Textron RANSOMES JACOBSEN HIGHWAY 2130 Guide

HIGHWAY 2130

RJ 100 / 112002

WARNHINWEIS: Wenn diese Maschine nicht ordnungsgemäß

verwendet wird, können ernsthafte Verletzungen verursacht

werden. Personen, die diese Maschine verwenden und

warten, müssen in ihrer richtigen Verwendung ausgebildet

sein, auf die Gefahren aufmerksam gemacht worden sein

und die Anleitung ganz gelesen haben, bevor sie versuchen,

die Maschine aufzustellen, zu bedienen, einzustellen oder

zu warten.

24287G-DE (rev.2)

Series: WJ - Engine type: KUBOTA V1305

2WD Product codes: LGEA070

Series: CS - Engine type: FORD VSG413

2WD Product codes: LGEA200

Series: CU - Engine type: KUBOTA V1305

4WD Product codes: LGEA100

Series: DK - Engine type: FORD VSG413

4WD Product codes: LGEA400

Safety and Operation Manual

Betriebs- und Sicherheitshandbuch

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

YEARS OF MOWING

EXCELLENCE

©2002, Ransomes Jacobsen Limited. All Rights Reserved

GB-1

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

1 CONTENTS

CONTENTS ......................................................................................................... PAGE

2 INTRODUCTION

2.1 IMPORTANT ......................................................................................................................... 2

2.2 PRODUCT IDENTIFICATION .............................................................................................. 2

3 SAFETY INSTRUCTIONS

3.1 OPERATING INSTRUCTIONS............................................................................................. 3

3.2 SAFETY SIGNS.................................................................................................................... 3

3.3 STARTING THE ENGINE..................................................................................................... 3

3.4 DRIVING THE MACHINE ..................................................................................................... 3

3.5 TRANSPORTING .................................................................................................................3

3.6 LEAVING THE DRIVING POSITION.................................................................................... 4

3.7 SLOPES ............................................................................................................................... 4

3.8 BLOCKED CUTTING CYLINDERS ..................................................................................... 4

3.9 ADJUSTMENTS, LUBRICATION AND MAINTENANCE .................................................... 4

4 SPECIFICATIONS

4.1 ENGINE SPECIFICATION.................................................................................................... 7

4.2 MACHINE SPECIFICATION................................................................................................. 7

4.3 DIMENSIONS ....................................................................................................................... 7

4.4 VIBRATION LEVEL ..............................................................................................................8

4.5 SLOPES ............................................................................................................................... 8

4.6 RECOMMENDED LUBRICANTS......................................................................................... 8

4.7 CUTTING PERFORMANCE................................................................................................. 8

4.8 CUTTING PERFORMANCE (AREA) ................................................................................... 8

4.9 CONFORMITY CERTIFICATES........................................................................................... 9

5 DECALS

5.1 SAFETYDECALS ................................................................................................................. 11

5.2 INSTRUCTIONDECALS ........................................................................................................ 11

6 CONTROLS

6.1 STARTERSWITCH ............................................................................................................... 12

6.2 THROTTLECONTROLLEVER .............................................................................................. 12

6.3 STEERINGWHEELRAKEADJUSTMENT .............................................................................. 12

6.4 FOOTPEDAL......................................................................................................................... 12

6.5 SPEEDLIMITER .................................................................................................................... 12

6.6 TRANSPORTLATCHES ........................................................................................................ 13

6.7 PARKINGBRAKE .................................................................................................................. 13

6.8 HYDRAULICLIFTLEVERS ................................................................................................... 13

6.9 UNITCOUNTERBALANCECONTROL .................................................................................. 13

6.10 CUTTINGUNITSWITCHES ................................................................................................... 14

6.11 VARIABLECYLINDERSPEED ............................................................................................... 14

6.12 BACKLAPPINGLEVER ......................................................................................................... 14

6.13 DIFFLOCKCONTROL .......................................................................................................... 15

6.14 INSTRUMENTPANEL ........................................................................................................... 15

7 OPERATION

7.1 DAILYINSPECTION .............................................................................................................. 17

7.2 OPERATORPRESENCEANDSAFETYINTERLOCKSYSTEM ............................................... 18

7.3 OPERATINGPROCEDURE ..................................................................................................... 19

7.4 STARTINGTHEENGINE ........................................................................................................ 21

7.5 DRIVING ............................................................................................................................... 21

7.6 MOWING .............................................................................................................................. 21

7.7 TOSTOPTHEENGINE .......................................................................................................... 21

7.8 PUSHINGTHEMACHINEWITHTHEENGINESTOPPED ........................................................ 22

8 ADJUSTMENTS

8.1 HEIGHTOFCUT ................................................................................................................... 23

8.2 FIXEDHEADUNITSADDITIONALADJUSTMENT ................................................................. 24

8.3 SEAT(GRAMMERGS85/90)................................................................................................. 24

8.4 SEAT(GRAMMERMSG 20) ................................................................................................. 25

9 MAINTENANCE

9.1 LUBRICATIONANDMAINTANANCECHARTDIESELPOWEREDMACHINES ....................... 26

9.2 LUBRICATIONANDMAINTANANCECHARTLPG POWEREDMACHINES ............................ 27

9.3 DAILYCHECKS .................................................................................................................... 28

10 GUARANTEE/ SALES& SERVICE .................................................................................................... 29

GB-2

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

2 INTRODUCTION

2.2 PRODUCT IDENTIFICATION

2.1 IMPORTANT

IMPORTANT: This is a precision machine and the service obtained from it depends on the way it is

operated and maintained.

This SAFETY AND OPERATORS MANUAL should be regarded as part of the machine. Suppliers of both

new and second-hand machines are advised to retain documentary evidence that this manual was

provided with the machine.

This machine is designed solely for use in customary grass cutting operations. Use in any other way is

considered as contrary to the intended use. Compliance with and strict adherence to the conditions of

operation, service and repair as specified by the manufacturer, also constitute essential elements of the

intended use.

Before attempting to operate this machine, ALL operators MUST read through this manual and make

themselves thoroughly conversant with Safety Instructions, controls, lubrication and maintenance.

Accident prevention regulations, all other generally recognized regulations on safety and occupational

medicine, and all road traffic regulations shall be observed at all times.

