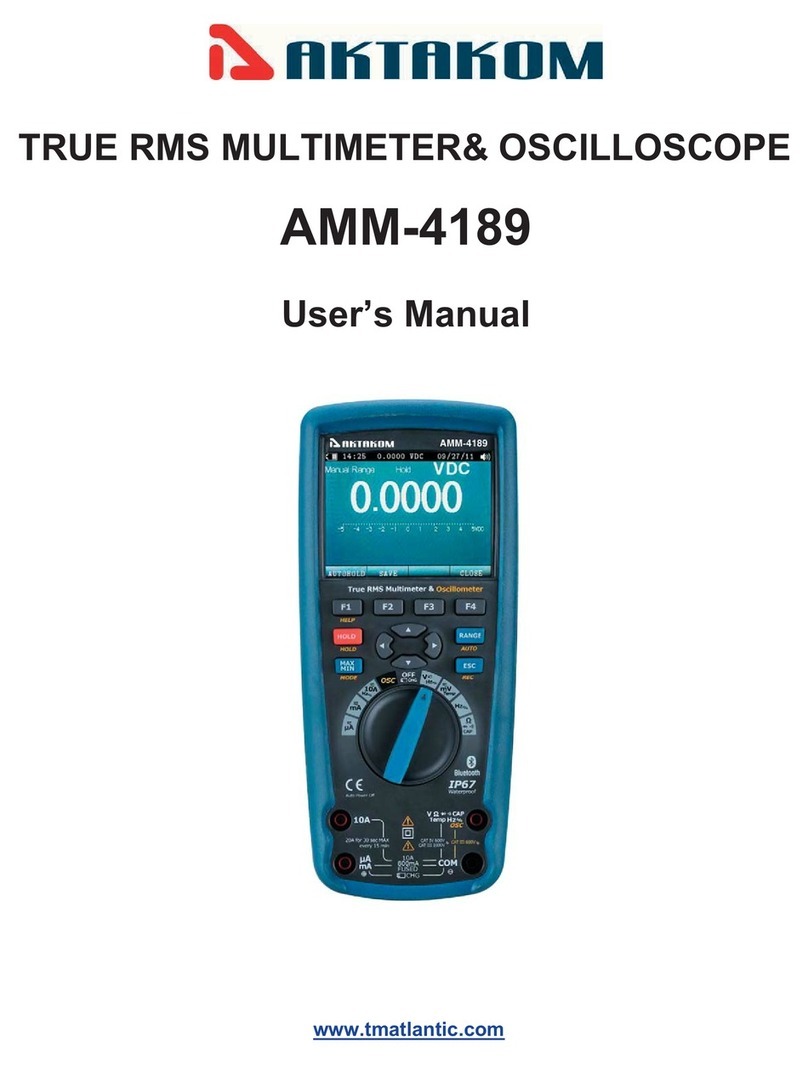

Teradyne Neptune User manual

Neptune Operator Manual

Version 1.1, March 8, 2011

Operator Manual /

Teradyne Confidential - i -

Table of Contents

1 Safety Information 1

1.1 Safety Standards Compliance 1

1.1.1 EMI/EMC 1

1.2 General Safety Guidelines 1

1.3 Use of Genie Lift for System Maintenance 2

1.4 Safety and Product Labels and Symbols 2

1.4.1 Product and Safety Compliance Labels 4

1.5 Warnings and Cautions 7

1.5.1 General Warnings and Cautions 7

1.5.2 Physical Warnings and Cautions 8

1.5.3 Electrical Warnings and Cautions 9

1.5.4 Chemical Warnings and Cautions 10

1.6 Electrostatic Discharge Guidelines 11

1.6.1 Wrist Strap and Ground Clip 11

1.6.2 Static-Producing Materials 12

1.6.3 Hardware Handling and Shipping 13

1.6.4 Humidity in the Work Area 13

1.6.5 Optional Equipment to Avoid Static 13

1.7 Types of ESD Equipment Failures 14

1.7.1 Catastrophic Failure 14

1.7.2 Soft Failure 14

2 Entering and Exiting the System 15

2.1 Safely Stopping Automation 15

2.2 Entering the System 15

2.3 Exiting the System and Restarting Automation 17

3 Check or Reset Host and System PC 19

4 Misaligned Drives on the Conveyor Events 22

5 Exception Drawer Events 23

6 Sled Garage Replenishment 26

7 Verifying Compressed Air Pressure 27

8 System Power Down/Up 29

8.1 Powering the System Down 29

8.2 Powering the System Up 30

8.3 Unexpected System Power Down 30

9 Clean/Inspect the Atrium 32

10 Appendix A - Terms, Acronyms and Abbreviations 33

Operator Manual /

Teradyne Confidential - ii -

Operator Manual Revision History

Date: March 8, 2011

Section Page Comments

Safety Information 1Added new Safety Information

section.

