Texmate, Inc. Tel. (760) 598-9899 • www.texmate.comFL-B101Q-DCA _ FL-B01Q-DCV (d0084) Page15

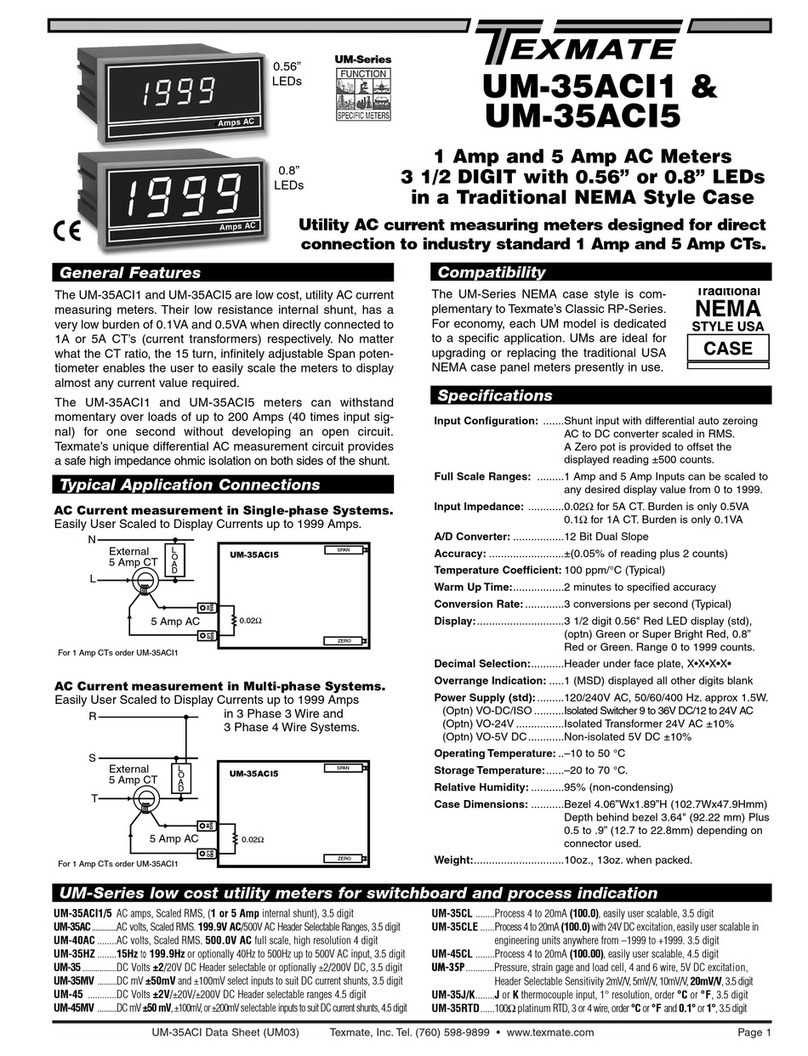

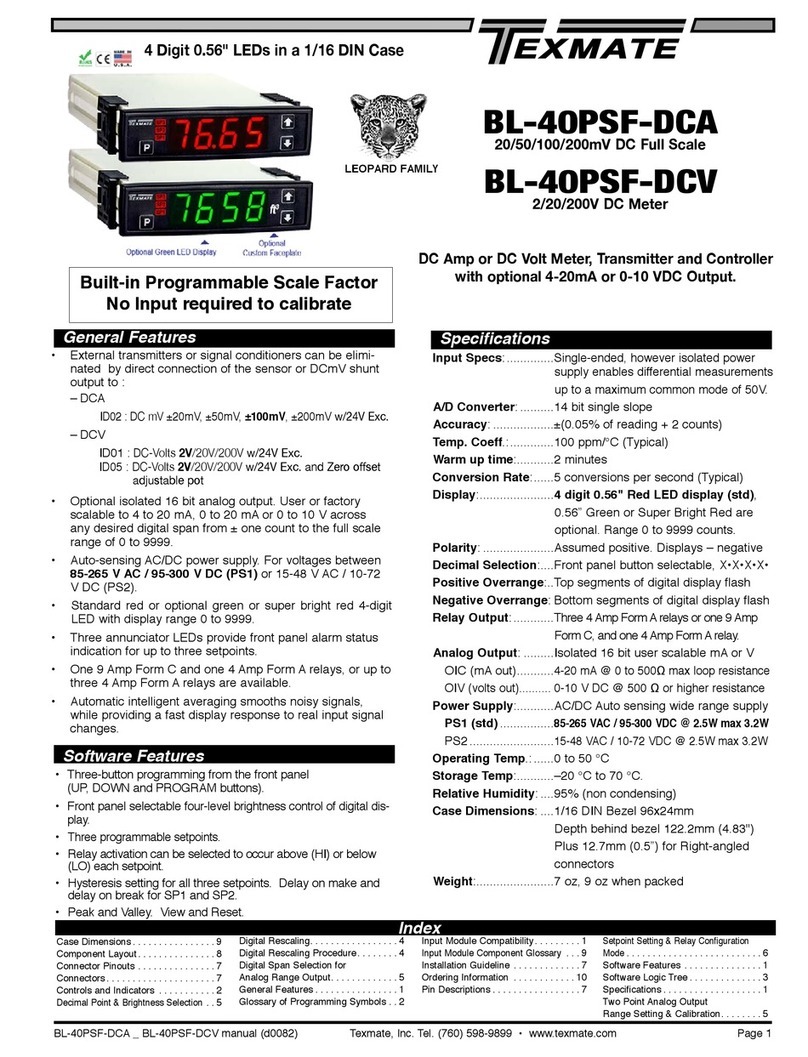

BASIC MODEL #

DISPLAY POWER SUPPLY INPUT MODULES ANALOG OUTPUT RELAY OUTPUT OPTIONS / ACCESSORIES

OA____

FL-B101Q-DCA

Add to the basic model number the order code suffix for each standard option required. The last suffix is to

indicate how many different special options and or accessories that you may require to be included with this product.

Ordering Example: FL-B101Q-DCA-RVR-PS1-IA01-OIC-R11-OA2. OA2 are ZR and an OP-N4/144X36 (Two "Options and Accessories")

BASIC MODEL NUMBER

FL-B101Q-DCA

144x36mm, DC Amps, 101 Segment Bargraph ...$180

FL-B101Q-DCV

144x36mm, DC Volts, 101 Segment Bargraph ....$180

Standard Options for this Model Number

Order Code Suffix Description List

DISPLAY

BHG. .GreenLEDBargraph,Horizontal,Bottomposition . $20

BHR....... RedLEDBargraph,Horizontal,Bottomposition...$5

CHG....... GreenLEDBargraph,Horizontal,Centerposition ..$20

CHR....... RedLEDBargraph,Horizontal,Centerposition....$5

CHT....... CenterHorizontal-Tri-Color...................$50

CVG....... GreenLEDBargraph,Vertical,Centerposition....$15

CVR....... Red LED Bargraph, Vertical, Center position

...N/C

CVT....... CenterVertical-Tri-Color.....................$45

LVG........ GreenLEDBargraph,Vertical,Leftside.........$15

LVR ........ RedLEDBargraph,Vertical,Leftside...........N/C

