Tips and Tricks for

Model Building and Experiments

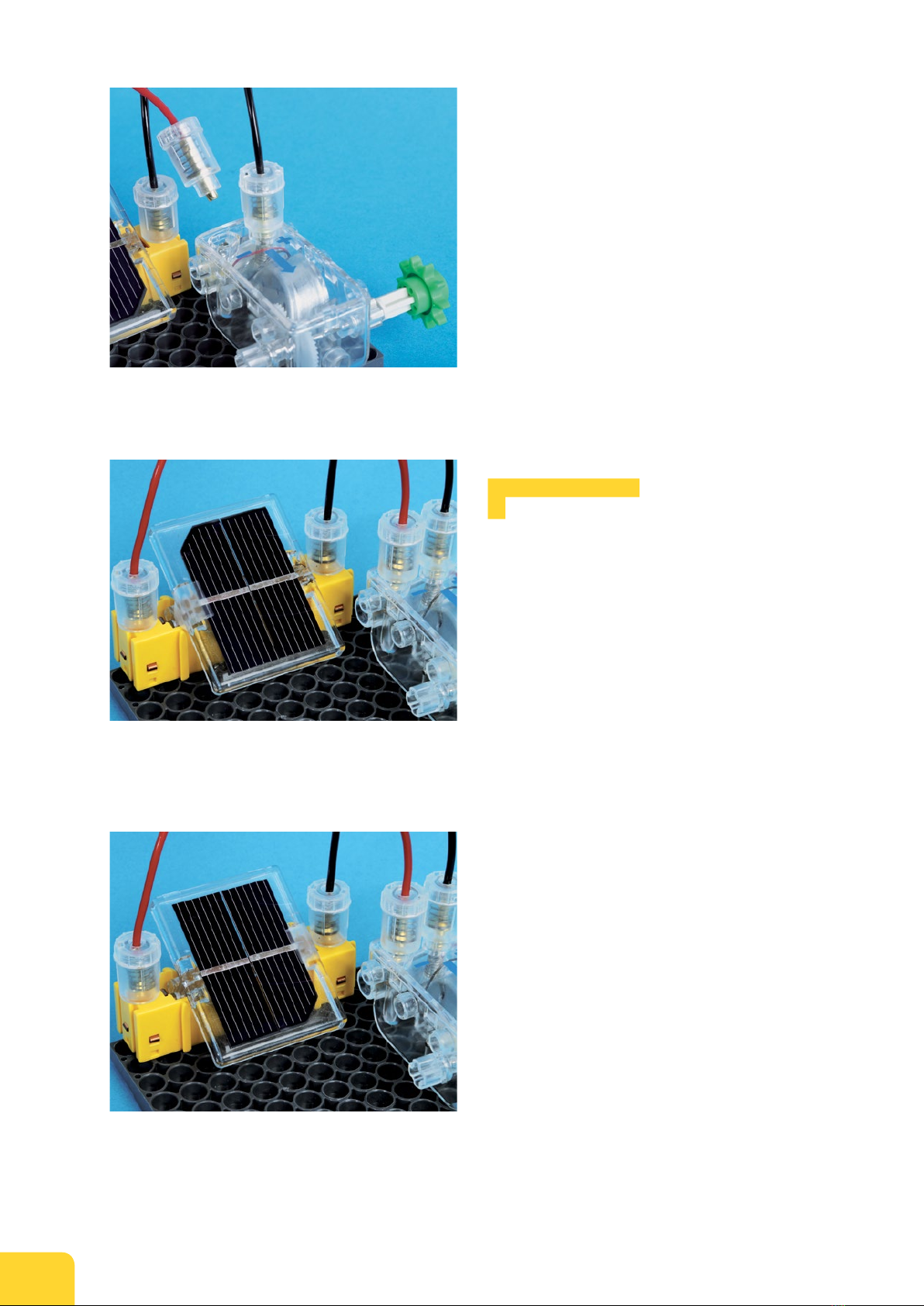

Frames (2, 3) and rods (4, 5) are

connected to each other with the help

of the anchor pins (26).

The short end of the axle

shaft (16, 17, 18) is built

so that the shaft can’t

slip through a hole.

If wheels or pulleys are

mounted too close to

other components, it is

hard to turn them.

If a wheel is mounted too

tightly on an axle shaft,

you can push out the axle

shaft with another.

