SLVUA41E

4

Flutter meters can analyze the FGOUT signal and calculate a jitter percentage. This jitter, or

variation in edge timing, is a measure of motor speed consistency. Good flutter values are

typically in the 0.03% to 0.5% range. Some causes of jitter are:

a. Magnetic cogging force. Motors with high detent torque will have more speed variation

when spinning.

b. Non-ideal motor windings.

c. Improperly-tuned DRV8308 register settings when in Clock Frequency Mode. The

device’s speed control loop has configurable pole and zero frequencies and gain values,

and they significantly affect jitter performance.

Some BLDC outrunner motors have a PCB mounted to the backside with a board trace antenna

that senses magnetic reluctance. This “FG trace” is drawn like a square wave leading in a

circle. When the motor spins, a low-level sinusoidal voltage is generated on the trace. The

DRV8308 can use this signal to sense motor speed with FGSEL = 10b. Since implementations

often cause about 30-60 FG cycles per physical revolution, and there often only 3-6 Hall U

cycles per physical revolution, FG has an advantage of providing faster speed feedback, and

that can improve jitter performance. For motors that lack FG, it is best to set FGSEL = 00b to

use HALL U; this can achieve very similar performance as FG. Setting FGSEL = 01b for XOR

has been generally seen to produce worse results.

3. Frequency-to-voltage converter and oscilloscope –It is useful to convert the FGOUT frequency

to be represented by an analog voltage, and send the signal to a scope. This allows observing

spin-up and spin-down profiles, and any overshoot. Some flutter meters have an integrated

frequency to voltage converter.

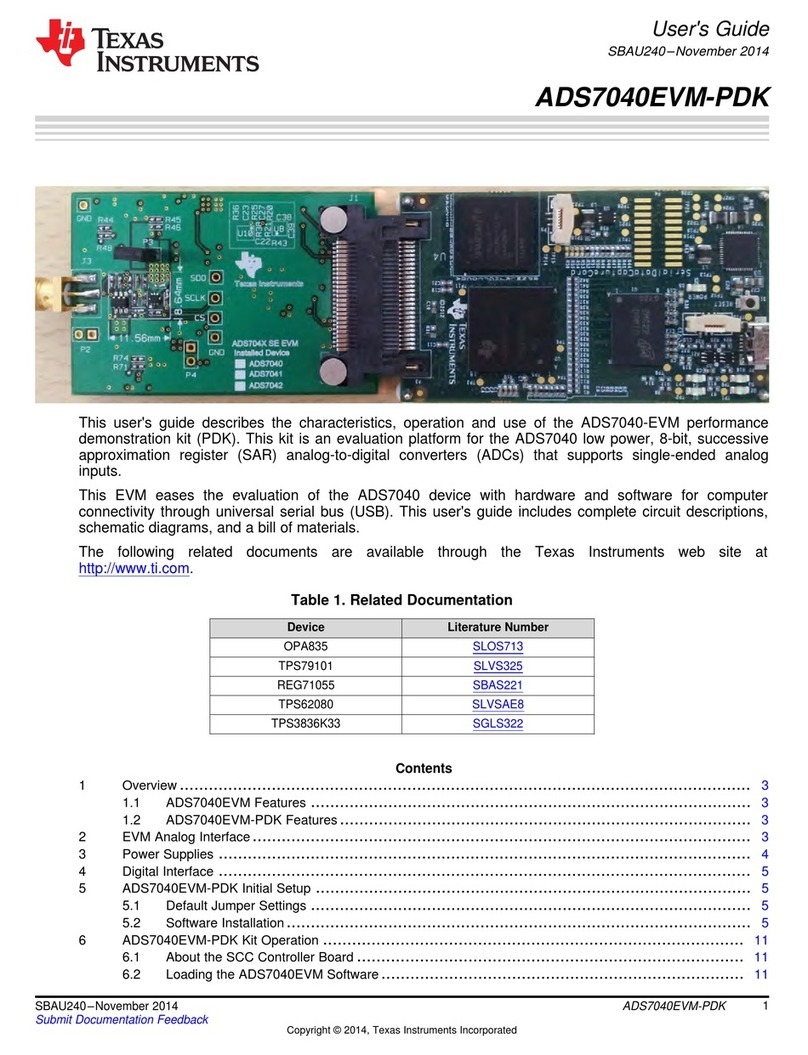

4. Computer –The computer connects to the PCB with a USB cable, and the GUI controls the

MSP430G2553 microcontroller (MCU). This MCU can generate a clock, set High and Low

voltages on the control inputs, read the status outputs, and read/write DRV8308 registers using

SPI. The bus isolation jumpers provide a simple way to disconnect the MCU from the

DRV8308, if you want to use a different controller.

5. Function generator (not shown) –While the MCU can generate a clock with different duty cycles

and frequencies, you can instead use an external clock source attached to connector P5.

When doing this, be sure to disable the MCU clock to prevent contention. That can be done by

removing the CLKIN bus isolation jumper, or selecting GUI option “External Signal” in the first

two tabs, or unchecking “Enable MCU CLK” on third tab. While the MCU clock is not quite as

accurate as a function generator, there’s a negligible difference on flutter.

1.3 Configuration jumpers

The DRV8308EVM board has 3 groups of configuration jumpers.

Hall sensor power is “5V”or “current”

Differential or single-ended Hall sensors