Any arbitrary modifications carried out on this machine may relieve the manufacturer of liability for any

resulting damage or injury.

A Machine Name

B Serial Number

C Year of Manufacture

D Machine Weight

E Engine Power

GB-3

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

3 SAFETY INSTRUCTIONS

This safety symbol indicates important safety

messages in this manual. When you see this

symbol, be alert to the possibility of injury, carefully

read the message that follows, and inform other

operators.

3.1 OPERATING INSTRUCTIONS

• Ensure that the instructions in this book

are read and fully understood.

• No person should be allowed to operate

this machine unless they are fully

acquainted with all the controls and the

safety procedures.

• Never allow children or people unfamiliar

with these instructions to usethis

machine. Local regulations may restrict

the age of the operator.

3.2 SAFETY SIGNS

• It is essential all safety labels are kept

legible, if they are missing or illegible they

must be replaced. If any part of the

machine is replaced and it originally

carried a safety label, a new label must be

affixed to the replacement part. New

safety labels are obtainable from

Ransomes dealers.

3.3 STARTING THE ENGINE

• Before starting the engine check that the

brakes are applied, drives are in neutral,

guards are in position and intact, and

bystanders are clear of the machine.

• Do not run the engine in a building without

adequateventilation.

3.4 DRIVING THE MACHINE

• Before moving the machine, check to

ensure that all parts are in good working

order, paying particular attention to

brakes, tyres, steering and the security of

cutting blades.

• Replace faulty silencers, mow only in

daylight or good artificial light

• Always observe the Highway Code both

on and off the roads. Keep alert and

aware at all times. Watch out for traffic

when crossing or near roadways.

• Stop the blades rotating before crossing

surfaces other than grass.

• Remember that some people are deaf

or blind and that children and animals

can be unpredictable.

• Keep travelling speeds low enough for

an emergency stop to be effective and

safe at all times, in any conditions.

• Remove or avoid obstructions in the

area to be cut, thus reducing the

possibility of injury to yourself and/or

bystanders.

• When reversing, take special care to

ensure that the area behind is clear of

obstructions and/or bystanders. DO

NOT carry passengers.

• Keep in mind that the operator or user is

responsible for accidents or hazards

occurring to other people or their

property.

• When the machine is to be parked,

stored or left unattended, lower the

cutting means unless the transport

locks are being used.

• While mowing, always wear substantial

footwear and long trousers. Do not

operate the equipment when barefoot or

wearing open sandals.

• Check the grass catcher frequently for

wear or deterioration. After striking a

foreign object. Inspect. the lawnmower

for damage and make repairs before

restarting and operating the equipment.

• If the machine starts to vibrate

abnormally, check immediately.

3.5 TRANSPORTING

• Ensure that the cutting units are

securely fastened in the transport

position. Do not transport with cutting

mechanism rotating.

• Drive the machine with due

consideration of road and surface

conditions, inclines and local

undulations.

• Sudden decelerating or braking can

cause the rear wheels to lift.

• Remember that the stability of the rear

of the machine is reduced as the fuel is

used.

3.6 LEAVING THE DRIVING POSITION

• Park the machine on level ground.

• Before leaving the driving position, stop

the engine and make sure all moving

parts are stationary. Apply brakes and

disengage all drives. Remove the

starter key.

GB-4

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

3 SAFETY INSTRUCTIONS

3.7 SLOPES

TAKE EXTRA CARE WHEN WORKING ON

SLOPES

• Local undulations and sinkage will change

the general slope. Avoid ground

conditions which can cause the machine

to slide.

• Keep machine speeds low on slopes and

during tight turns.

• Sudden decelerating or braking can

cause the rear wheels to lift. Remember

there is no such thing as a “safe” slope.

• Travel on grass slopes requires particular

care.

DO NOT USE ON SLOPES GREATER THAN 15°

IMPORTANT: When working on any slope set the

weight transfer, if fitted to its maximum (+) setting.

3.8 BLOCKED CUTTING CYLINDERS

• Stop the engine and make sure all moving

parts are stationary.

• Apply brakes and disengage all drives.

• Release blockages with care. Keep all parts

of the body away from the cutting edge.

Beware of energy in the drive which can

cause rotation when the blockage is

released.

• Keep other people away from the cutting

units as rotation of one cylinder can cause

the others to rotate.

3.9 ADJUSTMENTS, LUBRICATION AND

MAINTENANCE

All vehicles

• Stop the engine and make sure all moving

parts are stationary.

• Apply brakes and disengage all drives.

• Read all the appropriate servicing

instructions.

• Use only the replacement parts supplied by

the original manufacturer.

• When adjusting the cutting cylinders take

care not to get hands and feet trapped when

rotatingcylinders.

• Make sure that other people are not touching

any cutting units, as rotation of one cylinder

can cause the others to rotate.

• To reduce the fire hazard, keep the engine,

silencer and battery compartments free of

grass, leaves or excessive grease.

• Replace worn or damaged parts for safety.

• When working underneath lifted parts or

machines, make sure adequate support Is

provided.

• Do not dismantle the machine without

releasing or restraining forces which can

cause parts to move suddenly.

• Do not alter engine speed above maximum

quoted in Engine Specification. Do not

change the engine governor settings or

overspeed the engine. Operating the engine

at excessive speed may increase the hazard

of personal injury.

• When servicing batteries, DO NOT SMOKE,

and keep naked lights away.

• Do not place any metal objects across the

terminals.

Diesel & Petrol vehicles

• When refuelling, STOP THE ENGINE, DO

NOT SMOKE. Add fuel before starting the

engine, never add fuel while the engine is

running.

• Use a funnel when pouring fuel from a can

into the tank.

• Do not fill the fuel tank beyond the bottom of

the filler neck.

• Replace all fuel tank and container caps

securely.

• Store fuel in containers specifically designed

for this purpose.

• Refuel outdoors only and do not smoke while

refuelling.

• If fuel is spilled, do not attempt to start the

engine but move the machine away from the

area of spillage and avoid creating any

source of ignition until fuel vapours have

dissipated.

• Allow the engine to cool before storing in any

enclosure.

• Never store the equipment with fuel in the

tank inside a building where fumes may

reach an open flame or spark.

• If the fuel tank has to be drained, this should

be done outdoors.

