Terratek TDP13 User manual

User Manual - Please

read and retain for future

reference.

See page 1

Guide d’utilisation

– Veuillez lire et

conserver ceguide

pour vous y reporter

ultérieurement.

Voir page 16

Manual del usuario –

Por favor lea este

manual y guárdelo para

referencia futura.

Ver la págeina 29

5 Speed Drill Press

Perceuse à colonne à 5 vitesses

Prensa Taladradora con 5 Velocidades

TDP13

227541

Exploded Assembly Diagram

Vue éclatée

Dibujo despiezado del conjunto

NOTICE: Actual product may vary from pictures shown.

NOTIFICATION: Le produit réel peut varier des images montrées

AVISO: El producto real puede variar de los cuadros mostrados.

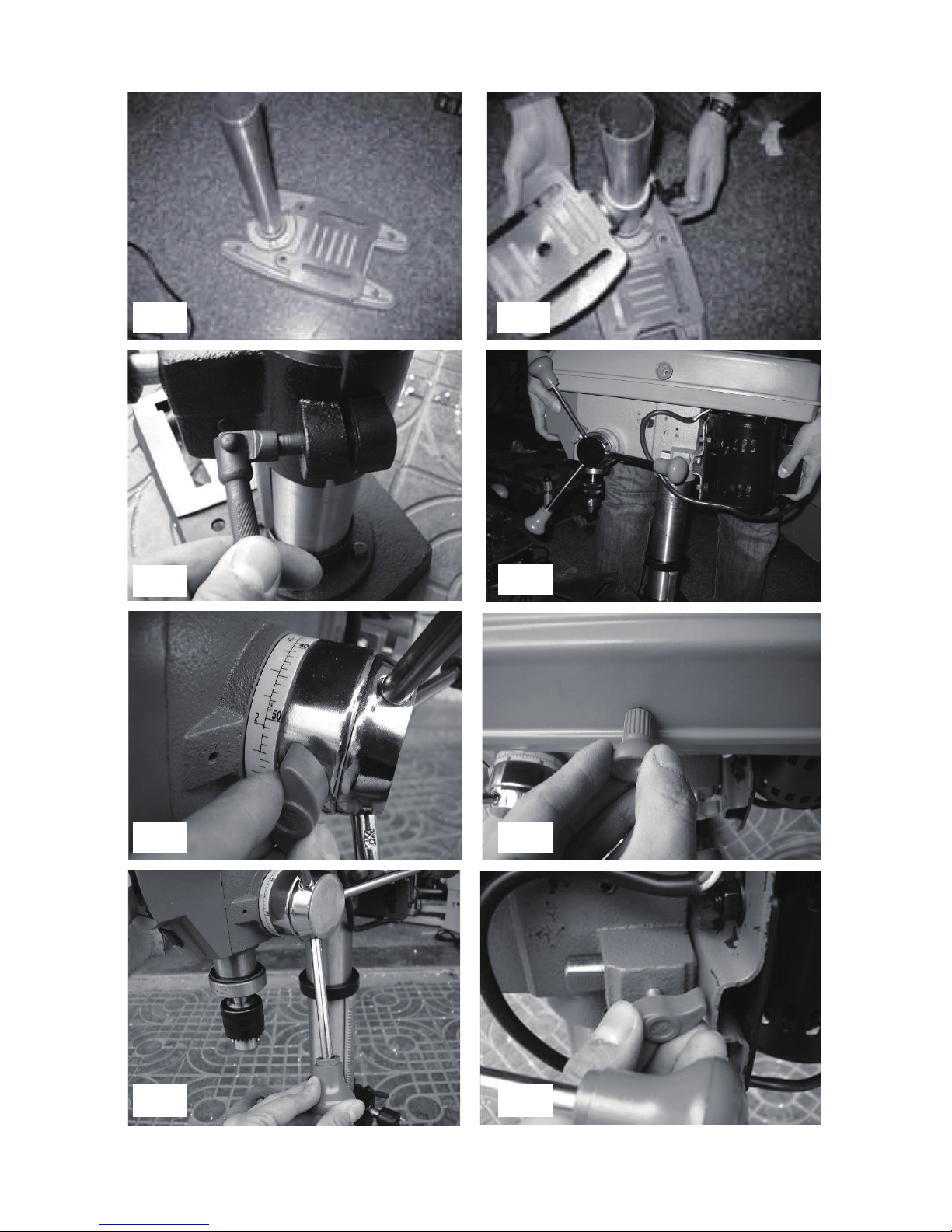

Fig.1 Fig.2

Fig.3 Fig.4

Fig.5

Fig.7

Fig.6

Fig.8

1

Contents

Parts List

Technical Spec.

Safety Instructions

Assembly

Using drill press

Maintenance

Warranty

Parts List

1 Base 32 Washer 4

2 Column Support 33 Switch board

3 Washer 8 34 Nut M10×1

4 Elastic washer 35 Spring cover

5 Bolt M8×20 36 Spring cap

6 column 37 point

7 screw 38 Limit bolt

8 Nut M8 39 Gauge seat

9 Allen hex head bolt 40 Nut M6

10 Locking knob 41 Transformer

11 Gear shaft 42 LED light

12 Handle bar 43 Clamping handle

13 Knob 44 Base

14 spring 45 rivet 2×3

15 Slide bar 46 Angle label

16 Damping pad 47 Work table

17 Rubber pad 48 Bolt M12×25

18 Screw M6×12 49 Elastic washer

19 Washer 6 50 chuck

20 Bolt M8×18 51 spindle

21 Motor pulley 52 Ball bearing

22 Screw M6×10 53 Spindle sleeve

23 V-belt K-660 54 Rubber gasket

2

24 Knob 55 Retaining Ring 12

25 Pulley cover 56 Retaining Ring 40

26 eyeglass 57 Spindle sleeve

27 Power cord 58 Ball bearing

28 Toggle switch 59 Retaining Ring

29 Little switch 60 Spindle pulley

30 Take-up 61 Machine body

31 Screw M4×10 62 Induction motor

3

Technical Information

Voltage: 120V ~ 60Hz

Power: 2.4 amp

Speed: 760 to 3070 RPM

Max Spindle Travel: 2” (50mm)

Chuck Size: ½” (13mm)

Drilling Capacity: ½” (13mm)