System Power Up Down 29 Added new UnexpectedSystem

Power Down sub-section.

Acronyms and Abbreviations 33 Added new Appendix for Acro-

nyms and Abbreviations.

Operator Manual / 1 Safety Information

Teradyne Confidential - 1 -

1 Safety Information

1.1 Safety Standards Compliance

With isolation of the Neptune chamber power, the system has built-in fail-safe

operations that are compliant with:

lEmergency Machine Off (EMO)

lCircuit breaker protection

lPhase Fault Detection

All hazardous voltages are covered and warning labels attached per international

standards and circuit breaker 30A meets factory main DB requirements.

The Neptune system, as designed, has an IP2X degree of protection to IEC 60529.

Regarding robot safety compliance and guidelines: the KUKA documentation

includes extensive safety information. Operator, service and maintenance

personnel should read the KUKA KR 16 L6-2 safety instructions before operating

the robot.

1.1.1 EMI/EMC

The Neptune system complies with the EMC Directive 2004/108/EC and the

following EMC/EMI standards:

lEN61326-1:2005

lEN55011 Radiated and Conducted Emissions

lEN6100-6-2 Immunity

lEN61000-4-2:2001 Electrostatic Discharge

lEN61000-4-3:2002 Radiated Fields

lEN61000-4-4:2004 EFT/Burst

lEN61000-4-5:2001 Surge

lEN61000-4-6:2003 RF Coupled Fields

1.2 General Safety Guidelines

To prevent serious accidents to yourself against shock, static, or heavy objects, and

against damage to any hardware, review the guidelines provided in the following

sections. These guidelines are suggested by Teradyne and do not override the

safety procedures that apply to your site. Follow the internal guidelines, policies,

and procedures that are documented and supported within your organization.

Operator Manual / 1 Safety Information

Teradyne Confidential - 2 -

Topics include:

lSafety and Product Labels and Symbols

lWarnings and Cautions

lElectrostatic Discharge Guidelines

lTypes of ESD Equipment Failure

1.3 Use of Genie Lift for System Maintenance

A GL8 Genie Lift, equipped with ladder and lifting tray, is provided for use in

maintaining the system. Field service personnel will be required to use the lift to

service all system components that cannot be safely managed at floor level.

To operate the lift safely, field service personnel are referred to the Genie

Operator’s Manual, Genie Lift (Part # 35566).

Seagate site procedures for working at elevated heights must be followed. Prior to

performing work, contact the facility manager for clarification of procedures.

1.4 Safety and Product Labels and Symbols

The information provided in this section is not product specific and, therefore, all

labels might not appear on your hardware.

Carefully review the safety symbols, Electrostatic Discharge (ESD) symbols and

labels that appear on hardware.

These labels and symbols are derived from International Electro-technical

Commission (IEC) 417 and from Occupational Safety and Hazard Administration

(OSHA) 29 CFR 1920, or ANSI Z535, or a combination thereof.

Safety labels and symbols can include one or more of the following. This is not a

complete listing; your hardware can contain other labels that do not appear here.

