Thames Side XT2000 User manual

XT2000 Quick Start Guide

Page 1of 8

Turn your XT2000 on and wait until the instrument has fully completed

its countdown sequence and the display has stabilised.

If turning on for the first time it is advisable to leave the XT2000 for 30

minutes prior to calibration.

Press both the and keys together which will change the display

to Id0000 with the first 0flashing.

Pressing the up key ( ), allows you to change each 0to 1,2,3etc.

Pressing the left ( ) and right ( ) keys then moves you to

each position. E.g. _000,2_00,28_0,280_

Change these 0’s to read 2802 which is the factory access code.

Once you have changed Id0000 to read Id2802 press the enter

button.

The XT2000 will then briefly display UnPro to confirm that the

instrument is in the unprotected mode and the parameters can be

altered.

Once it has shown UnPro the display will change to show to dEF (Scale

Definition)

In order to calibrate your system you will first have to define the scale.

For more detail please see section 3.2 in the user manual.

XT2000 Quick Start Guide

Page 2of 8

Press on dEF and you will then see CAP, which is the maximum

capacity of your scale that you will require.

Press again and this allows you to input the maximum capacity of

your scale using up to 6 digits. You input this number using the ,

and keys.

Once you have entered your maximum capacity press to store this

value and you should again see CAP.

Note: CAP ÷ D1 ≤ 100000 or you will see ErrCAP.

Press to move to d1, which is the division of the scale that you

require. This division is determined by taking the higher value of:

i. CAP (value you have used for the maximum capacity of your

scale) ÷ 100,000

ii. (Load cell capacity, expressed in the same unit of measure as used for CAP

÷ 10,000) x √(number of load cells)

iii. Maximum product load ÷ division of the load cell (e.g. 3000

division for a C3 cell.)

Once you have calculated the highest value, press and using the

or keys choose the next closest value (rounding up) from

1,2,5,10,20 or 50. If you require a number smaller than 1 you can

choose the DP (decimal place) in the next step, for example if 0.05 is

required choose 5in d1 and then 0.00 in dP.

Once you have chosen your division press to store and you will then

again see d1.

Note: CAP ÷ D1 ≤ 100000 or you will see Errd1

XT2000 Quick Start Guide

Page 3of 8

Press to move to dP, which is the position of the decimal point that

you require in relation to the capacity of the scale, (for example in a

3000KG scale you may only require 1KG intervals so 0decimal places)

Press and choose your dP using the or keys.

Once you have made your choice press to store this value and get

back to dP.

Press to see 0-trAC, which is the level at which the system is

automatically zeroed as long as the weight is within the selected band

and it is stable.

Press to choose your required value using the and keys.

The default setting is 0.5d. Press to store this value and get back

to 0-trAC.

Press to see 0-toP, which is the range within which the scale may

be zeroed.

Press to choose your required value, the default setting is 1.9but

can be altered if required using the or key.

Press to store this value and get back to 0-toP.

Press to see 0.StArt, which zeroes the indicator when it is turned

on. Press and using the or keys choose either oFF (which

is the default setting recommended for silos/tanks and hoppers), or

change to on (recommended for platform scales)

Press to confirm and go back to 0.StArt.

XT2000 Quick Start Guide

Page 4of 8

Press to see UndErL, the point at which the computer indicates

the input error signal below the minimum range.

Press and choose your option using the or keys, the

default is setting is –oUErL, once you have chosen your option press

to confirm and go back to UndErL.

Press to see UnIt, press to choose your unit of weight using

the and keys. The options are:

K 9= Kilogram,

t= Ton,

g= Gram,

Lb = Pound,

o= Ounce,

nonE = None)

Press to confirm your choice and go back to UnIt.

The XT2000 scale has now been defined.

By pressing you will return to dEF where pressing either the or key and scroll until you see:

CAL 1, to perform a calibration with verified weights. (Section 4.1 in the user manual)

CAL 2, to perform a theoretical calibration if you do not have any verified weights. (Section 4.2 in the user manual)

Pressing again when you are on dEF exits the configuration level completely.

Note: If you exit the configuration level you will have to re-enter the Factory Access Code 2802 to calibrate your XT2000.

XT2000 Quick Start Guide

Page 5of 8

CALIBRATION WITH VERIFIED WEIGHTS (CAL 1)

Section 4.1 in the user manual

Ensure that there is no unwanted weight on the system and that you

are in the configuration level.

Using the or keys scroll from dEF until you see CAL 1.

Press when you see CAL 1 and you will then see 0Ero,

Press again and you will see the preset coefficient value

Press again you should see -CALI- flashing which will store this as

your zero point.

Once it has stored this value it will return to 0ERo.

Press on 0ERo you will see SPAn.

Place your verified weight onto your scale and press where you will

see a value displayed.

XT2000 Quick Start Guide

Page 6of 8

Ensure that the value shown on the XT2000 matches the weight placed

on the scale.

You can alter this value using the , and keys.

Once you have the correct weight showing press and -CALI- will

again flash storing this value.

Normally this is sufficient for most calibration purposes and at this point you can press and again to leave

the configuration level completely and your X2000 should now be calibrated and ready to weigh.

XT2000 Quick Start Guide

Page 7of 8

THEORETICAL CALIBRATION (CAL 2) when no verified weights are available.

Section 4.2 in the user manual

Ensure that there is no unwanted weight on the system and that you

are in the configuration level.

Using the or keys scroll from dEF until you see CAL 2.

Press and you will see LCAP.

Press and enter the nominal capacity of one of the load cells being

used.

This value is expressed in the same decimal point used in CAP and d1

Press to store this value and return to LCAP.

Press to see Lno, which is the number of load supports.

