TerraKing 45-0582 User manual

PRINTED IN USA FORM NO. 3-177 (02/25/22)

45-0582

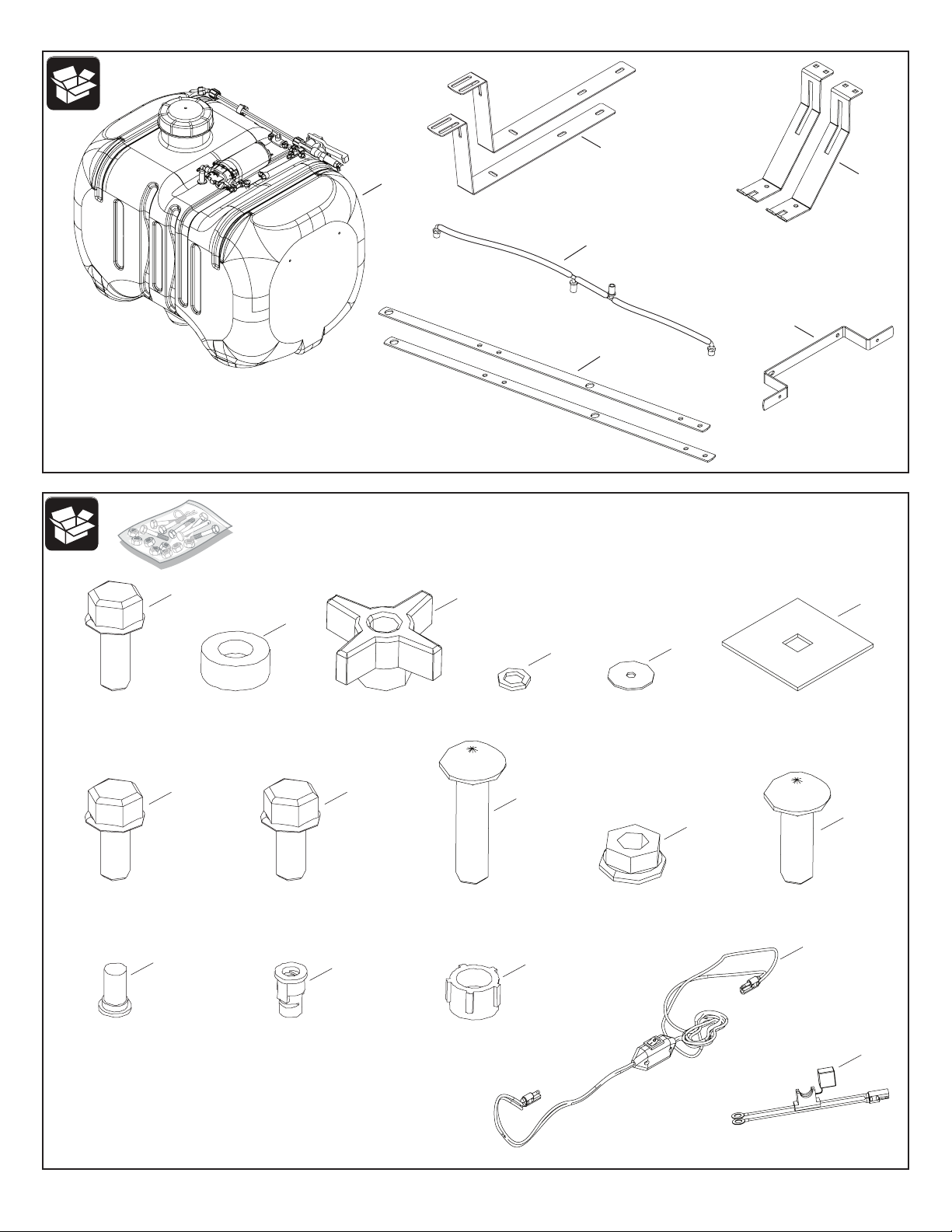

2

1

2

4

6

3

ST44023

ST43493

ST43494

ST62006

ST43495

A

2x B

8x

C

4x

D

4x

E

2x

F

2x

M

3x

L

3x

K

4x

J

6x

I

4x

N

3x

O

1x

P

1x

ST65005 ST65006

ST43016 ST43410 ST43012

ST43472

ST43483

ST65004 ST65003 ST43506ST43289ST43176

ST65014

G

4x

ST65007

H

2x

ST65011 ST65008

5

1

2

4

6

3

ST44023

ST43493

ST43494

ST62006

ST43495

A

2x B

8x

C

4x

D

4x

E

2x

F

2x

M

3x

L

3x

K

4x

J

6x

I

4x

N

3x

O

1x

P

1x

ST65005 ST65006

ST43016 ST43410 ST43012

ST43472

ST43483

ST65004 ST65003 ST43506ST43289ST43176

ST65014

G

4x

ST65007

H

2x

ST65011 ST65008

5

3

3

J

4

C D

E

3

FI

2

I

D

4

N

M

L

C

5

5

6

J

3

K

6

H

3

G

B

A

2

B

J

1

Tighten to no more

than 7.5 ft lbs

4

8

Recirculation Valve

Boom Valve

ENGLISH

SAFETY

1. Read this owners manual and the vehicle owners manual before

using this sprayer.

2. Never allow children to operate this sprayer.

3. Do not allow anyone to ride on or sit on this sprayer.

4. Keep the area clear of all persons, especially small children.

5. Read the chemical label before handling or mixing chemicals.

6. Wear eye and hand protection and protective clothing when

handling and applying lawn chemicals.

7. Always release pressure in the system before lling, cleaning, or

servicing the sprayer.

8. Liquid spray material is recommended. Sprayer does not agitate

wettable powders.

9. Do not spray on windy days.

10. Stop sprayer when tank is empty.

11. Be aware of your vehicle's capabilities. The 45 gallon sprayer

weighs 45 lb (20 kg) empty and 420 lb (191 kg) full.

12. Attaching this sprayer may aect your vehicle's braking and

stability.

13. STAY OFF STEEP SLOPES. Refer to the vehicle owner's manual

concerning safe operation on slopes.

14. Operate at reduced speed on rough terrain, along ditches, and on

hillsides to prevent loss of control.

15. Stopping distance increases with speed and weight. Travel slowly

and allow extra time and distance to stop.

ASSEMBLY

The meanings of symbols used in the illustrations are as follows:

