Tettex 2293 User manual

Operating

Instructions

HAEFELY TEST AG

2293

Winding Analyser

Version 1.9

4842186

Title

Operating Instructions

2293 Winding Analyser

Date

07-2011

Authors

MM, LWA, SG, SM

Layout

LWA

Part number

4842186

Revision History

V0.9

06/2011

LWA

Initial release of the document

V1.0

07/2011

SG

Additional features added, manual completed

V1.1

03/2012

MM

Remote control chapter added

V1.2

06/2012

LWA

3rd LED added, CE with new address

V1.3

04/2013

SM, LWA, MM

Turns Ratio, graphical updates, connection hints

V1.4

06/2013

SM, LWA

Cooling curve & Temperature Rise added

V1.5

02/2014

SM

Magnetic Balance, dry type temperature rise added

V1.6

06/2014

SM, LWA, MM, SG

License screen updated, Additional Demag information

V1.7

07/2014

SM

Magnetic Balance updated

V1.8

09/2014

LW

Additional info to temperature probes

V1.9

11/2014

LW

Additional info to calibration and classic mode

V2.0

08.2015

SG

Tap changer and short circuit impedance added. Interlock

connection explanation. CT connection description

WARNING

Before operating the instrument, be sure to read and fully

understand the operating instructions. This instrument

produces hazardous voltages. It is the responsibility of the user

to ensure that the system is operated in a safe manner.

This equipment contains exposed terminals carrying hazardous

voltages. There are no user serviceable components in the unit.

All repairs and upgrades that require the unit to be opened must

be referred to HAEFELY TEST AG or one of their nominated

agents.

HAEFELY TEST AG and its sales partners refuse to accept any responsibility for consequential or

direct damage to persons and/or goods due to none observance of instructions contained herein or due

to incorrect use of the equipment.

Further be aware that safety is the responsibility of the user!

Any correspondence regarding this instrument should include the exact type number, instrument serial

number and firmware version number. With the exception of the firmware version number, this

information can be found on the registration plate on the right panel of the instrument. The firmware

version specified in the miscellaneous folder under the setup menu.

Unauthorized opening of the unit may damage the EMI protection of the system and will reduce its

resistance to interference and transients. It may also cause the individual unit to be no longer compliant

with the relevant EMC emission and susceptibility requirements. If the unit has been opened, the

calibration will be rendered invalid.

Note

HAEFELY TEST AG has a policy of continuing improvement on all their products. The design of this

instrument will be subject to review and modification over its life. There may be small discrepancies

between the manual and the operation of the instrument, particularly where software has been

upgraded in the field.

HAEFELY TEST AG retains the right to modify the functionality, specification or operation of the

instrument without prior notice.

All rights reserved. No section of this manual may be reproduced in any form, mechanical or

electronic without the prior written permission of HAEFELY TEST AG.

2014, HAEFELY TEST AG, Switzerland

Manual Conventions

In the manual, the following conventions are used:

Indicates a matter of note.

If it refers to a sequence of operations, failure to follow the instructions could result in errors

in measurement.

Indicates hazards.

There is a risk of equipment damage or personal injury or death. Carefully read and follow

the instructions. Be sure to follow any safety instructions given in addition to those for the

site at which tests are being performed.

Introduction

I

Foreword

Welcome as a new user of the “Winding Analyzer 2293”. Thank you for placing your confidence in our

product.

With the purchase of this measuring instrument you have opted for all the advantages that have built a

world-wide reputation for a Tettex Instrument: robustness, performance and quality is assured. As a

result this instrument provides a solution which achieves the optimal combination of traditional know-

how and leading edge technology.

This operating manual is designed for completeness and easy location of the required information.

Customers who already have experience with this kind of equipment will find this document to be of

assistance as an extended help.

If you find a mistake or inconsistency in the operating manual then please feel free to inform our

Customer Support department with your corrections so that other users may benefit.

