TER TANGO Quick setup guide

259

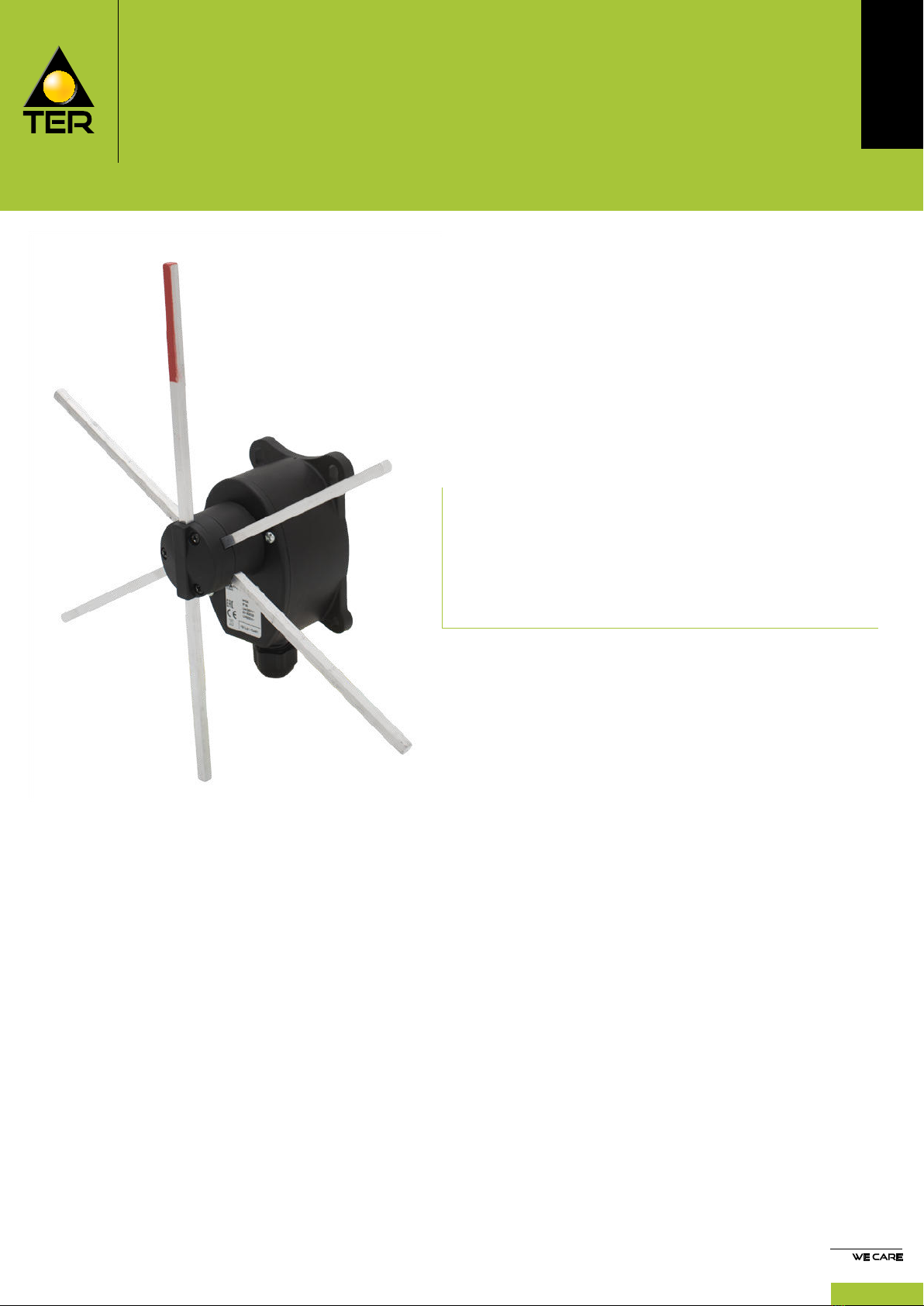

TANGO

Position limit switch

FEATURES

Modern design and overall dimensions studied to facilitate

installation and maintenance operations.

Rods with 4 maintained positions every 60°.

Positive opening NC contacts for safety functions.

Mechanical life of switches: 1 million operations.

Operation frequency: 3600 operations / hour max.