Do not overtighten. Tighten now.

OPERATION

CAUTION: Connect to a 12 V battery only.

PUMP PRESSURE SWITCH

The pump pressure switch turns o the pump when it reaches

its maximum pressure setting. Very low ow demand may cause

the switch to rapidly cycle the pump on and o. Rapid on and o

cycling must be limited to no more than 6 times per minute. Cycling

could cause the motor to heat beyond the recommended maximum

temperature and reduce the operational life of the pump and pressure

switch.

SPRAYER CONTROLS

Boom ON-OFF valve shuts o the ow to the boom nozzles.

ADJUSTABLE SPRAY WAND NOZZLE

Twisting the nozzle will adjust the spray pattern from a cone shaped

mist to a solid stream.

SPRAYER RECIRCULATION

1. The sprayer is equipped with a recirculation valve to aid in material

agitation and pressure control.

2. This valve is in the “open” position when the valve handle is in line

with the hose, “closed” when perpendicular to the hose.

3. Adjusting the recirculation valve between the open/closed positions

will aect the pressure coming through the spray wand.

4. Closed position is full pressure through spray wand.

5. It may be helpful to adjust the pressure when spraying with the

spray wand to avoid damage to plants from excess pressure.

BEFORE STARTING

1. Connect the wire harness from the switch to the pump.

2. Check for leaks using plain water. Fix leaking ttings with thread

tape.

CAUTION: Wear eye and hand protection and protective

clothing when handling and working with lawn chemicals.

PO

7

Install part ST43509 here (Optional)

Install part ST43509 here (Optional)

5

CHECKING MACHINE GROUND SPEED

1. Check ground speed in an open area.

2. Measure a test area that is 30.5 m (100 ft) in length.

3. Operate machine at a low speed and drive the machine the test

distance. Record the time needed to travel that distance.

4. Make three passes, recording the time for each pass. The average

time should be 23 seconds to achieve the recommended operating

speed range.

5. The recommended operating speed is 4.8 km/h (3 mph). At this

speed, the average time traveling the test distance should be 23

seconds.

