EPAX DX1 Pro User manual

DENTAL

USER

MANUAL

SECTION I

02

SECTION II

Touchscreen Menu

03

SECTION III

Dental Resins

04

SECTION IV

Slicing Software - ChiTu Box

SECTION V

The Printing Process

SECTION VI

Trouble Shooting

SECTION VII

Warnings

SECTION VIII

Warranty and Return Information

TABLE OF

CONTENTS

DX Series Specifications

05

08

11

12

13

1

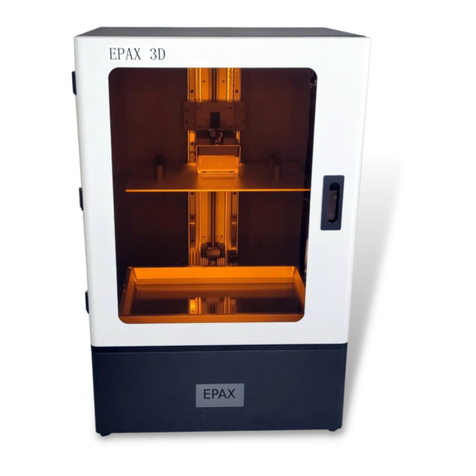

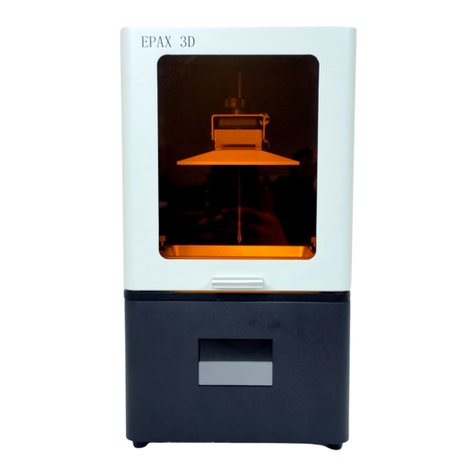

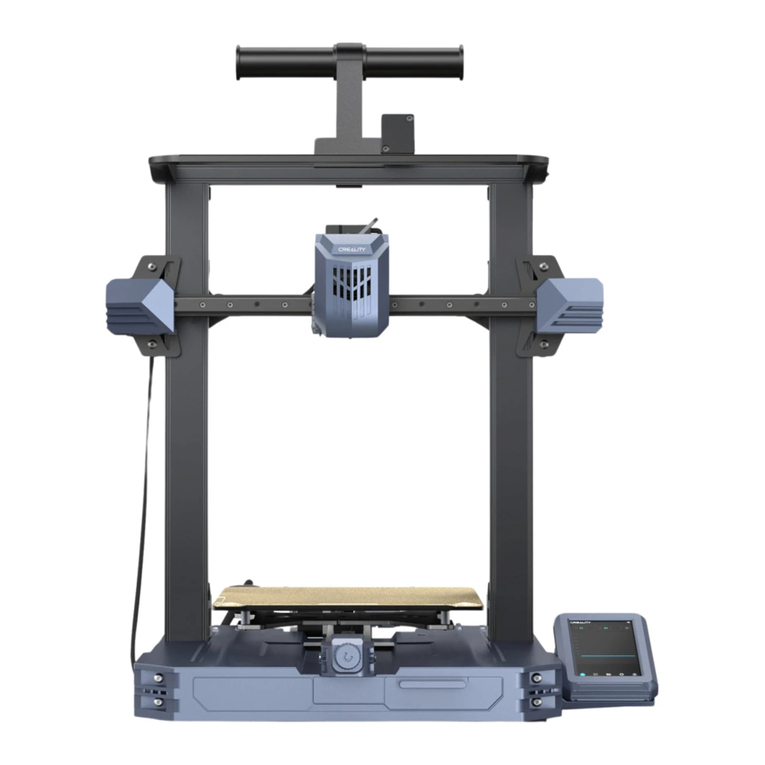

DX SERIES

SPECIFICATIONS

Section I

.

