Terri ATD User manual

1

Operator‘s manual

Before taking your Terri in use read the manual

carefully and get familiar with the contents

TERRI ATD

FromChassinr:20017068 604688D

2

Foreword

Thismanualexplainshowtooperateandmain-

tainyournewTerri ATD.Evenifyouarealready

familiarwithTerri,thereisalotofinformationin

thismanualwhichyouwillneedtoknow.

Youcancarryoutlubricationandroutinemainte-

nanceyourself,butfortheotherservicingwork

westronglyadvicethatthemachineshouldbe

handedovertoyourdealer,whohasawell-trained

workshopstaffavailable.

Wereservetherighttoalterthespecicationsand

equipment,aswellasinstructionsformaintenance

andotherservicemeasures,withoutpriornotica-

tion.

Manufacturer: Alcab, THT AB

Viksdal

74451Morgongåva

Tel.+46-224-60070

Fax+46-224-60811

Fax+46-224-60972

Typeofmachine:

TERRI ATD

Powerrating:24,4 kW(DIN70020)

Serialnumber: ............................................................

Motornumber: ............................................................

Machineplate:

Placedattheleftfrontoftheengine

house

3

CONTENTS

2 Foreword

2 Manufacturer

2 Machine plate

2 Serial number

3 Contents

4 Description

5 Safety

7 Working in the vicinity of aerial lines

8 Terry ATD main parts

9 Instruments and controls

10 Control board

10 Instrument board

19 Driving seat

20 Driving instructions

22 Maintenance

22 Motor

24 Fuel system

25 Air cleaner

26 Cooling system

27 Electrical system

29 Hydraulic system

30 Hydraulic oil container

31 Track roller bogie system

33 Brakes

34 Winch

35 Gear box unit

36 Adjustment possibilities of the wagon

36 Towing

37 Lubrication

38 Recommended lubricants

39 Maintenance Chart

40 Trouble shooting

41 Technical data

42 Alphabetical contents

4

DESCRIPTION

TERRI ATD

Terri ATD isatrackdrivecross-countryvehiclewithAckermannsteeringsystemandaloadingcapacityof3tons.

Terri ATD isaspecialpurposemachinewithanextensiveandmany-sidedrangeofapplication.

Terri ATDisequippedwithafour-cylinder,uidcooledLombardiniLDWdieselunitengine.

Terri ATDisequippedwithahydrostatic/mechanicalsteeringassemblywithsealedhydrauliccircuit.Aneffect

limitedvariablehydraulicpumpthatisdirectlycoupledtoaninternalcombustionengineoperatesthesystem.

Inthetractorunitahigh-speedhydraulicmotorisrunninga2-speedgearboxofpreselectiontypewithamechanicaldifferen-

tialblocking.Thegearboxrunsthetracksviatwogearwheels.

Terri ATD iseasytodrivewithsmoothrunningcharacteristicsandgreattractiveforceinallsituations.Theclosed

hydraulicsystemisequallyeffectiveasabrakeasitprovidesgreattractiveforce.

Thedriver’scabisspaciousandthecontrolcomponentsusedforworkarewithinconvenientreach.Thenumbersof

functionsnecessarytooperateTerri ATD areminimised.Thereforeboththedriving-andworkingpositionis

comfortableforthedriver.Theexiblegrabloaderiseitheroperatedviaaconventionalmultipleleversystemorviaa

doubleleversystem,inthatcaseequippedwithbuilt-indrivingfunctions.Thedriver’sseatisobtainablewith

mechanicspringsorairsprings.

Atthefrontofthemachinethereisabuilt-inwinch.Thewinchcanbeusedtopulloffthemachineortodrawout

timberfrominaccessibleterrain.

LOADING UNIT EQUIPPED WITH HYDRAULIC DRIVE

Thewagonisequippedwithtwolowspeedhydraulicmotorsthatoperatethetracksviaagearpinion.Thewagonis

equippedwithanautomatichydraulicdifferentialbrake.Anelectricswitchinthecabinswitchesthewagonoperation

onandoff.Whenthewagonoperationisdisconnectedthehydraulicmotorsarebalancedatthesametimesothat

thewagoncanrunfree.Maximumtransportspeedisachievedbydisconnectingthewagonoperationandputtingin

thehigh-speedgear.

Thewagonisequippedwithabuilt-inparkingbrakethatisoperatedviaanelectricswitchinthecabin.Whenthe

motorisstoppedthewagonisbrakedautomatically.

Remember! Security always depends upon the driver, therefore

follow the security instructions carefully.

5

GENERAL SECURITY REGULA-

TIONS

Readandtrytounderstandthecontentsofthischapter.It

containsatableofrulesthatalwaysmustbefollowedwhen

workingwithTerri.

However,theserulesdonotexcusethedriverfromnotfol-

lowingstatutoryorotherregulationsvalidnationallyinthe

eldofsafetyintrafcandoccupationalsecurity.

As a matter of precaution

Itisthedriver’sdutytobewellacquaintedwiththemain-

tenanceinstructionsandsecurityregulationsconcerningthe

machine.

Damages

Itisthedriver’sdutytotakeimmediatelycareofdamages

andwearandtearthatcanbehazardoustosecurity.

Maintenance

Performregularlythemaintenancemeasuresaccordingto

thechart.Whenperformingservice-andinspectionmeasu-

res,putdownthegrippingapplianceandstopthemotor.

Danger-zone

Thedanger-zoneforthemachineis20m,withinthisrange

nobodymayloiterwhenthemachineisinoperation.

Driver’s mates

Therearenoseatsfordriver’smates.

Carbon monoxide danger

Neverstartthemotororletitrunindoors.Dangerofcarbon

monoxidepoisoning.