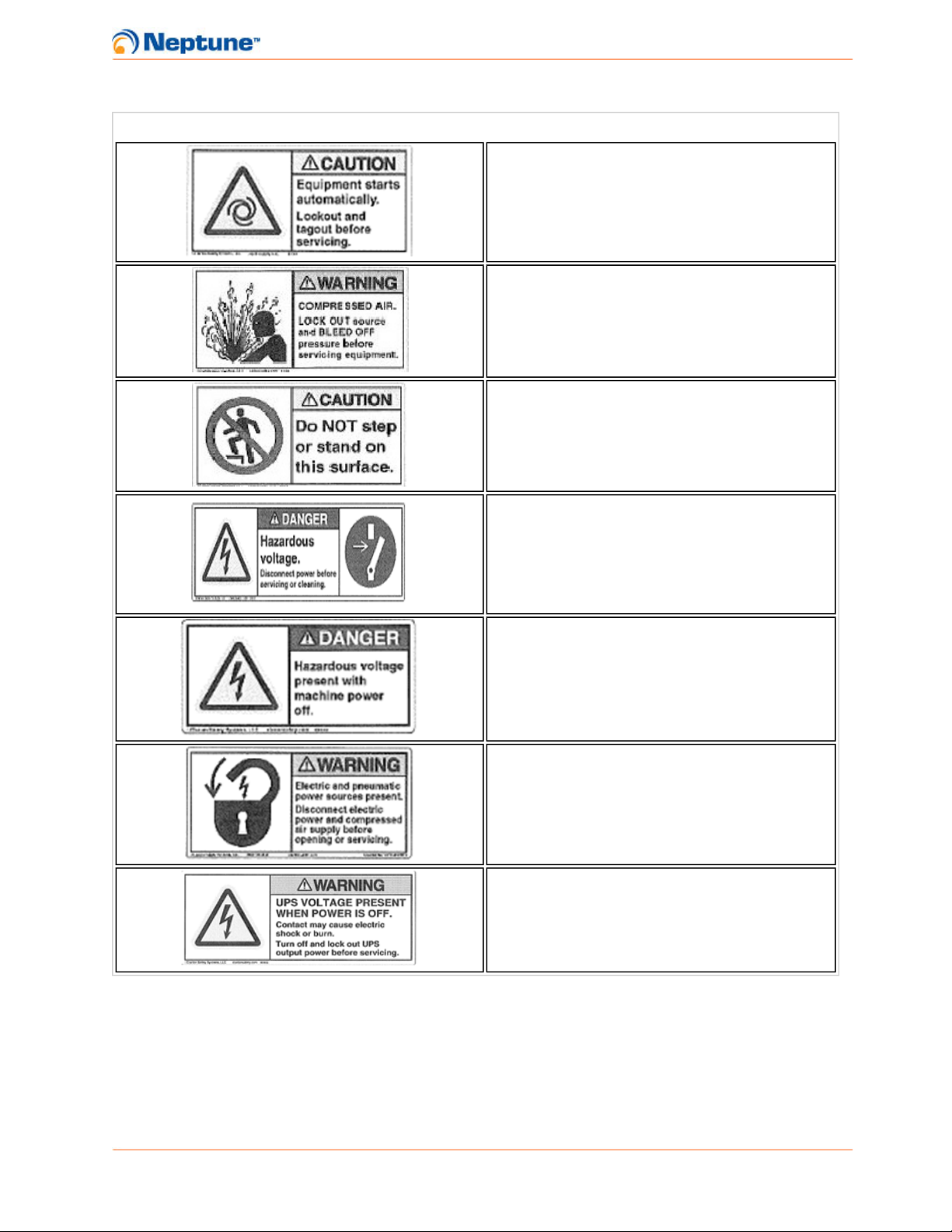

Table 1-1: Safety Labels

Symbol Description

IEC yellow CAUTION label. Iden-

tifies a specific area of hardware that

has important servicing operating

requirements described in the accom-

panying documentation

Operator Manual / 1 Safety Information

Teradyne Confidential - 3 -

Symbol Description

HEAVY OBJECT label. Cautions

that there is a heavy object that can

cause injury if proper lifting pro-

cedures are not used when removing

or replacing it.

ANTISTATIC label. Indicates that

special antistatic or preventive meas-

ures must be taken to avoid hard-

ware damage or equipment

malfunction.

Safety symbols can include one or more of the symbols as shown in the following

table.

Table 1-2: Additional Safety Symbols

Symbol Description

HIGH-VOLTAGE FLASH. Defines a con-

nection where a dangerously high volt-

age, above 60 V, either AC or DC, may

be present. (Black signifies 60-999 V; red,

1000 V or more.)

CIRCUIT GROUND. Identifies a con-

nection point where instrumentation is ref-

erenced to ground. Instrumentation

grounds include: protective, chassis,

radio frequency, signal, and so on. Typ-

ically, this symbol is near coaxial con-

nections.

WARNING, RISK OF ELECTRIC

SHOCK. Indicates presence of dan-

gerous voltages and risk of electric shock.

