Texas Instruments LOG200EVM User manual

Other Texas Instruments Motherboard manuals

Texas Instruments

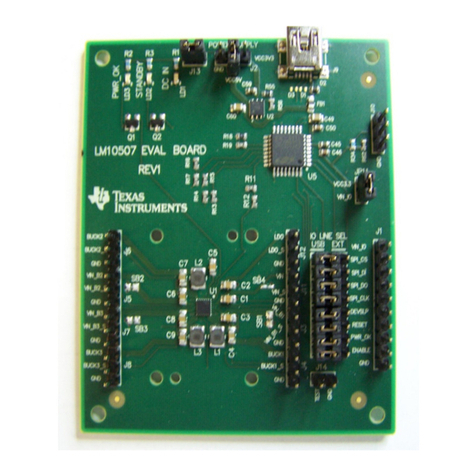

Texas Instruments LM10507 User manual

Texas Instruments

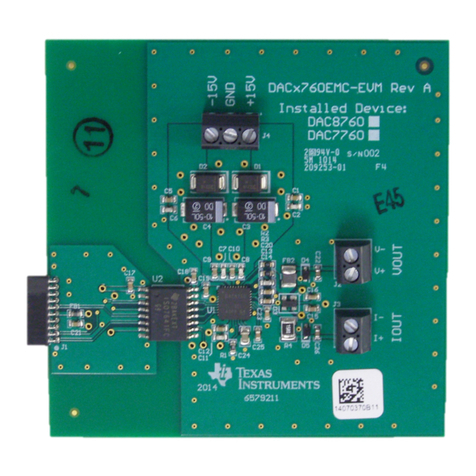

Texas Instruments DACx760EMC-EVM User manual

Texas Instruments