Model EPAX DX1 Pro EPAX DX10 Pro EPAX DX Cure Pro

Build Volume

(L*W*H)

143.43mm*89.66mm*

120mm

221.4mm*129.6mm*

120mm

Printing Technology Monochrome LCD Monochrome LCD UV Curing Box

Material Resin Resin Washed Resin Prints

Resolution 4098*2560 (4K) 4920*2880 (5K)

Layer Thickness 0.02 ~ 0.1 mm 0.02 ~ 0.1 mm

Connection USB Flash Drive,

Ethernet

USB Flash Drive,

Ethernet

Wi-Fi No No No

Build Platform Soft Aluminum with Steel

FBS

Soft Aluminum with Steel

FBS

Clear Acrylic Turntable

Resin Vat Hard Aluminum Hard Aluminum

Heated Vat Yes Yes

Max Resin Volume 300mL (With Platform) 700mL (With Platform)

Air Purifier Yes Yes

Light Source Parallel Light LED Matrix Parallel Light LED Matrix Lensed UV LEDs

Film nFEP Film nFEP Film

Touch screen 4.3-inch Color TFT 4.3-inch Color TFT No

File Type .stl .ctb .stl .ctb N/A

Slicer ChiTuBox ChiTuBox N/A

Product Size

(W*D*H)

9.5 x 9.5 x 14.5 inches

11.75 x 12.5 x 15.25

inches

11.75 x 11.75 x 8.5 inches

Product Weight 20lbs 35lbs 12lbs

2

https://epaxdental.com

The system page

contains product

information, contact info,

network info, and a

touchscreen calibration

figure.

SYSTEM PAGE PRINT PAGE TOOL PAGE

The tool page contains

manual z-axis controls,

exposure tests, and a

cleaning feature. You

mat also rest the Z=0

(logical position) here.

The manual page, also

allows you to manually

move the printer to the

home (physical zero)

position.

Exposure/Clean, on the

page above set the

amount of time you

want the screen to run

with these features.

Exposure tests are

for ensuring the

screen is working as

intended.

The cleaning

feature allows you

to check the screen

for dead pixels and

clean the vat.

The information screen

above informs which

firmware you are

running and what

resolution your screen is

displaying.

The print page displays

the select files to print

from your USB drive. This

is also where you can

perform updates as well.

From the print screen

you can choose to print

or delete the file from

the USB

You may also edit your

bottom layer count and

exposure settings mid-

print if needed.

TOUCHSCREEN

MENU

3

Section II

.

INFORMATION

PAGE

https://epaxdental.com

Porcelain-Like Resin Model 48052 Veriguide OS

Alongside our own Dental Model resins and all other EPAX

resins

,

we

’

ve verified compatibility with mainstream

3

rd

party resins listed above

.

Model 48213

Model Align

DENTAL

RESIN LIST

We have tested and validated a

wide range of dental resins for

you to utilize with the DX series of

printers and have more coming

as we grow.

If you are using a resin that is not listed in

the tested resins, we recommend talking

to the resin manufacturer about settings.

Many dental resins can differ greatly

despite being for the same purpose, so

while we may be able to give general

guidance, we won’t have concrete

settings.

For assistance at any time please visit our

ever-growing Facebook Dental group.

Many of our users are very active and give

advice on the page, including slicer

settings for specific resins that we may not

have tested yet. Request to join at the link

below:

http://www.facebook.com/groups/epaxdental

EPAX Dentona Optiprint Keystone Whipmix

Dental Model Resin Guide 385nm and 405nm KeyModel Ultra Verimodel OS Ivory

Bio-Based Soy Resin Gingiva 385nm KeySplint Hard Vericast OS

All other EPAX resins are

compatible and verified

Model 48053

Hard Resin IBT 385nm KeySplint Soft Verimodel OS White

Section III

.

4

https://epaxdental.com

SLICING

SOFTWARE

Section IV

.

For the latest slicer download, please visit:

https://epaxdental.com/pages/software

Slicer Settings

The latest version of ChiTuBox also has settings preloaded for most resins

including dental resins. After you open the ChiTuBox slicer for the first

time, you will need to add your printer in. Click the "Settings" button on

the right bottom side. Then click the "+" button on the top left side of the

"Settings" window. Then in the pop-up window select "EPAX" and then

select printer model. "DX1 PRO" and "DX10 PRO" are our dental printers.

Make sure you do this before your first print. Displayed below is how

everything should look once you select your printer.

5

https://epaxdental.com

THE CORRECT PRINT SETTINGS ARE CRITICAL FOR SUCCESSFUL

AND ACCURATE PRINTS, BUT THERE IS AN ACCEPTABLE RANGE

FOR MOST TYPES OF RESIN. SOME RESINS ARE ALSO IMPACTED

BY THE TEMPERATURE IN THE PRINTING ENVIRONMENT, AND

YOU WILL NEED TO ADJUST YOUR SETTINGS ACCORDINGLY.