• Do not spill fuel onto hot components.

LPG vehicles

• Only trained & competent personnel in the

use of LPG as a road vehicle fuel are

allowed to work on LPG aspects of the

vehicles engine or fuel system.

• When refuelling, STOP THE ENGINE,

DO NOT SMOKE. Add fuel before

starting the engine, never add fuel while

the engine is running.

• Vehicles should not be parked within 3

meters of any heat source, open flame or

other sources of ignition.

• Vehicles should not be serviced over an

inspection pit

• If for any reason a leak in the fuel system

is suspected, the vehicle should be

moved to an isolated area clear of

buildings & people and as far as possible

from drains and any source of ignition.

GB-5

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

DANGER - Indicates an imminently hazardous

situation which, if not avoided, WILL result in death

or serious injury.

WARNING - Indicates a potentially hazardous

situation which, if not avoided, COULD result in

death or serious injury.

CAUTION - Indicates a potentially hazardous

situation which, if not avoided, MAY result in minor

or moderate injury and property damage. It may

also be used to alert against unsafe practices.

IMPORTANT: Transport speed is for highway

use only. Never select transport speed on

grass areas or uneven or unsurfaced roads or

tracks.

The operating Instructions for the Cutting Units are

contained in a separate Publication .

• The fuel filler bayonet on the vehicle

should be inspected regularly for any

signs of damage.

• The gas used to fill the vehicle must be

sourced from a reputable supplier.

• If a machine starts to vent gas when it is

running it should be moved to an area

away from any sources of ignition and

stopped. If it vents when static the

machine should not be started, all

potential sources of ignition should be

inhibited until the venting has stopped and

the local Ransomes Jacobsen dealer

should be contacted.

• Where practical LPG fuelled vehicles

should be parked in the open air, in a well

ventilated position. Where this is not

reasonably practical due to lack of space,

security ect. vehicles should be parked

inside suitably designed buildings or

garages. Please refer to HELA

publication LAC No. 52/6 rev

GB-6

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

3 SAFETY INSTRUCTIONS

California Proposition 65

Engine Exhaust, some of its constituents,

and certain vehicle components contain

or emit chemicals known to the state of

California to cause cancer and birth

defects or other reproductive harm.

WARNING

Batteries produce explosive gases and

contain corrosive acid and supply levels

of electrical current high enough to cause

burns.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds

WASH HANDS AFTER HANDLING

WARNING

Hydraulic Fluid escaping under pressure

can penetrate skin and do serious

damage. Immediate medical assistance

must be sought.

WARNING

DO NOT USE ON SLOPES GREATER THAN 15°

WARNING

VENTING GAS CAN CAUSE FROST BITE

WARNING

Cutting Unit Transport Latches are a

Secondary Safety Devise.

When Transporting the machine the

Cutting units should be held in the

Transport position on the Hydraulics with

the Transport Latches Engaged.

1. Park the machine on level ground.

2. Whilst seated in the driving position

With the engine at operating speed

raise the cutting units fully by

operating lift levers, return the lever to

the neutral position.

DO NOT move the lever into the

lower position.

3. Disengage drives, stop the engine and

make sure all moving parts are

stationary. Apply brakes and remove

the starter key.

4. Transport latches can now be engaged

or released.

Before releasing transport latches

it is important that all cutting units

are fully raised.

WARNING

GB-7

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

4 SPECIFICATIONS

4.1 ENGINE SPECIFICATION

4.1.1 DIESEL

TYPE: Kubota 25Kw @ 3000rpm, 4

cylinder (in-line) vertical Diesel

engine, 4-stroke, water cooled,

1335cc, with 12v electric start.

Model: V1305-BBS-EC-1

Maximum Speed: 3150 ± 50 RPM (No load)

Idle Speed: 1500 +100 RPM

Oil Sump Capacity: 6 litres

Fuel: No. 2-D Diesel fuel (ASTM D975)

CoolantCapacity: 5 litres 50/50 Anti-freeze

CoolantSpecification

:Ethyleneglycol anti-freeze with

softened water.

4.1.2 LPG

TYPE: Ford 25Kw @ 3000rpm, 4

cylinder (in-line) vertical Petrol

engine, 4-stroke, water cooled,

1297cc, with 12v electric start.

Model: VSG 413

Maximum Speed: 3150 ± 50 RPM (No load)

IdleSpeed: 850 ± 50 RPM

Oil Sump Capacity: 3.1 litres

Fuel: LPG (Propane)

CoolantCapacity: 5 litres 50/50 Anti-freeze

CoolantSpecification:

Ethyleneglycolanti-freezewith

softened water.

4.2 MACHINESPECIFICATION

Frameconstruction:

Heavy duty formed steel chassis.

Transmission: Hydrostatic power provided by a

servo-controlledtransmission

pump. Driving 2 indivdual wheel

motors with Diff-lock facility.

4WD: Driving 4 individual wheel

motors with a patented parallel

series transmission system.

Selectable forward all wheel drive

lock and reverse front axle diff-

lock facility.

Cutting unit drive: Hydraulic, with forward, neutral,

reverse control valve. Electric

dash mounted switch for on/off

control, with floor mounted switch

for cyclinder engage.Hand

control valve for reel speed

adjustment

Speeds:

Cutting: 12 km/h

Transport: 25 km/h

21 km/h (4WD)

Reverse: 6 km/h (4 mph)

Steering: Hydrostatic powered steering to

rear wheels.

Ground pressure: 1.00 bar (14psi)

Brakes, Service: Positive hydrostatic braking.

Parking: Fail safe, Oil immersed wet disc

brakes.

