3

Table of contents: Page

1TECHNICAL INFORMATION ....................................................................................................................... 4

1.1 MAX K160S .............................................................................................................................................. 4

1.2 AIR HOSE.................................................................................................................................................... 4

1.3 MAX-LUBRICATOR....................................................................................................................................... 4

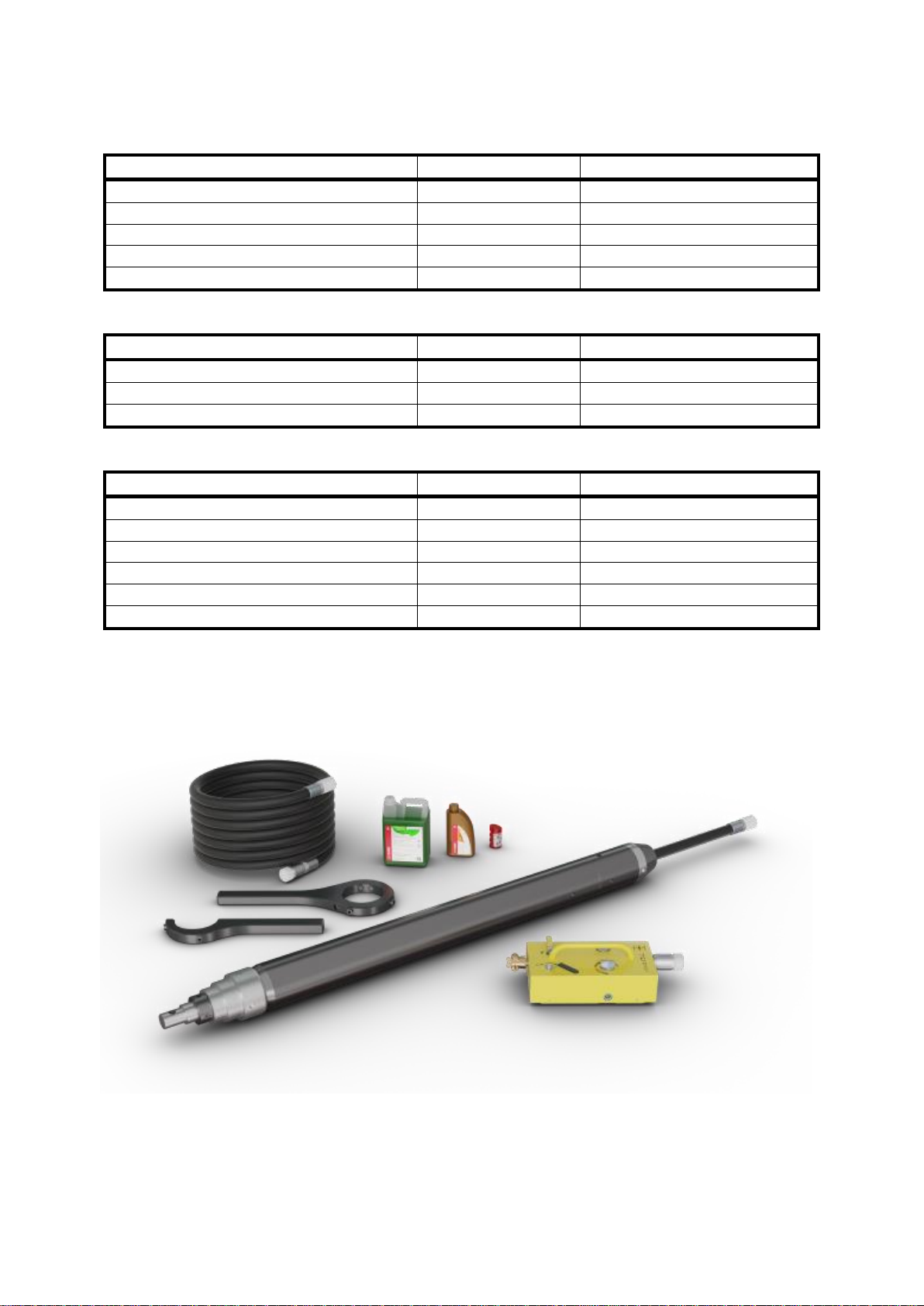

2ACCESSORIES ............................................................................................................................................ 5

3SAFETY INSTRUCTIONS ............................................................................................................................. 7

3.1 WARNING SIGNS:......................................................................................................................................... 7

3.2 PROHIBITORY SIGNS:..................................................................................................................................... 8

3.3 MANDATORY SIGNS:..................................................................................................................................... 8

4USE OF MAX K160S................................................................................................................................... 9

5OPERATION PRINCIPLE ............................................................................................................................. 9

6CONSTRUCTION...................................................................................................................................... 10

6.1 MAX K160S ............................................................................................................................................ 10

6.2 AIR PRESSURE HOSE .................................................................................................................................... 11

6.3 MAX-LUBRICATOR WITH REVERSING MECHANISM........................................................................................... 12

7TRANSPORTATION.................................................................................................................................. 13

8PREPARATIONS BEFORE USE................................................................................................................... 14

8.1 GENERAL INSTRUCTIONS.............................................................................................................................. 14

8.2 STARTING PIT............................................................................................................................................. 14

8.3 TARGET PIT ............................................................................................................................................... 15

9INSTRUCTIONS........................................................................................................................................ 15

9.1 SAFETY INFORMATION................................................................................................................................. 15

9.2 CONVERT THE MAX K160S......................................................................................................................... 15

9.3 CONNECTING THE AIR HOSE......................................................................................................................... 17