Tipping over

Ifthemachinetipsover,holdontothedriver’sseatorthe

handles.DONOTJUMP!

Fire extinguisher

Thereextinguishermustalwaysbeincludedwhendriving

Terri.Befamiliarwiththeinstructionsforthereextinguis-

her.Inspectregularlythatthemanometerneedleofthere

extinguisheriswithinthegreeneld.

Support

Alwaysusethesupportbraceswhenworkingwiththecrane.

Load

Neverloadhigherthantheheightofthesafeguardposts.

Load in the crane

Neverdrivethemachinewithloadhangingintheloading

crane.

Hanging load

Nevergoorstandunderhangingload.

ThissymbolmeansDANGER, be careful.Yourand

otherpeople´ssecurityandhealthareatstake.

6

Before driving

Checkwhetherthefunctionsofthedrivingleversandbrake

controlisallright.

Driving

Neverdrivethemachinemerelywithwagonoperation.This

cancausethemachinetotipundercertaincircumstances.

Thelowgearofthetractorunitmustalwaysbeengaged

whenwagonoperationisengaged.Whendrivingonuphill

anddownhillslopesthewagonoperationmustalwaysbe

engaged.

PRIOR TO leaving the machine

Beforeyouleavethemachine:putdowntheloggrips,stop

themotorandswitchoffthemainswitch.

Fluid levels

Whencontrollingtheuidlevelorllingthefueltankorthe

uidlevelofthebatteryneveruseopenames.

Terrain

Ifpossible,inspecttheterrainwhereyouaretodrive,especi-

allyduringthewintertimewhenthesnowiscoveringbumps.

Payattentiontotheangleofinclinationandtheconsequen-

cesthiswillhaveonthestabilityofthetractor.

Children

Neverallowchildreninthecabinorinthevicinityofthe

machinewhenthemotorisrunning.

Emergency exits

Getfamiliarwiththeemergencyexitsofthecabin.

1.Sidedoor

2.Roofhatch

3.Windscreen

Thesecuritypinsoftheroofhatchmustbewithdrawnwhen

drivingonanice-coveredlake.

Whenthewindscreenisusedasemergencyexit,smashrst

thescreenwiththehammer,placedinsideontherightinthe

cabin.

7

Körning med upplyftad kranarm får ej ske

under eller i närheten av elektriska luftledningar.

Vältä työskentelyä sähköisten avojohtojen alapuo-

lella tai läheisyydessä.

Use of the loader under or near open electrical

Wires is forbidden.

Der Betricb des Ladekranes unler oder nahe bei

offenen elektrischen Leitungen ist nicht gestallet.

Totalheight

Beawareofthetotalheightofthecraneandtheloadbefore

drivingwheretheheightislimited.Beextracarefulwhendriving

wheretherearetemporaryarrangements,pendulousaerialcablesetc.

Whendrivingintheforestoronaforestroaddorememberthatit

maybedifculttoobserveaeriallinesovertheroad.Besides,these

cablescanhangsurprisinglylowwhentheyarecoveredwithsnow

andice.

WORKINGINTHEVICINITYOFAERIALLINES

When working in the vicinity of aerial lines no part of the mach-

ine or the load is permitted to come nearer the lines than stated

below:

Low tension 2 meters

High tension < 40 kV 4 meters

High tension > 40 kV 6 meters

Ifitisnotpossibletokeeptheabovesecuritydistance,thepower

stationmustbecontactedwiththerequesttocutoffelectricitywhile

oneisworkingthere.Onemustundernocircumstancesrelyongood

luckwhenworkinginthevicinityofaeriallines.Ifitisnotpossible

tohavethepowercutoffonemusttrytomovethetimberbyother

meansbeforeusingthecraneforloading.

ELECTRICITYNEEDSNOCONTACT.HIGHTENSION“HITS”

EVENATAGREATERDISTANCE.

