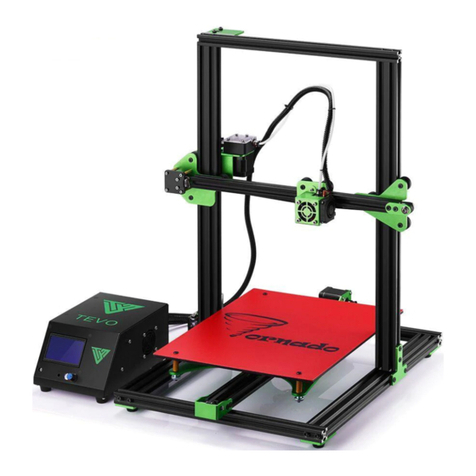

Tevo Black Widow User manual

1

READ ME FIRST!

READ THIS MANUAL COMPLETELY BEFORE ASSEMBLING AND POWERING UP YOUR

PRINTER!

Hazards and Warnings

The TEVO Black Widow 3D printer has motorized and heated parts. When the printer is in

operation always be aware of possible hazards.

Electric Shock Hazard

Never open the electronics bay of the printer while the printer is powered on. Before

removing the access door, always power down the printer and unplug the AC line cord.

Burn Hazard

Never touch the extruder nozzle, heater block, or the heated bed without first turning off

the hot end (or heated bed) and allowing it to completely cool down. The hot end (or

heated bed) can take up to twenty minutes to completely cool down. Also, never touch

recently extruded fliament. The filament can stick to your skin and cause burns.

Fire Hazard

Never place flammable materials or liquids on or near the printer when powered on or in

operation. Liquid acetone and vapors are extremely flammable.

Pinch Hazard

When the printer is in operation, be careful never to put your fingers in the movings parts,

including the belts, pulley, gears, wheels or leadscrew.

Static Charge

Make sure to ground yourself before touching the printer, especially the electronics.

Electrostatic charges can damage electronic components. To ground yourself, touch a

grounded source.

Age Warning

For users under the age of 18, adult supervision is recommended. Beware of choking

hazards around children.

2

1. Table of Contents

1. Table of Contents.............................................................................................................2

2. Letter from Tevo..............................................................................................................3

3. Lower Frame Assembly....................................................................................................4

4. Y Endplate and Idler Assembly.........................................................................................5

5. Y Motor and Idler Assembly B-13, B-18............................................................................7

6. Bed Carriage Assembly ..................................................................................................10

7. Second Y Endplate Assembly .........................................................................................12

8. X Axis Assembly B-3, B-4................................................................................................13

9. Z Axis Uprights...............................................................................................................16

10. Z Axis Assembly ..........................................................................................................18

11. Z Motor Bracket Assembly..........................................................................................23

12. Extruder Plate Assembly and Installation....................................................................25

13. Extruder Assembly and Installation ............................................................................29

14. X Motor and Belt Installation......................................................................................32

15. Limit Switch Installation..............................................................................................37

16. Control Box Assembly.................................................................................................40

17. Mainboard Connections .............................................................................................42

18.Wiring Schematic........................................................................................................43

19. Setting Up Repetier-Host for Printing .........................................................................44

20. BLTouch Calibration (only if you have BLTouch option) ..............................................48

21. Slicer Settings for Repetier-Host.................................................................................49

22. First Test Print ............................................................................................................51

3

2. Letter from Tevo

Dear User,

Thank you for purchasing the Black Widow 3D printer.

This guide will step you through the assembly and the first runs of the printer. If you have

any problems during assembly, please go to our Facebook group:

https://www.facebook.com/groups/TEVO.Black.Widow.owners/

If you cannot resolve your problem there, do not hesitate to contact us through the website

http://support.tevoprinter.com

The manual begins by showing all needed parts for the frame assembly. Please check if

those parts are all in your package and check if all rods are straight. You can do this by

placing them on a flat table and see if they roll. While checking the parts please do not mix

the parts of the Bags A-1 to A-8. Keep them separated to prevent using the wrong parts

during assembly.

After the parts check, to complete each step use the parts listed for that step.

Please make sure that the frame is completely square and tight in every angle by using a

geometrical triangle or any other more sophisticated square tool (not supplied with the

printer).