Fuel Tank

CapacityDiesel: 45 Litres

CapacityLPG: 72 Litres

Hydraulic Tank

Capacity: 35 Litres

Battery: Exide 093

4.3 DIMENSIONS

Width of cut: 2.14 metres

Transport width: 1.5 metres

Overallheight: 1.56metres

Overalllength: 2.68 metres

Overall weight of

machine:

Diesel 1276Kg*

1302Kg* (4WD)

LPG 1304Kg*

1330Kg* (4WD)

* With 6 knife fixed head sport 200 units, full fuel

tank, and optional Lighting and Beacon kits

Wheel Track: 1.5 metres

Wheel Base: 1.5 metres

Uncut Circle: 0.66 metres Radius

0.75 metres Radius (4WD)

SERUSSERPERYT

tcudorP leehWtnorF leehWraeR

eziSeryTepyTeryTerusserPeryTeziSeryTepyTeryTerusserPeryT

DW40312yawhgiH21-05.01x32 rp6carTitluMnatiTisp02-41rab73.1-00.1 8-05.8x5.81 rp4carTitluMnatiTisp02-41

r

ab73.1-00.1

)ralveK(xxamfruTsixxaM rp4s561-Cnrettapdaert isp22-02rab05.1-73.1 )ralveK(xxamfruTsixxaM rp4s561-Cnrettapdaert isp22-02

r

ab05.1-73.1

DW20312yawhgiH21-05.01x32 rp6carTitluMnatiTisp02-41rab73.1-00.1 8-00.01x02 rp4natiTisp02-41

r

ab73.1-00.1

)ralveK(xxamfruTsixxaM rp4s561-Cnrettapdaert isp22-02rab05.1-73.1 )ralveK(xxamfruTsixxaM rp4s561-Cnrettapdaert isp22-02

r

ab05.1-73.1

GB-8

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

ERUTAREPMETYTISOCSIVLIO

)F°93(C°4EVOBA03EAS

)F°93(C°4WOLEB03-W01ro03-W5EAS

4 SPECIFICATIONS

4.4 VIBRATION LEVEL

The machine was tested for whole body and hand/

arm vibration levels. The operator was seated in

the normal operating postion with both hands on the

steering mechanism. The engine was running and

the cutting device was rotating with the machine

stationary.

Standard ISO 5349: 1986 Mechanical vibration.

Guidelines for the measurement and the

assessment of human exposure to hand-

transmittedvibration.

Standard ISO 2631-1: 1985 Evaluation of human

exposure to whole body vibration -- Part 1: General

requirements.

4.5 SLOPES

DO NOT USE ON SLOPES GREATER THAN 15°

The slope 15° was calculated using static stability

measurements according to the requirements of

EN 836.

4.6 RECOMMENDED LUBRICANTS

Engine oil: Should be to MIL-L-2104C or to

A.P.I. Classification SE/SF/SG

grades. [10W-30]

HydraulicOil: Shell Tellus 46 to ISO VG46, or

equivilant

Grease: Shell Darina R2, or equivilant.

4.7 CUTTING PERFORMANCE

47 cuts per meter at 12 km/hr with 8 knife floating

head units.

65 cuts per meter at 12km/hr with 11 knife floating

head units.

24 cuts per meter at 12 km/hr with 4 knife fixed

head units.

35 cuts per meter at 12 km/hr with 6 knife fixed

head units.

4.8 CUTTING PERFORMANCE (AREA)

2.3 Hectares/hour at 12 km/hr with float head units.

2.3 Hectares/hour at 12 km/hr with fixed head

units.

A 10% allowance is included for normal overlaps

and turning at the end of each cut.

0312yawhgiH KD/SC/UC/JWseireS noitareleccAmrA/dnaH level

HRroHLxaM

s/msnoitareleccA

2

qeAXqeAYqeAZ

313,0953,0422,0

eulaVtnanimoD 953,0

0312yawhgiH UC/JWseireS KD/SC/ ydoBelohW noitareleccA level

noitacoLroolF

s/msnoitareleccA

2

noitacoLtaeS

s/msnoitareleccA

2

xyzxyz

naeM8420,09510,02570,0010,0<0910,03310,0

GB-9

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

4 SPECIFICATIONS

4.9 CONFORMITY CERTIFICATES

EC Declaration of Conformity • Déclaration de Conformité CE •

EG Conformiteits-Declaratie • EG-Konformitatsbescheinigung •

Certificato di Conformità CE • EF Konformitetserklæring •

EU Uppfyllandecertifikat • Ilmoitus yhdenmukaisuudesta ey:n sääntöjen kanss •

Declaración de Conformidad de la CE • Declaração de Conformidade da CE

We the undersigned • Nous, soussignés • Wij, ondergetekenden • Wir, die Unterzeichnenden • Noi sottoscritti Undertegnede •

Undertecknarna • Me allekirjoittaneet • Los abajo firmantes • Nós, abaixo assinados

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

Declare that the machine Described Below • Certifions que la machine suivante • verklaren dat onderstaand beschreven machine •

erklären, dass die nachfolgend beschriebene Maschine • Dichiariamo che la macchina descritta di seguito • Erklærer, at følgende maskine •

Deklarerar att den maskin som beskrivs nedan • vahvistamme, että alla kuvattu kone • Certificamos que la máquina descrita abajo •

declaramos que a máquina a seguir descrita

Make & Type • Nom & Type • Merk & Type • Marke und Typ • Marca e tipo •

Fabrikat og type • Fabrikat & typ • Malli ja tyyppi • Marca y Tipo • Marca & Tipo .............. Ransomes Highway 2130

Category • Modèle •Categorie • Kategorie • Categoria • Kategori • Luokka •

Categoría • Categoria ......................................................................................................... Ride on Cylinder Mower

Series • Série • Serie • Sarja .............................................................................................. WJ, CU, CS, DK

Engine • Motor • Moteur • Motore • Moottori ....................................................................... Kubota / Ford

Type • Typ • Tipo • Tyyppi .................................................................................................. Kubota V1305-E / Ford VSG413

Net Installed Power • Puissance nette • Netto geïnstalleerd vermogen •

installierte Antriebsleistung • Potenza installata netta • Nettoeffekt installere •

Installerad nettoeffekt • Asennettu nettoteho • Potencia instalada neta •

Potência real instalada ....................................................................................................... 25 KW

Cutting Width • Largeur de coupe • Maaibreedte • Schnittbreite •

Larghezza di taglio • Klippebredde • Klippbredd • Leikkuuleveys •

Anchura de corte • Potência real instalada ....................................................................... 214cm

Complies with the provisions of the following European directives and amendments and the regulations transposing it into national law •

Est conforme aux prescriptions des normes, modifications et règles européennes suivantes • voldoet aan de bepalingen van de volgende