Extreme temperature resistance: -25°C to +70°C.

Enclosure and head in thermoplastic material (nylon

technopolymers to guarantee long life-cycle and constant

performance.

All materials and components used are wear resistant and

guarantee protection of the unit against water and dust.

OPTIONS

Slow action switches with 1NC or 1NO contacts.

Available with 2, 3 or 4 switches and different rod lengths.

CERTIFICATIONS

TANGO

5

Cross position limit switches designed for controlling

the movement of overhead travelling cranes, hoists and

complex machine tools.

Tango has rods with maintained positions every 60°.

circumstances can their description have a contractual value.

TANGO

5

260

CERTIFICATIONS

Conformity to Community Directives 2014/35/UE Low Voltage Directive

2006/42/CE Machinery Directive

Conformity to CE Standards

EN 60204-1 Safety of machinery - Electrical equipment of machines

EN 60947-1 Low-voltage switchgear and controlgear

EN 60947-5-1 Low-voltage switchgear and controlgear - Control circuit devices and switching

elements - Electromechanical control circuit devices

EN 60529 Degrees of protection provided by enclosures

Markings and homologations C

GENERAL TECHNICAL SPECIFICATIONS

Ambient temperature Storage -40°C/+70°C

Operational -25°C/+70°C

IP protection degree IP 65

Insulation category Class II

Operation frequency 3600 operations/hour max

Cable entry Cable clamp M20

TECHNICAL SPECIFICATIONS OF THE MICROSWITCHES

Code PRSL1000PI PRSL1001PI

Utilisation category AC 15

Rated operational current 3 A

Rated operational voltage 250 Vac

Rated thermal current 10 A

Rated insulation voltage 500 Vac

Mechanical life 1x106operations

Connections Screw-type terminal

Wires 1x2.5 mm2, 2x1.5 mm2

(UL - (c)UL: use 60°C or 75°C copper (CU) conductor and wire 16-18 AWG)

Tightening torque 0.6 Nm

Microswitch type Double break, slow action Double break, slow action

Contacts 1NO

1NC

(All NC contacts are of the positive opening

operation type )