RVG....... GreenLEDBargraph,Vertical,Rightside........$15

RVR....... RedLEDBargraph,Vertical,Rightside ..........N/C

THG....... GreenLEDBargraph,Horizontal,Topposition....$20

THR....... RedLEDBargraph,Horizontal,Topposition......$5

POWER SUPPLY

PS1 ........85-265VAC/95-300VDC

.........................N/C

PS2........ 15-48VAC/10-72VDC........................$35

INPUT MODULES

UnlessotherwisespecifiedTexmatewillshipallmodulesprecalibratedwith

factorypreselectedrangesand/orscalingsasshownin

BOLD

type.

For FL-B101Q-DCA

ID02. .

DCmV±20mV,±50mV,±100mV,±200mV

w/24VExc.

....... $40

For FL-B101Q-DCV

ID01. .

DCVolts,2V/20V/200Vw/24VExc.

....................... $35

ID05. .

DCVolts,2V/20V/200Vw/24VExc.w/zerooffsetadjustablepot

. $55

ANALOG OUTPUT

OIC ........Isolated16BitCurrentOutput,4-20mA........$40

OIV ........Isolated16BitVoltageOutput,0-10VDC.......$40

RELAY OUTPUT

R1.........Single4AFormARelay.....................$35

R2.........Dual4AFormARelays.....................$65

R11 ........Single9AFormCRelay....................$40

R12........Dual9AFormCRelays....................$75

R13........Dual9AFormC&One4AFormARelays......$105

R14........Dual9AFormC&Dual4AFormARelays ......$125

R15........Single9AFormC&Dual4AFormARelays....$90

R16........Single9AFormC&Single4AFormARelays...$70

Special Options and Accessories

Part Number Description List

SPECIAL OPTIONS

(Specify Inputs or Outputs & Req. Reading

)

