5

RECOMMENDATIONS CONCERNING THE INSTALLATION OF VARIABLE-SPEED

APPLIANCES AND PERSONAL SAFETY

These recommendations apply to machines equip-

ped with an induction motor and a single-phase or

three-phase wobbulator.

NB:

-The electrical circuit and the protective devices

must comply with national regulations.

- The machine must be wired in by a qualified elec-

trician

Protecting your appliance

• Like all electronic devices, wobbulators in clude

components that are sensitive to electrostatic

discharges (ESDs). Before conducting any work

on these wobbulators, technicians must therefore

rid themselves of electrostatic charges.

• The machine must be disconnected from the

mains supply before any internal connection ope-

rations are carried out.

• Repeatedly switching on the appliance will cause

the wobbulator to overload and may result in its

destruction. After the machine has been switched

off, you must wait for 3 minutes before switching

it back on again.

50 or 60 Hz single-phase power supply

• The appliance runs on single-phase or three-

phase current as far as the variator, which turns

the current into variable frequency three-phase

current to supply the motor.

• You must connect the machine to a 200-240 V

/ 50 or 60 Hz single-phase alternating current

supply with an earthed socket. A higher voltage

will destroy the wobbulator.

• The earthed socket ensures operator safety.

Circuit interrupters ensuring user safety

Ground fault circuit interrupters (GFCIs) intended

for variable-speed appliances need to be selected

with great care in order to ensure operator safety.

GFCIs may be sensitive to alternating current (type

AC), impulse current (type A) or all currents (type

B).

Danger! Wobbulators feature a bridge-connec-

ted rectifier of the mains supply voltage. For this

reason, in the event of an earth contact, a

continuous fault current may fail to trip a differential

circuit breaker that is only sensitive to alternating

current (type AC).

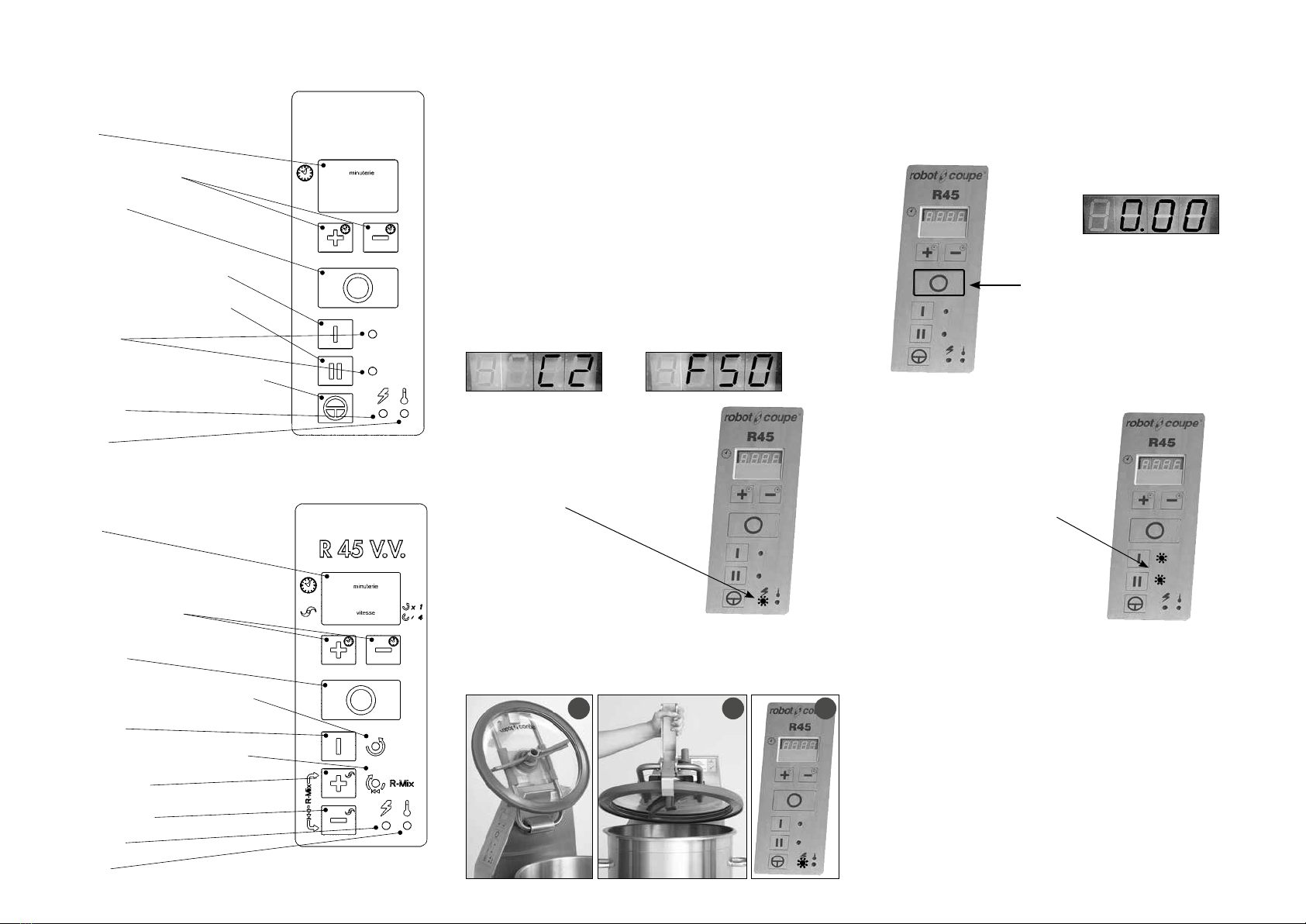

It is therefore advisable to use a GFCI that is

sensitive to impulse current (type A), identified by

the following symbol: or (B) .