Texas Instruments PCMx140Q1EVM-PDK User manual

Texas Instruments

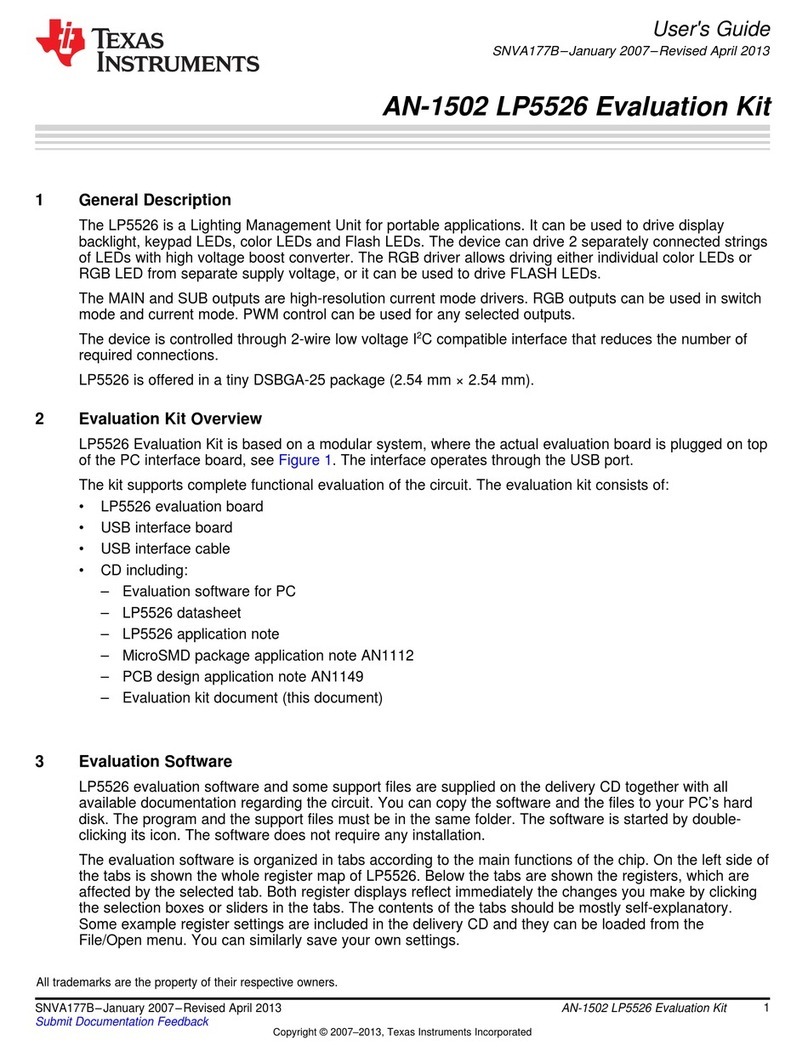

Texas Instruments AN-1502 LP5526 User manual

Texas Instruments

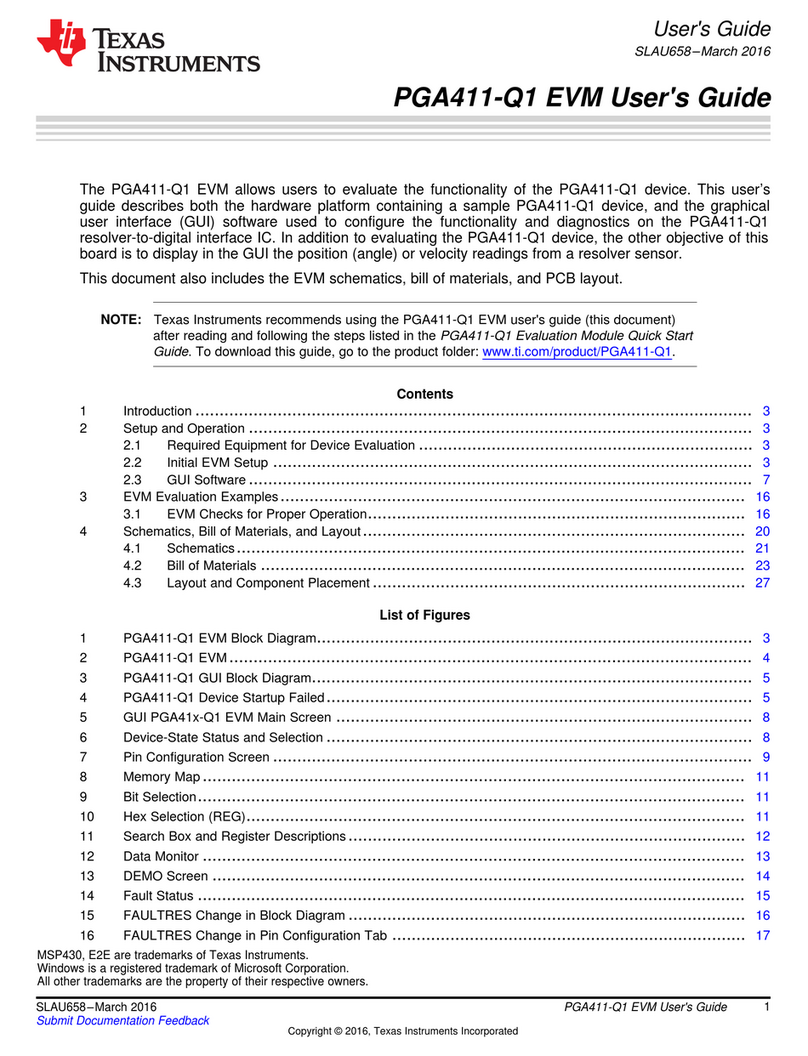

Texas Instruments PGA411-Q1 EVM User manual

Texas Instruments

Texas Instruments SCAU020 User manual