Chuck to Table Max. Distance: 9-1/2”

Chuck to Base Max. Distance: 14”

Table Size: 7” Square

Table Adjustment: 0/45 Deg. Tilt (left & right)

360 Degrees Swivel.

Net Weight: 36/40 lbs

Copyright© 2012 by ACL Group Ltd. All rights reserved. This manual or any

artwork contained herein must not be reproduced in any shape or form without

the express written consent of ACL Group Ltd. Diagrams within this manual may

not be drawn proportionally. Due to continuing improvements, actual product

may differ slightly from the product described herein.

Read this entire manual before using this product.

Failure to do so can result in serious injury. Save this manual

for future reference.

4

Read and Keep This Manual

Important SAFETY Information

General Safety Rules

Please read carefully all instructions within this manual. Failure to follow all safety

warnings can result in serious personal injury. The term “Power Tool” in all of the

following warnings refers to your main operated (corded) or battery operated (cordless)

power tool.

WARNING! Read all instructions. Failure to follow all instructions listed below may

result in electric shock, re and/or serious injury. The term “power tool” in all of the

warnings listed refers to corded or cordless power tools.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Before use, ensure that the power outlet you are using matches the plug on your

power tool and that the voltage of the outlet matches that of your power tool.

Only use grounded extension cords with power tools tted with 3 pin plugs and if using

outdoors ensure any extension cord is suitable for outdoor use.

Always try to avoid body contact with grounded surfaces, such as radiators, cooking

ranges and any other xed appliance with metal surfaces.

Do not expose your power tool to wet or damp conditions and NEVER use in rain.

Check regularly the power cord of your machine and any extension cord that you are

using for damage.