GENERALLY, RESINS PREFER WARM TEMPERATURES, AND MANY

DO WELL BETWEEN 25°C AND 30°C (~77°F AND 85°F) .

BRIEF EXPLANATION

OF STANDARD PRINT

SETTINGS

Layer Height: 0.05mm is recommended (range: 0.02- 0.1mm) The

thicker the layer height, the longer the exposure time per layer needed,

but the shorter the print time. Models may be less accurate with thicker

layer height.

Exposure Time: Amount of time it takes to cure each layer of the print

and varies depending on resin.

Bottom Exposure Time: Amount of time it takes to cure the bottom

layers of the model to adhere to the and varies depending on resin. The

longer the bottom exposure time, the better the bottom layer will stick

to the plate. Don’t go too long, or you’ll end up needing to chisel the

print off.

Bottom Layer Count: More bottom layers will allow for stronger

adhesion. We recommend sticking with 4.

Rest Time/Light off Delay: For resins requiring exposure times higher

than 4s, we recommend adding rest time or light of delay to allow heat

to disperse between layers. This will increase print times, but the print

will better retain its intended properties and accuracy.

Lift Distance/Bottom Lift Distance: How much the platform lifts

between layers.

Lifting Speed/Bottom Lift Speed: How fast the platform lifts after

finishing layers.

Retract Speed: How fast the platform lowers to the next layer.

Section IV

.

6

https://epaxdental.com

Lifting Speed - Increasing this will speed up how fast the build plate

lifts the print off of the film. WARNING: Going too fast could result in

failed prints or torn film meaning wasted resin and potential damage

to the screen/machine. Do not increase too much.

Retract Speed - Increasing this will speed up the build plate lowering

back down after lifting. WARNING: Going too fast could result in prints

prematurely lowering before resin fills in gaps in the vat. This will result

in missing layers and potentially broken or failed prints.

Lifting Distance/ Bottom Lift Distance: The preset values we have on

our website, and in ChiTuBox can be decreased depending on the print

job and layer height to save slightly more time. WARNING: Lowering

too far can result in the print not fully peeling off the film. Can result in

missing layers, failed prints, and broken nFEP in worst cases.

NOTES ON SPEEDS AND DISTANCES

BRIEF EXPLANATION

OF STANDARD PRINT

SETTINGS

(

CONT

.)

Section IV

.

Light: Small Contact area. Best for small prints and in detailed areas.

Medium: Larger contact area, and stronger than light supports.

Heavy: Largest contact area and are the strongest support settings.

Models that cannot sit flat on the platform (Guides, Splint, etc.) will need

additional supports while printing. (All supports will need to connect with

the foundation or stable part of the print for success. You can always

remove them from your final product.)

There are 3 default support options:

Rafts are recommended for prints that aren’t touching the platform at all

i.e. the print is suspended. Can be edited for stronger adhesion to the build

platform.

SUPPORTS

7

https://epaxdental.com

Install Build Platform

Move the platform arm a bit higher than the

printer’s Home position. Goto Tools→ Manual,

select the 10mm increment, then hit up a few

times so that you can move the z axis a bit

above Home position. Then put platform on and

ensure platform fits into this location and secure

its screw.

Install Resin Vat

Move Z axis about 100mm up so that you have

room to put the vat on. Make sure there is no

paper or plastic wrap between the screen and

the vat. On the DX series the back of the vat will

have a wire running out the back right for the

heating feature. The vat slots on the two screws

on each side and you can use the knob screws

to secure it in place. Once this step is complete,

we can move onto to the first print. The vat also

has a heating feature and can be plugged in on

the back right . For now, we only recommend its

use for our EPAX line of resins. For use with our

other compatible dental resins, leave

unplugged.

All the accessories are packed inside the printer.

Be careful when you remove the foams. Remove

each foam layer starting from the top. You should

find:

Metal vat and build plate, metal and plastic

spatulas, 2.5 and 3mm Allen Keys, USB, Power

Supply, Vat Knobs, and Build Platform Knob Screw.

Check the Light Source and LCD Functionality

After turning on the printer, you should check the

light source and LCD by pressing Tools→ Exposure→

Next. It will turn on UV light and a rectangle shape

will be displayed that will match the image on the

touchscreen. Press the return button to stop the

testing. Do this after every time you replace the

LCD to test its functionality.

Check the Z-axis Movement

Test the Z-axis movement by pressing Tools→

Manual→Auto Home. It will move the build platform

arm to the Home position. You can also press the

Up button to move the Z-axis up. Do not try to

move the Z-axis down below the home position.

DX PRO PRINTER QUICK

SETUP

DX PRINTER

AND CURE PRO

SETUP

The DX cure pro is a very simple setup. Most of the

machine is already put together, the only part

you’ll need to put on is the acrylic turntable. The

acrylic turntable slots right into the middle post.

Please ensure that you remove any protective

paper on the acrylic turntable before installation

to provide best performance when post-curing.

Before post-curing a print, make sure it is fully dry

from its wash so it doesn’t come out tacky after

the post-cure. Go ahead and test the machine by

pressing the play button to make sure the

turntable is rotating, and the lights are coming

on.

DX CURE PRO

Our Quick Start guide

goes through the setup of

the printer as well

.

We

’

ll

go over the cure pro and

the printer setup here so

you can reference either

.

Section V

.

8

https://epaxdental.com

https://epaxdental.com

THE PRINTING

PROCESS

:

DENTAL MODEL

MAKE SURE YOUR MACHINE IS PLACED ON A STABLE, FLAT

SURFACE. BY THIS POINT YOU SHOULD HAVE CHITUBOX

INSTALLED, AND THE PRINTER’S CONFIG LOADED ONTO THE

SETTINGS (REF: SECTION IV)

Section V

.

Open up Chitubox and start with a basic dental arch model and place it flat on the platform. If

your dental model doesn’t have a flat base, you can lower its z-height a couple of mm using

the move tool on the left-hand side of the slicer. Dental models are best printed flat to the

plate, but you can use supports if needed. Once the dental model is set up, slice the model.

After the software has finished slicing you may save the file directly to the USB.

If you’re printer is connected via ethernet to a router, you can opt to send the print via the

network send feature instead. When doing this, make sure the USB is plugged into the

machine. You can select your printer from the Dropdown menu on Chitubox. Once sent, you’ll

be prompted if you want to go ahead and start the print as well. If you choose to do so later,

you can start the print manually from the printer as the print is now on the USB.

1: SLICE YOUR PRINT

Each resin vat has a maximum capacity with and without the build plate. There are tick marks

indicating fill lines. It’s recommended to only fill to the first tick mark when starting a print.

Unless you are utilizing the full build volume, you will rarely ever need to fill the vat to max

capacity. Please make sure for whichever resin you are using, you shake the bottle well, or swirl

if the manufacturer says otherwise because resin can settle and may need a bit of mixing

before usage.

!EXTREME CAUTION! Always wear gloves, goggles, and a mask for your protection when

handling liquid resin. If liquid resin gets on your skin, immediately wash the afflicted area with

soap and hot water.

2: LOAD RESIN

Insert the USB onto the printer and tap the print button on the main menu. Find your file, tap

it, and hit the play button to start the print.

For the first print, it is a good idea to check on the print after around 30 minutes to confirm

that the first layers stuck to the build platform. If the print does not stick to the build platform,

then either the bottom exposure time is too low, or the platform is not leveled properly. In

which case, contact EPAX 3D to provide you guidance.

3: STARTING YOUR FIRST PRINT

9

THE PRINTING

PROCESS

:

DENTAL MODEL

Section V

.

When the printing is done, wait until no more residual resin drips from the platform and wear

gloves before removing it. You can wipe off any residual resin as well.

Our DX series comes with a Flexible Build System. Using the metal tab sticking out from the

platform, you can remove the Flex plate from the brown magnetic base. To remove the print,

simply flex the plate to pop the print off. It’s best to pop the print off directly into the IPA bath

to avoid the print popping off onto the floor or table. Soak the print in at least 91% IPA

(Isopropyl alcohol) for about 10-15 minutes. For some dental resins you may need to leave it in

for longer or agitate the IPA so that the residual liquid resin can be cleaned off.

After your model is clean, put it in a cool, dry, well-ventilated area until it dries, or dry it up with

a air blower. Please make sure to still be wearing gloves during this time. To cure it, you can

insert the model into our DX Cure Pro machine. Set the timer for 180s, and at the end the print

should be good to be used. The print should feel like plastic. If it still feels tacky, or not dry you

may not have let the print dry for long enough, or the environment may be too humid to dry

properly. In this case, consider utilizing a fan to blow on the print while drying.

4: POST-PROCESSING

10

https://epaxdental.com

Email us directly at [email protected].

We provide technical support Monday-Friday 9am to 5pm

EST. In certain cases, we may even provide video

conferences to provide solutions or direct troubleshooting.

Any questions related to your order may be directed to our

sales team at [email protected].

IF YOU ARE HAVING ISSUES:

TROUBLESHOOTING

Section VI

.

You can also join our Facebook Group to get help from

other users, especially if you need help tuning slicer

settings. There are too many resins out there for us to

cover every single one, but many experienced users

who have used a variety of resins and can help the

best when it comes to dialing in settings. Each

particular model might need different support

methods and positioning. These are the experience

related questions which we rely on our community to

help each other. Most of them are just fine tuning

your slicer settings for the particular scenario. Please

don’t hesitate to ask any questions you may have in

our Facebook group:

http://www.facebook.com/groups/epaxdental

FOR ADDITIONAL SUPPORT:

11

https://epaxdental.com

When you find that a print has failed or there is solid residue in

the resin vat, you must filter the resin in order to protect the LCD.

Clean the resin in the resin vat by filtering out the solid residue

using one of the provided filters or a paint filter which can be

found online or at your local hardware store. If ignored, when

the build plate dips into the vat, the force of the plate may crush

residues, puncture the film and damage the LCD. This is a costly

mistake.

If there is residual resin in the resin vat or on the build plate’s

outer surface, please clean with a soft tissue soaked in IPA to

avoid it dropping into the machine and curing inside.

Always wear gloves, a respirator mask and protective goggles

when handling liquid resin or a print before the post-processing.

Only touch the print without gloves after it’s been fully cleaned

and cured!

Print in a well-ventilated area. It is strongly recommended to use

a vent fan drawing air around the printer to outside the building.

Resin fumes can cause lung irritation!

PLEASE READ:

For printer instructions, videos, firmware updates, parts, supplies,

resins, and more please visit http://www.epaxdental.com/.

Customer Support Email: [email protected]

Join us on our Facebook group for active discussions and

knowledge-sharing:

https://www.facebook.com/groups/epaxdental/

IT IS STRONGLY RECOMMENDED THAT YOU WATCH OUR

TUTORIAL VIDEOS BEFORE OPERATING YOUR PRINTER FOR

THE FIRST TIME.

WARNINGS

Section VII

.

12

https://epaxdental.com

WARRANTY INFOMATION

New printers have a 1-year USA

warranty that begins from the date you

receive your printer. Our refurbished

printers are backed by a 3-month

warranty that begins from the date you

receive your printer.

Please note: The LCD screen, film,

precut tape, filters, and resin are

consumable technology which are

NOT covered by this warranty. The

warranty is also NOT valid for

international (non-USA) orders due to

high shipping costs. If you are outside

USA, please consider purchasing from

our distributors with warranty.

All other components of the printer are

covered by the warranty. In the event

of defect, we will ship you replacement

parts free of charge. It does not void

the warranty for you to open your

printer and perform maintenance. Our

printers were designed to be user-

friendly both inside and out.

Warranty does not cover willful

damages, tears and damages due to

accident, normal wear and tear,

improper care and misuse.

If you wish to have us repair or perform

maintenance on your printer for you,

we are happy to do so. We will provide

parts and labor, but you must cover the

round-trip shipping costs from your

location to our office in North Carolina,

USA. You must also cover any parts

not under warranty. You may use your

preferred carrier.

WARRANT

AND

RETURNS

RETURNS AND REFUNDS

If for some reason you decide our

printer is not for you, simply contact us

within 30 days from the date of your

purchase. Return shipping must be

covered by the customer. We can print

a label for you, however, the cost of the

label will be deducted from the refund.

For unopened products, a 5%

processing fee will be deducted from

your refund to help cover a portion of

our transaction and shipping costs.

For opened/used products there is a

15% restocking/processing fee and if

any parts/accessories are missing, the

cost for those items will be deducted

as well. Customer is responsible for

ensuring a clean product is shipped

back to us. Products that are shipped

in poor condition (e.g. resin on a printer

or still on the vat/platform) will have an

additional 5% deducted from their

refund.

You may opt to receive your refund in

the form of store credit. In the case of

unopened products, the 5% processing

fee will not be applied. In the case of

opened products, the 15%

restocking/processing fee will still be

applied. Refunds are only given out

once one of our technicians finishes

inspection on the product.

Section VIII

.

13

https://epaxdental.com

Visit our website at

:

www

.

epaxdental

.

com

This manual suits for next models

2

Table of contents

Other EPAX 3D Printer manuals