ZR............RangechangefromthestandardinputasshowninBOLDtype $20

ZS-AOB......CustomscalingofanalogoutputforQ-seriesbargraphs ........$45

ACCESSORIES

(Specify Serial # for Custom Artwork Installation)

75-DBZ144X36. Blackbezelfor144x36mmCase.....................$2.50

75-DMC14436B SideSlideBrackets-Wideopening(2pc) ...............$2.50

75-DMC144X36 SideSlideBrackets-stand.(2pc)-extraset............$2.50

93-PLUG2P-DP ExtraScrewTerminalConn.,2PinPowerPlug..........$2.50

93-PLUG2P-DR ExtraScrewTerminalConn.,2PinPlug................$2.50

93-PLUG3P-DR ExtraScrewTerminalConn.,3PinPlug................$4

93-PLUG4P-DR ExtraScrewTerminalConn.,4PinPlug................$5

93-PLUG5P-DR ExtraScrewTerminalConn.,5PinPlug................$6

DN.CAS144X36 Complete144x36mmCasewithbezel .................$25

OP-MTL144X36 MetalSurroundCase,includesscrewmountingclips.....$25

OP-MTLCLIP. .

ScrewMountingClips(2pc)-toscrewtightenslidebrackets

...$8

OP-N4/144X36 .

144x36mmclearlockablefrontcover-NEMA4X,splashproof

$30

OP-PA/144X36 . PanelAdapterfor144x36mmfrom6inchcutout......... $10

ForCustomFacePlatesandScalesseepage14.

Prices subject to change without notice.

Ordering Information

WARRANTY

Texmatewarrantsthatitsproducts arefreefromdefectsinmaterialandworkmanshipunder

normaluseandserviceforaperiodofoneyearfromdateofshipment.Texmate’sobligations

underthis warrantyarelimitedtoreplacementorrepair,atitsoption,atitsfactory,ofany of

theproductswhichshall,withintheapplicableperiodaftershipment,bereturnedtoTexmate’s

facility,transportationchargespre-paid,andwhichare,afterexamination,disclosedtothesat-

isfactionofTexmatetobethusdefective.Thewarrantyshallnotapplytoanyequipmentwhich

shallhave beenrepairedoraltered,exceptbyTexmate,orwhichshallhavebeensubjected

tomisuse,negligence,oraccident.InnocaseshallTexmate’sliabilityexceedtheoriginalpur-

chaseprice.Theaforementionedprovisionsdonotextendtheoriginalwarrantyperiodofany

productwhichhasbeeneitherrepairedorreplacedbyTexmate.

USER’S RESPONSIBILITY

Wearepleasedtooffersuggestionsontheuseofourvariousproductseitherbywayofprinted

matter or through direct contact with our sales/application engineering staff. However, since

we have no control over the use of our products once they are shipped, NO WARRANTY

WHETHER OF MERCHANTABILITY, FITNESS FOR PURPOSE, OR OTHERWISE is made

beyondtherepair,replacement,orrefundofpurchasepriceatthesolediscretionofTexmate.

Usersshalldeterminethesuitabilityoftheproductfortheintendedapplicationbeforeusing,and

theusersassumeallriskandliabilitywhatsoeverinconnectiontherewith,regardlessofanyof

our suggestions or statements as to application or construction. In no event shall Texmate’s

liability,inlaworotherwise,beinexcessofthepurchasepriceoftheproduct.

Texmatecannotassumeresponsibilityforanycircuitrydescribed.Nocircuitpatentorsoftware

licensesareimplied.Texmatereservestherighttochangecircuitry,operatingsoftware,specifi-

cations,andpriceswithoutnoticeatanytime.

FL-B01Q-DCA and FL-B101Q-DCV Technical Manual Copyright © 2019 Texmate

Inc. All rights reserved. Published by: Texmate Inc. USA. Information in this

Technical Manual is subject to change without notice due to correction or en-

hancement. The information described in this manual is proprietary to Texmate,

Inc. and may not be copied, reproduced or transmitted, in whole or in part, in

connection with the design, manufacture, or sale of apparatus, device or private

label product without the express written consent of Texmate, Inc.

1934KelloggAve.,Carlsbad,CA92008

Tel: 1-760-598-9899 • USA 1-800-839-6283 • 1-800-TEXMATE