Do not carry or pull the machine with the power cord.

Ensure the cord is clear from hot surfaces, oil or sharp objects.

This symbol is to warn you of potential personal

injury hazards. Please read carefully the notes along side this

warning to avoid possible injury or death.

5

Personal safety

Never use your machine whilst under the inuence of alcohol, drugs or medication.

Tiredness can often cause accidents, stay alert.

Never use your machine without the correct guards in place.

Always use ANSI approved eye protection and dust mask. Non slip safety shoes and

hearing protectors should be worn at all times when using your power tool.

Ensure any dust collecting device supplied with your machine is connected correctly

before use.

Ensure all loose clothing, long hair or jewelry is kept clear of the machine.

Before plugging your machine into the power outlet ensure the machine is in the OFF

position and that all blades and accessories being used are secure.

Check that wrenches or adjusting keys have been removed. Any wrench or key left

attached to a moving part can result in injury.

Power tool use and care.

Keep your machine clean and well serviced at all times.

Never adjust or service any power tool before disconnecting from the mains electricity

supply.

Always use the correct tool for the job.

Never force the tool to work harder than it is designed to do.

Never use your machine with broken parts such as switches, guide fences or leg

stands.

ALWAYS keep your power tools away from children.

Keep cutting tools sharp to ensure less stress on the motor.

Replace damaged or dull cutting tools.

Only have your power tool serviced by a qualied repair agent using manufacturers

recommended parts.

Service

Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is

maintained.

Develop a periodic maintenance schedule for your tool. When cleaning a tool

be careful not to disassemble any portion of the tool since internal wires may

be misplaced or pinched or safety guard return springs may be improperly

mounted. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia,

etc. may damage plastic parts.

When servicing a tool, use only identical replacement parts. Follow instructions

in the Maintenance section of this manual. Use of unauthorized parts or failure to

follow Maintenance Instructions may create a risk of electric shock or injury.

WARNING: For your own safety read Instruction Manual before operating your power

tool.

6

A) Wear eye protection.

B) Keep hands out of the path of blades/cutters.

C) Do not operate tool without guards in place.

D) Do not perform any operation freehand.

E) Never reach around cutting tools.

F) Turn off tool and wait for blade/cutter to stop before moving workpiece or changing

settings.

G) Disconnect power (or unplug tool) before changing blade/cutter or servicing.

GENERAL SAFETY INSTRUCTIONS

Read this owner's manual completely and make sure you understand all of its

safety guidelines.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS & WRENCHES. Before turning on the power tool,

make sure the keys and adjusting wrenches have been removed.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. ALWAYS REMAIN ALERT WHEN THE TOOL IS IN USE. Inattention on the part of

the operator may lead to serious injury.

5. DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations or expose them to rain. Keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors should remain at a safe distance from work

area.

7. MAKE WORKSHOP CHILD-PROOF with padlocks, master switches or by removing

starter keys.

8. USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was

not designed.

9. USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. Table (see Table 1) shows the

correct size to use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

10. DON’T FORCE THE TOOL. It has been designed to operate at maximum safety

and performance levels.

11. DO NOT FORCE THE MATERIAL BEING CUT. Always let the tool cut at its own

speed.

12. WEAR PROPER APPAREL. Do not wear loose clothing, neckties, rings,

bracelets or other jewelry which may get caught in moving parts. Non-slip foot wear

is recommended. Wear protective hair covering if you have long hair.

13. ALWAYS USE SAFETY GLASSES. Also use face or dust mask for commercial

cutting operations. Everyday eyeglasses only have impact-resistant lenses, they

are NOT safety glasses.

7

14. SECURE WORK. Use clamps or a vise instead of your hand to hold work. This

safety precaution allows for proper tool operation using both hands.

15. DON’T OVERREACH. Keep proper footing and balance at all times.

16. MAINTAIN TOOLS WITH CARE. Keep tools clean and in good working condition

for maximum safety performance. Follow instructions for lubricating and changing

accessories.