Abbreviations, definitions

Wherever possible the corresponding IEC definitions are used. The following abbreviations and

definitions are used in this manual:

LV Low voltage or low voltage transformer winding

HV High voltage or high voltage transformer winding

DUT Device under test

LED Light Emitting Diode

II

Introduction

Contents

1Introduction 9

1.1 Receiving Instructions.................................................................................. 9

1.2 General........................................................................................................ 9

1.3 Scope of Supply........................................................................................... 9

1.3.1 Standard scope of supply................................................................ 9

1.3.2 Options and accessories............................................................... 10

1.4 Optional features........................................................................................ 10

1.5 Technical Data........................................................................................... 12

1.5.1 Standard Features......................................................................... 12

1.5.2 Physical and Environmental Specifications................................... 12

1.5.3 Resistance Measurement.............................................................. 12

1.5.4 Ratio Measurement....................................................................... 13

1.5.5 Temperature Measurement........................................................... 14

1.5.6 User Interface System................................................................... 14

1.5.7 Printer paper Specification............................................................ 14

1.5.8 Tap Changer Interface .................................................................. 14

1.5.9 Interlock Interface (optional).......................................................... 15

1.5.10 Covered Standards ....................................................................... 15

2Safety 16

2.1 General...................................................................................................... 16

2.2 Essential Safety Recommendations .......................................................... 17

2.3 Interlock connection................................................................................... 17

2.4 Summary.................................................................................................... 18

3Theory 20

3.1 General Resistance Measuring Principle................................................... 20

3.2 Power Supply Modes................................................................................. 21

3.2.1 Parallel Mode on HV-side 16A ¦ 100V (A1) or 32A ¦ 50V (A2)....... 21

3.2.2 Parallel Mode on LV-side 16A ¦ 100V (B1) or 32A ¦ 50V (B2) ....... 22

3.2.3 Individual Mode 2x 16A ¦ 50V (C).................................................. 24

3.2.4 YNdx Mode 2x 16A ¦ 50V (D)........................................................ 26

3.3 Measuring sequences................................................................................ 27

3.3.1 Example 1 ..................................................................................... 27

3.3.2 Example 2 ..................................................................................... 28

3.3.3 Example 4 ..................................................................................... 28

3.3.4 Example 5 ..................................................................................... 29

4Front Panel 30

5Connection and Setup 32

Introduction

III

5.1 Connection Cables..................................................................................... 32

5.1.1 Cable extensions (optional)........................................................... 33

5.2 Connecting the Instrument......................................................................... 33

5.2.1 Connection without extenders....................................................... 34

5.2.2 Connection with extenders............................................................ 34

5.2.3 Connection in Automated mode to a 3 phase transformer............ 35

5.2.4 Connection in Automated mode to a 1 phase transformer............ 36

5.2.5 Connection in Classic mode.......................................................... 37

5.3 USB Type A Host Port............................................................................... 38

6User Interface 40

6.1 Startup ....................................................................................................... 40

6.2 Structure .................................................................................................... 41

6.3 Define DUT (Top Bar)................................................................................ 41

6.3.1 Selection of DUT Type.................................................................. 42

6.3.2 DUT data definition........................................................................ 43

6.3.3 Tap Changer configuration............................................................ 45

6.3.4 Test Name..................................................................................... 48

6.4 Applications (Side Bar) .............................................................................. 48

6.5 Active Window ........................................................................................... 49

6.6 Function Keys (Bottom Bar)....................................................................... 49

6.7 Device Information..................................................................................... 50

6.8Data Handling............................................................................................ 50