Operator Manual / 1 Safety Information

Teradyne Confidential - 4 -

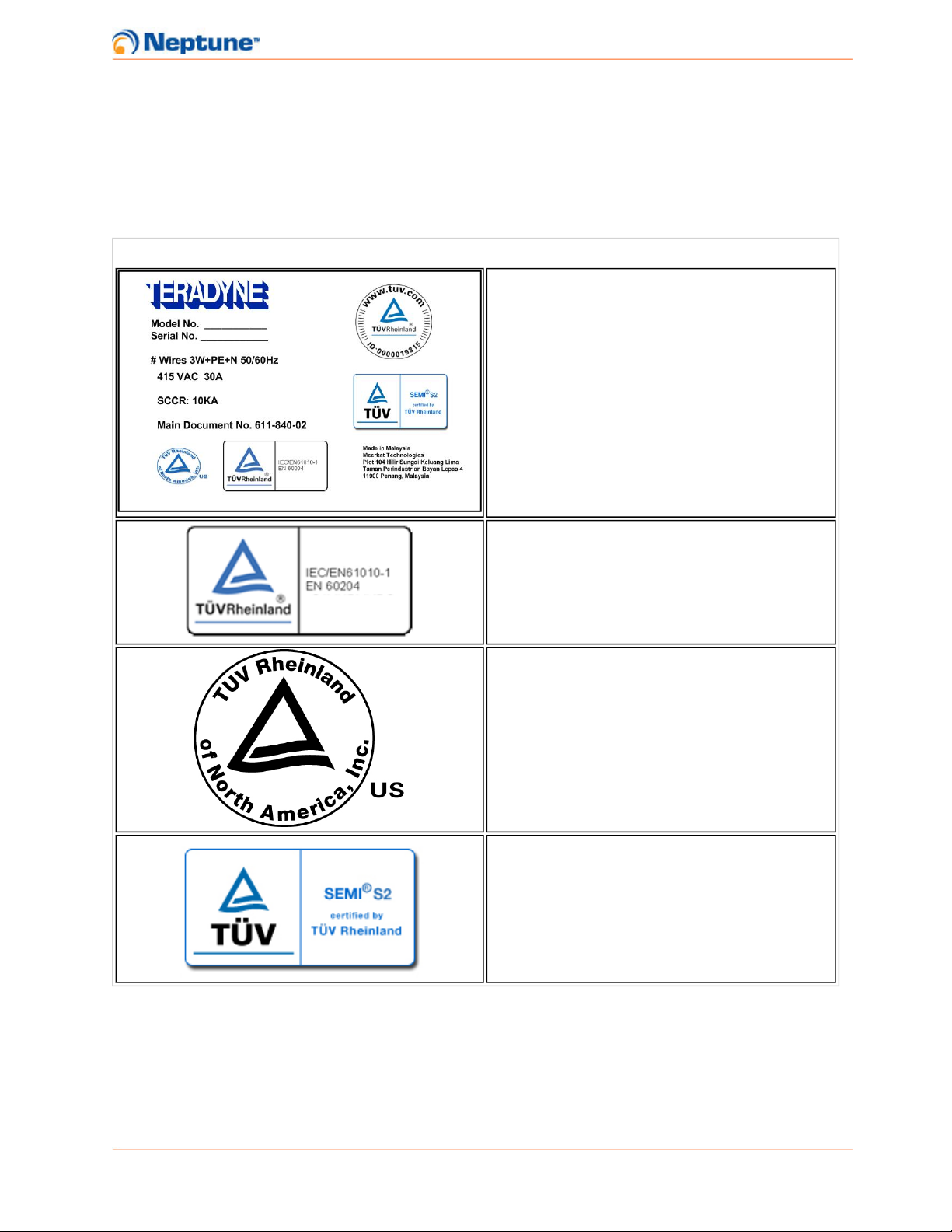

1.4.1 Product and Safety Compliance Labels

Product and safety compliance labels may include one or more of the following:

Table 1-3: Safety Compliance Labels

Label Comments

Neptune 2 product label (conveyer load-

ing system). Located on feeder and racks.

TUV Rheinland - T Mark

TUV Rheinland - NRTLMark

TUV Rheinland - SEMI S2 Mark

Operator Manual / 1 Safety Information

Teradyne Confidential - 5 -

Label Comments

TUV Rheinland - TUV ID Label

PROTECTIVE GROUND. Indicates the

entrance point of the safety ground wire of

the AC main input. Located next to safety

ground studs in the feeder and racks.

EARTH (GROUND) TERMINAL. Indi-

cates a conductive point that is ref-

erenced to the safety ground wire of the

alternating current (AC) main input, but

that is not part of the AC service wiring.

Located next to each earth ground ter-

minal in the feeder and racks.