17. DISCONNECT TOOLS BEFORE SERVICING – when changing accessories, such

as blades, bits, cutters, etc.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in

OFF position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for

recommended accessories. The use of improper accessories may increase risk of

injury.

20. MAKE SURE YOU USE THE CORRECT TOOL for the job you are doing.

21. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

22. CHECK DAMAGED PARTS. Before further use of the tool, damaged part(s),

(i.e., guard) should be carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and any other condition that may affect

the tools operation. A guard or other part that is damaged should be properly

repaired or replaced.

23. Replace damaged blades/cutters/ grinding wheels immediately. DO NOT USE

DAMAGED BLADES/CUTTERS/GRINDING WHEELS. They may cause bodily

injury.

24. DIRECTION OF FEED. Feed work into the blade/cutter against the direction of

rotation of the blade/cutter only.

25. DO NOT ALTER THE PLUG OR USE A 2-PRONG RECEPTACLE. This tool is

equipped with a 3-prong electrical plug.

26. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off. Don’t leave tool

until it comes to a complete stop.

27. Double insulated tools (one blade is wider than the other) are equipped with a

polarized plug. This plug will t in a polarized outlet only one way. If the plug does

not t fully in the outlet, reverse the plug. If it still does not t, contact a qualied

electrician to install a polarized outlet. Do not change the plug in any way. Double

Insulation eliminates the need for the three wire grounded power cord and

grounded power supply system.

This machine is supplied with all the relevant safety guards and features, it should be

checked before every operation, this manual should be read and kept in a safe place.

Whilst we warn you all the possible risks attached to using power tools any operator

must have read and understood the manual and apply their own caution and common

sense when using this machine.

Following this guide will greatly reduce your risk of electric shock or injury.

8

Only use qualied repair agents to service this machine.

Only use qualied electrician to repair any damaged wiring.

NEVER remove the grounding prong from the power toll or extension cord.

Grounding Tools

Electrical Powered Connections

Grounding Instructions

Any electric powered tool that is marked “Ground Required”, must be grounded. In the

event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. Any product that is equipped with

an electric cord having an equipment-grounding conductor and a grounding plug, the

plug must be plugged into a matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not t the outlet, have the proper outlet

installed by a qualied electrician.

Check with a qualied electrician or service personnel if the grounding instructions

are not completely understood, or if in doubt as to whether the product is properly

grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 V circuit and has a grounding plug similar to

the plug illustrated in Table1. Only connect the product to an outlet having the same

conguration as the plug. Do not use an adapter with this product.

3-Prong Plug and Outlet

Any electric powered tool that is marked Ground Required must have tted a three

wired power cord. The main importance of this is the green wire within the cord,

this green wire must at all times be connected to the grounding prong of the plug.

This prong must never be removed or discarded. The green wire Must NEVER be

connected to any other prong. The Three prong plug must only be connected to the

power supply through a three prong power outlet.

The Illustration above shows a three prong plug and outlet.

9

Double Insulated Power Tools

Plug and outlet, 2 prong

Outlets for 2-Prong Plug

Any electric powered tool that is marked Double insulated only need a two prong

connection and will be perfectly safe to operate.

These tools do not require grounding as they are tted with an additional insulation

system internally that complies with all relevant electrical safety standards.

Unlike the three prong tools these tools CAN be connected through outlets suitable for

two prong or three prong plugs.

The Illustration above shows the outlets that this type of tool can be connected to.

Power Extension Cords

Any power tool marked ‘Grounding required’ MUST only be connected to a three wire

extension cord. Only double insulated tools can be connected to two wire cords.

When using any extension cord the machine will suffer a power reduction due to

the drop in voltage caused by the length of the cord. This can be partially offset by

selecting extension cords with lower gauge wire.

MINIMUM GAUGE FOR CORD SETS

Total Length of Cord in Feet(Meter)

0-25 26-50 51-100 101-150

(0-7.6) (7.9-15.2) (15.5-30.5) (30.8-45.7)

Ampere Rating

AWG

4161618160

18 16 14 12

16 16 14 12

14 12 Not Recommended

6 10

10 12

12 16

More Not More

Than Than

Table 1

e.g. Cords marked 14 gauge can carry a higher current than cords marked 16 gauge

therefore when linking extension cords make sure each cords wire gauge matches.