6.8.1 File management........................................................................... 50

6.8.2 Printing results. ............................................................................. 51

6.8.3 Exporting measurement results..................................................... 51

6.8.4 Webserver access / Ethernet interface.......................................... 53

7Resistance Measurement 54

7.1 Operating modes ....................................................................................... 54

7.2 Automated mode........................................................................................ 54

7.2.1 General ......................................................................................... 54

7.2.2 Function keys during resistance in automated mode .................... 56

7.2.3 Active Window............................................................................... 56

7.3 Performing a test using Automated mode.................................................. 57

7.3.1 Measurement steps....................................................................... 57

7.3.2 Set up DUT data ........................................................................... 58

7.3.3 Test current selection.................................................................... 58

7.3.4 Test current recommendations...................................................... 59

7.3.5 Tap sequence ............................................................................... 59

7.3.6 Auto recording configuration ......................................................... 60

7.3.7 Tap Control ................................................................................... 61

7.3.8 Temperature correction................................................................. 62

7.3.9 Measurement ................................................................................ 62

7.4 Classic mode ............................................................................................. 65

7.4.1 Generalities................................................................................... 65

7.4.2 User Interface structure................................................................. 65

7.4.3 Active window ............................................................................... 66

IV

Introduction

7.5 Performing a test using Classic mode........................................................ 67

7.5.1 Test object connection on classic mode........................................ 67

7.5.2 Set up DUT data ........................................................................... 67

7.5.3 Temperature correction................................................................. 67

7.5.4 Test current selection.................................................................... 68

7.5.5 Auto recoding configuration........................................................... 69

7.5.6 Measurement ................................................................................ 69

7.6 Temperature Measurement........................................................................ 72

8Demagnetization 74

8.1 Theory........................................................................................................ 74

8.2 User interface............................................................................................. 75

8.2.1 Active Window............................................................................... 75

8.3 Performing a demagnetization................................................................... 76

8.3.1 Measurement steps....................................................................... 76

8.3.2 Parameters definition .................................................................... 76

8.3.3 Demagnetizing .............................................................................. 78

8.4 Application hints......................................................................................... 78

9Heat Run –Cooling Curve 79

9.1 Theory........................................................................................................ 79

9.2 User interface............................................................................................. 80

9.2.1 Active Window............................................................................... 80

9.3 Performing a resistance measurement (cooling curve).............................. 82

9.3.1 Phases and winding selection....................................................... 82

9.3.2 Resistance measurements recording interval ............................... 82

9.3.3 Test current selection.................................................................... 83

9.3.4 Temperature settings .................................................................... 84

9.3.5 Tap changer position selection...................................................... 84

9.3.6 Measurement Single Phase.......................................................... 85

9.3.7 Measurement 3 Phase Sequential ................................................ 85

9.3.8 View Results ................................................................................. 85

9.3.9 Export results................................................................................ 86

10 Heat Run - Temperature Rise 87

10.1 Overview.................................................................................................... 87

10.2 User Interface ............................................................................................ 87

10.2.1 Active Window............................................................................... 89

10.2.2 Function keys................................................................................ 89

10.3 Performing a Temperature Rise Test......................................................... 90

10.3.1 Measurement Steps...................................................................... 90

10.3.2 Recording Settings........................................................................ 91

10.3.3 Temperature Settings.................................................................... 92

10.3.4 Liquid Cooled Transformer Measurement..................................... 93

10.3.5 Dry Type Transformer Measurement ............................................ 95

10.3.6 View Results ................................................................................. 96

10.4 Export Results............................................................................................ 96

Introduction

V

11 Transformer configuration Detection 97

11.1 Overview.................................................................................................... 97

11.2 User Interface ............................................................................................ 97

11.2.1 Active Window............................................................................. 100

11.2.2 Function keys.............................................................................. 100

11.3 Performing a Detection ............................................................................ 101

11.3.1 Measurement steps..................................................................... 101

11.3.2 Parameters definition .................................................................. 101

11.3.3 Detection..................................................................................... 101

11.3.4 Export results .............................................................................. 103