Caution: sthese GFCIs may go under different

names, according to the manufacturer.

Appliances with wobbulators produce a fault

current on the earth wire. This current may be suffi-

cient to trip the differential circuit breaker unneces-

sarily. This may occur if :

• Several variable-speed appliances are connected

to the same GFCI.

• The appliance produces a fault current that is

above the GFCI’s actual trip threshold.

Caution: As there are manufacturing tolerances,

the actual trip threshold of a GFCI will be between

50% and 100% of its theoretical nominal threshold.

Should a problem arise, measure the fault current

and the GFCI’s actual trip threshold.

You can begin by consulting the characteristics of

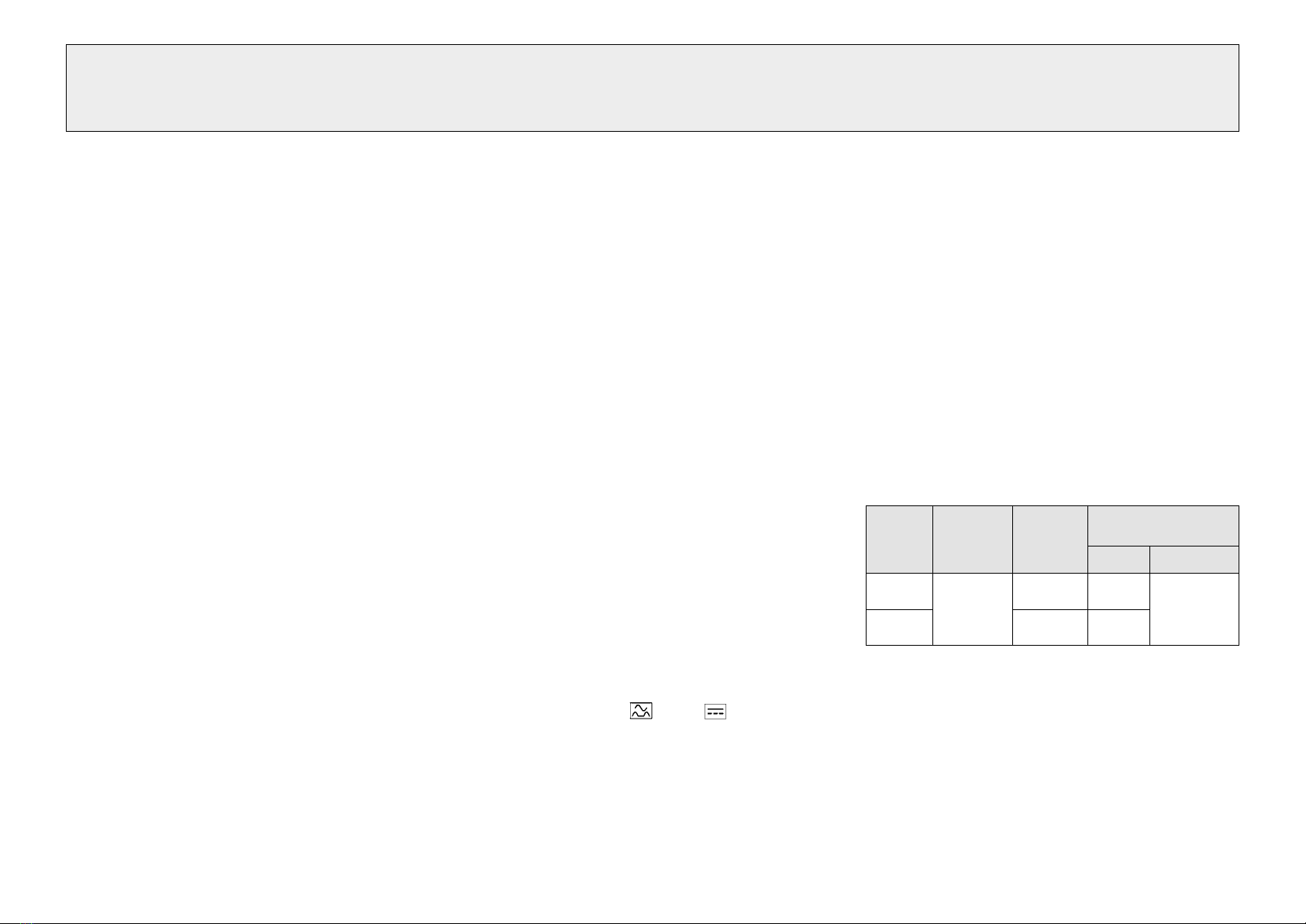

your appliance in the table below:

*Connection instructions:

To protect users, it is vital to connect the R 30 V.V.

and R 45 V.V. machines to the mains supply via a

connection unit equipped with the above-mentioned

residual current device. They must not be connected

through a plug and socket.

Appliance Mains supply

Conductor

Cross-section

(mm2)

GFCI

(Ph + N or 3 Ph)

Gauge (A) Threshold (mA)

R 30 V.V. 380 - 440V

50 or 60 Hz

Three-phase

4 B 20 A min.

100 mA*

R 45 V.V. 6 B 32 A