If wheels have enough

“play,” they turn easily.

short end

long end

Follow the Instructions Closely

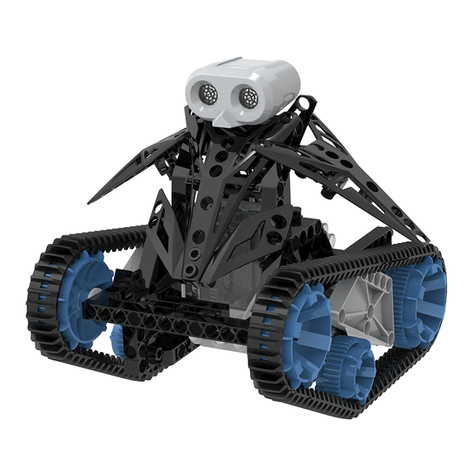

With this experiment kit, you will assemble a variety of

solar models and conduct a lot of experiments. It is best to

assemble the models in order. Then, it will be easier for you

to construct the complicated models at the end. For all the

models, it is important that all the individual components

are put together properly. Only then will everything work

right. To help you with this, there is a picture correspond-

ing to every step in the assembly process. The instructions

that go with the picture tell you exactly which pieces to use.

Following each piece mentioned in the instructions, there is

a number in parentheses. This is the number that you will

find in the overview of the kit contents on pages 2-3. So if

you aren’t quite sure which piece you are supposed to be

using, you can check on pages 2-3 to verify exactly which

piece it is.

About Connecting Frames and Rods

The basic construction of all of

the models consists of frames

and rods, which are connected

to each other with the help of

anchor pins. Some anchor pins

are already permanently mounted

to all of the frames and rods. But

for most of the connections, you

will need the red anchor pins

(26). They are simply inserted

into the holes of the frames and

rods and serve to ensure a secure

assembly.

To make it easier to remove

the anchor pins from the holes,

your kit comes with a small tool,

the anchor pin lever (30). It has

two different sides, marked “A”

and “B.” The narrow side with the

“A” serves to lever out the anchor

pins. The other side, marked with

the “B,” is wider. You can use it to

remove shaft plugs (25) from the

frames or rods.

You can use the narrow side of the

anchor pin lever (30) to pull the

anchor pin (26) out again.

With the help of the shaft plugs (25),

you can mount individual gear wheels or

sprocket wheels to frames or rods.

The shaft plugs can be levered out with

the broad side of the anchor pin lever.

About Wheels and Pulleys

In this box of solar experiments, you

will find four types of wheels: gear

wheels (6, 7, 8), sprocket wheels (9, 10,

11), pulley wheels (12, 13, 14), and tire

wheels (15). They all perform different

functions.

Gear and sprocket wheels are used

in all of the models. They have two

functions: first, they serve to transfer

the rotary motion of the solar engine

to other components. Second, they

are used to secure axles (16, 17, 18, 19)

so that they don’t slip. The tire wheels

are used to transfer the power of a

vehicle’s engine to the ground surface.

The pulley wheels serve to guide the

cord. In most cases, wheels and pulleys

are secured with the help of the axle

shafts (16, 17, 18). You can also attach

wheels and pulleys to the engine shaft

(19) or secure them individually with

the small red shaft plugs (25).

About Mounting Wheels

The axle shafts (16, 17, 18) and the en-

gine shaft (19) each have two different

ends: one short and one long. On the

short end, wheels and pulleys can only

be pushed on a little way. But if you

push them onto the long end, you can

position wheels and pulleys wherever

you want on the shaft.

The short end is constructed in

such a way that the axle shaft can’t slip

through a hole. To secure an axle shaft

to a rod or frame, it will suffice to push

a wheel, sprocket, or gear onto the

long end to serve as a bracket. When

building a model, you have to pay close

attention to which direction an axle

shaft is inserted.

With all of the models, wheels and

pulleys have to be able to rotate freely.

Otherwise, the solar engine won’t be

able to turn them. For that reason, it is

very important that wheels and pulleys

have enough “play” — as the profes-

sionals call it — and not be mounted

too close to other components. So

always leave a little room between a

wheel or pulley and other components.

Then, everything will go smoothly.

Sometimes, it may be difficult to

remove a wheel from its axle. If that

happens, use another axle shaft as a

tool; hold the wheel tight and push

with the other axle shaft against the

axle that the wheel is mounted on (see

picture at right).

4