4

Document No : CMM.0500.105 Rev :1

Version : 22.032

Section 2: INSTALLATION

Section 2.1 Disassembly of Horizontal Hinge Closure, not Installed

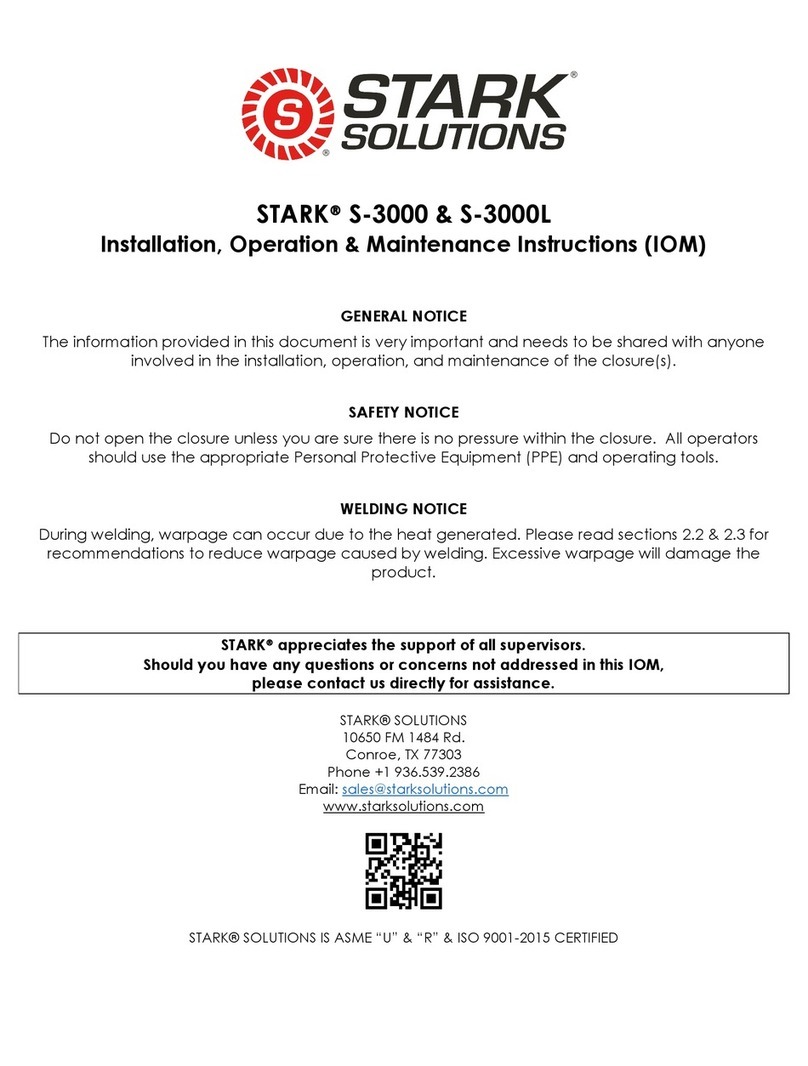

A. If a Pressure Alert Valve (PAV) is present, remove the

stem and screw it into the retainer on the cap. The

PAV is standard on all closures 6” and larger;

optional on sizes 2”, 3”, and 4”.

On closures 14” and under, unscrew the cap from

the hub and lift the attached hinge components

from the hinge base. A cotter pin may need to be

removed from the hinge arm to accomplish this on

some sizes.