Texas Instruments

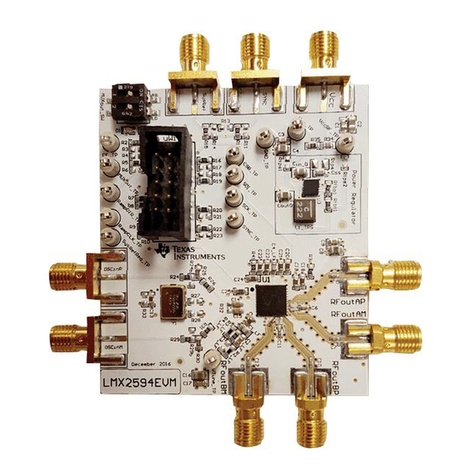

Texas Instruments LMX2594 User manual

Texas Instruments

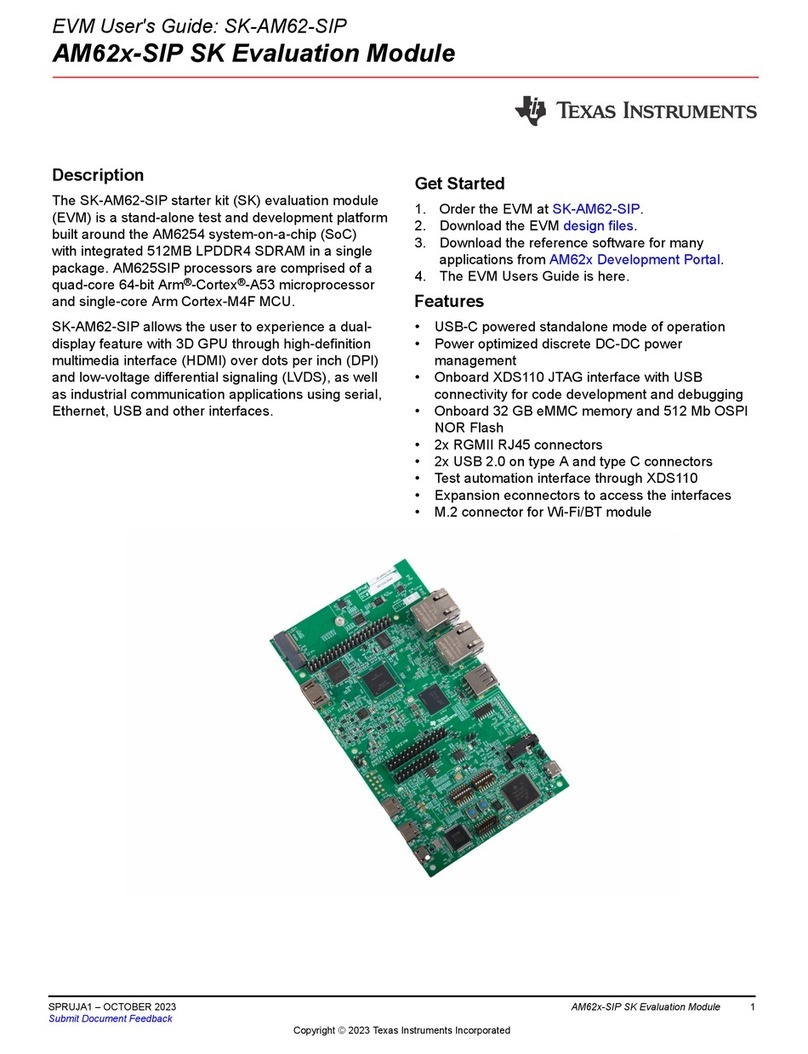

Texas Instruments AM62-SIP SK Series User manual

Texas Instruments

Texas Instruments bq24725 User manual

Texas Instruments