12 Turns Ratio Measurement 104

12.1 Overview.................................................................................................. 104

12.2 Theory...................................................................................................... 104

12.2.1 Definitions ................................................................................... 104

12.2.2 Measurement Example ............................................................... 105

12.2.3 Tables ......................................................................................... 108

12.3 User Interface .......................................................................................... 111

12.3.1 Function keys.............................................................................. 111

12.3.2 Active Window............................................................................. 112

12.4 Performing a Ratio Measurement............................................................ 112

12.4.1 Measurement steps..................................................................... 112

12.4.2 Set up DUT data ......................................................................... 113

12.4.3 Turns ratio measurement on Current instrument transformers.... 114

12.4.4 Data handling definitions............................................................. 116

12.4.5 Test Voltage Selection ................................................................ 117

12.4.6 Test frequency selection ............................................................. 117

12.4.7 Ratio deviation selection ............................................................. 117

12.4.8 Measuring mode selection .......................................................... 118

12.4.9 Measuring ................................................................................... 118

12.4.10 Exporting and printing results...................................................... 123

12.5 Arbitrary Phase........................................................................................ 124

12.6 Activate the Arbitrary Phase option.......................................................... 124

12.7 User Interface .......................................................................................... 126

12.7.1 Setup........................................................................................... 126

12.7.2 Function Keys and Setup............................................................ 126

12.7.3 Active Window............................................................................. 126

12.7.4 Measuring ................................................................................... 127

13 Magnetic Balance 131

13.1 Overview.................................................................................................. 131

13.2 Theory...................................................................................................... 131

13.3 Activate the Magnetic Balance option...................................................... 131

13.4 User Interface .......................................................................................... 133

13.4.1 Function keys.............................................................................. 133

13.4.2 Active Window............................................................................. 134

13.5 Measurement........................................................................................... 135

VI

Introduction

13.5.1 Measurement steps..................................................................... 135

13.5.2 Set up DUT data ......................................................................... 135

13.5.3 Data handling definitions............................................................. 136

13.5.4 Test Voltage Selection ................................................................ 136

13.5.5 Test frequency selection ............................................................. 137

13.5.6 Magnetic Imbalance selection..................................................... 137

13.5.7 Delta Winding Configuration selection......................................... 137

13.5.8 Measuring ................................................................................... 138

13.5.9 Exporting and printing results...................................................... 140

13.6 Application hints....................................................................................... 141

13.6.1 Core Magnetization..................................................................... 141

13.6.2 Winding short-circuits.................................................................. 141

14 Short circuit impedance 143

14.1 Overview.................................................................................................. 143

14.2 Theory...................................................................................................... 143

14.2.1 Definitions ................................................................................... 143

14.3 User interface........................................................................................... 144

14.3.1 Function keys.............................................................................. 144

14.3.2 Active window ............................................................................. 145

14.4 Measurement........................................................................................... 145

14.4.1 Measurement procedure............................................................. 145

14.4.2 Transformer connection .............................................................. 146

14.4.3 Set up DUT data ......................................................................... 147

14.4.4 Measurement Settings ................................................................ 147

14.4.5 Data Handling ............................................................................. 149

14.4.6 Tap Control ................................................................................. 149

14.4.7 Miscellaneous ............................................................................. 149

14.4.8 Measuring ................................................................................... 150

14.4.9 Measurement results................................................................... 150

14.4.10 Exporting and printing results...................................................... 151

15 Dynamic resistance on tap changer 152

15.1 Overview.................................................................................................. 152

15.2 Theory...................................................................................................... 152

15.2.1 Tap changer generalities............................................................. 152

15.2.2 Dynamic resistance test.............................................................. 153

15.3 User Interface .......................................................................................... 155

15.3.1 Function Keys ............................................................................. 155

15.3.2 Active window ............................................................................. 156

15.4 Measurement........................................................................................... 158

15.4.1 Measurement procedure............................................................. 158