Scheme

13

14

11

12

Markings and homologations CX

TANGO

5

261

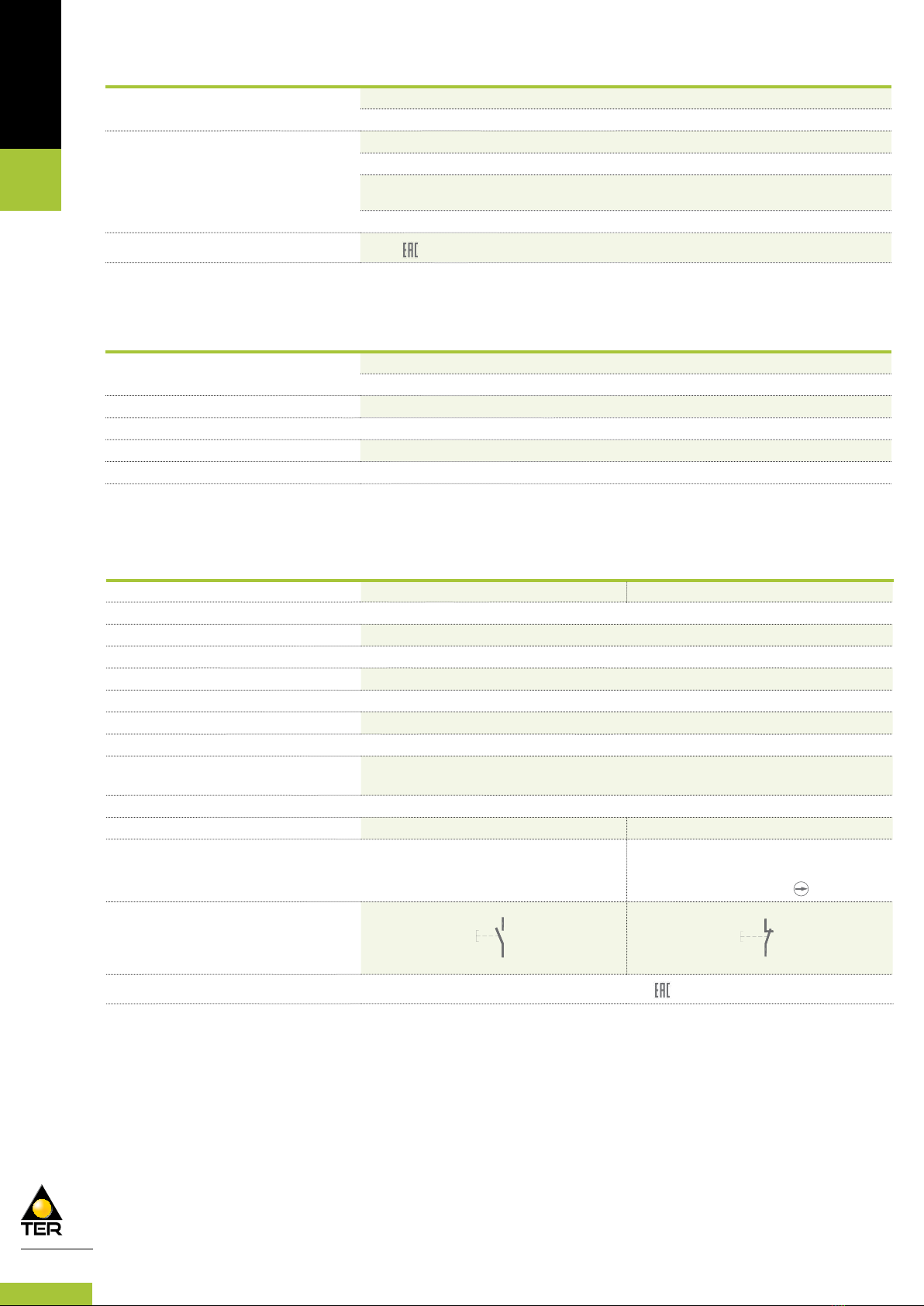

OVERALL DIMENSIONS (mm)