4

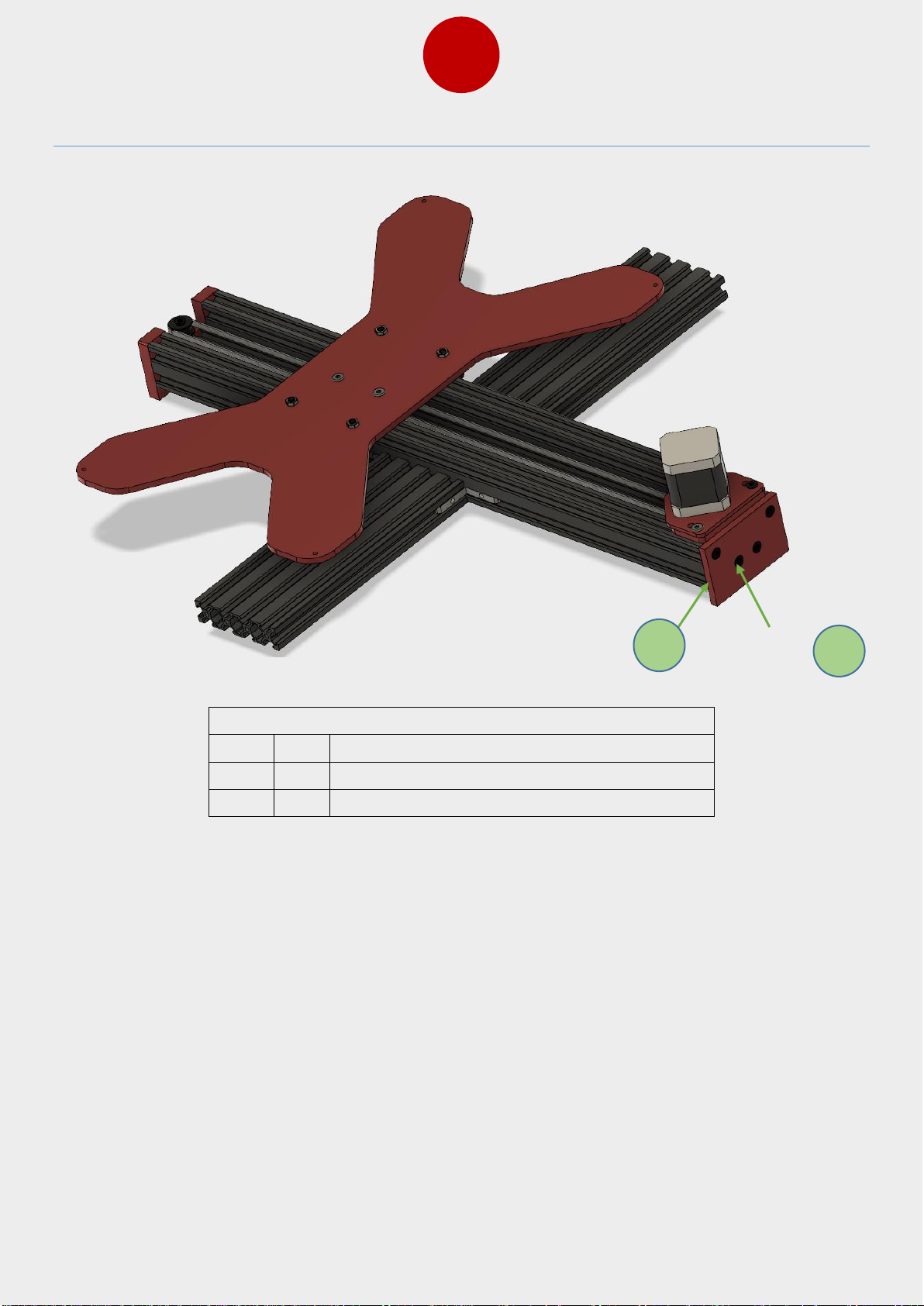

3. Lower Frame Assembly

Item

Qty

Part name

1

1

C beam extrusion L=550

2

2

2080 extrusion L=210

3

4

L corner connector

Start the assembly of the bottom of the frame by following the figure above to see how to

set the extrusions.

1

2

3

2

5

4. Y Endplate and Idler Assembly

Bag Name: B-1

Item

Qty

Part name

1

1

Y axis endplate 1

2

4

M5x20 bolts

Install the Y axis endplate 1 in place by using M5x20 bolts.