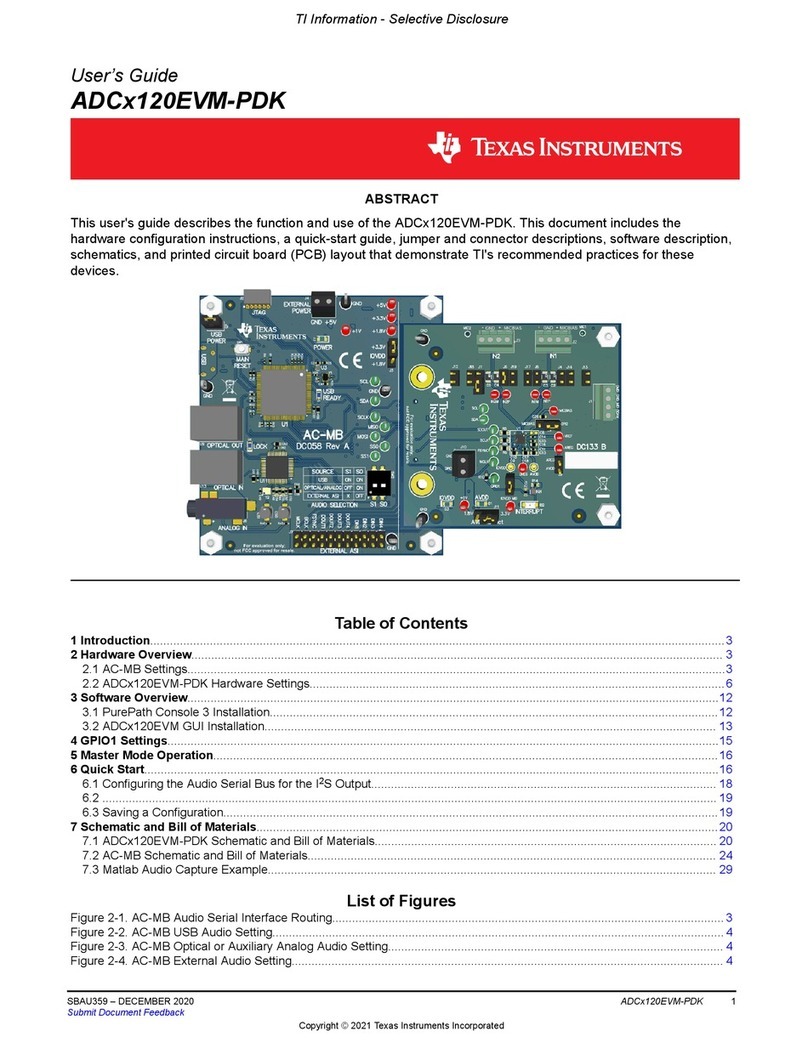

Texas Instruments ADC 120EVM-PDK Series User manual

Texas Instruments

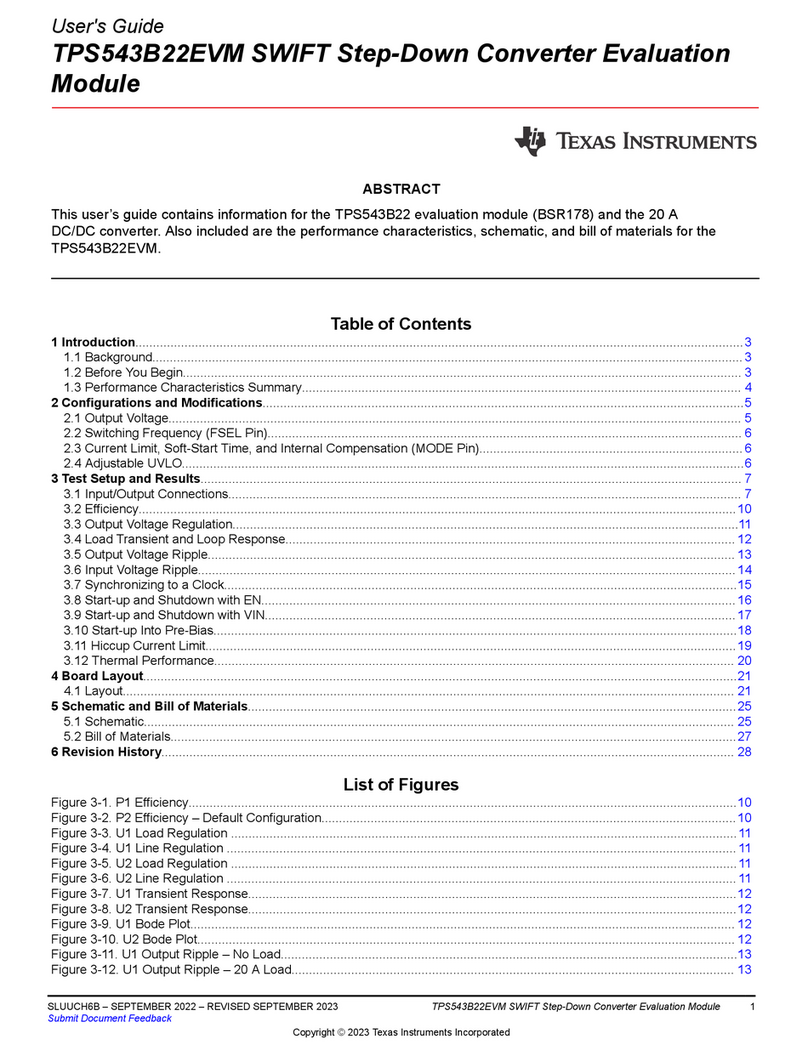

Texas Instruments TPS543B22EVM User manual

Texas Instruments

Texas Instruments Tiva C Series User manual

Texas Instruments

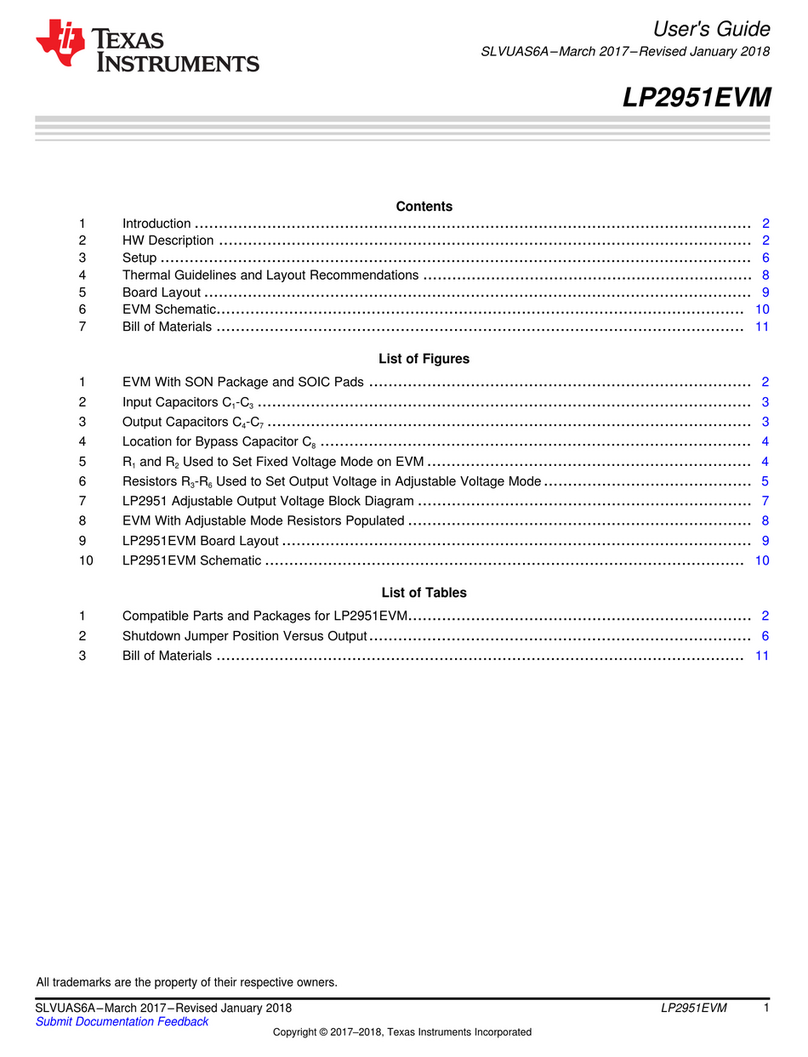