70

112

6

76.3

60°

60°

62 29.9

83.3

77.3

31.5

6

8

58

103.3

98.830

100

200

100

54

6.2

58

891.9 11.86

12.4

Ø6.2

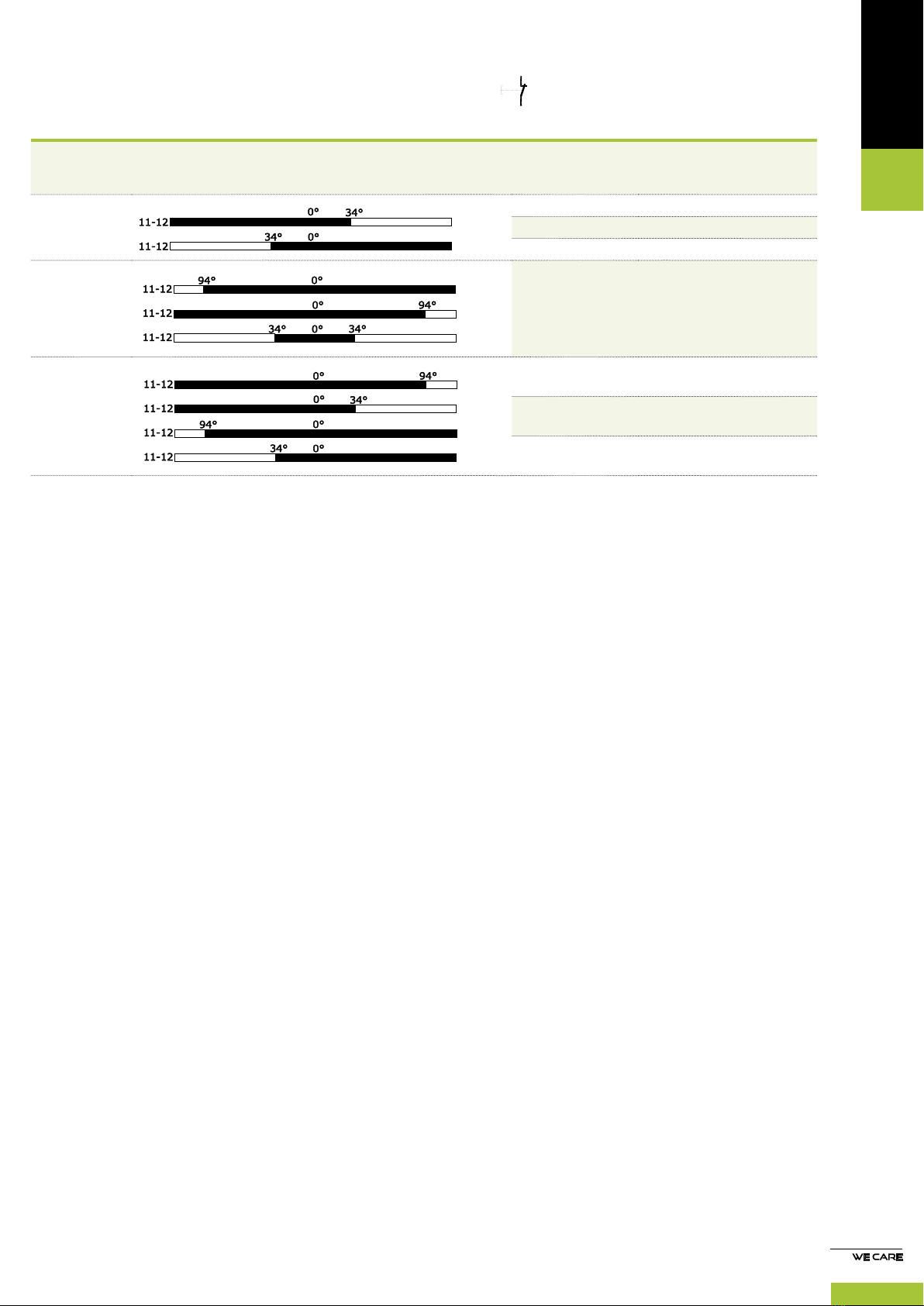

MAXIMUM ACTUATING DIMENSIONS

Rods with 4 maintained positions

Pre-travel angle for rotation contact operation: 34°

Maximum rotation angle for each maintained position: 60°

Average angle for the mechanical tripping: 30°

Maintained positions each: 60°

In order to ensure proper operations, the dimensions shall not be increased; anyhow, they can be decreased, taking into account

that the closer the impact point is to the center of the head, the higher the impact and the mechanical wear of rod and shaft are.

