Operation Manual of Elevating Work Platform

3

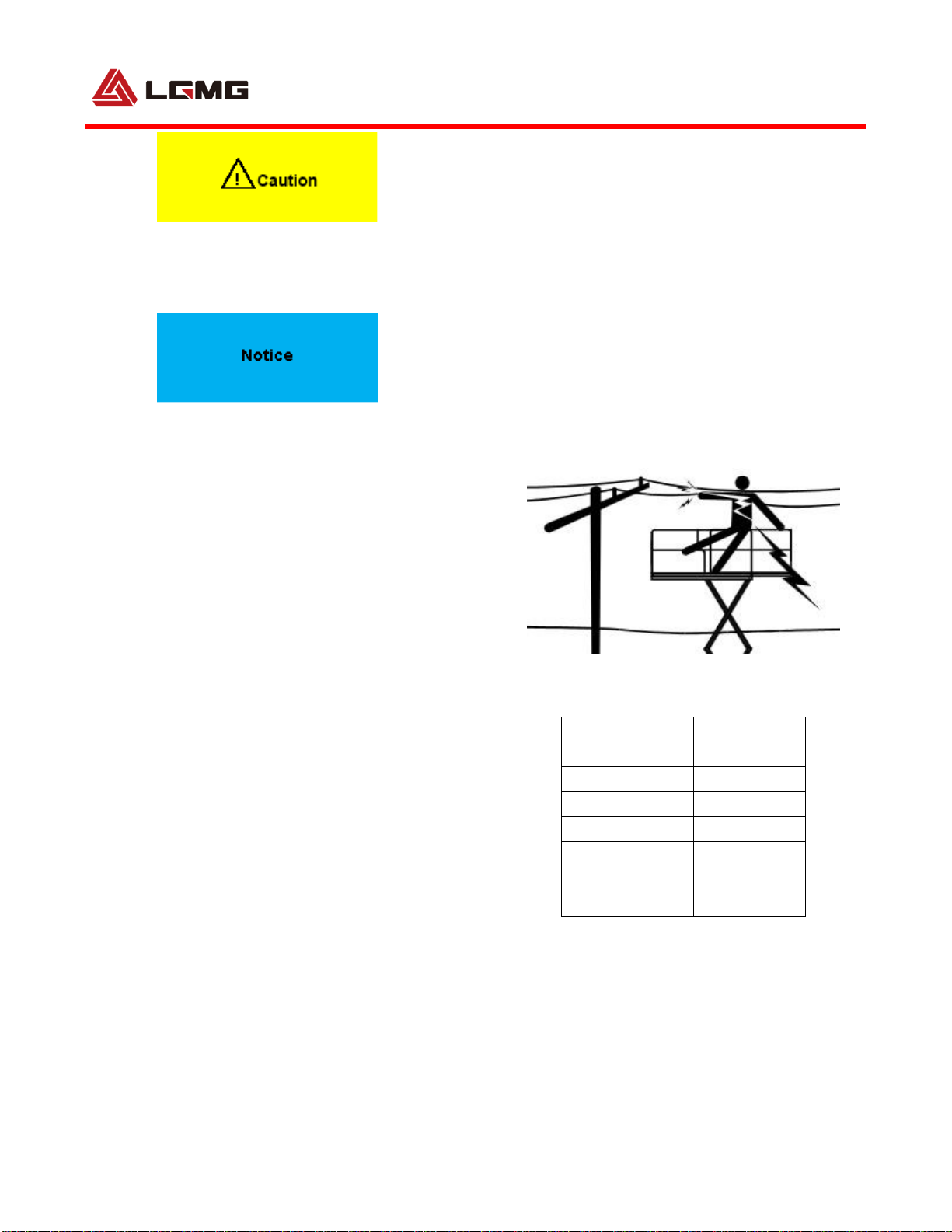

Stay away from the machine if it contacts a

live electric wire. Do not touch or operate the

machine from the ground or the platform

before cutting off the power supply.

Do not operate the machine in inclement

weather.

Do not use the machine as a ground for

welding. This could damage electrical

components on the machine.

Do not touch the battery charger when

charging the batteries.