15.4.2 Transformer Connection.............................................................. 159

15.4.3 Set up DUT data ......................................................................... 161

15.4.4 Measurement Settings ................................................................ 161

15.4.5 Static resistance settings............................................................. 162

15.4.6 Dynamic resistance settings........................................................ 163

15.4.7 Temperature settings .................................................................. 165

Introduction

VII

15.4.8 Miscellaneous ............................................................................. 165

15.4.9 Measuring ................................................................................... 165

15.4.10 Measurement results................................................................... 166

15.4.11 Exporting and printing ................................................................. 167

16 Optional Features activation 168

16.1 Software key Activation............................................................................ 168

17 Tap Changer Interface 170

17.1 General.................................................................................................... 170

17.1.1 Tap changer remote operation signal.......................................... 170

17.1.2 Tap changer feedback signal ...................................................... 171

17.2 Tap changer Remote operation ............................................................... 171

18 Temperature Interfaces 172

18.1 General Notes.......................................................................................... 172

18.2 Additional Interfaces ................................................................................ 172

18.3 Operation................................................................................................. 173

19 Troubleshooting 174

19.1 Warning and Error Messages .................................................................. 174

19.1.1 Polarity reverse or HV and LV reverse........................................ 174

19.1.2 Current to small........................................................................... 174

19.1.3 OVP - Overvoltage Protection..................................................... 174

19.1.4 OCP - Over current Protection.................................................... 174

19.1.5 OTP - Over temperature Protection............................................. 174

19.1.6 Hardware Error............................................................................ 175

19.2 Firmware Update ..................................................................................... 175

19.3 Unit locks up and/or does not discharge completely................................ 176

20 Printer Operation 177

20.1 Buttons and Status................................................................................... 177

20.1.1 Status LED.................................................................................. 177

20.1.2 Replacing Paper Roll................................................................... 177

21 Accessories & Spares 178

21.1 Temperature probe for liquids.................................................................. 178

21.2 Magnetic temperature probe.................................................................... 178

21.3 Temperature extension box 2293T.......................................................... 178

21.4 Tap changer connection cable................................................................. 179

21.5 Extension cables...................................................................................... 179

21.6 TTR-229x Adaptor ................................................................................... 180

21.7 HV cable set............................................................................................. 180

21.8 LV cable set............................................................................................. 180

21.9 Adaptor set LV & HV, bolted.................................................................... 180

21.10 Adaptor set LV & HV, twist lock ............................................................... 181

VIII

Introduction

22 Remote Control 182

22.1 Ethernet Connection ................................................................................ 182

22.1.1 RJ45 Socket................................................................................ 182

22.1.2 Direct connection......................................................................... 182

22.1.3 Switched Network........................................................................ 184

22.1.4 Routed Network / Internet ........................................................... 184

22.2 Protocol.................................................................................................... 185

22.2.1 Instructions.................................................................................. 186

22.3 Command Reference............................................................................... 187

22.4 Programming examples........................................................................... 201

22.4.1 Resistance Measurement............................................................ 201

22.4.2 Tap Changer Control................................................................... 203

22.4.3 Heat Run..................................................................................... 204

22.4.4 Demagnetization ......................................................................... 205

22.5 File & Data Transfer................................................................................. 208

23 Miscellaneous 209

23.1 Care and Maintenance............................................................................. 209

23.1.1 Cleaning the Instrument.............................................................. 209

23.1.2 Instrument Calibration................................................................. 209

23.1.3 Changing Fuses.......................................................................... 209

23.2 Instrument Storage .................................................................................. 209

23.3 Packing and Transport............................................................................. 210

23.4 Recycling ................................................................................................. 210

24 Customer Support 211

25 Appendix 212

25.1 Declaration of Conformity......................................................................... 213

25.2 Application Note “Temperature Measurement” ........................................ 214

25.2.1 1. Flat Surface............................................................................. 214

25.2.2 2. Round Surface (Tube)............................................................. 217

25.3 Application Note “Unit calibration”............................................................ 222

Introduction

9

1Introduction

1.1 Receiving Instructions

When received, any possible transport damage should be noted. A written record should be made

of any damage. A suitable remark should be recorded on the delivery documents.

A claim for damage must be reported immediately to the transport company and to the Customer

Support Department of HAEFELY TEST AG or the local agent. It is essential to retain the

damaged packing material until the claim has been settled.