Europese Richtlijnen en Amendementen, alsmede aan de verordeningen die deze omzetten in nationale wetgeving • den Bestimmungen der

folgenden Europa-Richtlinien einschließlich aller Änderungen und Ergänzungen sowie den Vorschriften, die diese in das nationale Recht

umsetzen, entspricht • soddisfa quanto previsto dalle seguenti direttive ed emendamenti europei e dalle normative che li riportano in legge

nazionale • Overholder bestemmelserne i følgende EF-direktiver med ændringer og i de forordninger, hvorved de omsættes til national lov •

Uppfyller kraven i följande europeiska direktiv med tillägg och regler transponerade till nationell lagstiftning • täyttää seuraavana mainittujen

Euroopan direktiivien ja muutosten ja säännösten asettamat edellyt

Machinery Safety Directive • Directive de sécurité des machines •

Richtlijn Machineveiligheid • Richtlinie zur Maschinensicherheit •

Direttiva sulla sicurezza del macchinario • Maskinsikkerhedsdirektivet •

Maskinsäkerhetsdirektiv • Koneen turvallisuutta koskeva direktiivi •

Directiva de seguridad de maquinaria • Directiva de segurança de máquinas ................ 98/37/EC

EMC Directive • Directive de compatibilité électromagnétique • EMC Richtlijn •

EMK-Richtlinie • Direttiva EMC • EMC-direktivet • Elektromagnetiskt kompatibilitetsdirektiv •

EMC-direktiivi • Directiva EMC ............................................................................................. 89/336/EC

ROPS Directive • Directive de ROPS • ROPS Richtlijn • ROPS-Richtlinie •

Direttiva ROPS • ROPS-direktivet • ROPS direktiv • ROPS-direktiivi • Directiva ROPS ...... 86/298/EC

Noise in the Environment Directive • Directiv • Richtlijn Milieulawaa •

Richtlinie zum Umgebungslärm • Direttiva sulla rumorosità nell’ambiente •

Støjemissionsdirektivet • Bullerdirektiv • Melu ympäristöä koskevassa direktiivissä •

Directiva sobre ruido en el ambiente • Directiva Ruído no Ambiente ................................ 2000/14/EC

Measured Sound Power Level • Niveau de puissance sonore assuré •

Gegarandeerd geluidsvermogenniveau • Garantierter Schallleistungspege •

Livello di potenza del suono misurato • Målt lydeffektniveau • Uppmätt ljudfraftsnivå •

Mitattu åånitehon taso • Nivel de Potencia Sonora • Nívelde intensidade de som medido .. 99 dB(A) LWA

Guaranteed Sound Power Level • Niveau de puissance sonore assuré •

Gegarandeerd geluidsvermogenniveau • Garantierter Schallleistungspege •

Livello di potenza del suono misurato • Garanteret lydeffektniveau •

Garanterad ljudtrycksnivå • Taattu äänitehon taso • Nivel Garantizado de Potencia Sonora •

Nível garantido de intensidade sonora .............................................................................. 105 dB(A) LWA

GB-10

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

4 SPECIFICATIONS

Conformity Assessment Procedure • Procédure de conformité•évaluation • Conformiteitsbeoordelingsprocedur • Verfahren zur Beurteilung

der Konformität • Procedura di valutazione conformità • Procedure for overensstemmelsesvurdering • Procedur för utvärderande av

uppfyllande • Yhdenmukaisuuden arviointiproseduuri • Procedimiento de evaluación de conformidad • Processo de avaliação de

conformidade

Annex VI, Part 1• Annexe VI, Part 1 • Bijlage VI, Part 1 • Anlage VI, Part 1 • Allegato VI, Part 1 • Anneks VI, Part 1 • Annex VI,

Part 1 • Liite VI, Part 1 • Anexo VI, Part 1 • Anexo VI, Part 1

U.K. Notifiable Body (No.1088) • Institut britannique à notifie(No.1088)r • Britse onderzoeksinstantie (No.1088) • in GB zu informierende

Institution (No.1088) • Ente notificabile Gran Bretagna • (No.1088) • Organ, som skal underrettes (No.1088) • Brittiskt meddelandeorgan

(No.1088) • Ison-Britannian ilmoitusosapuoli (No.1088) • Cuerpo notificable en el Reino Unido (No.1088) • Entidade a notificar no Reino

Unido ( No.1088)

Sound Research Laboratories Limited

Holbrook House, Little Waldingfield

Sudbury, Suffolk CO10 0TH

Operator Ear Noise Level • Bruit au niveau des oreilles de l’opérateur •

Geluidsniveau op oorhoogte bediener • Schallpegel am Ohr des Fahrers •

Livello rumorosità orecchio operatore • Støjniveau ved betjening •

Bullernivå vid operatörens öron • Käyttäjän korvaan kohdistuva äänitaso •

Nivel de ruido en el oido del operari • Nível de ruído nos ouvidos do operador ............... 85.8 dB(A)Leq (98/37/EC)

Complies with the following harmonised standard or technical provisions • est conforme aux normes harmonisées • Voldoet aan de

volgende geharmoniseerde norm of technische bepalingen • Diese Maschine entspricht den folgenden harmonisierten Normen oder

technischen Bestimmungen • Rispetta il seguente standard armonizzato o requisiti tecnici • Overholder følgende harmoniserede

standardbestemmelser eller tekniske bestemmelser • Uppfyller följande harmoniserade standard eller tekniska definitione • täyttää

seuraavat harmonisoidut standardit tai tekniset edellytykset • Cumple con los siguientes estándares de hramonización o provisiones

técnicas • Está em conformidade com a norma harmonizada ou com as provisões técnicas seguintes

Machinery Safety • Sécurité des machines • Machineveiligheid •

Maschinensicherhei • Sicurezza del macchinario • Maskinsikkerhed •

Maskinsäkerhet • Koneen turvallisuus • Seguridad de maquinaria •

Segurança de máquinas .................................................................................................... EN836

Hand Transmitted Vibration • Vibrations transmises aux mains •

Via de hand overgebrachte trilling • Auf das Hand-Arm-System übertragene Schwingungen •

Vibrazione trasmessa dalla mano • Håndoverført vibration •

Handöverförda vibrationer • Käsivälitteinen tärinä • Vibración transmitida a la mano •