30°

Rod length

300 mm

200 mm

250 mm

150 mm rod

125 mm rod

100 mm rod

Actuating point 60 mm

Actuating point 93 mm

Actuating point 76 mm

TANGO

5

262

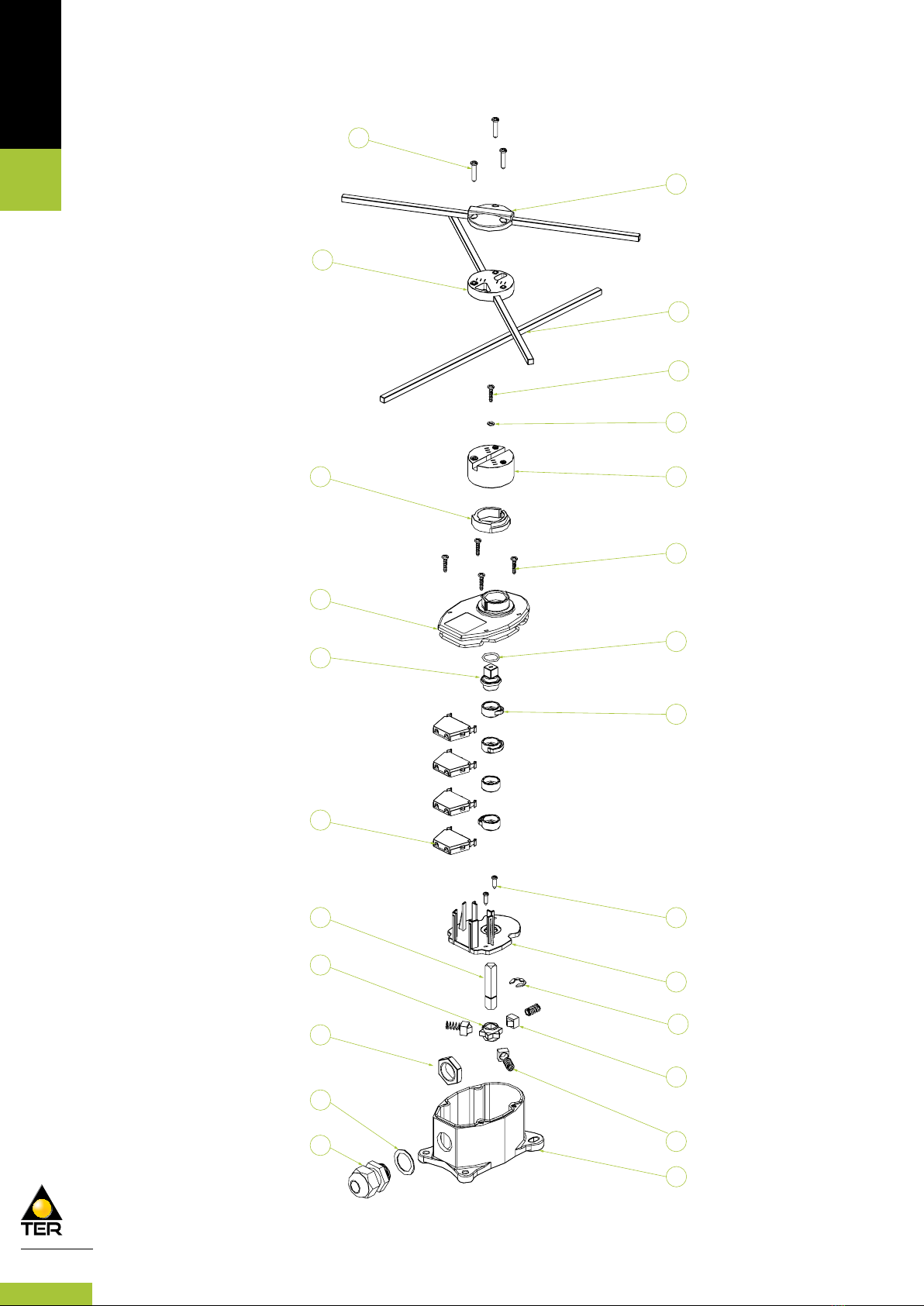

EXPLODED DRAWING

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

TANGO

5

263

LIMIT SWITCHES

The limit switches are equipped with 1NC slow action switches PRSL1001PI

11

12

.