Check the contents of the shipment for completeness immediately after receipt (See chapter

“Scope of Supply”). If the shipment is incomplete or damaged then this must be reported

immediately to the transport company and the Customer Support Department of HAEFELY TEST

AG or the local agent. Repair or replacement of the instrument can then be organised

immediately.

1.2 General

The Tettex 2293 is the result of extensive research and years of experience testing transformers.

It incorporates a fast and highly advanced procedure to measure winding resistance. A simple

one-time-connection system together with the simultaneous winding magnetization method

drastically reduces measuring time.

The simultaneous winding magnetization (SWM) method guarantees fast and reliable

measurements even on large power transformers with delta windings on the low voltage side,

where stable measurements can be seldom reached using traditional winding resistance

measurement instruments.

In addition, the new demagnetization function eliminates the magnetic remanence in the core

after the application of a DC voltage. This feature can be used before performing other tests such

as frequency response analysis (FRA), transformer turns ratio measurement (TTR) or recovery

voltage measurement (RVM) which are adversely affected by remanence effects.

The transformer is discharged by a state-of-the-art discharge circuit in a fraction of the time taken

by other instruments. The discharging function and the “Caution” indicator continue to operate

even when line power is lost.

1.3 Scope of Supply

1.3.1 Standard scope of supply

The following items are supplied with the standard instrument:

Qty

Description

10

Introduction

1

2293 Winding Analyzer Instrument

1

High voltage side (H) measuring adaptor, 0.5m

1

Low voltage side (X) measuring adaptor, 0.5m

4

High voltage side (H) measuring cables, 4 units, (U, V, W, N) with clamp, 10m

4

Low voltage side (X) measuring cables, 4 units, (u, v, w, n) with clamp, 10m

1

Mains cable

1

Operating Instructions

1

carrying bag for cables and accessories

1

Spare kit (Printer paper roll, Fuses)

Once receipt of the unit check that all items have been delivered. Also check that the correct

power cord for your location has been supplied. In the event of missing or damaged parts please

contact you local sales representative stating the serial number and type of the instrument and

the sales order number.

1.3.2 Options and accessories

For detailed information about accessories and options please refer to the chapter 21

“Accessories and spares”

1.4 Optional features

The 2293 is equipped with optional features. These optional features can be enabled using the

license manager. . For getting licenses for new features contact our sales department

(sales@haefely.com)

2293/SKTTR

3-phase transformer turns ratio measurement add on application

for 2293

2293/SKAP

Arbitrary phase shift add on application for the 2293,

(2293/SKTTR needed)

2293/SKTR

Heat rise add on application for the 2293

2293/SKMB

Magnetic balance add on application for the 2293

2293/SKSI

Short circuit impedance add on for the 2293

2293/SKTC

Tap changer add on for the 2293

Additional features will be added to the device regularly, for a complete list or for questions please

check in our web page (www.haefely-hipotronics.com).

To activate the additional features (software keys) please read chapter 16- Optional Features

activation, of this manual.

Introduction

11

Trial licenses for a number of tests are available under

request. Contact our sales department to get a trial

code.

12

Introduction

1.5 Technical Data

1.5.1 Standard Features

8 measuring channels (2 x 3 phases and 2 x 1 neutral)

6 temperature channels with automatic resistance correction

High efficient DC supply with SWM (simultaneous winding magnetization)

SWM mode and Classic mode (for traditional resistance measurement method)

Turbo discharge circuit

Automated demagnetizing function with flux indicator

Automatic heat run function

Tap changer control signal to automate test procedures on transformers with motorized tap

changer

Charges any inductive load and works with any resistive or inductive test object

Heavy duty protection circuit

Safety circuit ensures discharge even when line power is lost

Caution indicator

1.5.2 Physical and Environmental Specifications

Mains

90 VAC … 264 VAC

Maximum Power

1 kW

Frequency

47 Hz … 63 Hz

Operating temperature

-10°C … +60°C

Storage temperature

-20°C ... +70°C

Humidity

5% … 90% r.h. non-condensing

Dimensions (W x D x H)