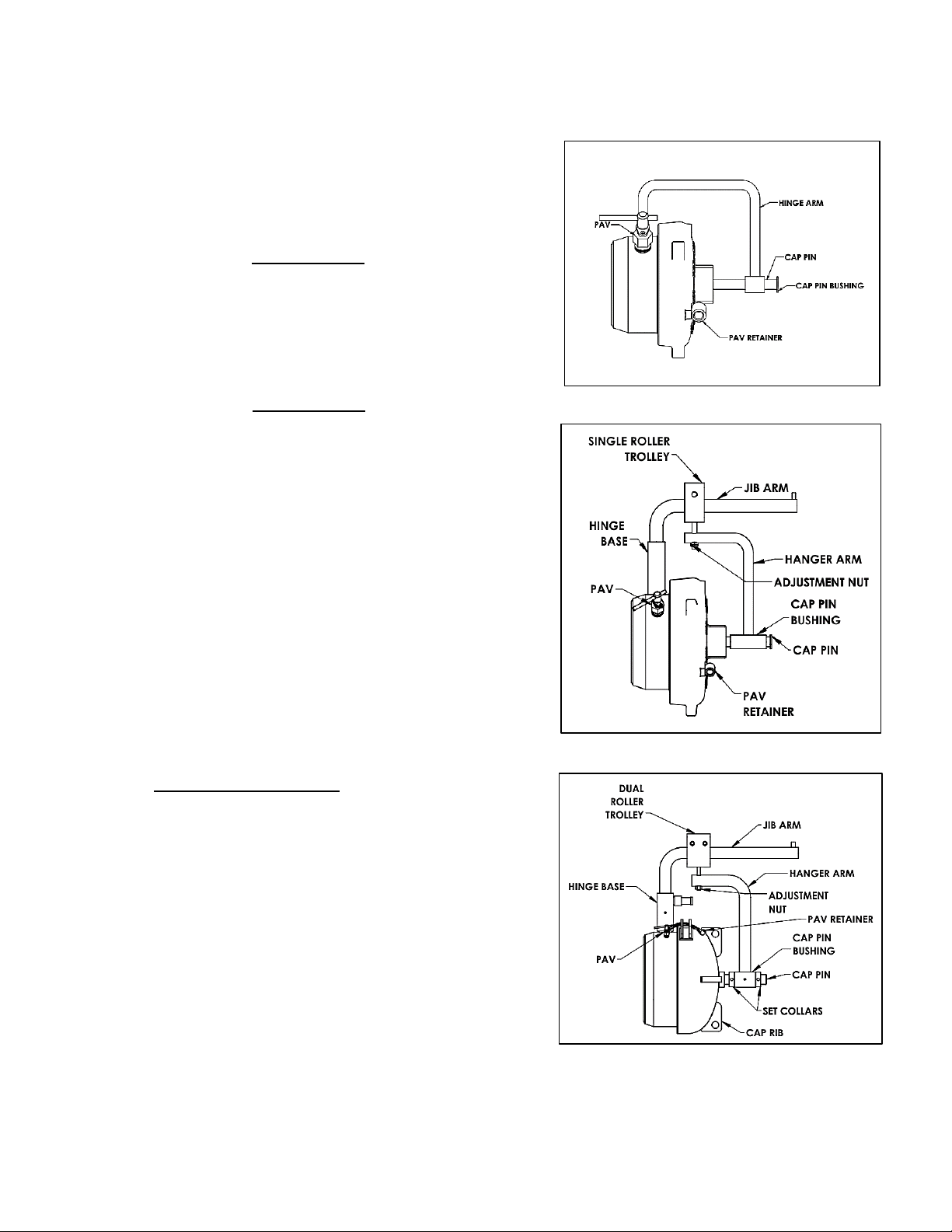

B. On closures 16” and larger, remove the outer set

collar from the cap pin and remove the hanger arm

from the cap pin. Leave the inner set collar in place,

this will retain the cap balance location set by the

manufacturer. On 30” SERIES 600 and larger

closures the cap pin bushing has roller bearings

inside. Make sure the cap pin is free of all burrs to

ease removal of the inner bearing race. Store

bearings with care and keep them protected from

dust, grit, and other contaminants.

NOTE: A burr may be left behind by the set screw in the

collar. Using a file or emery cloth, remove the burr prior

to removal of the hanger arm and/or related

components.