8

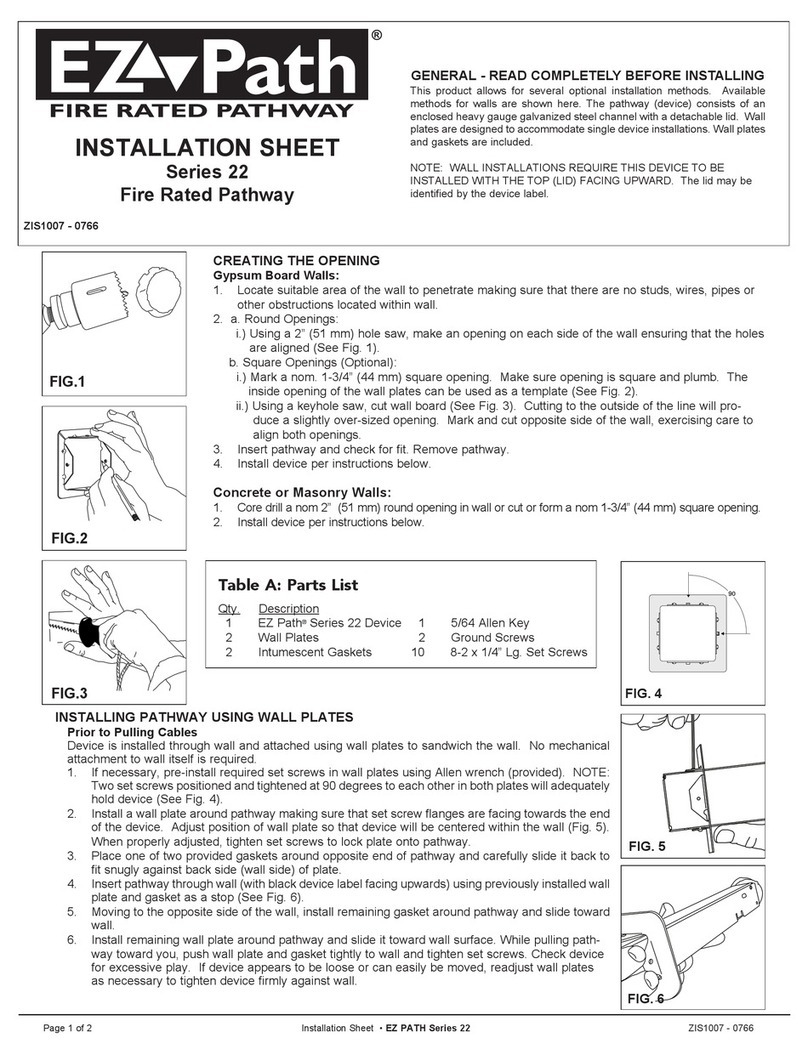

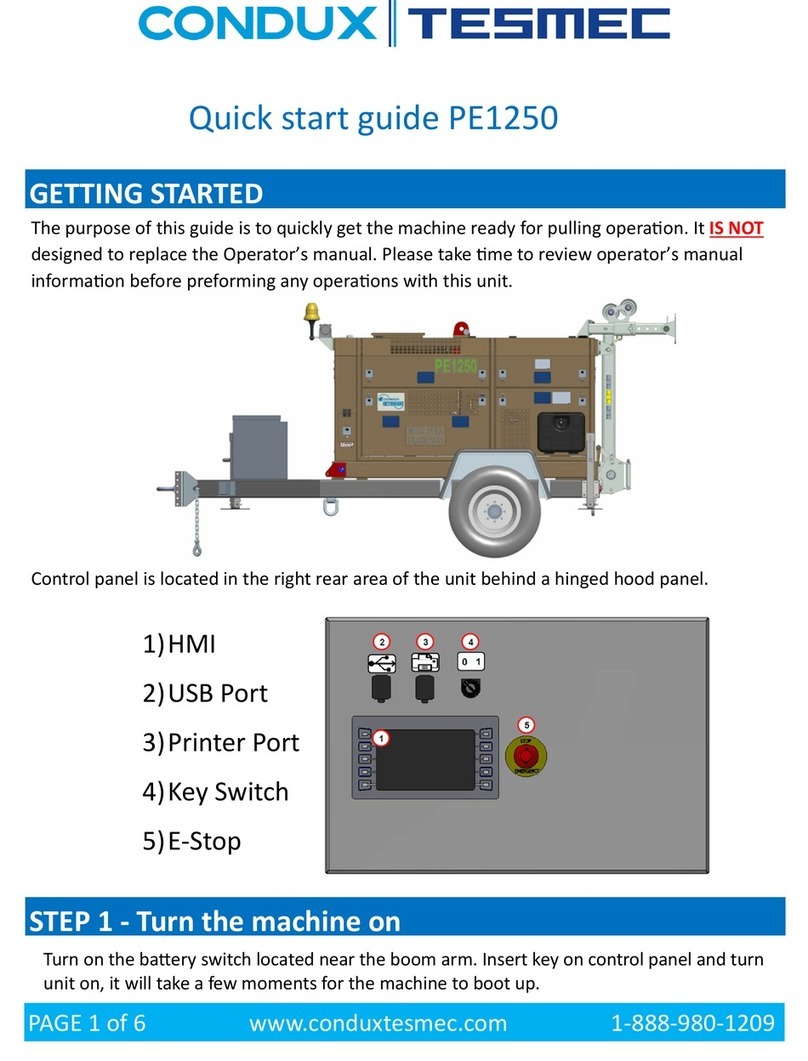

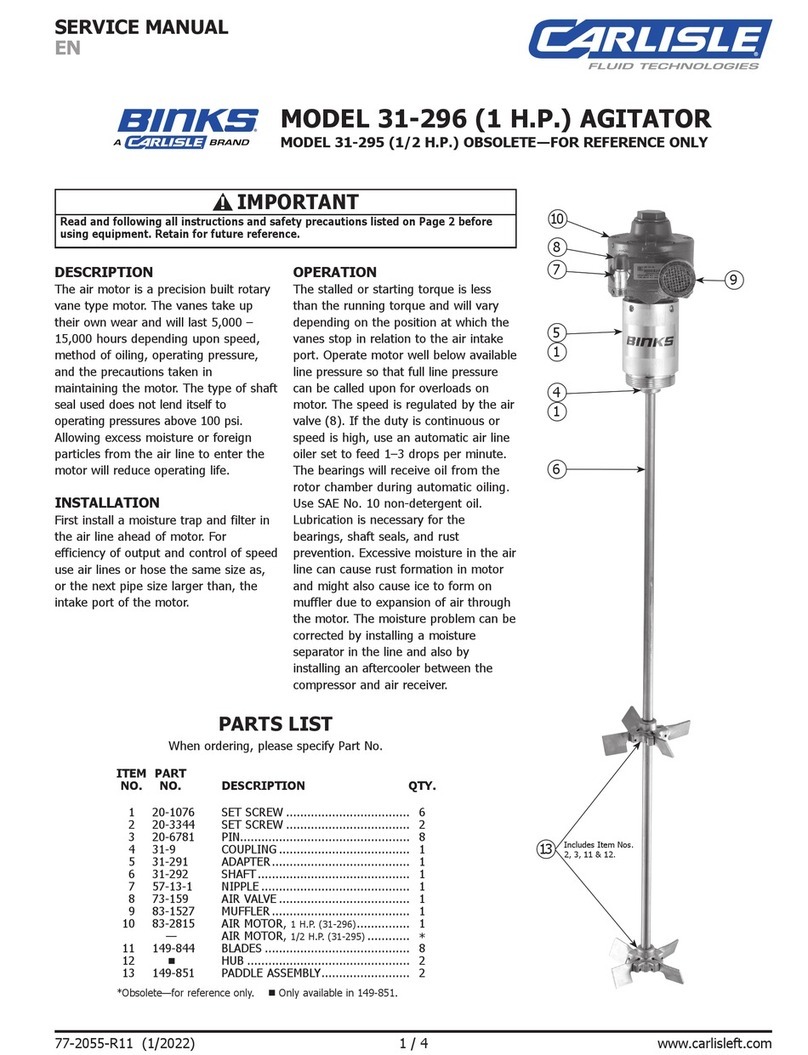

The main parts of Terri ATD

1 operation unit

2 cabin

3 control unit

4 grab loader

5 safeguard for displacement of load

6 loading space

7 track operation – bogie system

8 wagon

9 track operation – bogie system

10 winch

9

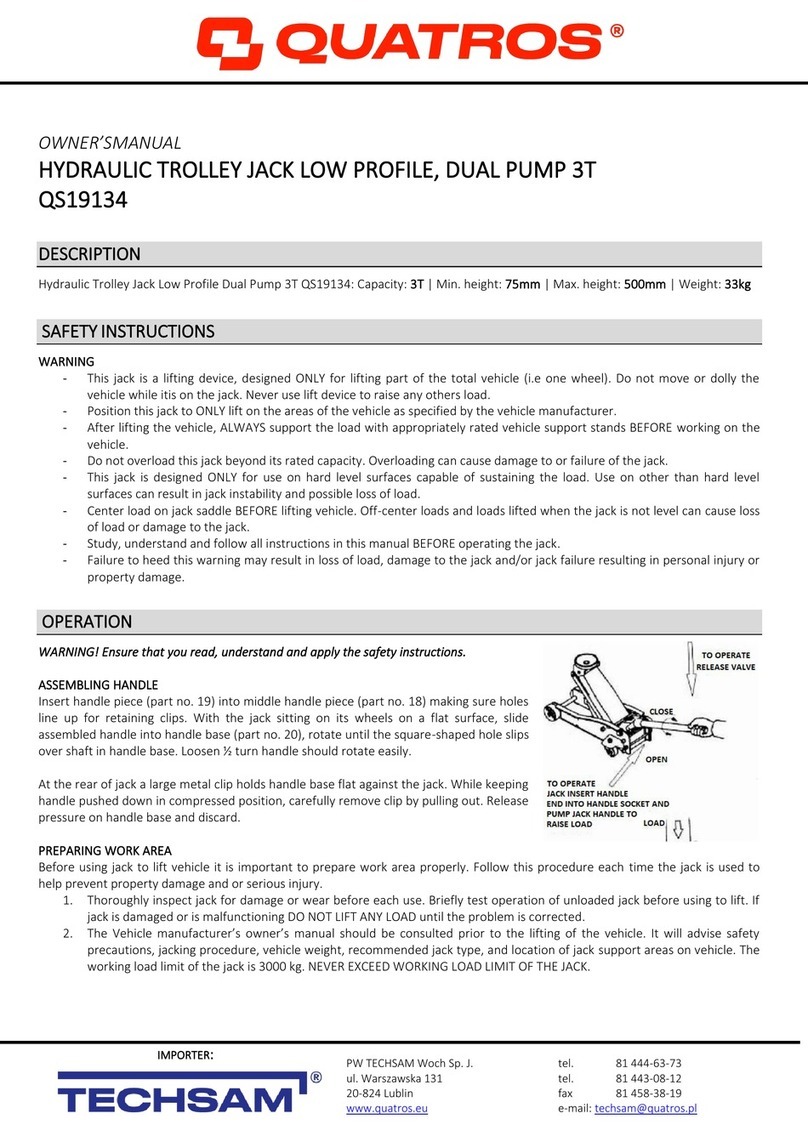

Instruments and controls

1 parking brake

2 air vents

3 air vents

4 control for winch

5 lockcontrol for double action hydraulic cylinder

6 differential lock (not for Sweden)

7 panel for diesel heater (extra equipment)

8 ventilation fan

9 brake

10 winch control

11 gear lever

12 throttle pedal forward

13 driving lever

13b change-direction switch

13c ow devider-function

14 electrical socket (cigarette lighter)

15 fuse boxes

16 starter lock

17 control for cabin heating

18 hand accelerator

19 air vents

20 switch panel

21 instrument panel

26 emergency hammer

10

Free

Locked

Broms

Brake

P1. Parking brake

Thisleveraffectsamechanicalbrake.Whentheleverismo-

vedbackwardsthebrakeisengaged.Viathebuttonontopof

theleverthelockisunbolted.

2. Front air vents screen

Theairventsregulatethedirectionoftheincomingair.For

defrosterpurposestheairisdirectedtowardsthewindscreen.

3. Front air vents oor

Theairventsregulatethedirectionoftheincomingair.

4. Winch lock

Thewinchlockpreventsthecablefromrunningoutcom-

pletely.Thewinchlockiscontrolledviaaleverontheleft

sideontheinstrumentboard.Thewinchlockisreleased

whentheleverisinitsfrontposition.Releasethewinchlock

andpullthecableout.

Attention! Use protective gloves.

Attention! Never push the driving lever backwards when the

winch is in use. This can cause damage to the gearbox.

5. Double action hydraulic cylinder

Viathedoubleactionhydrauliccylinder,installedbetween

thetractorunitandthewagon,thepositionforthefrontof

thetractorunitcanbeadjustedtodifferentconditions.

Position 1: Operatingleverpushedup=thetractorunit

“oats”free,i.e.thetractorunitcannobstructedly

followtheterrain.Thisisthenormaldrivingposition.

Attention! Spring-loaded locking of the lever in this posi-

tion.