10

Note: Outdoor extension cords used in must carry the letters “W-A” (USA) or “W”

(Canada)

Check all extension cords for damage before use.

Avoid sharp objects.

Do not position the cord where it could be subject to trafc passing over it.

Symbols

IMPORTANT: Some of the following symbols may be used on your tool.

V…………………………volts

A…………………………amperes

Hz………………………..hertz

~…………………….…...alternating current

…/m……………….........revolutions per minute

..................................class II construction (double insulated)

Kg………………………..kilograms

n0………………………...No load speed

..........Conforms to relevant safety standards

DC ………………..…Direct Current

Unpacking

Carefully remove the product and any accessories from the box. Make sure that all

items listed in the packing list are included.

Package contents

A) Drill press

B) Base

C) Column

D) Table

E) Handles

F) User manual

Functional Description

WARNING:Disconnect the plug from the power source before making any assembly,

adjustments or changing accessories. Such preventive safety measures reduce the

risk of starting the tool accidentally.

Assembly

Installing column to base

1. Bolt the column assembly to the base with the three hex screws provided. (Fig.1)

NOTE: Ideally, the base with column attached, should be rmly bolted to a

workbench, prior to the assembly of other components.

11

Installing the work table

1. Thread the Table Locking Handle into the Table Clamp, and leave it loose at this

stage.

2. Slide the Table Clamp with Table over the Column put at desired height and tighten

locking handle. (Fig.2)

Installing the drill press head

1. With assistance, raise the Head, and locate it on top of the Column, ensuring it

slides home fully (Fig.4).

2. Align the head with the base, and rmly secure to the Column with the hex socket

Head Screws.

3. Tighten the two head locking screws with the Allen wrench provided.

Installing handles

Screw the three feed handles rmly into the hub of the feed shaft. (Fig.7)

Installing the drill chuck

1. Slide the work table up the column to within 6" of the spindle.

2. Open the jaws of the chuck to their maximum, using the chuck key supplied.

3. Put a piece of scrap wood on to the table to protect the chuck nose.

4. Ensuring all parts are thoroughly clean, dry, and burr free, place the chuck over

the end of the spindle and pull the spindle down using the feed handles, pressing

the chuck hard against the piece of scrap wood until the chuck is forced home.

Replacing drill bits

1. Use the chuck key provided to loosen the drill chuck.

2. Insert drill bit into chuck all the way up into chuck.

3. Depending on the drill size bring the drill bit out until the whole ute is showing.

4. Tighten by hand until drill bit is centered in chuck.

5. Once centered use chuck key to tighten drill bit.

6. Tighten all three jaws to ensure drill bit is tight so the bit doesn’t slip while drilling.

7. REMOVE chuck key before turning on the drill press.

Mounting the drill press

For your own safety and others around you this drill press should be secured to a

stable work bench, to secure:

1. Place the drill press on the workbench.

2. Secure the drill press onto the workbench using two carriage bolts, at washers, and

nuts through the holes in the base. (hardware not included).

Height adjustment

1. Raise or lower the work table by loosening the table clamp, re-tighten, once at

desired position and height. The work table can also be rotated up to 360 degrees.

(Fig.3)

12

Tilting the work table

1. The worktable can be tilted left or right by loosening the pivot bolt.

2. When returning the table to the level position, line up the register mark with the tilt

scale.

