unscrew the screw 65 and unscrew the screw 49 from guide arm 47 (Pic. 2.3.17,

2.3.18).

Pic. 2.3.17. Pic. 2.3.18.

2.4. Disassembly of cutting unit.

2.4.1. With the help of hex key S = 5mm unscrew four screws 78, disconnect side cover

5 from frame 4, using tapping (ø5mm) (pic. 2.4.1…2.4.3).

Pic. 2.4.1. Pic. 2.4.2.

17

Pic. 2.4.3.

2.4.2. Remove sealer handle 2 in collecting with excentric shaft 13, washers 12 and set

of support rollers 91 (31pcs.) carefully, not to sprinkle rollers (pic. 2.4.4).

Pic. 2.4.4.

2.4.3. Disconnect four washers 12 from handle 2, remove excentric shaft 13 with roll pin

22, roll pin 84 and rollers 91 in quantity 31pcs. (pic. 2.4.5).

Pic. 2.4.5.

18

2.4.4. Disconnect die holder 15 from frame 4 (pic. 2.4.6).

Pic. 2.4.6.

2.4.5. Remove strap lifters 6 from holes in frame 4 (pic. 2.4.7).

Pic. 2.4.7.

2.4.6. Remove die holder shaft 17, then remove from die holder 15 cam follower 16 and

rollers 91 in quantity 28pcs. (pic.2.4.8 - 2.4.10).

Pic. 2.4.8. Pic. 2.4.9.

19

Pic. 2.4.10.

2.4.7. Using hex key S = 2,5mm remove screws 75 and 79 of fixing of dies 19 to die

holder 15 and remove dies from roll pin 92 (pic. 2.4.11).

Pic. 2.4.11.

2.4.8. With the help of hex key S = 3mm unscrew screws 74 of fixing of blade to frame

4. Remove blade from roll pin 92 (pic. 2.4.12, 2.4.13, 2.4.14).

Pic. 2.4.12.

20

This manual suits for next models

1

Table of contents

Other Tepack Packaging Equipment manuals