△

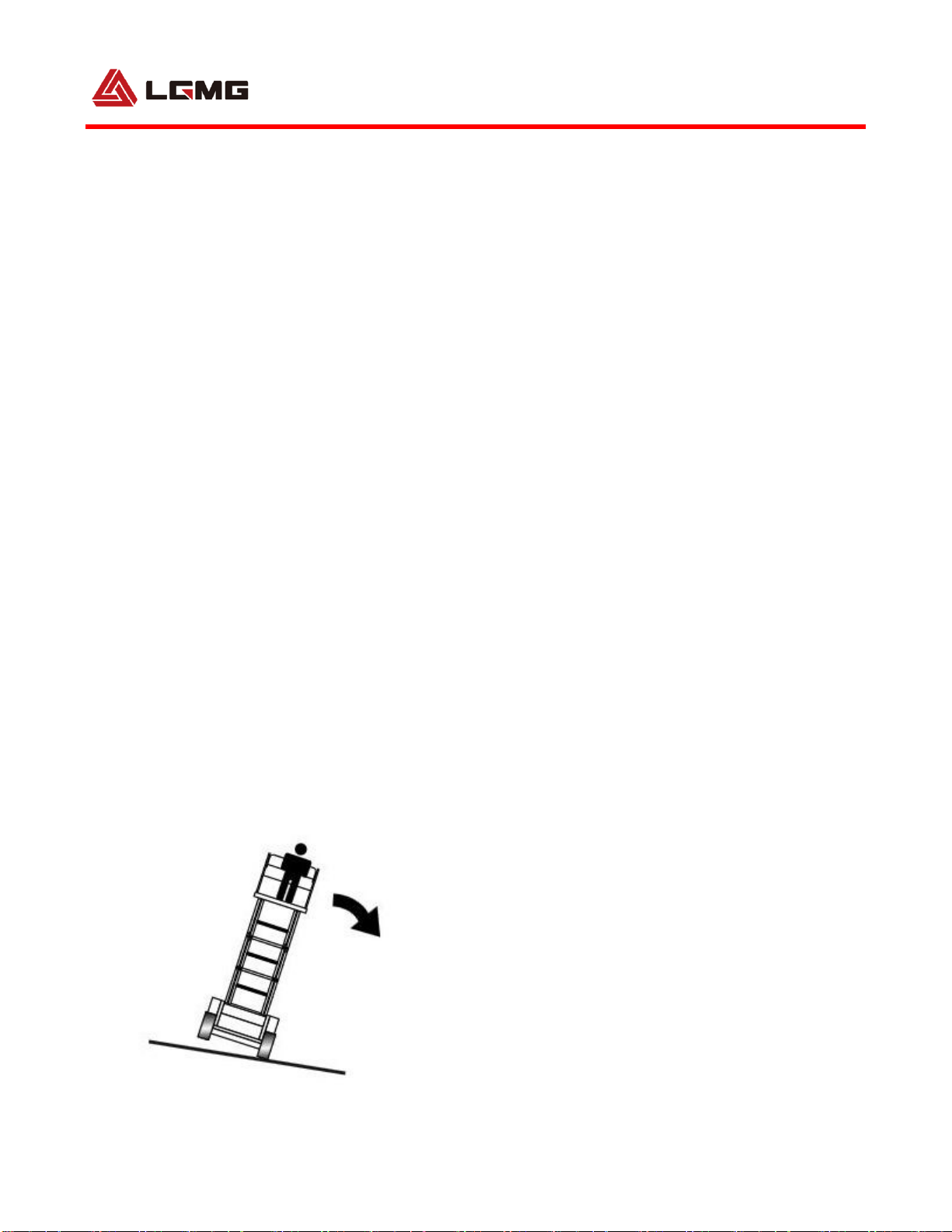

!Tip Over Hazard

The personnel, equipment, and material

on the platform shall not exceed the

maximum bearing capacity of the

platform and the extending platform.

Refer to Chapter 10 –Specifications for

model capacities.

1) The platform can only be elevated on flat,

solid ground.

2) The maximum elevated drive speed for

models AS0607E/AS0607WE/AS0608E/

AS0808E/AS0612E/AS0812E/AS1012E/AS1

212E/AS1413E/AS0607/AS0607W/AS0608/

AS0808/AS0612/AS0812/AS1012/AS1212/A

S1413 is 0.8 kph. The maximum elevated

drive speed for models

SS0407E/SS0507E/SS0607E is 0.5 kph.

3) Do not use the tilt alarm as a level indicator.

The tilt alarm only sounds when the machine

is severely tilted.

4) If the tilt alarm sounds: lower the platform and

move the platform to flat, solid ground. If the

tilt alarm sounds when elevating the platform,

lower the platform immediately.

5) If the machine is used outdoors, do not

elevate the platform when wind speed is

above 12.5 m/s. If wind speed exceeds the

limit after elevating the platform, immediately

lower the platform and stop all machine

operation.

6) If the machine is used indoors, do not elevate

the platform when wind speed is above 0m/s.

7) The ambient temperature range for use of

this machine is -20℃to 40℃.

8) The relative humidity for use of this machine

shall be no greater than 90% (20℃).

9) The allowable voltage fluctuation of the

machine is ±10%.

10) Do not increase the surface area of platform

or load. Increasing the exposure area in wind

will reduce the stability of machine.