CHASSIS GROUND. Identifies where a

wire is connected to a chassis point for

ground reference or other function, such

as static discharge. Located at each chas-

sis ground stud in the feeder and rack.

FUSE REPLACEMENT. Indicates that a

fuse must be replaced by one of the same

type and rating to ensure safe and proper

operation. Located on feeder high voltage

box.

HAND CRUSH LABEL near tote drawer.

Apply to manual feeder.

Operator Manual / 1 Safety Information

Teradyne Confidential - 6 -

Label Comments

Use lockout tag out before servicing sys-

tem. Located on feeder NEMA box.

Lock out compressed air source and

bleed off pressure before servicing.

Located on feeder NEMA box.

Do not step or stand on labeled surface.

Located on top canopy.

WARNING, RISK OF ELECTRIC

SHOCK. Indicates presence of dan-

gerous voltages and risk of electric

shock.Disconnect power before servicing.

Located on feeder and all racks.

Live voltages present after EMO acti-

vation. Located on feeder NEMA box.

Electric and pneumatic power sources

present. Disconnect services before serv-

icing. Located on feeder NEMA box.

Uninterruptible Power Supply (UPS) volt-

age present when power is off. Located

on feeder NEMA box.

Operator Manual / 1 Safety Information

Teradyne Confidential - 7 -

Label Comments

UPS supply output. Located near ends of

UPS supply outputs.

1.5 Warnings and Cautions

The following are listings of warnings and cautions associated with the use of the

Neptune system. Specific warnings and cautions are repeated in every procedure

to which they apply. The categories are:

lGeneral

lPhysical

lElectrical

lChemical

1.5.1 General Warnings and Cautions

Table 1-4: General Warnings and Cautions

Symbol Description

Procedures performed by unqualified per-

sonnel represent a serious health hazard

that could result in serious injury and/or

damage to the equipment. Maintenance

must be performed by qualified per-

sonnel, trained by Teradyne.

Safety shoes and safety glasses must be

worn by all personnel involved in assem-

bling and moving the system.

Do not use toxic or dangerous sub-

stances for cleaning the Neptune system

equipment. If specific cleaning instruc-

tions are not presented, use the mildest

method (e.g. small quantity of detergent

and water on external cabinets)

Operator Manual / 1 Safety Information

Teradyne Confidential - 8 -

Symbol Description

Adherence to the recommended schedule

of maintenance is not a reason to post-

pone maintenance if the system’s per-

formance degrades. Take the appropriate

steps to check and resolve any per-

formance problems immediately.

1.5.2 Physical Warnings and Cautions

Figure 1-1: Physical Warnings and Cautions

Symbol Description

Tip over hazard. Do not move this equip-

ment without mechanical assistance.

Crush hazard moving and uncrating

equipment. Safety shoes and safety

glasses are worn by all personnel

involved in assembling and moving the

system.

Uncrating components may expose sharp

objects.

Safeguard your hands and fingers while

handling any fixture or other accessory.

Be sure it is securely supported if you

reach under it. If it is heavy, you must

have another person help to move it.

Possible airborne particles and pro-

jectiles when drilling into floor. Wear

approved eye protection or safety

glasses.

Pressurized device. Possible airborne par-

ticles and projectiles. Wear approved eye

protection or safety glasses.

Operator Manual / 1 Safety Information

Teradyne Confidential - 9 -

Symbol Description

Interlocks to enclosure doors and access

ports should never be bypassed except in

the performance of servicing and only by

trained personnel. Any interlock overrides

must be removed immediately upon com-

pletion of the service task.

DO NOT attempt to make adjustments to

the safety interlocks as they are critical

safety features. Improper adjustment can

cause potential harm to personnel and

damage to critical components.

Protect the floor by and route to the instal-

lation site by placing down floor mats.

1.5.3 Electrical Warnings and Cautions

Table 1-5: Electrical Warnings and Cautions

Symbol Description

When operating high-voltage or high-

power systems:

lHave an assistant present or notify

someone nearby before and after

completing the work.

lRemove conductive items and jew-

elry before installing an instru-

ment, or other hardware, and

operating the test system.

Learn the areas containing high voltage

in each piece of equipment. Do not con-

tact high voltage connections when install-

ing or operating this equipment.

Operator Manual / 1 Safety Information

Teradyne Confidential - 10 -

Symbol Description

Use caution when near the following elec-

trical hazards:

lDirect current voltages greater

than 30 volts (V) root-mean-square

(42 V peak)

lPulses greater than 24 V

lPower combination greater than

240 volt-ampere

lReactive energy greater than 10 J

High-current (greater than 10 A)

system power supplies.