521 mm x 425 mm x 216 mm

Weight(2)

17.8 kg (Instrument only)

1.5.3 Resistance Measurement

Max. Meas. Current DC

32 A (user selectable)

Max. Charge Voltage DC

100 V

Range

0.1 μ… 320 k

Resistance

Accuracy(1) See graphic

0.1 μ... 320 μ

0.1% ± 0.5 μ

Introduction

13

320 μ… 32 k

0.1%

32 k… 320 k

1%

(1) at temperature -10 …+60°C at highest available current

32μΩ

320μΩ

3.2mΩ

32mΩ

320mΩ

3.2Ω

32Ω

320Ω

3.2kΩ

32kΩ

320k

320μA

32A

3.2A

320mA

32mA

3.2mA

±0.1%

±1%

10mV

25V 50V

100V

16A

640mΩ

1mV

Current

Resistance

±0.5%

640μΩ

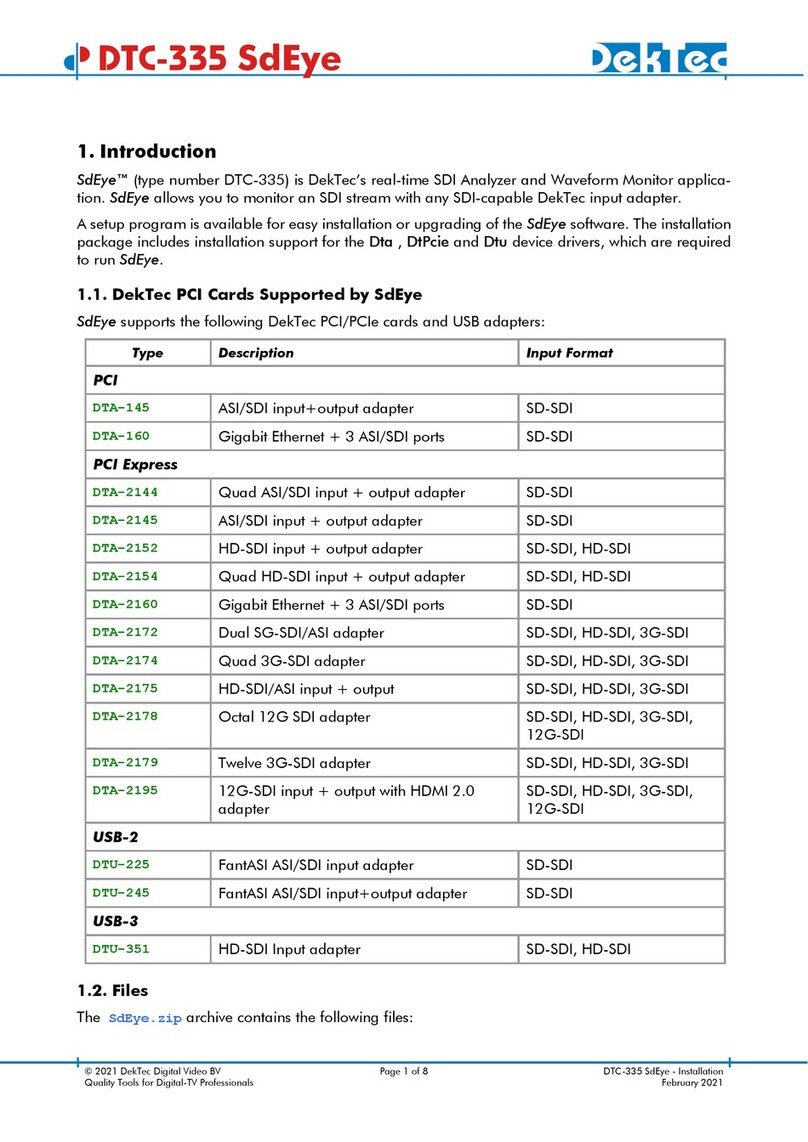

1.5.4 Ratio Measurement

General

Max. Supply Current AC

1 APeak ≈ 700 mARMS

Max. Meas. Voltage AC

95 VPeak ≈ 67 VRMS

Range

1.0 … 10’000

Ratio

Accuracy at highest measuring voltage

1.0 … 100

0.05%

100 … 2’000

0.1%

2’000 … 20’000

1%

20’000 … 100’000

5%

Phase (AC Meas.)