No. of switches

PRSL1001PI Actuating travel Rod length Code

2

300 mm PF48020001

250 mm PF48020005

200 mm PF48020006

3300 mm PF48030001

4

300 mm PF48040001

250 mm PF48040006

200 mm PF48040007

TANGO

5

264

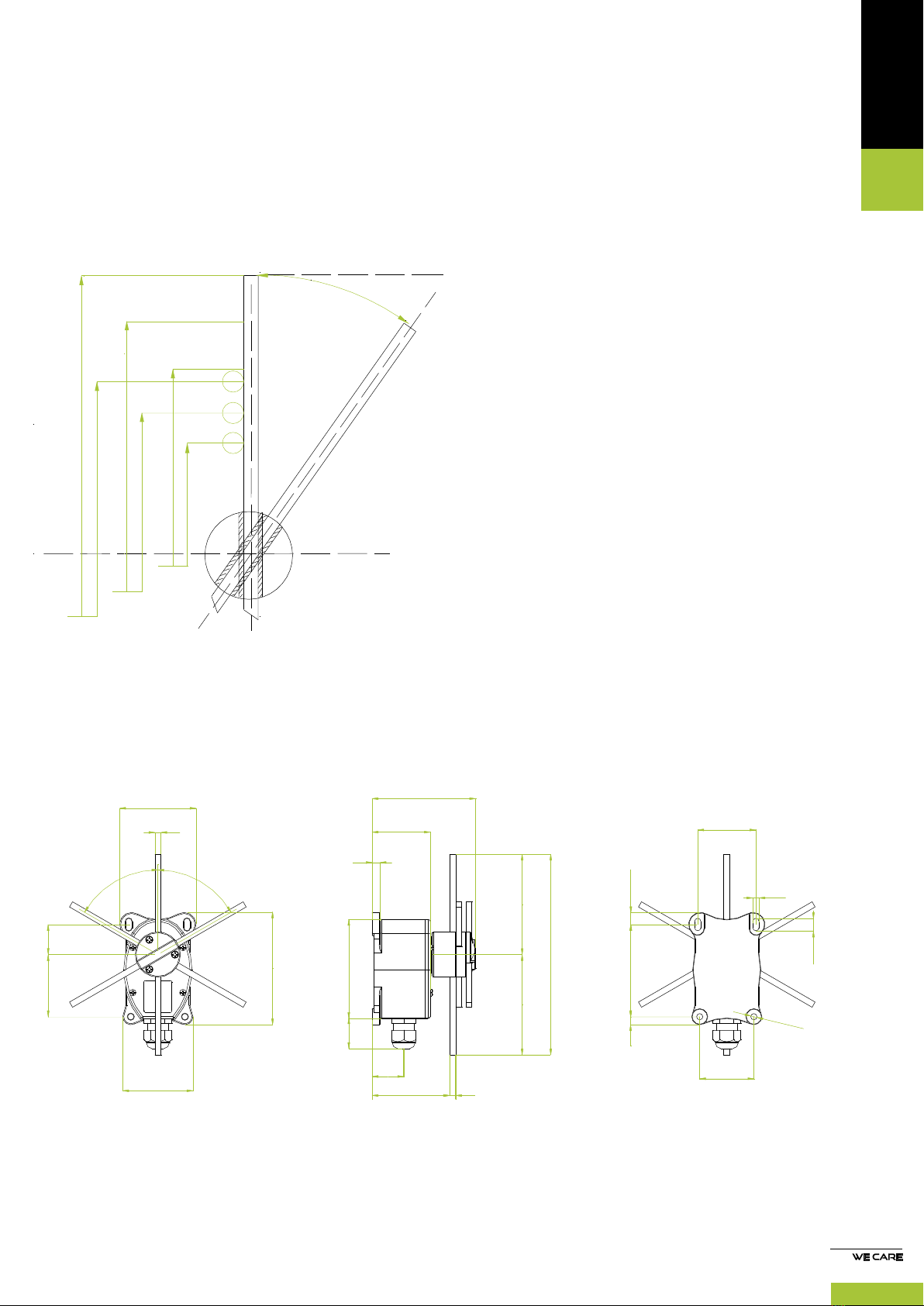

ASSEMBLY DRAWING

A1

A1

A1

A2

A2

A3

TANGO

5

265

COMPONENTS

Accessories

Ref. Drawing Description Code

A1

Rod 6x6x200 mm PRTO3006PE

Rod 6x6x250 mm PRTO3011PE

Rod 6x6x300 mm PRTO3012PE

A3 Cable clamp M20 PRPS0064PE

Switches

Ref. Drawing Description Scheme Code

A2

1NO switch

13

14

PRSL1000PI

1NC switch

11

12

PRSL1001PI

TANGO

5

266

USE AND MAINTENANCE INSTRUCTIONS

The Tango limit switch is an electromechanical device for low

voltage control circuits (EN 60947-1, EN 60947-5-1) for use as

electric equipment on machines (EN 60204-1) in compliance with

the essential requisites of the Low Voltage Directive 2014/35/UE

and the Machine Directive 2006/42/CE.

The limit switch is designed for use in industrial environments

with even very severe climatic conditions (working

temperatures from -25°C to +70°C and is suitable for use

in tropical environments). The equipment is not suitable for

use in environments with a potentially explosive atmosphere,

in the presence of corrosive agents or high percentage of

sodium chloride (saline mist). Contact with oil, acids and

solvents may damage the equipment; avoid using them

for cleaning. The limit switches is not suitable for use in

environments with a potentially explosive atmosphere.

The Tango limit switch must be fastened through the holes

on the side of the case (12)*; in particular the top holes

are slots to facilitate fastening and adjustment of the limit

switch, which must be suitably position to ensure correct

impact on the drive rods (24). To prevent malfunctions or

problems; examine the technical documentation to view the

recommended impact points.

Turn the closing screws (1) and loosen the closure of the

rod holder (25, 21, 2), then you can move the rods to adjust

them; afterwards, tighten the closing screws (1) with a force

of 100cN m to ensure secure fastening of the rod holder.

We recommend adjusting the impact point of the rods (24)

by adjusting the fastening of the entire limit switch and not

simply moving the rods.