High voltage is present in the AC vaults

(certain sections of the wedges) of the

Neptune system. Serious injury or death

may result if personnel fail to observe

safety precautions.

Before performing any electrical task, lock-

out/tagout procedures should be used to

ensure safety. All procedures must be per-

formed by qualified personnel.

Before performing any AC vault main-

tenance task, turn power OFF at the

supply circuit breaker, and ground points

of high voltage potential before touching

them, to avoid the risk of electrocution.

Static-sensitive devices are present. Fol-

low the approved ESD handling pro-

cedures while working with static

sensitive components.

1.5.4 Chemical Warnings and Cautions

Table 1-6: Chemical Warnings and Cautions

Symbol Description

Contact with epoxy may cause skin irri-

tation. Use gloves when handling glue

gun and epoxy containers.

Operator Manual / 1 Safety Information

Teradyne Confidential - 11 -

Symbol Description

Do not use toxic or dangerous sub-

stances for cleaning the Neptune system

equipment. If specific cleaning instruc-

tions are not presented, use the mildest

method (e.g. small quantity of detergent

and water on external cabinets)

1.6 Electrostatic Discharge Guidelines

The discharge of static electricity, sometimes as a visible spark, is called

electrostatic discharge (ESD). Static potentials can be in excess of several

thousand volts. Many semiconductors, such as metal-oxide semiconductor field-

effect transistors (MOSFET), have terminals that can easily be damaged by static

potentials as low as 20 volts. For this reason, all ESD-sensitive hardware must be

transported and maintained in areas free of electrostatic charges.

To help ensure safe handling of hardware from electrostatic discharge (ESD),

review the following guidelines:

lWrist Strap and Ground Clip

lStatic-Producing Materials

lHardware Handling and Shipping

lHumidity in the Work Area

lOptional Equipment to Avoid Static

1.6.1 Wrist Strap and Ground Clip

Wrist straps consist of conductive straps worn around the wrist and conductive

cords that connect the straps to electrical or earth ground. When used properly, the

wrist straps discharge the static charge on your body to ground, or bring your body

to the same static potential as that of work surfaces, or both. You should also:

lWear a grounded wrist strap before you touch any ESD-sensitive hardware (for

example, component, assembly, or instrument). The strap should fit snugly

around your wrist and contact your skin. If the strap is too loose, it will not provide

sufficient ESD protection.

Note: Do not wear the wrist strap over clothing, as this will prevent the strap from

discharging static charges.

Operator Manual / 1 Safety Information

Teradyne Confidential - 12 -

lExamine or test the wrist strap daily for conductivity and correct fit.

lAttach a ground clip to ESD-sensitive hardware before you remove it from an

anti-static box or static-shielding bag.

lRemove the ground clip from ESD-sensitive hardware after you put it in an anti-

static box or static-shielding bag.

lInspect conductive and grounded work surfaces

lWork surfaces consist of the tabletops and the floor of the work area.

Check for the following:

oWork surfaces that are constructed from a conductive material, like

metal, or that have conductive mats or carpets on the tabletops and

floors.

oConductive cords that connect the work surfaces to electrical or

earth ground.

oResistors used in each grounding cord to keep ESD currents at

safe levels.

oFloor mats that are not worn.

oFloor mats using the correct connections and conductivity.

oTabletops using the correct connections and conductivity.

oYou should also make periodic checks of the work area to deter-

mine the effectiveness of ESD suppression methods and materials.

1.6.2 Static-Producing Materials

Move static-producing materials and tools away from ESD-sensitive hardware. This

material includes but is not limited to:

lPlastic and foam coffee cups

lFood containers and wrappers

lClothing and shoes containing man-made materials

lRubber-soled shoes

lCellophane or paper tape

lAvoid or minimize the following activities:

oAny action that can generate static charge, including putting on and taking

off smocks, wiping feet, rubbing hands, and any similar activities.

oUnnecessary sliding movements, such as dumping devices out of bags,

rapidly sliding ESD-sensitive hardware across a tabletop, and so on.

oUse of adhesive tape. Labels and inspection arrows and dots are per-

mitted (peel slowly from backings to reduce the chance of static buildup).

oContact between paper and ESD-sensitive hardware. Do not enclose

paper in the same ESD container holding the hardware. Enclose doc-

umentation in its own static shielding bag when storing or transporting the

hardware.

oContact between your clothing or hair and electrical devices.