Typical Accuracy at highest measuring voltage

1.0 … 500

±0.10°

500 … 10’000

±1.00°

Phase (Clock Number)

Accuracy at highest measuring voltage

1.0 … 500

±0.05°

14

Introduction

1.5.5 Temperature Measurement

Built-in Channels

6

Max. Meas. Channels

30 (6 internal + 3x external 8CH box “2293T”)

Sensor Probe

PT100 Class A

Temperature

Accuracy

-20°C … +150°C

± (0.41°C + 0.2% TMeas)

1.5.6 User Interface System

MMI

7” graphical touch screen interface

Memory:

>10'000 measurements

Communications:

USB 2.0

LAN connection

Data can be saved on a memory stick or directly transferred to

PC

Printer:

Thermal

1.5.7 Printer paper Specification

Paper Type:

Thermal Roll

Paper Width:

58mm

Paper Capacity:

32mm Diameter (10m length) Inner Diameter 12mm

1.5.8 Tap Changer Interface

Feedback (sense input)

Function

Connect the feedback contactor of the tap changer

Ratings

3.3V, 1mA (input impedance 100kΩ)

Up/Down (set output)

Function

Connect the Up/Down control contacts of the tap changer

Ratings

Max. 250V AC

Max. 230V DC, 300mA

Max. 30V DC, 2000mA

Introduction

15

1.5.9 Interlock Interface (optional)

Function

Connect an external contactor of interlock circuit

Connector

Socket: LEMO2 (2P ERA 1S)

Plug: LEMO2 (FFA 2S 302 CLAC62 2P)

Ratings

Max. 5V, 100mA

1.5.10 Covered Standards

CE mark

Compliant

Standards

IEC 61010, General IEC 61326-1, IEC 61000-4-X,

61000-3-X, EN 55011, ANSI/IEEE C37.90

Safety

VDE 0411/part 1a , IEC/EN 61010-1:2002

16

Safety

2Safety

Remember:

Hazardous voltage can shock, burn or cause death !

The unit should only be operated after carefully reading the user manual which is an

integral part of the instrument.

Haefely Test AG and its sales partners refuse to accept any responsibility for consequential

or direct damage to persons and/or goods due to none observance of instructions

contained herein or due to incorrect use of the equipment.

Further be aware that Safety is the responsibility of the user!

2.1 General

Safety is the most important aspect when working on or around high voltage electrical equipment.

Personnel whose working responsibilities involve testing and maintenance of the various types of

high voltage equipment must have understood the safety rules written in this document and the

associated safety practices specified by their company and government. Local and state safety

procedures should also be consulted. Company, regional or national regulations must be fulfilled

beyond Tettex recommendations.

If the instrument is damaged or it is possible that damage has occurred, for example during

transportation, do not apply any voltage. The instrument may only be used under dry operating

conditions.

Do not open the unit, it contains no user replaceable parts.

People with heart pacemakers should not be in the vicinity of this system during operation.

Safety is the responsibility of the user. Always operate the equipment in accordance with

the instructions, always paying full attention to local safety practices and procedures.

This equipment must be operated only by trained and competent personnel who are

aware of the dangers and hazards involved in testing transformers.

Do not operate the 2293 from a variable power supply. The 2293 adjusts to the local line

voltage at start-up. Changing the line voltage while the unit is in operation may cause

damage to the unit and to the test object

Table of contents

Other Tettex Measuring Instrument manuals