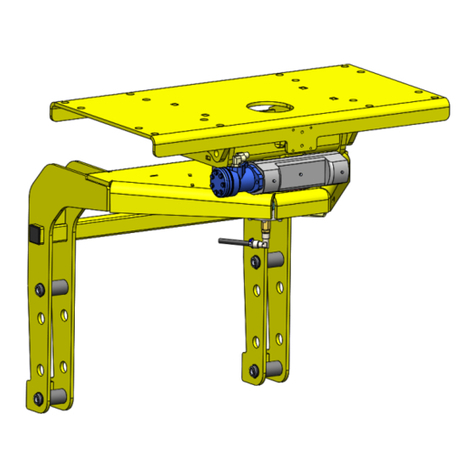

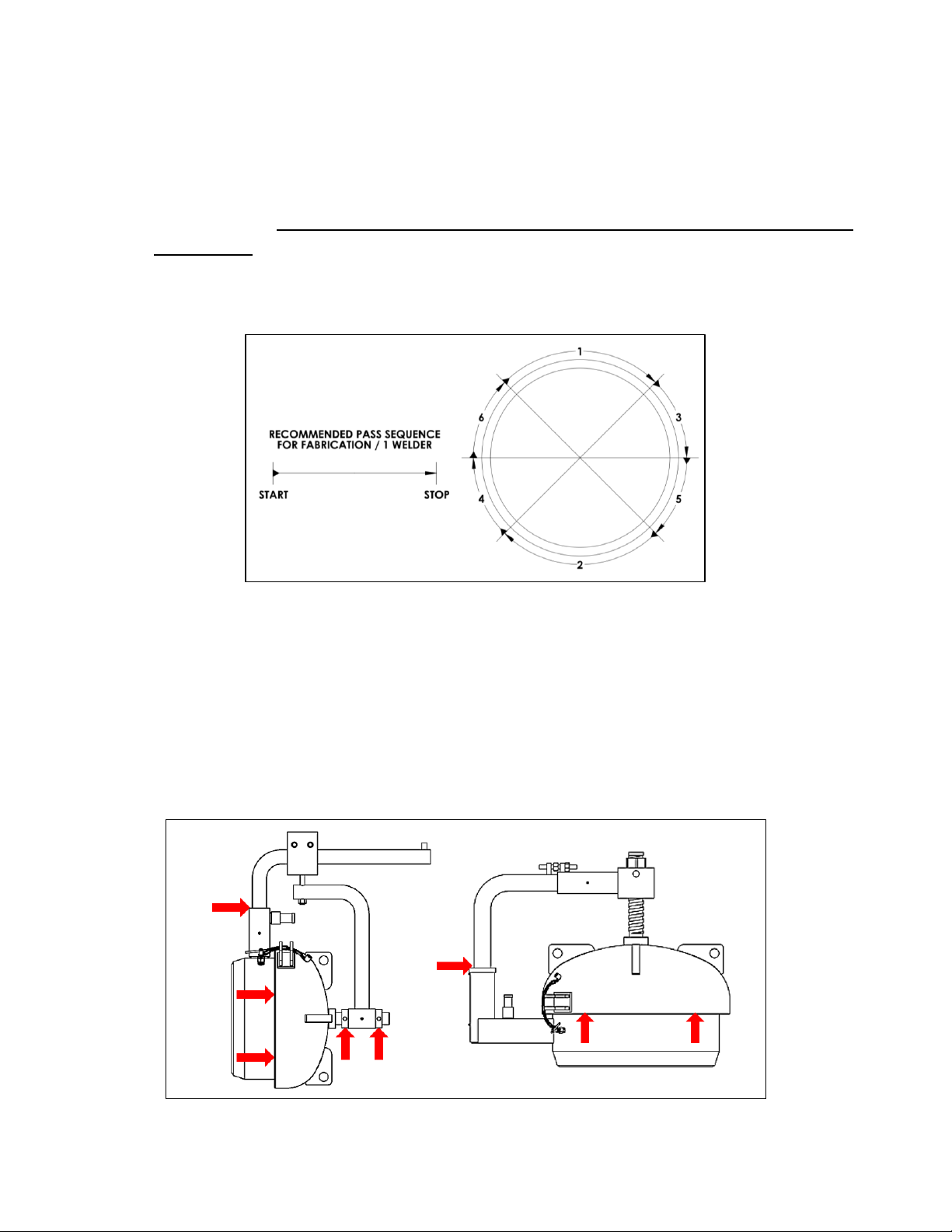

D. 16” and larger closure are equipped with a dual

roller or wheel trolley. Measure the distance from

the bottom of the jib arm to the top of the hanger

arm or put a reference mark on the adjustment bolt

above the hanger arm. Remove the nut, V-block on

24” SERIES 600 and larger, and hanger arm from the

closure. Do not remove the trolley from the jib arm.

E. Remove the jib arm from the hinge base. The jib

assembly of 24” SERIES 600 and larger closures are

equipped with a brass bushing and tapered roller

(Figure 2) 2” to 4” Closure (hinged)

(Figure 3) 6” to 14” Closure

(Figure 4) 16” to 24” SERIES 300