Vibrações transmitidas através das mãos........................................................................ ISO5349: 1986

Whole Body Vibration • Vibrations du corps entier • Trilling hele lichaam •

Auf den gesamten Körper übertragene Schwingungen • Vibrazione di tutto il corpo •

Vibration i hele kroppen • Hel kropps vibrationer • Koko kehoon kohdistuva tärinä •

Vibración de todo el cuerpo • Vibração em todo o corpo ................................................. ISO2631-1: 1985

ROPS .................................................................................................................................. OECD Code 4, ROPS Static Test

Keeper of Technical File, Place & Date of Declaration • Lieu & Date de déclaration • Plaats & datum verklaringsaflegging • Ort und Datum

dieser Erklärung • Luogo e data della dichiarazione • Sted og dato for erklæringen • Plats & datum för deklaration • Lausunnon paikka ja

päivämäärä • Lugar y fecha de la declaración • Local e data da declaração

Technical Director

Ransomes Jacobsen Limited

West Road, Ransomes Europark,

Ipswich, England, IP3 9TT

01.09.2004

T Lansdell

Technical Director

Certificate Number • Numéro du certificat • Certificaatnummer • Zertifikat Nummer •

Numero certificato • Certifikatnummer • Certifikat nummer • Sertifikaattinumero •

Número de certificado • Número do Certificado 4117926 (Rev.3)

GB-11

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

5 DECALS

5.1 SAFETY DECALS

A903491 Read Operator's Manual.

A903489 Keep a Safe Distance from the

Machine.

A903492 Stay Clear of Hot Surfaces.

A903488 Do Not Open or Remove Safety

Shields While the Engine is Running.

A903494 Caution Rotating Blades.

A903493 Avoid Fluid Escaping Under Pressure.

Consult Technical Manual for Service

Procedures.

A903490 Do Not Remove Safety Shields While

Engine is Running.

A911410 Danger of Explosion if the Battery

Terminals are Short Circuited.

A911416 Maximum permitable working slope.

A911434 Caution Diesel fuel.

5.2 INSTRUCTION DECALS

1 Speed Limiter Position

2 Centre Cutting Unit Latch

3 Bonnet latch Point

4 Hydraulic Oil Filter

5 Parking Brake On/Off

6 Horn

7 Hydraulic Oil Level

8 Diff Lock Foot Switch

9 Traction Foot Pedal Control

10 Unit Ground Weight Adjustment

11 Throttle Lever

12 Tyre pressure

13 Cylinder Speed Adjustment

14 Cylinder Engage Foot Switch

15 Cylinder Engage Rocker Switch

16 Ignition Switch - Diesel

18 Jacking Points

19 Hydraulic Oil Tank

20 Diesel Fuel Tank

22 Lift Points

GB-12

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

6 CONTROLS

6.1 STARTER KEY SWITCH

The starter key (A) should be turned anti-clockwise to the

'pre-heat'(No.2)position(Dieselonly)toheattheglowplugs

when the green warning lamp goes out on warning lamp

displymoduleturnthestarterkeyclockwisetothe'start'(No.

3)positiontostarttheengine.Afterstarting,thekeyshould

bereleased andallowedto returnautomaticallyto the'on'

(No. 1) position for normal running.

6.2 THROTTLE CONTROL LEVER

Thelever (B) shouldbemoved away fromtheoperatorto

increase the engine speed and towards the operator to

decreasetheenginespeed.

NOTE: Engine should be used at full speed.

6.4 TRACTION FOOT PEDAL

To move the machine forward press the front of the foot

pedal (A). To reverse depress the rear of the foot pedal.

When the pedal is released it will return to its neutral

position.

6.5 SPEED LIMITER

The speed limiter (B) is operated by sliding the black

knob to the right or left. When slid to the right the

machine is limited to cutting speed, when slid to the left,

transportspeed is available. In transport mode, reverse

isnot available.

IMPORTANT: To enable mow engage the speed

limiter must be in the cutting speed position. If

cutting units are rotating, moving the speed liniter

between the mow and transport positions will

engage and disengage cylinder rotation.

6.3 STEERING WHEEL RAKE ADJUSTMENT

The steering wheel is adjustable for rake. The clamping

release knob (A) is situated on the side of the control

consoleontherighthandside. Toadjustturntheclamping

knobanticlockwisetoreleaseandpivotthesteeringwheel

backwardsandforwardstoobtaindesiredsettingthenlock

in position by turning clamping knob clockwise.

GB-13

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

6 CONTROLS

6.6 TRANSPORT LATCHES

When transporting the machine ensure the cutting

units are raised and the transport latches (A) are

engaged.

6.7 PARKING BRAKES

The parking brake (B) is engaged when the lever is

moved toward the operator. The brake is fitted with

a micro switch that sensors brake position. The

brake must be applied to start the machine, and

when stopping and leaving the seat.

CAUTION:- The parking brake must not be

applied whilst the vehicle is moving.

6.8 HYDRAULIC LIFT LEVERS

The cutting units can be raised and lowered by three

controllevers(A)situatedontherighthandsideofthe

operators seat and can be operated as follows:

Centre lever controls Rear Unit No. 1

Right hand lever controls R.H. Unit No. 2

Left hand lever controls L.H. Unit No. 3

NOTE: If any unit is raised out of work then lowered

intoworkagainthecylinderwillnotrotateuntilthemow

foot switch is depressed.

Tolift:Movethelever(s)upwardsandholdinposition

until the units are at the required height.

To lower: Move the lever(s) fully downwards and

release,theunit(s)willlowertogroundlevel.DONOT

hold lever in down position.

NOTE: The units will only lift and lower when the

engine is running.

IMPORTANT: If, when cutting, a lift control lever is

accidentlypulledup,thecuttingunitswillnotfloatover

groundundulationsuntiltheleverispushedfullydown

and allowed to return to neutral again.

6.9 UNIT COUNTERBALANCE CONTROL

Cutting unit ground pressure can be varied within

preset limits and is controlled by the handwheel (B)

on the right hand side of the operator's seat located

next to the lift/lower levers. The handwheel is

turned clockwise to reduce the groundweight of the

cutting unit, improving slope climbing ability.