6. Adjust accordingly to achieve recommended speed range.

GENERAL SPRAYING INFORMATION

The 45 Gallon Sprayer operates at a xed pressure of 620 kPa

(90 psi).This yields 29 minutes of spraying time using the spray

boom or 68 minutes of spraying time using the sprayer wand. When

operating the spray boom, plan on driving about 4.8 km/h (3.0 mph)

or 80 m/min. (264 fpm). That provides 7063 m

2

(76,032 sq ft) of spray

coverage per tank. Plan on about 10 percent overlap, so put enough

chemical in the tank for 6363 m

2

(68.500 sq ft) of spray coverage.

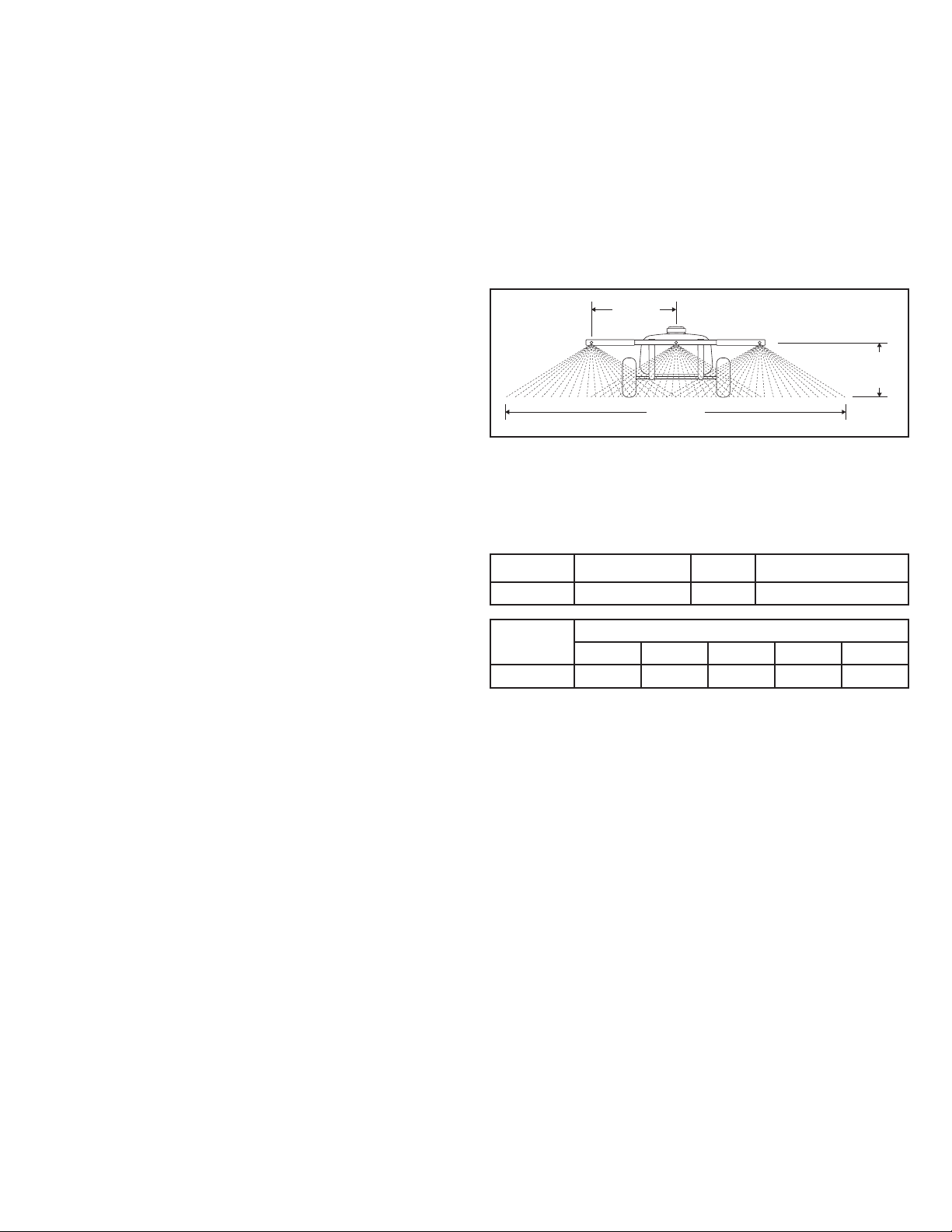

ADJUSTING TIP SPRAY PATTERN

1. Check spray tips:

• Center spray tip should be aligned with boom, and spray

straight back from boom.