9.4 FUNCTIONS OF THE LUBRICATOR ................................................................................................................... 18

9.5 ALIGNMENT OF THE MAX K160S ................................................................................................................. 18

9.6 SOLO-BORING ........................................................................................................................................... 19

9.7 REVERSING MAX K160S ............................................................................................................................ 20

9.8 MANUAL PULLING OF PLASTIC PIPES ............................................................................................................... 21

9.9 DIRECT INSTALLING PE/PVC PIPES................................................................................................................ 21

9.10 INSTALLING STEEL PIPES (RAMMING-JACKING).................................................................................................. 22

9.11 CLEANING OF STEEL PIPES AFTER RAMMING ..................................................................................................... 23

9.12 EXPANDING DRILL HOLE WITH WIDENING ACCESSORIES. ..................................................................................... 25

9.13 INSTALLING OF PIPES MM WITH EXPANDERS..................................................................................................... 26

9.14 AFTER CARE .............................................................................................................................................. 27

10 MAINTENANCE ................................................................................................................................... 27

10.1 DAILY INSPECTION ...................................................................................................................................... 27

10.2 WHEN MAX HAS NOT BEEN IN USE FOR A WHILE.............................................................................................. 28

10.3 TECHNICAL INSPECTIONS.............................................................................................................................. 29

11 TROUBLESHOOTING............................................................................................................................ 30

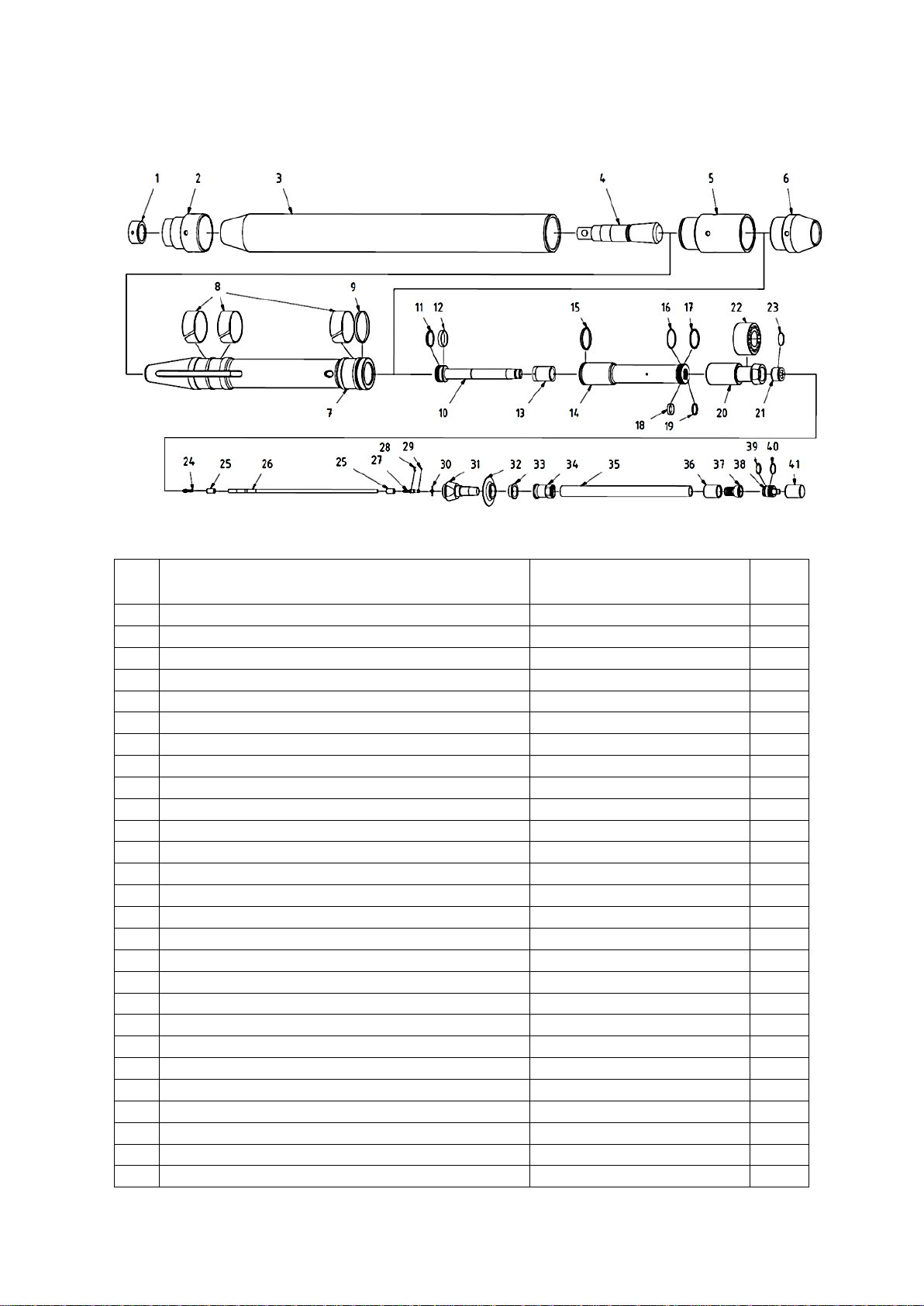

12 SPARE PARTS ...................................................................................................................................... 32

12.1 MAX K130S –MOLE SPARE PARTS LIST ......................................................................................................... 32

12.2 PNEUMATIC AIR HOSE 20 M SPARE PARTS LIST ................................................................................................. 34

12.3 LUBRICATOR WITH REVERSING MECHANISM..................................................................................................... 36