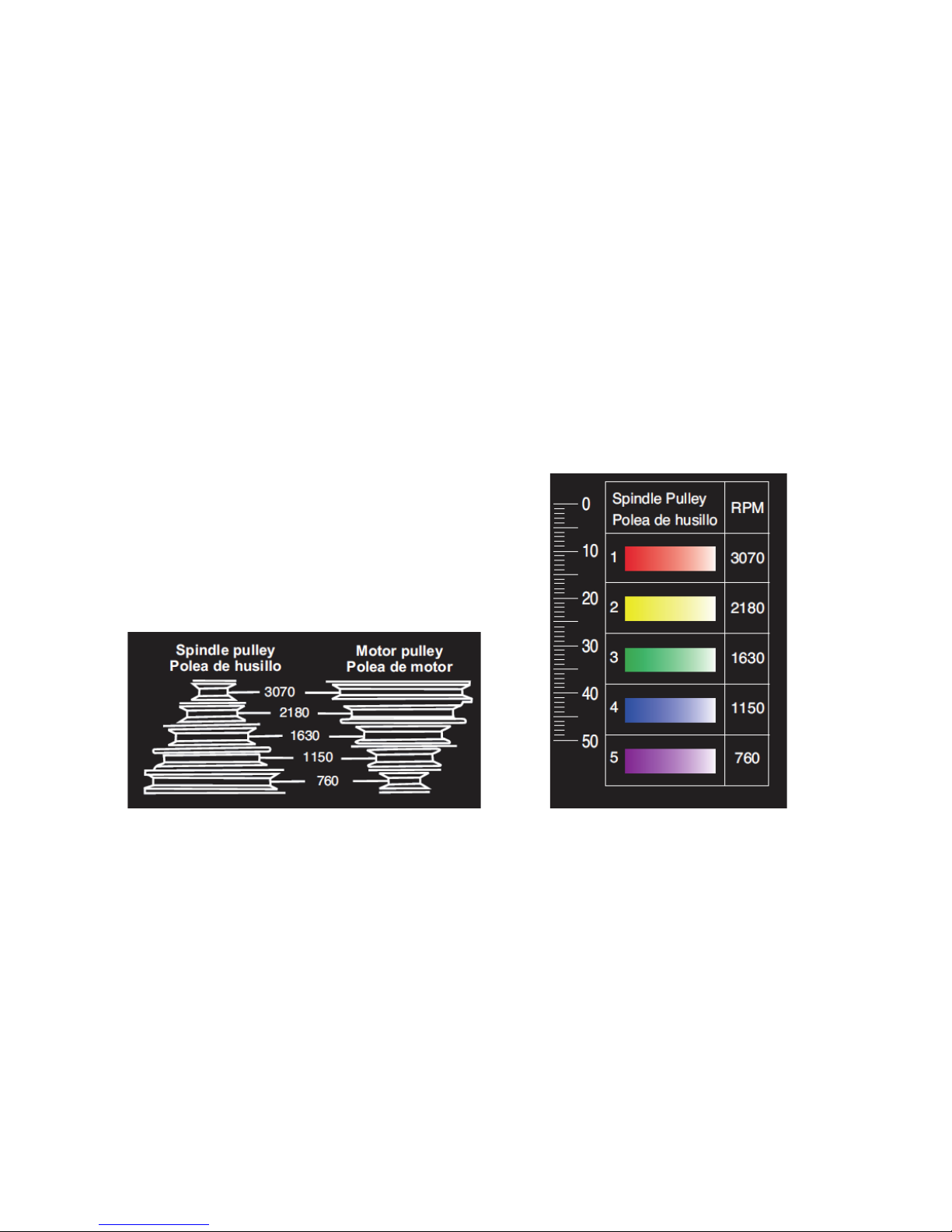

Changing spindle speeds

1. Switch machine off and unplug it.

2. Open the pulley cover. (Fig.6)

3. Undo the Belt Tension Locking Knob (Fig.8) to relieve any tension on the belt, and

referring to the chart, install the belt in the position corresponding to the spindle

speed required.

4. Lever the motor, on its bracket, away from the head, so that tension is applied to the

belt. Tension is correct, when the belt deects by approx. ½” at its centre, when

using reasonable thumb pressure. Lock the motor in this position using the Locking

Knob.

Diag.1

Note:

Tighten the belt only so far that the slippage is eliminated.

A too tight belt will deform during a longer period of rest, which reduces the power of

the motor.