• Outer two spray tips should be angled out 30 degrees, as

shown.

2. If necessary, loosen spray tip cap nut. Align spray tip and tighten

cap nut.

3. Test spray pattern with water on driveway or sidewalk, and adjust

as necessary. There should be some spray overlap between each

tip and the spray patterns should be consistent.

SELECTING SPRAY WAND OR BOOM NOZZLES

• To use spray wand: Turn boom valve so that it is perpendicular with

hose. You can now use the spray wand for spraying.

• To use sprayer boom: Turn boom valve so that it is perpendicular

with hose. Turn pump on and operate spray wand to remove all

air from hose. After spray wand sprays liquid, turn pump o. Turn

boom valve so that it is parallel with hose. You can now use the

boom nozzles for spraying.

USING SPRAY WAND

NOTE: Spray wand should only be used when operator is seated.

1. Turn boom valve so that it is perpendicular with hose.

2. Squeeze handle to spray.

3. Push lock forward to lock handle in the on position.

NOTE: Removal of nozzle allows for quick cleaning or rinsing of

sprayer tank.

4. Adjust nozzle:

• Nozzle Angle - Loosen locknut. Turn nozzle as desired and

tighten locknut.

• Nozzle Spray Pattern - To change the spray pattern, tighten or

loosen nozzle as desired.

USING THE BOOM SPRAYER

1. Determine the application rate (gallons per 1,000 sq. feet) based on

the chemical manufacturers recommendations.

2. Estimate the size of the area to be sprayed and the amount of

solution that will be needed. This can help avoid unneeded solution

left in the tank.

3. Refer to the application chart below to help determine the speed

required to achieve the manufacturers recommended application

rate.

4. Use plain water to set the correct boom spraying pressure. Turn

the boom valve to the ON position. If misting occurs, gradually start

closing the valve until misting stops.

5. Add the chemical solution to the tank, following the manufacturers

recommendations.

67 in.

170 cm

20 in.

51 cm

24 in.

61 cm

6. Begin spraying, making each pass so that the spray pattern slightly

overlaps the spray pattern from the previous pass.

7. Stay clear of owers, shrubs, and evergreen trees when spraying to

prevent contact of the solution with these sensitive plants.

APPLICATION CHART

Sprayer Tip Size PSI GMP One Nozzle

45 Gallon TF-VP3 30 0.52

Sprayer Gallons per 1000 Sq. Ft.

2 mph 3 mph 4 mph 5 mph 6 mph

45 Gallon 1.8 1.2 0.88 0.71 0.59

MAINTENANCE

AFTER EACH USE

1. Fill the tank part way with water and pump the water out through

the boom assembly and the spray gun. Use the spray gun to wash

the inside of the tank.

2. Rell the tank about half full with water and a chemical neutralizer

solution and repeat the cleaning instructions above. Follow the

manufacturers instructions for disposal of all chemicals.

AS NEEDED

1. Periodically clean the tank strainer on the end of the intake hose.

Remove the nylon swivel nut from the hose, pull out the screen,

and ush it with water.

2. Periodically clean the strainers in the boom nozzles. Remove the

nozzle, pull out the screen, and ush it with water.

WINTER STORAGE

1. Drain all water out of the sprayer, especially the pump and spray

gun. These items are prone to damage from freezing temperatures.

2. Winterize the sprayer by pumping a 50-50 solution of water and

R.V. antifreeze through the boom assembly and the spray gun.

6

45-0582

38

5

41

6

46

52

15

30

7

51

49

4

45

31

8

47

9

10

16

49

14

24

1

36

48

29

27

26

32

33

28

47

35

20

13

11 11

29 50

2

34

3

36

25

3

44

43

37

26

49

12

2

21

22

23

25

28

33

42

6

40

39

7

45-0582

the fastest way to purchase parts

www.speedepart.com

REF.

NO.

PART

NO.