Position 2: Operatingleverincentre,withspring-loadin

centreposi-

tion=“lockedposition”.

Thepositionofthetractorunitinrationtothewagonis

locked.Thispositionisonlyrecommendedwhendrivingin

lightsnowwithouttrackandwhencrossingaditchorother

obstacle.

Position 3: Bypushingtheoperatingleverforwardthe

frontofthetractorunitgoesdown.Theoperatinglevergoes

owingtothespring-loadbackto“lockedposition”(2)when

releasingthelever.

CAUTION! Do not swivel sharply with the machine when

the front is down.

Position 4: Bypushingtheoperatingleverdownwardsthe

frontofthetractorunitgoesup.Theoperationlevergoes

owingtothespring-loadbackto“lockedposition”(2)when

theleverisreleased.

11

Open

Closed

Practical example:Drivingoveraminorditch.

Raisethefrontsomewhatwhenyouapproachtheditch.

Lowerthefrontbeforethebogieofthetractorunithas

whollycrossedtheditchsothatthefrontpartofthe

bogietouchesthegroundontheothersideoftheditch.

Drivewiththedoubleactionhydrauliccylinderinlock-

edpositionuntilthewheelofthewagonhascrossedthe

ditch.

Continuedrivingwiththedoubleactionhydrauliccylin-

derin“owingposition”(1)

6. Differential lock (not applicable for Sweden)

Thegearboxofthetractorunitisequippedwithamechani-

caldifferentiallock,controlledviaaleverontheinstrument

board.Thedifferentiallockisdisengagedwhentheleveris

initsbottomposition.

7. Panel for diesel heater (extra equipment)

Onthispanelthedieselheateriscontrolled.Seemanualfor

dieselheater.

8. Ventilation fan

Thecontrolhasthreepositions; OFF-LOW-HIGH.

9. Brake pedal

Withthebrakepedalthebrakesforthemachineareapplied.

12

Engaged

Disengaged

10. Winch

Thewinchiscontrolledviaaleverontherightsideonthe

instrumentboard.Whenoneputstheleverintofrontposi-

tion,gear(11)intoneutralposition,wagonoperationdisen-

gaged,drivinglever(13)forwardandonepressesthethrottle

pedaldown,thewinchcableishoistedinontothewinch

cabledrum.

CAUTION!

Prior to operating the winch make sure that the cable

is not damaged. If a cable breaks during operation it

can cause great damage.

Attention! Never move the driving lever backwards when the

winch is in use. This causes that the winch cable is rolled up

in the wrong direction on the winch cable drum.

11. Gear lever

Withthegearlevertwogearscanbechosen.Iftheleveris

movedforwardthehigh-speedgearisengagedandwhenthe

leverisintherearpositionthelowspeedgearisengaged.

Whentheleverisincentrepositionneutralpositionisenga-

ged.

CAUTION!

The machine must never be driven with wagon opera-

tion only. This can cause the machine to tip under certain

circumstances. The low gear of the tractor unit must always

be engaged when wagon operation is engaged.

When driving on uphill and downhill slopes the wagon

operation must always be engaged.

12. Throttle pedal forward

Thethrottlepedalcontrolstheenginespeedduringdriving.

13. Driving lever

Thedrivinglevercontrolssteering.

Whentheleverismovedtotherightthemachineturnstothe

right.Whentheleverismovedtotheleftthemachineturns

totheleft.

Steeringdoesnotautomaticallyreturnto“forward”buthas

tobesteeredbackwiththedrivinglever.

Viathelockthedrivinglevercanbelockedintoneutralposi-

tion.

13b Change-direction switch

Theswitchisplacedfrontofthedrivingleverandhasthree

positions.

Whentheswitchisdownwardsthemachinemovesforward.

Whentheswitchisupwardsthemachinemovesbackwards.

Themiddlepositionsisneutralposition.

13c Flow-devide-function

Theengagebleow-deviderisinstalledbetweenthetractor

unitandwagonsdriveengines.Whenwagonoperationisen-

gagedandtheswitch13cispresseddown,thehydraulicoil

owisdevidedbetweenthehydraulicenginesinthetractor

unitandthewagon.Thisfunctionincreasewagonspulling

powerevenifthewagonisspinning.Caution ! wagon ope-

ration must always be engaged when using ow-devide-

function.

High speed

Low speed

13

14 Electrical socket (cigarettelighter)

Amobilephonee.g.canbeconnectedtotheelectrical

socket.

Fuse boxes

Fusesareanoverloadprotectionoftheelectriccircuits.The

fuseboxesareinstalledinthefrontpartontheinstrument

board.

LIST OF FUSES

No. Amp Consumer unit

VI. 15 Ventilationfan

Directionindicators

Fuelpump

Controllampoillevel

Controllampoilpressure

Controllampoiltemperature

Fuelgauge

Coolantthermometer

Cabinlights

Stoptaillamp

Enginestoppingdevice

V2. 15 Workinglightsrear,front

V3. 15 Workinglightsside

V4. 15 Instrumentboardlight

Positionlights

Rearlights

V5. 15 Wagonbrake

Trailerdrive

V6. 15 Glow

Enginestoppvalve

H1 15 Headlights

H2. 15 Dippedheadlights

H3. 15 Windscreenandrearscreenwipers

Windscreenwasher

H4 15 Cigarettelighter

Signalhorn

H5 15 Radio

2-levers

H6 15 Extra

14

16. Starter lock

Thestarterlockhasthreepositions,OFF-ON-ST

OFF–locked

ON-unlocked

ST-start(resilient)

17. Control for cabin heating

Theheatcontrolisstepbystepoperated.

Whenthecontrolleristurnedtotherighttheheatisoffand

whenthecontrolleristurnedtotheleftonegetsmaximum

heat.