Spindle stop

Your drill press is equipped with a depth stop for drilling multiple holes to a specic

depth.

1. Put drill bit in chuck.

2. Lower the chuck with the power OFF, until the drill contacts the surface of the

work piece, and hold in that position.

3. Turn the stopper nut ring (Fig.5) until the pointer is aligned with the desired depth of

13

the hole required. Tighten the lock nut and lock it.

4. Drill a test hole and make any necessary adjustments.

Secure the tool to a supporting structure before use.

Insert the drill into the jaws of the chuck, ensuring that the jaws do not touch the utes

of the drill. Before tightening the chuck, ensure that the drill is centered within the jaws.

Make sure the table height and position is set so that the drill travel range is sufcient

for the material to be drilled.

Make sure the work is securely clamped. That it is held in a drill vice or bolted to the

table. Never hold the material with your bare hands while drilling. Severe personal

injury can result if the material is ung out of the operator’s hand.

IF THE MATERIAL IS IRREGULARLY SHAPED and cannot be laid at on the table, it

should be securely blocked and clamped. Any tilting, twisting or shifting will result not

only in a roughly drilled hole but also increases the chances of damage to the drill and

personal injury.

FOR SMALL MATERIALS that cannot be clamped to the table, use a drill press vise.

Make sure the vise is clamped or bolted to the table.

WHEN DRILLING COMPLETELY THROUGH WOOD, always position a piece of scrap

wood between the material and the table to prevent splintering on the underside of the

material as the drill breaks through. The scrap piece of wood must be clamped. Also,

set the depth of the drill so that the drill will not come in contact with the table or align

the table so that the hole in its center is in line with the drill bit.

Note: The motor housing may get hot under normal operating conditions

Cutting Speeds

Factors which determine the best speed to use in the drill press operation are:

Type of material to be drilled.

Size of hole.

Type of drill bit.

Finish of the hole desired.

On-Off Switch

Ensure that the switch is in the “OFF” position. If the plug is connected to a receptacle

while the switch is in the “ON” position, the power tool will start operating immediately

and can cause serious injury.

Operation

Always wear eye protection when using this or any other drill press.

Turn on the drill press and wait until it reaches full speed before you start drilling. Use a

clamp or vise to keep the work piece steady. Keep a steady even pressure on the work

piece to avoid burning or dulling of the drill bit. Do not push too hard because this may

overheat the motor and prematurely wear out the drill, work slowly. Obtain a tray with

water and place it next to the drill press to dip your work and keep from overheating or

burning as this will weaken the metal.

14

WARNING: For your own safety, make sure switch is OFF and unplugged from the

power source before doing any maintenance or adjustments. Replace the power cord

immediately if it is cut, worn, or damaged in any way.

WARNING: The use of any other accessories is not recommended because it may

result in serious injury.

Never touch the drill bit while spindle is turning.

Select proper spindle speed and bit for job.

Always remember to remove chuck key before starting.

DANGER: Do not use any drill larger than the stated capacity of the drill press.

Maintenance

WARNING: For your own safety, make sure switch is off and unplugged from the

power source before doing any maintenance or adjustments. Replace the power cord

immediately if it is cut, worn, or damaged in any way.

CLEANING: Regularly clean the work surface with dry brush or clean a cloth. Keep

machined parts of the drill press lightly greased. Always keep the motor and drill chuck

clean.

Prevent metal, wood, dust or other debris from accumulating in this area. If jaws do not

operate smoothly, have the chuck serviced by a qualied technician.

LUBRICATION: For average use, lubricate twice a year with a 20-30 weight household

oil. Lubricate more frequently with increased usage.

POWERCORD: Inspect the power cord periodically and, if damaged, have it repaired

by an authorized technician.

REPLACEMENT PARTS: Replace belts at the rst sign of slippage or fraying. When

servicing, use only identical replacement parts. Use of any other parts will void the

warranty.