The handwheel is turned anti clockwise to increase

the ground weight of the unit. Increased down

pressure will reduce the likelyhood of cutting unit

bounce when cutting undulating ground. When

cutting level ground the normal setting is midway

way between the maximum and minimum positions.

GB-14

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

6 CONTROLS

6.10 CUTTING UNIT SWITCHES

To commence cutting ensure speed limiter is in

mow position and the cylinders have been lowered

Push bottom of the rocker switch (N) and depress

foot switch (B) Push top of rocker switch to stop

cutter unit rotation. (Cutting units stop rotating

automatically when raised.)

NOTE: The backlapping lever must be in the

drive position before cylinders wil rotate.

6.11 VARIABLE CYLINDER SPEED

The speed of rotation of the cutting cylinders is

adjustablebymeansofthehandwheel(A)situatedon

the left hand side of the operator. Cylinder speed

shouldbesettomaximuminnormalcuttingconditions.

Inverylonggrowthconditions,cylinderspeedshould

bereducedtoobtainbestfinish,cylinderspeedshould

alsobereducedwhencutting very short, dry grass to

prevent excesive cylinder and bottom blade wear.

Rotatethehandwheelclockwisetoincreasecylinder

speed, anticlockwise to decrease cylinder speed.

6.12 BACKLAPPINGLEVER

The lever (B) sets cutting cylinder rotational direc-

tion with three positions:

(a) fully towards the seat for mowing, (b) fully away

from the seat for backlapping and (c) set in the mid

position for neutral. See the separate cutting unit

operator's manual for an explanation of the

backlapping procedure.

GB-15

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

6.13 DIFF LOCK CONTROL

The Diff lock (A) is operated by depressing the foot

switch. When the foot switch is released the Diff

Lock ceases to operate. The Diff Lock should only

be used in severe situations, and should never be

used on tarmac or whilst steering

6.14 INSTRUMENT PANEL

A. ENGINE PREHEAT INDICATOR LAMP

DIESEL ONLY

Colour green, on when the ignition switch is turned

clockwise to the pre-heat position. Once the lamp

goes out the engine can be started.

B. ENGINE TEMPERATURE GUAGE

Indicates current temparature of engine, whilst

running.

C. ENGINE OVERHEAT WARNING LAMP

Colour red, on when the engine temperature reaches

a preset level. If the lamp comes on and a warning

horn is sounded bring to machine to a stop,

disengage the cutting cylinders, apply the parking

brake and allow the engine to cool by running the

engine at half speed for two minutes before

stopping and investigating the cause.

D. CHARGING WARNING LAMP

Colour red, on when ignition is switched on and will go

out when the engine is started. If the light comes on

while the engine is running, the fan belt may be slipping

or broken or a fault in the electrical system is indicated

andshouldbe investigated. STOP IMMEDIATELY.

E. ENGINE OIL PRESSURE WARNING LAMP

Colour red, on when the ignition is switched on, and will

go out once the engine has started. If the light comes on

while the engine is running - STOP IMMEDIATELY as

this indicates that the engine oil pressure is too low.

Check the level of oil in the sump and top up as

necessary. Check the oil pressure sender switch.

Continuedoperationmaycauseextensivedamageto

theengine.

GB-16

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

F. ROTATING BEACON

Press the bottom half of the switch to activate the

flashing beacon. (Where fitted)

G. HEAD LIGHT/SIDE LIGHT

Depress the bottom half of the switch to turn on the

headlights and sidelights. (Where fitted)

H. DIRECTIONAL INDICATORS

Depress left hand-side of switch to signal left, and

right hand-side of switch to signal right. (Where

fitted)

I. HAZARD WARNING LIGHTS.

Press the top half of the switch to turn on the

hazard warning lights. (Where fitted)

J. BLOCKED HYDRAULIC FILTER

INDICATOR.

Monitors Hyd filter condition. Colured red,

Illuminates prior to filter bypass valve operating,

when illuminated filter requires changing. The lamp

should illuminated while the engine is preheating as

a test. It is not unusual for the lamp to stay light for

up to 3 minutes after a very cold start. But should

not stay on for longer than 5 minutes.

K. HOURMETER

Located on the lefthand side of the steering tower,

above the parking brake . Records engine running

hours.

L. FUEL GUAGE

Located to the left of the engine temparature

guage. Monitors fuel level.

M. HORN

Press button to sound horn.

GB-17

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

GB

7 OPERATION

7.1 DAILY INSPECTION

1. Perform a visual inspection of the entire unit, look for signs of wear, lose hardwear and missing or

damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and

tubes are in good condition.

2. Check the fuel supply, radiator coolant level, crankcase oil level and air cleaner indicator. All fluids

must be at the full mark with the engine cold.

3. Make sure all cutting units are adjusted to the same height of cut.

4. Check all tyres for proper inflation.

5. Test the operator presence and safety interlock system.

The daily inspection should be performed

only when the engine is off and all fluids

are cold. Lower implements to the

ground, engage parking brake, stop

engine and remove ignition key.

CAUTION

GB-18

GB

RANSOMES HIGHWAY 2130

SAFETY AND OPERATORS MANUAL

7 OPERATION

7.2 OPERATOR PRESENCE AND SAFETY INTERLOCK SYSTEM

1. The operator presence & safety interlock system prevents the engine from starting unless the

parking brake is engaged, the traction pedal is in neutral, the mowing device is off and the operator

is not in the seat. The system also stops the engine if the operator leaves the seat with the mowing

device engaged or the traction pedal out of neutral.

2. Perform each of the following tests to ensure the operator presence & safety interlock system is

functioning properly. Stop the test and have the system inspected and repaired if any of the tests

fail as listed below:

• The engine does start in test 1;

• The engine does not start during tests 2,3 or 4;

• The engine continues to run during test 5.

3. Refer to the chart below for each test and follow the check tick marks across the chart. Shut engine

off between each test.

Test1: Represents normal starting procedure. The operator is seated, parking brake is

engaged, the operators feet are off the pedals and the mower engagement device is off. The

engine should start.

Test 2: The engine must not start if the mower engage device is on.

Test 3: The engine must not start if the operator is not seated.

Test 4: The engine must not start if the traction pedal is depressed.