1

2

6

Bag Name: B-1

Item

Qty

Part name

1

1

M5x25 bolt

2

1

Idler

3

1

8x5x1mm shim

4

1

M5 nut

Install the idler wheel on the Y axis front endplate as shown in the figure above. Tighten the

nut against the plate so that bolt will stay rigidly in place. The idler should be able to freely

rotate with no drag.

1

2

4

3

7

5. Y Motor and Idler Assembly B-13, B-18

Install the motor on the Y motor upper bracket using the M3x8 bolts. Install the GT 2 gear

pulley on to the motor shaft. Make sure that you tighten 1 set screw on the flat side of the

motor shaft to prevent the gear from slipping.

Bag Name: B-13, B-18

Item

Qty

Part name

1

1

GT2 pulley

2

1

Stepper motor

3

3

M3x8 bolt

4

1

Y motor upper bracket

3

1

2

4

8

Put the Y motor and upper bracket on the lower bracket and use M5 bolts and T-nuts to

install on the extrusion. Leave 2 mm gap from the end of extrusions to allow tightening of

the belt later on.

Item

Qty

Part name

1

1

Lower Y bracket

2

2

M4x16 bolt

1

2

9

Item

Qty

Part name

1

1

Bed belt bracket

2

1

GT2 belt

3

2

Zip ties

Loop the belt around idler and GT2 pulley and put end of belt through holes in the part no

1. (Bed belt bracket). Install the bed belt bracket on the right side (looking from the front

otherwise the bed will move in the wrong direction. Use zip ties to tighten the loops. The

belt needs to be tight in this step, you will be able to adjust the belt tension by adjusting

the Y motor upper bracket.

1

2

1

10

6. Bed Carriage Assembly

Bag Name: B-10

Item

Qty

Part name

1

4

M5 locknut

2

2

6mm spacer

3

4

8x5x1mm shim

4

4

V-slot wheel

5

4

M5x30 bolt

6

2

Eccentric nut

7

1

Heated bed carriage

2

3

1

4

5

6

7

11

Remove the Y motor and brackets with the motor and slide the hotbed carriage in place.

Use the provided wrench to adjust the eccentric nuts to adjust wheels, so the carriage

moves smoothly in grooves. After this, use two M5 bolts to fasten the belt bracket in place

to bed. Mount the Y motor and brackets back in place and put belt back around the idler

and GT2 pulley. Slide the bracket with motor towards the back of the frame, so that belt

gets tensioned and tighten the bolts.

12

7. Second Y Endplate Assembly

Bag Name: B-2

Item

Qty

Part name

1

4

M5x20 bolts

2

1

Y axis endplate 2

1

2

13

8. X Axis Assembly B-3, B-4

Bag Name: B-3, B-4

Item

Qty

Part name

1

4

M5 locknut

2

4

8x5x1 shim

3

4

V slot wheel

4

1

Z slide plate

5

2

Eccentric nut

6

6

M5x25 bolt

7

2

6mm spacer

8

2

M5 nut

9

1

POM trapezoid nut

10

2

5mm brass spacer

1

2

8

5

3

7

6

10

0

4

9

14

When you have both Z slides assembled, try them in the extrusions and adjust the eccentric

nuts so the wheel feels snug, but still rolls smoothly inside the extrusion.

15

Bag Name: B-3, B-4

Item

Qty

Part name

1

8

M5x15 bolts

Assemble the X axis by mounting the Z slides to 2040 extrusions by using M5x15 bolts.

1

16

9. Z Axis Uprights

Bag Name: B-5, B-6

Item

Qty

Part name

1

2

C beam extrusion

2

4

L corner bracket

3

2

Z axis endplate

4

8

M5x20 bolt

5

2

Bearing

Prepare two pieces of the Z uprights as shown in above picture. Put bearing in the slot

located in the plate.

1

2

4

3

5

17

Install the Z uprights to the bottom frame and tighten in place. Make sure you use a square

to check squareness before tightening.

18

10. Z Axis Assembly

Bag Name: B-7, B-8

Item

Qty

Part name

1

1

X Gantry assembly

2

2

Z Rods

Screw the leadscrews in POM nuts as shown in picture above.

Other manuals for Black Widow

1

Table of contents

Other Tevo 3D Printer manuals