QTY. DESCRIPTION

1 ST44023 1 45 Gallon Tank

2 ST43495 2 Boom

3 ST43176 8 Rubber Bumper

4 ST43918 1 Pump 12v, 100psi, 2.2GPM

5 2-340 1 Hose, 3/8" x 20'

6 ST43014 2 In-Line Valve 3/8" Barbed

7 ST43235 1 Tee 3/8" Barb - 3/8" Barb

8 ST43258 1 Sump Strainer 3/8"

9 ST43182 1 Sump Fitting 3/8" Barb

10 ST43183 1 Elbow 3/8" Mp - 3/8" Barb

11 ST43192 2 3/8 Barbed Tee, W/ Nut

12 ST43011 2 3/8" Elbow Fitting W/ Nut

13 ST43499 1 3/8" Barb Fitting For Wing Nut

14 ST43175 1 Tank Fill Cap

15 ST43287 1 Spray Wand Holder, Large

16 ST43130 1 Spray Wand Holder, Small

20 ST43498 1 Plastic Wing Nut

21 ST43016 3 Spray Tip Screen

22 ST43410 3 Spray Tip TF-VP3

23 ST43012 3 Tip Fitting Cap Nut

24 ST43516 1 Drain Cap

25 ST43493 2 Tank Support

26 ST43494 2 Boom Support

27 ST43506 2 Square Washer 2"

28 ST43289 4 3/8 Plastic Knob

29 ST65005 4 3/8 X 1-1/2 Carriage Bolt

30 ST65000 2 #10-24 X 3/8" Truss Head

31 ST65001 4 #10-24 X 1" Truss Head

REF.

NO.

PART

NO.

QTY. DESCRIPTION

32 ST65003 2 3/8" Washer

33 ST65004 4 3/8" Lock Washer

34 ST65014 2 5/16 X 1 Flange Bolt

35 ST65006 4 5/16 X 3/4 Carriage Bolt

36 ST65008 6 5/16 Flange Nut

37 ST65007 4 5/16 X 3/4 Flange Bolt

38 ST43652 12 Hose Clamp, 3/8" – 1/2"

39 ST43472 1 Switch Wire Harness

40 ST43483 1 Battery Wire Harness

41 ST43673 1 Spray Wand W/ Tip

42 ST43013 1 3/8 Barbed, Tee

43 ST62006 1 Hose Wrap Bracket

44 ST65011 2 5/16-18 X 5/8" Flange Bolt

45 ST43191 1 Hose Holder 3/8"

46 ST43844 2 Grommet 5/8 ID, 1-1/8 OD, 7/8

47 2-314 1 Hose, 3/8" x 22"

48 2-323 1 Hose, 3/8" x 48"

49 2-318 3 Hose, 3/8" x 12"

50 2-319 1 Hose, 3/8" x 8.5"

51 2-342 1 Hose, 3/8" x 3.25"

52 2-321 1 Hose, 3/8" x 6.5"

- ST43684 1 Washer For Drain Cap*

- ST44017 1 Lanyard For Tank Fill Cap*

- 3-70 1 Label, Terra-King*

- ST43523 1 Label, 45 Gallon*

- ST43488 1 Label, Warning - Chemical Hazard*

- ST43509 1 Wire Harness Extension 8'*

- 3-177 1 Owners Manual*

* Not Shown

ADDITIONAL SERVICE PARTS

PART

NO.

DESCRIPTION

ST43921 Pump Head 2.2 GPM, 100 PSI

ST44032 Pressure Switch 80 PSI

ST50749 15a ATO/ATC Fuse

ST43124 Spray Wand Valve

ST43514 Spray Wand Brass Tip

ST43515 Spray Want Extension

REPAIR PARTS

Agri-Fab, Inc.

809 South Hamilton

Sullivan, IL. 61951

800-448-9282

www.agri-fab.com

the fastest way to purchase parts

www.speedepart.com

© 2022 Agri-Fab, Inc.

This document (or manual) is protected under the U.S. Copyright Laws and the copyright laws of foreign countries, pursuant to the Universal

Copyright Convention and the Berne convention. No part of this document may be reproduced or transmitted in any form or by an means,

electronic or mechanical, including photocopying or recording, or by any information storage or retrieval system, without the express written

permission of Agri-Fab, Inc. Unauthorized uses and/or reproductions of this manual will subject such unauthorized user to civil and criminal

penalties as provided by the United States Copyright Laws.

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions