SWRU197F

June 2013

2/23

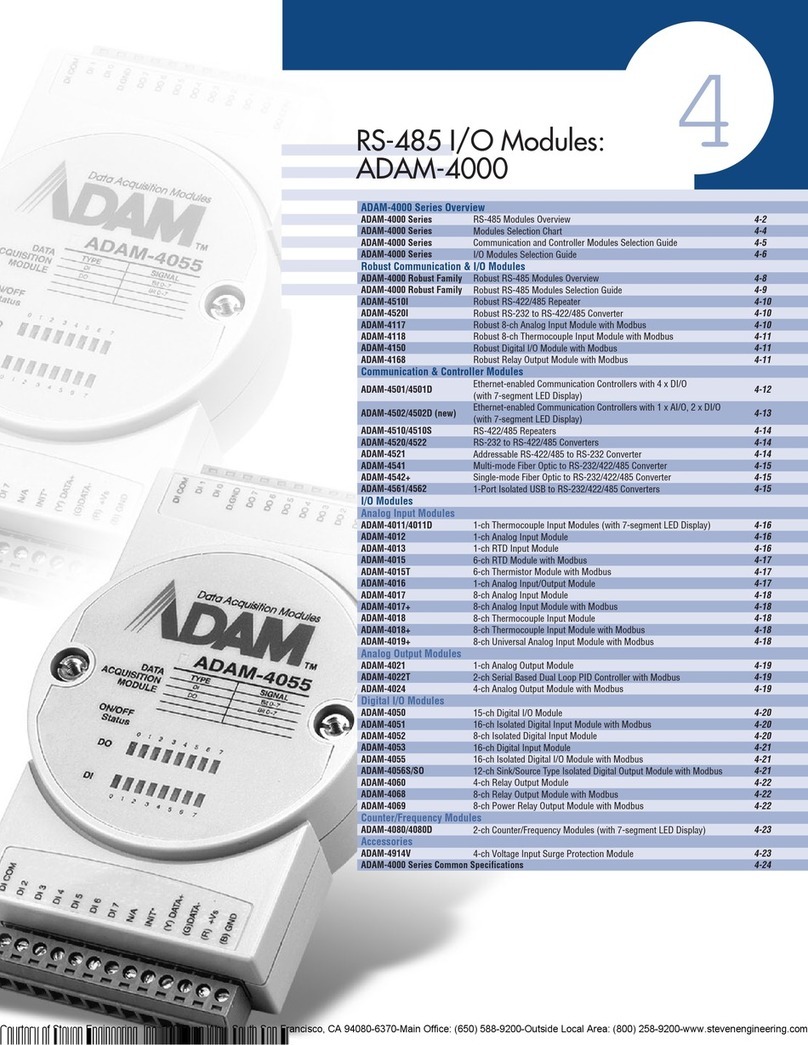

Table of Contents

1Introduction................................................................................................................................. 3

2Abbreviations and Acronyms.................................................................................................... 3

3Box Contents .............................................................................................................................. 4

4Operating Conditions of the CC Debugger.............................................................................. 4

5Initial Steps.................................................................................................................................. 5

5.1 Installing the USB driver ........................................................................................................... 5

5.2 Supported PC Tools.................................................................................................................. 5

6Connecting the CC Debugger to the Device............................................................................ 6

6.1 Target Connector Details.......................................................................................................... 6

6.2 Connecting the CC Debugger to a System on Chip ................................................................. 8

6.2.1 Minimum connection for debugging....................................................................................................................... 8

6.2.2 Minimum connection for SmartRF Studio .............................................................................................................. 8

6.2.3 Minimum connection for SmartRF Packet Sniffer .................................................................................................. 9

6.3 Connecting the CC Debugger to a Transceiver...................................................................... 10

6.4 Connecting the CC Debugger to a CC85xx............................................................................ 12

7Using the CC Debugger ........................................................................................................... 13

7.1 Understanding the LED........................................................................................................... 13

8Updating the Firmware............................................................................................................. 14

8.1 Updating the firmware automatically in SmartRF Studio........................................................ 14

8.2 Updating the firmware manually in SmartRF Flash Programmer........................................... 16

8.3 Forced boot recovery mode.................................................................................................... 17

8.4 Resurrecting the CC Debugger............................................................................................... 17

9Troubleshooting ....................................................................................................................... 20

10 Schematics................................................................................................................................ 21

11 References ................................................................................................................................ 21

12 Document History..................................................................................................................... 22