STORAGE: Always remove and store drill bits

Accessories

CAUTION: Use only accessories or attachments recommended for use with your

Terratek tool specied in this manual. The use of any other accessories or attachments

might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

General Maintenance

1. Keep the air vents free from obstruction and clean regularly

2. Check regularly for any dust particles entering the grills around the motor and the

trigger switch. Use a soft brush to remove any dust particles. Wear safety glasses

to protect your eyes whilst cleaning.

3. Monitor the dust bag (IF EQUIPPED) and empty when approximately half full.

Always empty into an appropriate container. REMEMBER: dust can be hot and

cause re.

4. If the Blade has become dull, replace it. Dull blades will cause increased tear-out

15

and ragged edges on the cuts.

5. Lubricate all moving parts at regular intervals

6. To clean the body of the power tool, only use a soft damp cloth. Do NOT immerse in

water. A mild detergent can be used but NOT petrol or any alcohol based product.

7. Should the power cord become damaged only allow a fully qualied electrician to

replace or repair

Please read the following carefully

ACL Group Ltd. and/or its distributor has provided the parts list and assembly

diagram as a reference tool only. Neither ACL Group Ltd. or its distributor makes any

representation or warranty of any kind to the buyer that he or she is qualied to do any

repairs or replace any parts of this product. ACL Group Ltd. and its distributor expressly

state that all repairs or parts replacement should be done by certied or licensed

technicians. The buyer assumes all risk and liability arising out of his or her repairs or

parts replacement to the original product.

LIMITED WARRANTY

This product is covered by a two year warranty from the date of purchase. If the

product is defective in workmanship or material and upon returning the product to its

distributor/dealer in its original packaging, the distributor will repair and/or replace it

free of charge. This warranty DOES NOT COVER normal wear, or any damage as a

result of accidents, misuse, abuse or negligence. ACL Group Ltd. obligations under this

warranty shall be limited to the repair and/or replacement of the product. ACL Group

Ltd. is not responsible for direct, indirect, or incidental damages. This warranty is void if

the product or any of its components are modied, altered, or in any way changed, or if

the product is used in a manner or with parts that are not recommended by ACL Group

Ltd. To receive a replacement power tool or requested warranty service, you must

present proof of purchase and return all original equipment packaged with the original

product. The replacement power tool will be covered by the limited warranty for the

balance of the two year period from the date of the original purchase. This warranty

applies only to the original purchaser and cannot be transferred.

16

Contenu

Liste des pièces

Fiche technique

Consignes de sécurité

Assemblage

Utilisation de outil

Entretien

Guarantie

Liste des pièces

1 Socie 32 Rondelle

2 Colonne d'appui 33 Panneau d'interrupteur

3 Rondelle 34 Écrou

4 Rondelle élastique 35 Couvert de ressort

5 Boulon 36 Capuchon de ressorte

6 Colonne 37 Index

7 Vis 38 Circuits légers

8 Écrou 39 Siège de l'indicateur

9 Vis hexagonale (Allen) 40 Écrou

10 Blocage de bouton 41 Transformateur

11 Engranage l'unité 42 Voyant DEL

12 Barre de poignée 43 Mangue de serrez

13 Bouton 44 Socie

14 Ressort 45 Rivet

15 Barre coulissante 46 Étiquette d'angle

16 Coussin de l'amortisseur 47 Table de travail

17 Coussin de gomme 48 Boulon

18 Vis 49 Vis

19 Rondelle 50 Mandrin

20 Boulon 51 Arbre

21 Poulie du moteur 52 Roulement à bille

22 Vis 53 Douille d'axe de rotation

23 Courroie-V 54 Ensemble de gomme

17

24 Bouton 55 Anneau de retenue

25 Poulie couvrir 56 Anneau de retenue

26 Verre de l'oeil 57 Douille d'axe de rotation

27 Câble de courant 58 Roulement à bille

28 Inverseur 59 Anneau de retenue

29 Petit interrupteur 60 Poulie de broche

30 Compensation 61 Bâti

31 Vis 62 Moteur

Table of contents

Languages:

Other Terratek Power Tools manuals