The switches (6) of the Tango are designed for the auxiliary

control of contacts or electromagnetic charges in general

(utilization category AC-15 in accordance with EN 60947-5-

1). The switches (6) have contacts with positive mechanical

opening operation (EN 60947-5-1). Do not connect more

than one phase for the switches (6). Never oil or grease the

switches (6).

To facilitate wiring the switches (6) the limit switches can

be removed from the case (12); after wiring, the switches (6)

must be replaced correctly in the case (12), then assemble the

cover (4) and tighten the screws (23) with a minimum force of

100cN m.

Installation of the limit switches should be done by

competent, trained personnel. The electric wiring must be

compliance with the regulations in force.

Before performing installation and maintenance of the limit

switches, disconnect the machine from the power mains.

Operations for installation and correct wiring of limit switch

- Fasten the limit switch securely to prevent malfunctions

during use of the device; to fasten it, use the holes on the

sides of the case (12); fasten the limit switch so that the

drive rods (24) function correctly, by examining the technical

documentation to identify the recommended point of impact;

adjust the rods (24), by turning the closing screws (1) on the

relative rod holder elements (25, 21, 2). Afterwards, tighten the

screws (1) with a force of 100 cNm.

- Introduce the multi-pole wire in the limit switch through

the wire clamp (11), strip the multi-pole cable for a length

- Wire the switches (6) as shown in the wiring diagrams on

each (6) (tighten the terminal screws with a torque of 0.6 Nm

(5.3 lbs/inch); insertability of wires into the switch terminals

equal to 2x1.5mm2– 1x2.5 mm2(UL (c)UL: use 60°C or 75°C

copper (CU) conductors)).

- After wiring tighten the wire in the wire clamp (11).

- Close the limit switch with its cover (4) with the closing

screws (20); applying a force of at least 100cN m.

Operations of routine maintenance

- Check the correct tightening of the closing screws (20) on

the cover (4).

- Check the conditions of the wires on the switches (6) (if

necessary, tighten the screws on the terminals).

- Tighten the multi-pole wire in the wire clamp (12).

- Check the conditions of the complete limit switch (25, 24, 21,

12, 4, 2).

- Check the fastening of the limit switch.

Any change to parts of the limit switch will invalidate the

the warranty null and void. In case of replacement of any part,

use only original replacements.

TER is not liable for damages caused by improper use of the

device and installation which is not made correctly.

*Please refer to the exploded drawing in the catalogue.

Table of contents

Other TER Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Sumitomo

Sumitomo 82C+ Guide to Operation

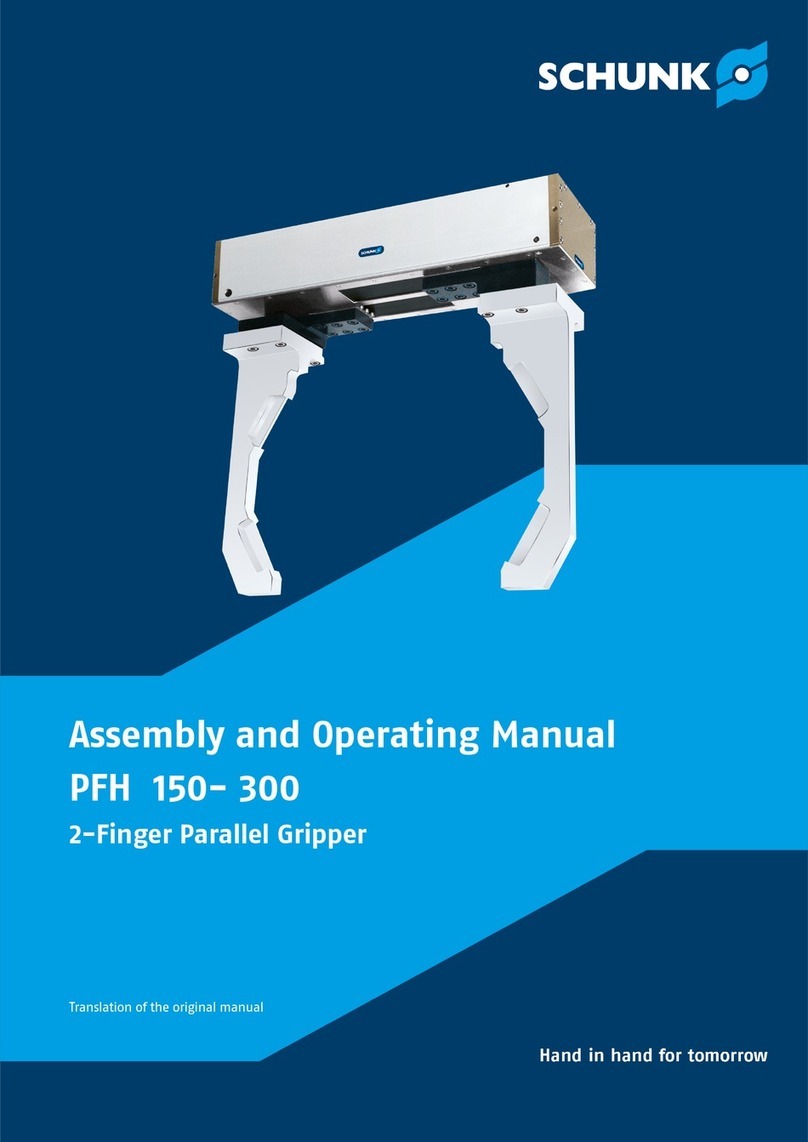

SCHUNK

SCHUNK PFH 150 Assembly and operating manual

Stark

Stark S-500 Installation, operation & maintenance instructions

Interroll

Interroll PF 1100 user manual

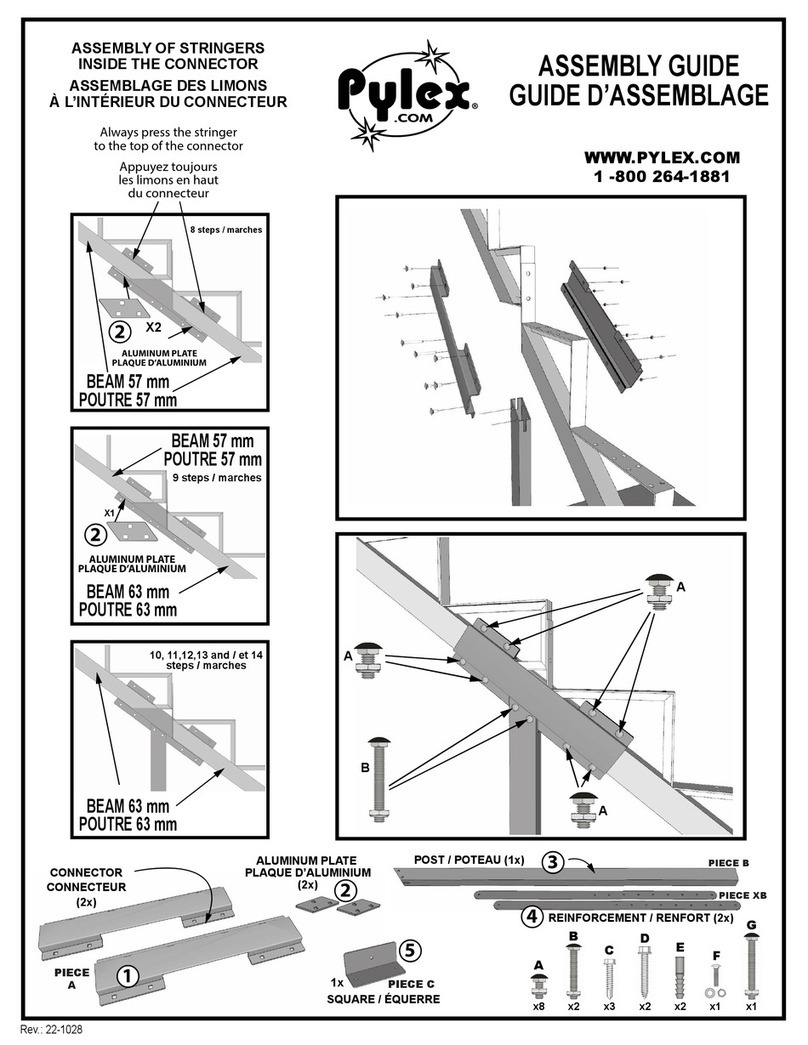

Pylex

Pylex 16020 Assembly guide

INOXPA

INOXPA KIBER KS Ex Installation, service and maintenance instructions