Texas Instruments LP2951EVM User manual

Texas Instruments

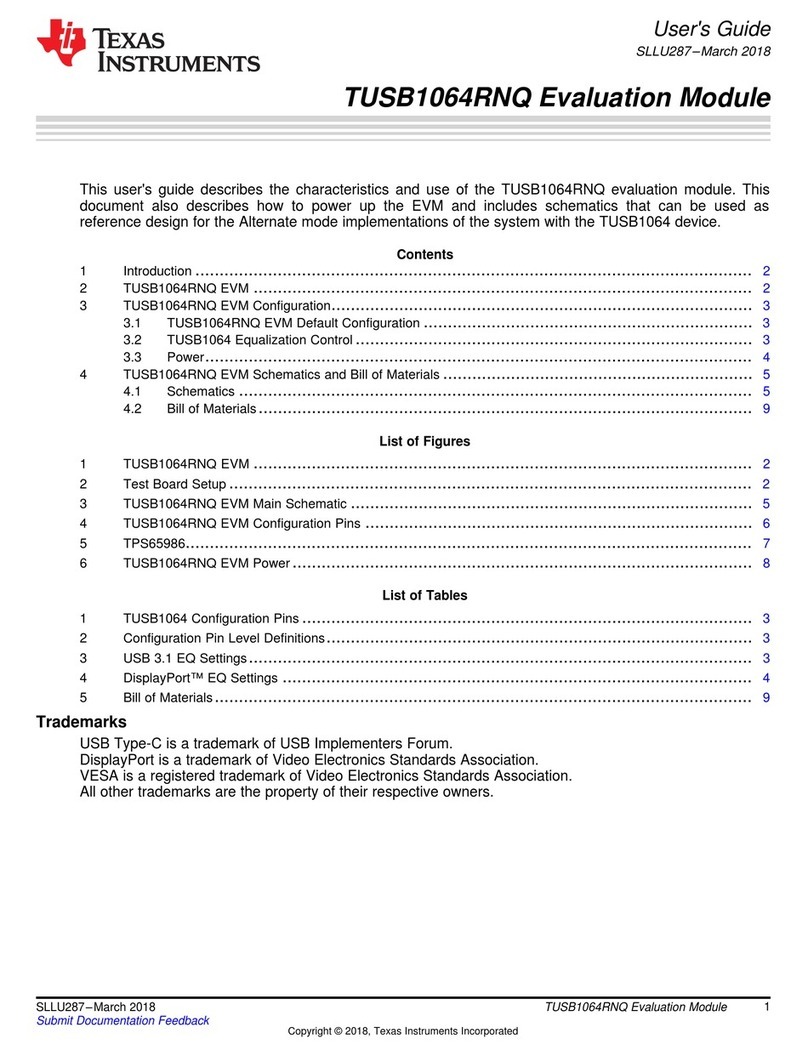

Texas Instruments TUSB1064RNQ User manual

Texas Instruments

Texas Instruments TPS62065EVM User manual

Texas Instruments

Texas Instruments INA296EVM User manual

Texas Instruments