Please note that all supports must be counted including those without

load cells.

Press to enter the number of supports using the button.

When correct press to store this value and you will return to Lno.

XT2000 Quick Start Guide

Page 8of 8

Press to see LSn which is the mv/v value of the load cell(s) being

used. Typically this information is on a sticker on the load cell.

If you have more than one cell in your system then average out the

mv/v values and use this average figure.

Press to enter the mv/v value using the , and keys,

Once correct press to store this value and you will return to LSn.

Press to see 0Ero which is your automatic Zero adjustment.

Press the and you will see the preset coefficient value.

Press again you should see -CALI- flashing which will store this

as your zero point.

Normally this is sufficient for most calibration purposes and at this point

you can press and again to leave the configuration level

completely and your X2000 should now be calibrated and ready to

weigh.

Table of contents

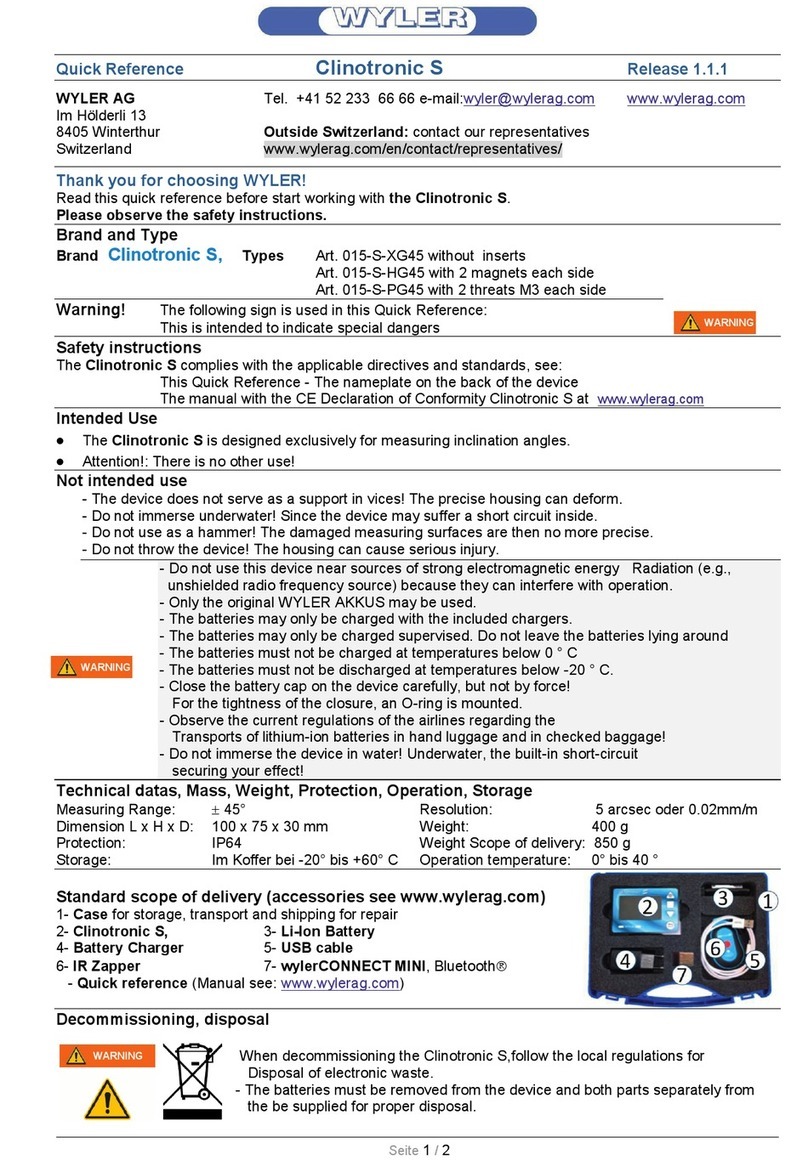

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Analytik Jena Biometra TS1 ThermoShaker Short manual

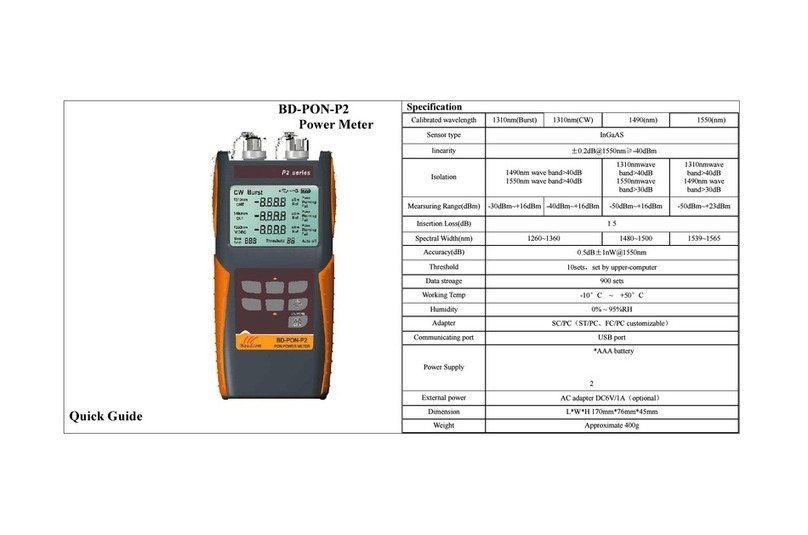

Baudcom

Baudcom BD-PON-P2 quick guide

M-Sure

M-Sure MS-200 Series user manual

QuadTech

QuadTech 1657 RLC Digibridge instruction manual

GESTRA

GESTRA LRGT 16-1 Installation & operating instructions

Lightware

Lightware SF02/F product manual