Operator Manual / 1 Safety Information

Teradyne Confidential - 13 -

1.6.3 Hardware Handling and Shipping

When handling ESD-sensitive hardware:

lHandle one piece of hardware at a time.

lAssume all unidentified hardware is ESD-sensitive.

lObey the warnings and safety labels on ESD-sensitive hardware and their con-

tainers.

lUse the correct extraction tools for hardware, if applicable.

lKeep an anti-static box and static-shielding bag closed until you insert or remove

hardware.

lPut anti-static boxes or static-shielding bags on a grounded surface before you

open them.

lAvoid unnecessary touching of leads on assemblies. Where possible, hold

printed circuit boards by the edges and avoid touching the contact fingers, pins,

or connectors.

lWhen moving and storing ESD-sensitive hardware:

oPut an unprotected assembly (or other hardware), after removal from the

system, on an ESD-safe table or in an anti-static box or static-shielding

bag.

oPut only one piece of hardware into an anti-static box or static-shielding

bag before putting them in a shipping box. The shipping box may not have

ESD protection.

oStore full anti-static boxes or static-shielding bags closed, in a horizontal

position, and in an ESD-safe location (grounded cart or table mat).

1.6.4 Humidity in the Work Area

A relative humidity of at least 40-50% is required in all Neptune work areas. Less

than 40% humidity increases the generation of static electricity, making ESD

protection more difficult to accomplish.

1.6.5 Optional Equipment to Avoid Static

The following optional equipment can improve ESD protection:

lClothing designed for ESD protection, including long-sleeved smocks

lTopical anti-static spray or treatment that can be applied to floors, carpets, walls,

ceilings, chairs, clothing, system parts, trays, tools, paper, plastic, and other mate-

rials

lConductive or anti-static chair or stool covers

lConductive shoes or shoe straps

lAir ionizers

Operator Manual / 1 Safety Information

Teradyne Confidential - 14 -

1.7 Types of ESD Equipment Failures

Electrostatic Discharge (ESD) can damage sensitive hardware such as

semiconductor devices, transistors and integrated circuits, which can cause two

types of equipment failures.

1.7.1 Catastrophic Failure

If there is a catastrophic failure, ESD can damage the hardware and make it

inoperative. Catastrophic failures can be identified during troubleshooting due to

damage or loss of functionality.

1.7.2 Soft Failure

If there is a soft failure, ESD can cause increased stress on the hardware without

destroying it. Soft failures will reduce the operating life of the hardware, and can

cause intermittent operation or sporadic malfunctions with no obvious cause.

An accumulation of soft failures can also cause a catastrophic failure. Soft failures

can be difficult to identify and repair because the equipment can continue to

operate correctly most of the time.

Operator Manual / 2 Entering and Exiting the System

Teradyne Confidential - 15 -

2 Entering and Exiting the System

2.1 Safely Stopping Automation

To safely stop automation when the system is running in production mode, the

white STOPbutton must always be pressed first. This must also be done prior to

opening any rack doors because opening a rack door trips the operator safety gate.

Figure 2-1: Stop Button

2.2 Entering the System

1. Once the STOP button has been pressed, the system will unlock the service

access door for approximately one second. During this time, if the operator

needs to enter the atrium, the door can be opened. If the door is not opened dur-

ing this time period, the door will be re-locked for safety purposes. If the door

needs to be opened after it has re-locked, the STOP button can be pressed

again to unlock the door for another short duration. Once the door has opened, it

will remain unlocked.