18. Hand accelerator

Whenoperatingthegrabloadertheaccelerationoftheeng-

inecanbeadjusted.Forquickadjustmentpressthebutton

andpullthecontrolleruntilrequiredaccelerationisattained.

Forprecisionadjustmentturnthecontrolleruntilrequired

accelerationisattained.

19 Rear air vent screen

Theairventscontrolthedirectionoftheincomingair.For

defrosterpurposestheairisdirectedtowardstherearwin-

dow.

15

20. Switch board

20.1 Control for direction indicators

Ifthebuttonispresseddownwardstheleftdirectionindica-

torwillash.Ifthebuttonispressedupwardstherightdirec-

tionindicatorwillash.Thecontrollampasheswhenthe

directionindicatorisengaged.

Attention! If a lamp has fallen out the control lamp is as-

hing faster.

20.2 Light change over switch

Thelightchangeoverswitchswitchesthelightfromhead

lightstodippedlights.Thecontrollampisalightwhenthe

headlightsisengaged.

20.3 Switch for dipped lights

Thecontrollampisalightwhenthedippedlightsareenga-

ged.

20.4 Switch working light front

Extraequipment.Thisswitchturnsthefrontworkinglights

on.Thecontrollampisalightwhenthefrontworkinglightis

engaged.

20.5 Switch working light side

Thisswitchturnsthelightsonthesidesofthemachineon.

Thecontrollampisalightwhenthesidelightsareengaged.

20.6 Switch working light rear

Thisswitchturnstherearworkinglightson.

Thecontrollampisalightwhentherearlightisengaged.

16

20.8 Extra switch

Hereisaplaceforanextraswitchforaccessoriescanbe

installed.

20.9 Windscreen wipers

Thispushbuttonoperatesthewindscreenwipers

20.10 Push button for horn

Ifthepushbuttonispresseddownthehornwillsound.

20.11 Wagon operation

Thispushbuttonengagesanddisengagesthewagonopera-

tion.Thecontrollampisalightwhenwagonoperationis

engaged.

Attention! Driving with wagon operation engaged only with

low speed gear.

20.12 Trailer brake

Thetrailerbrakeisappliedandreleasedwiththeswitch.

Theindicatorisalightwhenthetrailerbrakeisapplied.

Whentheoilpressuredropsbelow10bar,appliesthetrailer

brakeautomatically.

N.B. The trailer brake is a parking brake. Always release the

trailer brkae when driving the machine; the brake may oth-

erwise be damaged.

20.13 Wiper and washer for rear window

Theswitchhastwopositions.Therstpositionsstartsthe

wiperandthesecond,theresilientpositionstartsthewasher.

Attention! The rear window has a protective pane being very

resistant against knocks and impacts. However it is not as

scratch resistant as normal glass. Therefore never engage

the wiper on a dry pane. Neither should you clean the pane

with a dry cloth.

17

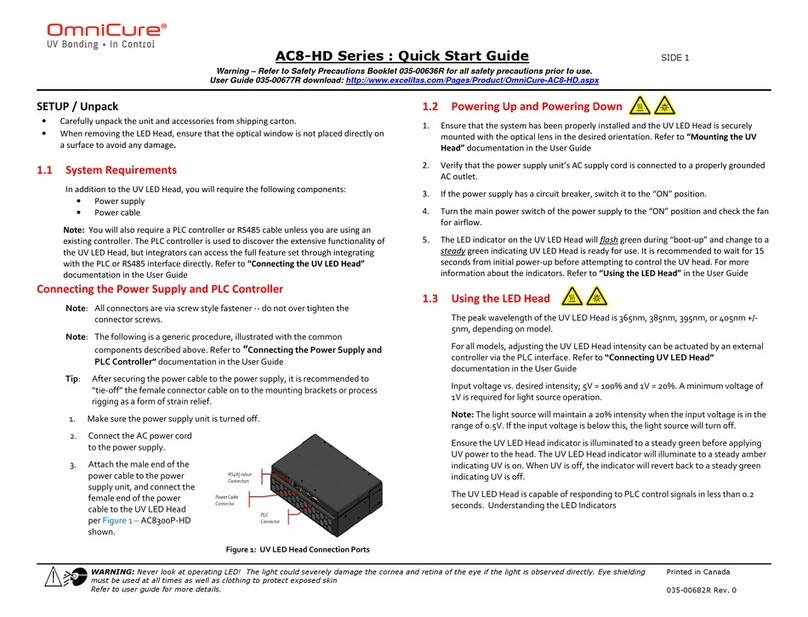

21 Instrument board

21.1 Revolution indicator

Therevolutionindicatorshowstherotationspeedoftheen-

gine.

21.2 Working hours indicator

Thisindicatorshowstherunninghoursofthemachine.The

indicatorisengagedwhentheengineisrunning.

21.3 Temperature control for hydraulic oil

Showsthetemperatureofthehydraulicoil

21.4 Engine temperature indicator

Theenginetemperatureindicatorshowsthetemperatureof

thecoolantoftheengine.Whenrunningnormally,withthe

enginewarm,thetemperatureshownshouldbe90–95de-

grees.

21.5 Fuel meter

Registersthefuellevelinthetank.

21.6 Control lamp oil pressure engine

Thecontrollampshouldbeoutwhentheengineisrunning.

However,iftheoilpressureoftheenginedropsbelow0.5

barthecontrollampwilllightup.Ifthisshouldhappen,stop

theengineimmediatelyanddeterminethesourceofthetrou-

bleandtakecareofitbeforeyoustarttheengineagain.

21.7 Glow indicator

Theindicatorbecomesextinctwhentheglowingprocessis

completed.

21.8 Charging control lamp

Normallythelampshouldbeoutwhentheengineisrunning.