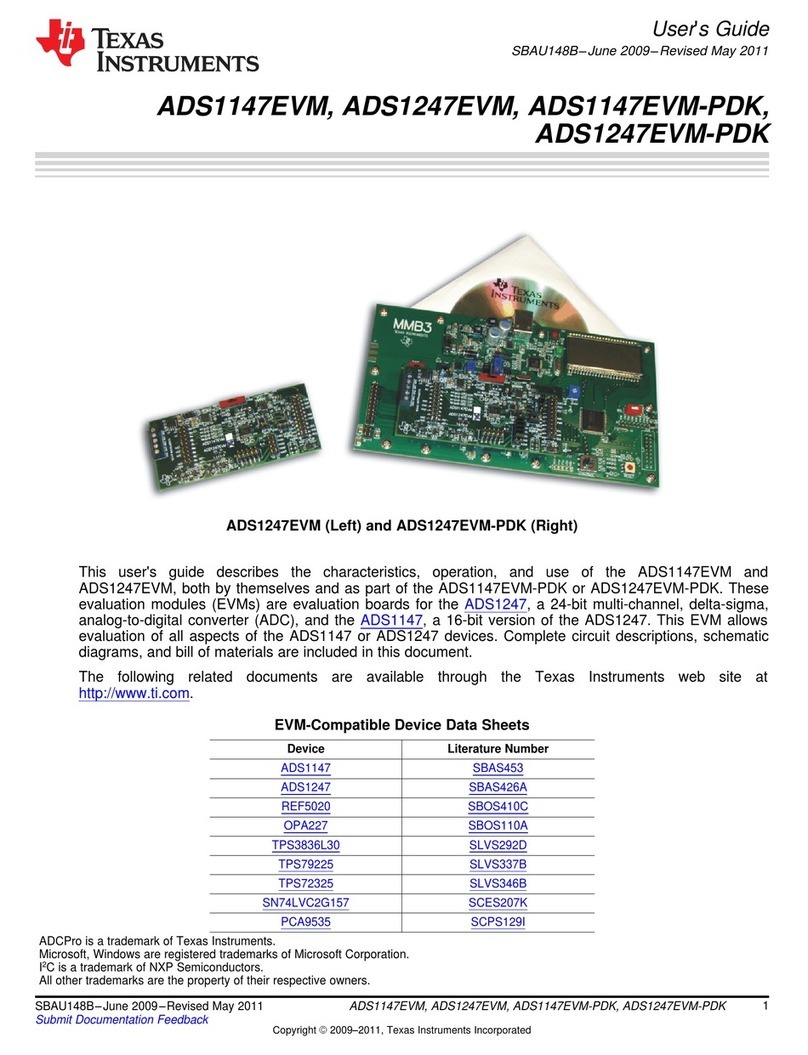

Texas Instruments ADS1147EVM User manual

Texas Instruments

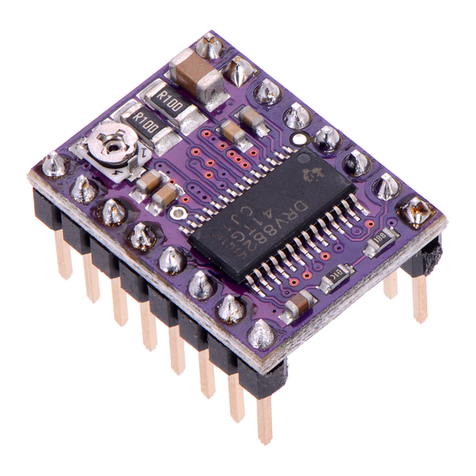

Texas Instruments DRV88 Series User manual

Texas Instruments

Texas Instruments ADS62PXXEVM User manual

Texas Instruments

Texas Instruments TPA6020A2 User manual