Test 5: Start the engine in the normal manner, push speed governor into Cut position, engage

mower switch on dash, engage cutting cylinders by depressing foot switch and lift your

weight off the seat.

tseT rotarepO detaeS

gnikraP ekarB deilppA

egagnEwoM hctiwS enignE stratS

seYoNseYoNtuC -siD degagnE seYoN

199

9

9999

9

9999

9

9999

9

99

299

9

9999

9

9999

9

9999

9

99

399

9

9999

9

9999

9

9999

9

99

499

9

9999

9

9999

9

9999

9

99

599

9

99

99

9

9999

9

99

)7(nevesnihtiwgnitatorpotstsumstinugnittucehT.taesffothgiewruoytfiL sdnoces

Never operate the equipment with the

operator presence & safety interlock

system disengaged or malfunctioning.

Do not disconnect or bypass any switch.

WARNING

Table of contents

Languages:

Other Textron Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Phcbi

Phcbi MCO-5AC operating instructions

Anderson

Anderson TRB-2000 Operator's manual

Hurricane

Hurricane 3-PT 42 quick start guide

HE-VA

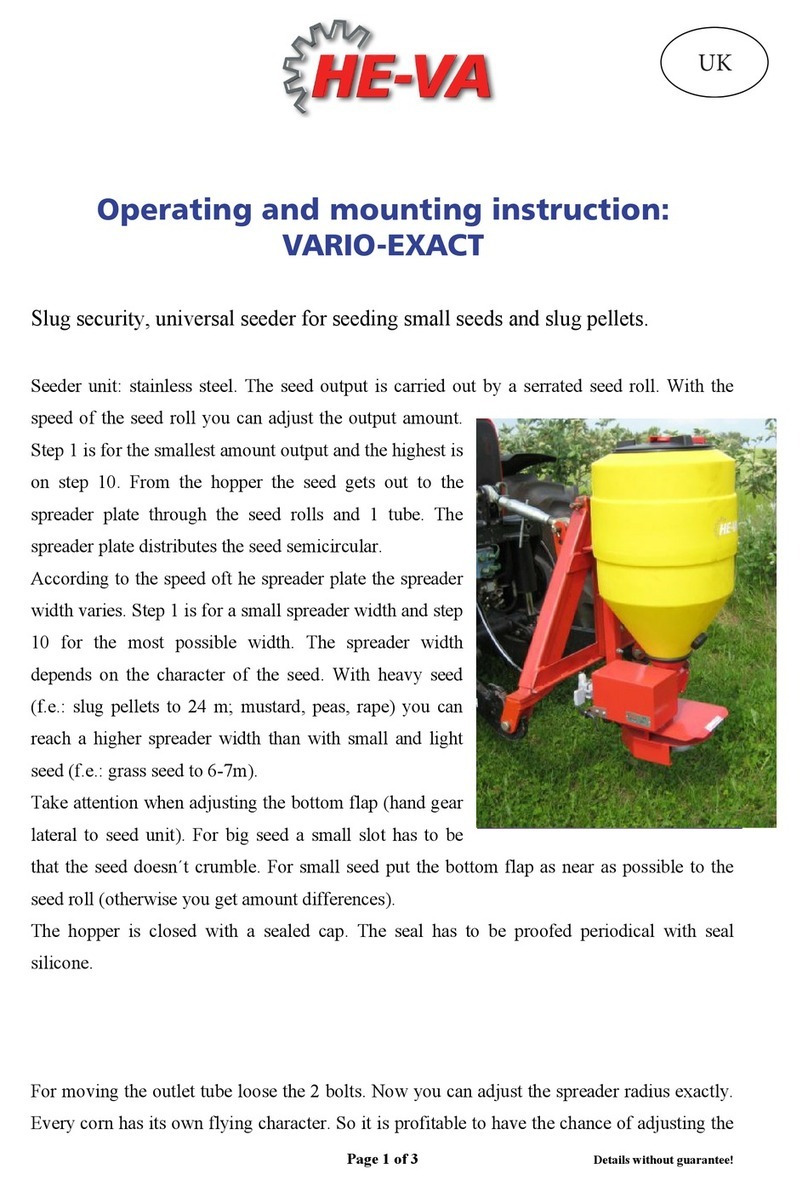

HE-VA VARIO-EXACT Operating and mounting instructions

Kerbl

Kerbl Air Buddex Instructions for use

CrustBuster

CrustBuster 4600 Series Operation maintenance manual & parts list

AXT ELECTRONIC

AXT ELECTRONIC VSE Insruction manual

Powerfix Profi

Powerfix Profi 76607 translation of original operation manual

enorossi

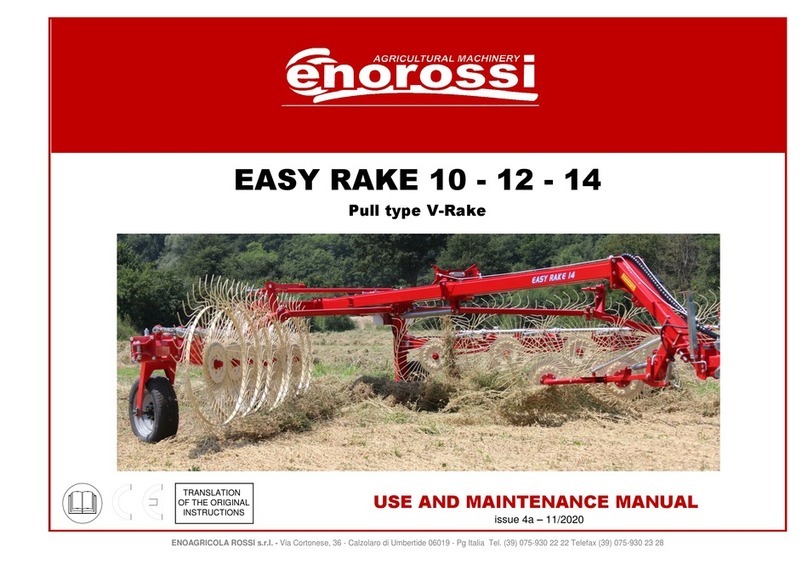

enorossi EASY RAKE 10 Use and maintenance manual

AGCO

AGCO Cumberland Flex-Flo 220 installation manual

Kemper

Kemper 460plus Operator's manual

Helm Welding

Helm Welding LuckNow BP744 Instruction book