Ifthelamplightswhilerunningthisindicatesthatthereis

afaultintheelectricalsystemandthesourceofthetrouble

mustbedeterminedandtakencareof.

21.9 Warning lamp for low hydraulic oil level

Thewarninglampwilllightupwhenthehydraulicoillevel

dropstothelowestlimit.

1/minx100

18

22. Control for crane

Seeseparateoperationinstructions

23. Throttle pedal rear

Controlstherotationspeedoftheenginewhenengagingthe

crane.

24. Fire-extinguisher

Thereextinguisherisa2-kilogrampowder-extinguisher.

Foroperationseetheinstructionsfortheextinguisher.

CAUTION!

Inspect regularly that the manometer needle is

within the green eld.

25. Main switch

Theentireelectricsupplycanbeturnedoffwiththemain

switch.

Attention! Never turn off the main switch while the engine is

running.

CAUTION!

The main switch must be turned off when carrying out

service- and maintenance measures on the machine!

26. Emergency hammer

Whenthewindscreenisudesasemergencyexit,smashthe

screenwiththehammer,placedinsideontherightinthe

cabin.

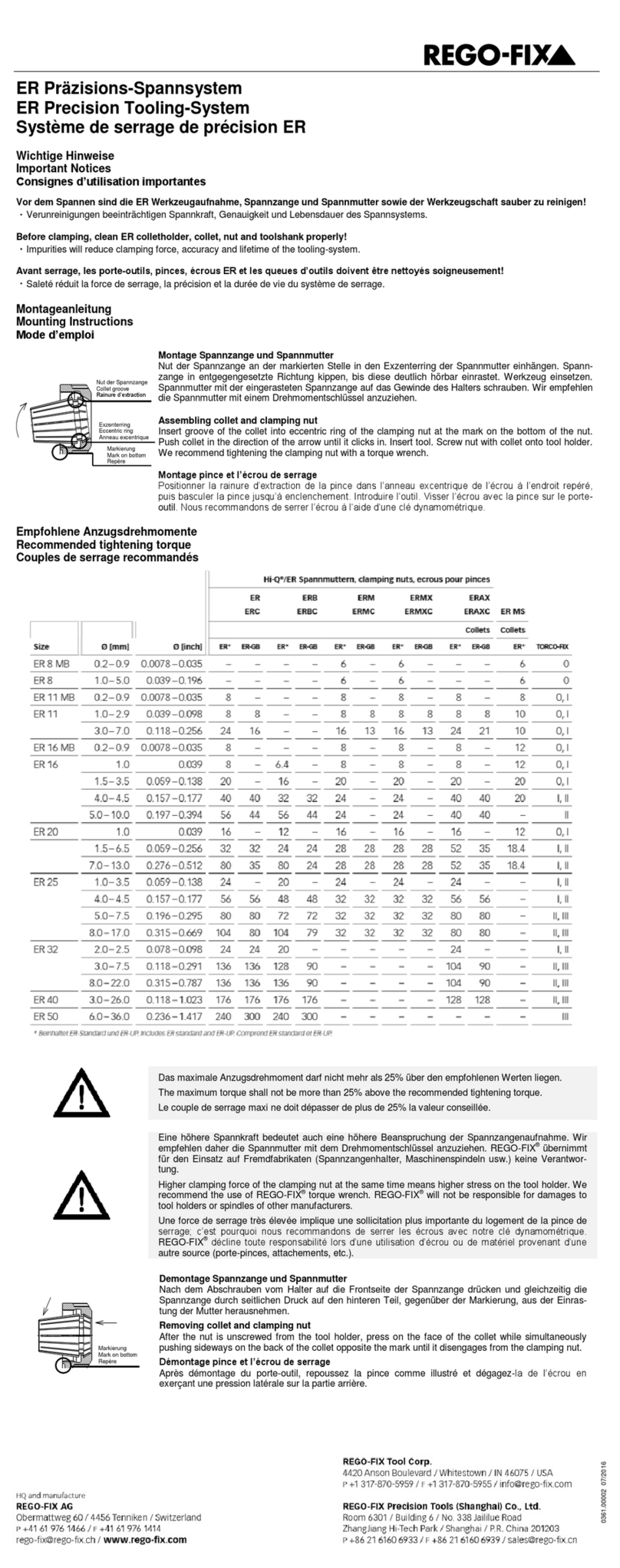

Driving seat

The swivelling of the driver’s seat

Thedrivingseatcanbeswivelledandxedinthreeposi-

tions.Forwardfordriving,60degreestotheleftforentering

andleavingthemachineaswellasbackwardsforoperating

thegrabloader.Theseatisdetachedviafootpedal1.

Adjustment of the driving seat

Viacontrol2theseatcanbemovedforward–backwards.

Viacontrol3theverticalspringingoftheseatisadjusted.

Thespringingcanbeseenonthescaleandthesetvalue

shouldcorrespondtotheweightofthedriver.

Viaknob4theheightofthearmrestisadjusted.

Viacontrol5theseatheightofthefrontpartoftheseatis

adjusted.

Viacontrol6theseatheightoftherearpartoftheseatisad-

justed.Byalternatelyraisingandloweringthefrontandrear

partoftheseattheheightoftheseatcanbeadjusted.

Viacontrol7theangleofthebackrestoftheseatcanbead-

justed.

19

STARTING THE ENGINE

Routine measures prior to starting the engine

Ø Seetoitthatthethrottlepedalreturnsautomatically

to neutralposition

Ø Seetoitthatthedrivingleverisincentreposition

and thewinchisdisengaged.

Start with cold engine

Turntheignitionkeytopositiondriving(ON).Nowthe

glowindicatorandthecontrolsforchargingandoilpressure

willbecomealight.Whentheglowindicatorlampbecomes

extinctturnthekeytostartposition(ST)-

Seetoitthattheignitionkeyautomaticallyreturnstoposi-

tion“driving”(ON)whentheengineisrunning.