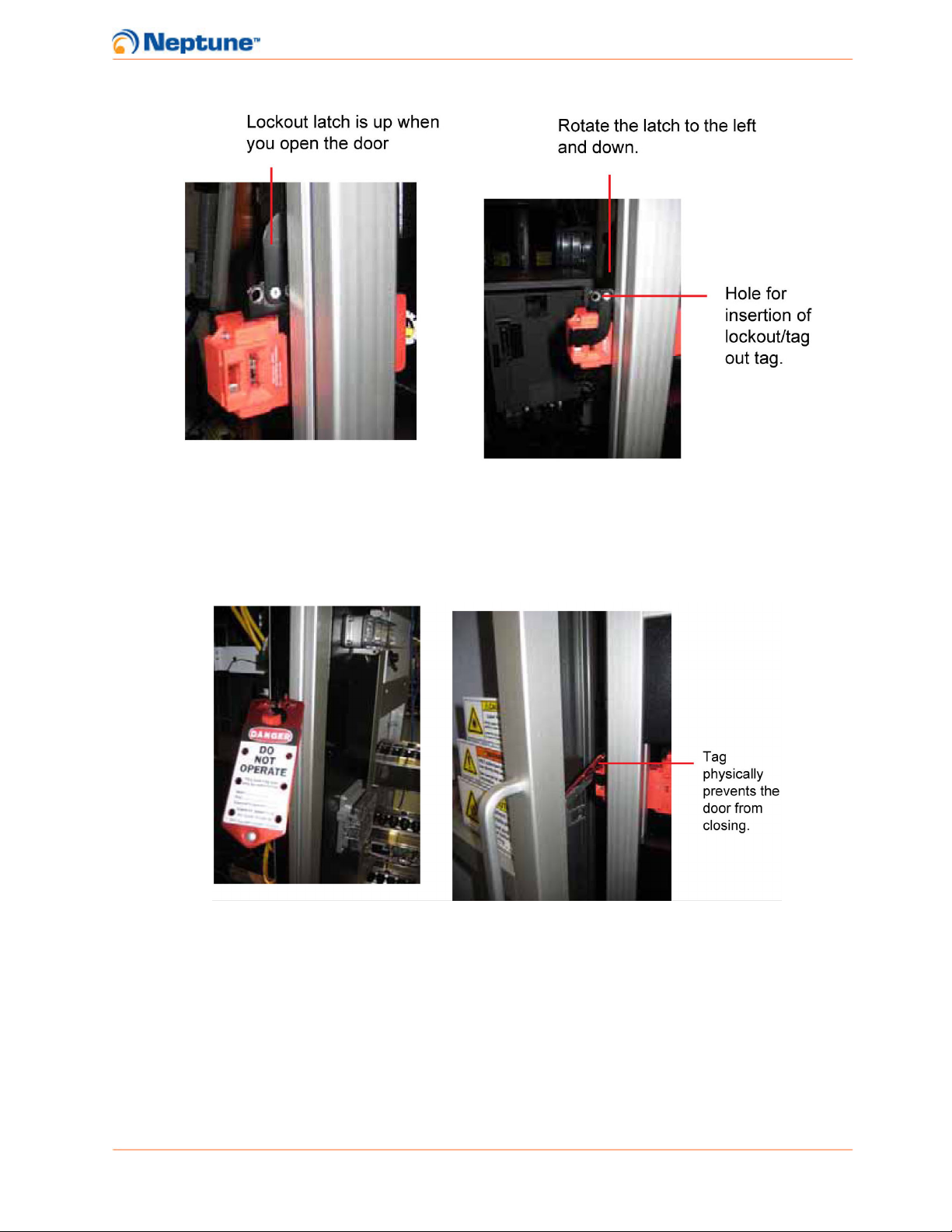

2. Open the service access door and flip down the lockout/tagout latch.

Operator Manual / 2 Entering and Exiting the System

Teradyne Confidential - 16 -

Figure 2-2: Lockout Latch Location

3. Attach the lockout/tagout tag and secure with lock. This will prevent the door

from closing and automation from being restarted while servicing the system.

The robot will remain in safe mode while the system is locked out.

Figure 2-3: Lockout/Tagout Tag in Use

4. If the door locks while an operator is inside of the system, the door can be man-

ually unlocked by flipping the override switch.

Note: It is not necessary to flip this switch when entering the system under normal

circumstances.

Operator Manual / 2 Entering and Exiting the System

Teradyne Confidential - 17 -

Figure 2-4: Manual Override Latch Positions

2.3 Exiting the System and Restarting Automation

1. Once the servicing tasks have been completed, inspect the atrium for tools,

parts or other materials that may have been left behind. Verify that all materials

have been cleaned up and the atrium has been restored to its operating state.

2. If the robot was moved during service, verify that the End-of-Arm Tool (EOAT) is

in a safe position to restart automation. The EOAT should be facing either one

of the racks or feeder approximately one foot from its face. The KUKA Control

Panel (KCP) should also be placed back into automatic external mode.

3. Remove the lockout/tagout tag and flip the latch into the up position.

Figure 2-5: Lockout Latch in Upright Position

4. Firmly close the door and verify that the manual override latch is in the locked

position.

Table of contents

Other Teradyne Test Equipment manuals