Duringextremelycoldweathertwo“glowings”insucces-

sionof15secondsmayberequired.Bygivingfullthrottle

theinjectionpumpsuppliesmaximumamountoffuel.

Donotrunthestartermotorcontinuouslyformorethan10

secondsatatime.Repeattheglowingpriortothenextstart

attempt.

Engine pre-heater (optional)

Duringcoldweatheritisadvisabletouseanelectricordie-

seloperatedenginepre-heaterthatwarmsthecoolantofthe

engine.

Warming up

Theenginerequiresabout4to5minutesofwarminguptime

beforethemachinecanbeusedforfulloperation.

Start with warm engine

Ifstartingwithawarmenginenoglowingisnecessary.Turn

thekeydirectlytostart(ST).

Stopping the engine

Lettherotationspeedoftheenginegodowntoidlingspeed

andturntheignitionkeytoposition“OFF”.

CAUTION!

When you leave the machine:

Put down the grab loader, stop the engine, switch

off the main switch and take the ignition key

with you when you leave the machine. By doing

so you make sure that all current consumers are

disengaged and unauthorised persons cannot

start the machine.

20

DRIVING

The gearbox of Terri is of pre-selection type with 2-speed.

This implies that changing may only be done when the ma-

chine is stationary.

Ø Releasethebrakes

Ø Putthepositionofthedoubleactionhydrauliccylinder

to“oatingposition”

Ø engageagear(high/low)

Ø Chosedirectionviathechange-directionswitch13b.

Ø Increasetherotationspeedoftheengineviathethrottle

pedal.

Therotationspeedoftheengineregulatestheamountof

oilgettingtothehydraulicmotorsandthusthespeed.The

speedcanthereafterbecontrolledwiththerotationspeedof

theengine(throttle).

Stopping the engine

Theenginestopsifthethrottlepedalreturnstoitsidleposi-

tionorifthedriving-direction-switchisputtocentreposi-

tion.Iftheswitchisincentrepositionthehydrauliccircuitis

closedandthehydraulicsystemhasaslowingdowneffect.

(Seetextaboutbrakes).

Driving with wagon operation

Wagonoperationmayonlybeengagedwhenthelowspeed

gearisputin.Ifthewagonoperationisengagedwhenthe

highspeedgearisengagedtheoilowtothewagonengines

isnotsufcientwiththeresultthatthewagonisslowed

down.

Popular Industrial Equipment manuals by other brands

Rego-fix

Rego-fix ER 8 MB manual

Excelitas Technologies

Excelitas Technologies OmniCure AC8-HD Series quick start guide

NPC

NPC NHE Series Product instruction manual

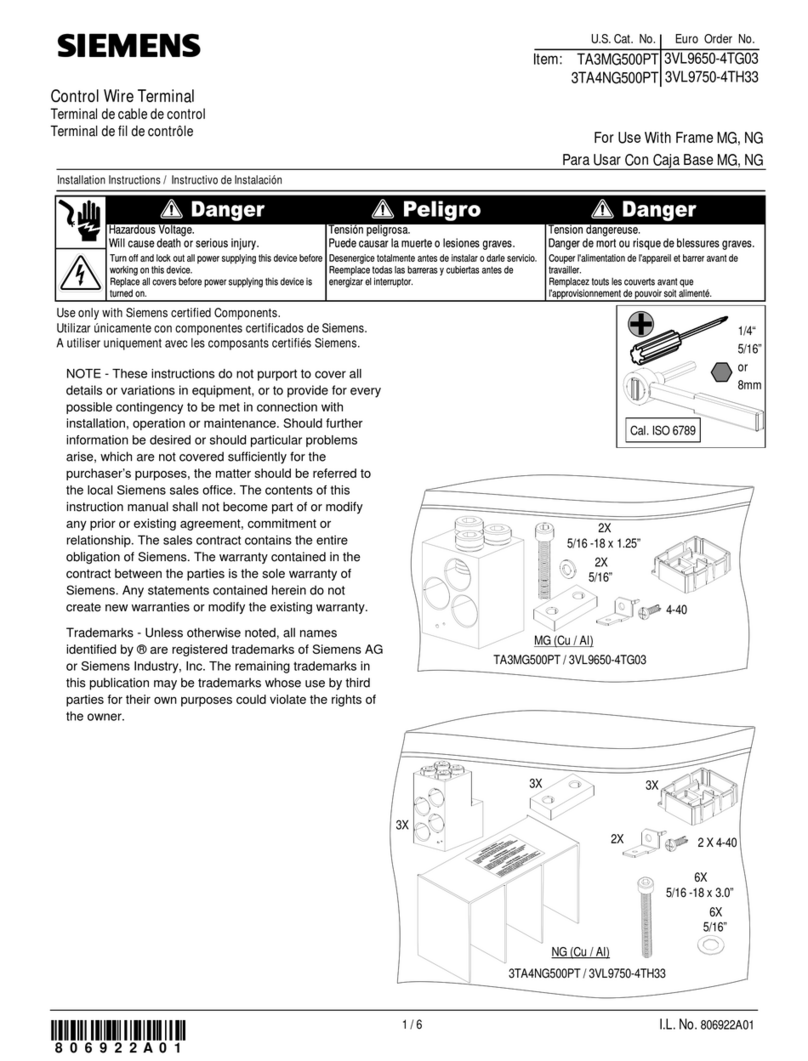

Carlisle Fluid Technologies

Carlisle Fluid Technologies BINKS 31-296 Service manual

MIYAWAKI

MIYAWAKI SD1 user manual

Siemens

Siemens TA3MG500PT manual