Tharo Systems V-425E User manual

V-425E and V-434E

Users Manual

Date: 01-26-2015

CONTENTS

1

Barcode Printer

1

1.1

1.2

Box Contents

Getting to Know Your Printer

1

2

2

Printer Setup

4

2.1

2.2

2.3

2.4

2.5

Opening the Top Cover

Opening the Print Mechanism

Loading Ribbon the Host Computer

Loading Labels

4

4

5

3

Printer Setting and Control

17

3.1

3.2

3.3

Operation Panel

Label Calibration and Self-Test

Error Alerts

17

18

19

4

NetSetting for Ethernet

4.1

4.2

Installing the NetSetting Software

NetSetting Interface

20

21

5

Accessories

28

5.1

5.2

5.3

Preparation

Installing the Label Dispenser

Installing the Cutter

28

29

6

Maintenance and Adjustment

38

6.1

6.2

6.3

6.4

6.5

Cleaning the Thermal Print Head

Adjusting the Print Head Pressure

Adjusting the Print Line

Clearing Cutter jams

Troubleshooting

38

38

39

39

40

Appendix

Label Supply Hub Installation 9

7

34

41

Product Specifications

Interface Specifications

41

42

20

2.6

2.7

2.8

2.9

10

11

12

15

Preparation for Tag Printing

Connection the Printer to your Computer

EASYLABEL Start Installation

Windows Driver Installation

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a CLASS A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at their own expense.

EMS AND EMI COMPLIANCE STATEMENT

FOR EUROPEAN USERS

This equipment has been tested and passed with the requirements relating to electromagnetic compatibility

based on the standards EN 55022:2006/A1:2007 Class A, EN61000-3-2:2006, EN 61000-3-3:2008 and

EN55024:1998/A1:2001/A2:2003, IEC 61000-4-2:2008 series, The equipment also tested and passed in

accordance with the European Standard EN55022 for the both Radiated and Conducted emissions limits.

V-400E SERIES

TO WHICH THIS DECLARATION RELATES

IS IN CONFORMITY WITH THE FOLLOWING STANDARDS

IEC 60950-1:2005(2nd Edition)+Am 1:2009, GB9254-2008 (Class A ) ; GB17625. 1-2003; GB4943.1-2011,

EN 55022:2006/A1:2007 Class A, EN61000-3-2:2006, EN 61000-3-3:2008 and EN55024:1998/A1:2001/A2:2003,

IEC 61000-4-2:2008 series, UL 60950-1, 1st Edition, 2007-10-31, CSA C22.2 No. 60950-1-03, 1st Edition, 2006-07,

CFR 47, Part 15

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to correct the interference at their own expense.

㭋ḡClass AẎ⒨Ə✏䔆㴢䎖⡪ḔƏ富Ẏ⒨⏖僤怇ㇷ㗇亦䔜⹙㉗Ə✏忀䦴ガ↜Ə⏖僤曧奨䔏㈞⯠⅝⹙㉗憮⎽⇮⮅⏖堳

䙫㎑㖤˛

SAFETY INSTRUCTIONS

During the print process the Printhead will become hot. Do NOT attempt to clean the

Printhead until it has had time to cool.

The Printhead is the most fragile part of your Printer. Do NOT use sharp or hard objects to

clean the Printhead. Do NOT touch the glass surface of the Printhead with your hand.

This Printer is built exclusively to print labels, tickets and tags, continuous paper, etc. Only

use media that is recommended for a direct thermal or thermal transfer Printer.

The Printer is configured for input voltages of 110 to 240 V. Connect only to a power outlet

with a grounded contact. Always ensure the Printer is switched OFF before connecting the

power cord to an electrical outlet.

Do not expose the Printer to moisture or operate it in wet or damp areas.

The Printer will operate with the cover open if necessary. This is not recommended, as the

Printer’s moving or rotating parts can cause injury. Keep long hair, jewelry and loose

clothing away from any moving parts.

Remove the power cord from the rear of the Printer when disconnecting or attaching

accessories such as rewind units, cutters, etc.

**** There is a Danger of explosion if the battery is replaced incorrectly.

**** Dispose of used batteries according to the manufacturer’s instructions.

****Only replace the battery with an equivalent type.

Specifications are subject to change without notice.

Caution

This printer is equipped with a button cell lithium battery. This battery on the main circuit board.

1

1 Barcode Printer

1.1 Box Contents

Please check that all of the following items are included with your printer.

=V-425E / V-434E Printer

=Power Cord

=AC Adapter

=USB Cable

=Quick Start Guide

=Ribbon Hubs ( 2 )

=Empty Ribbon Core

=Label Supply Hub

=Label Guide Plates ( 2 )

=CD ( EASYLABEL Start software and Users Manual )

1 Barcode Printer

1.2 Getting To Know Your Printer

4Overview

=Front

=Rear

TOP COVER

COVER RELEASE BUTTONS

FRONT COVER

SERIAL PORT ( RS-232 )

POWER SWITCH

- ON

- OFF

FAN-FOLD LABEL SLOT

Feed slot for external label feeding

POWER JACK

USB PORT

2

OPERATION PANEL

ETHERNET PORT

1 Barcode Printer

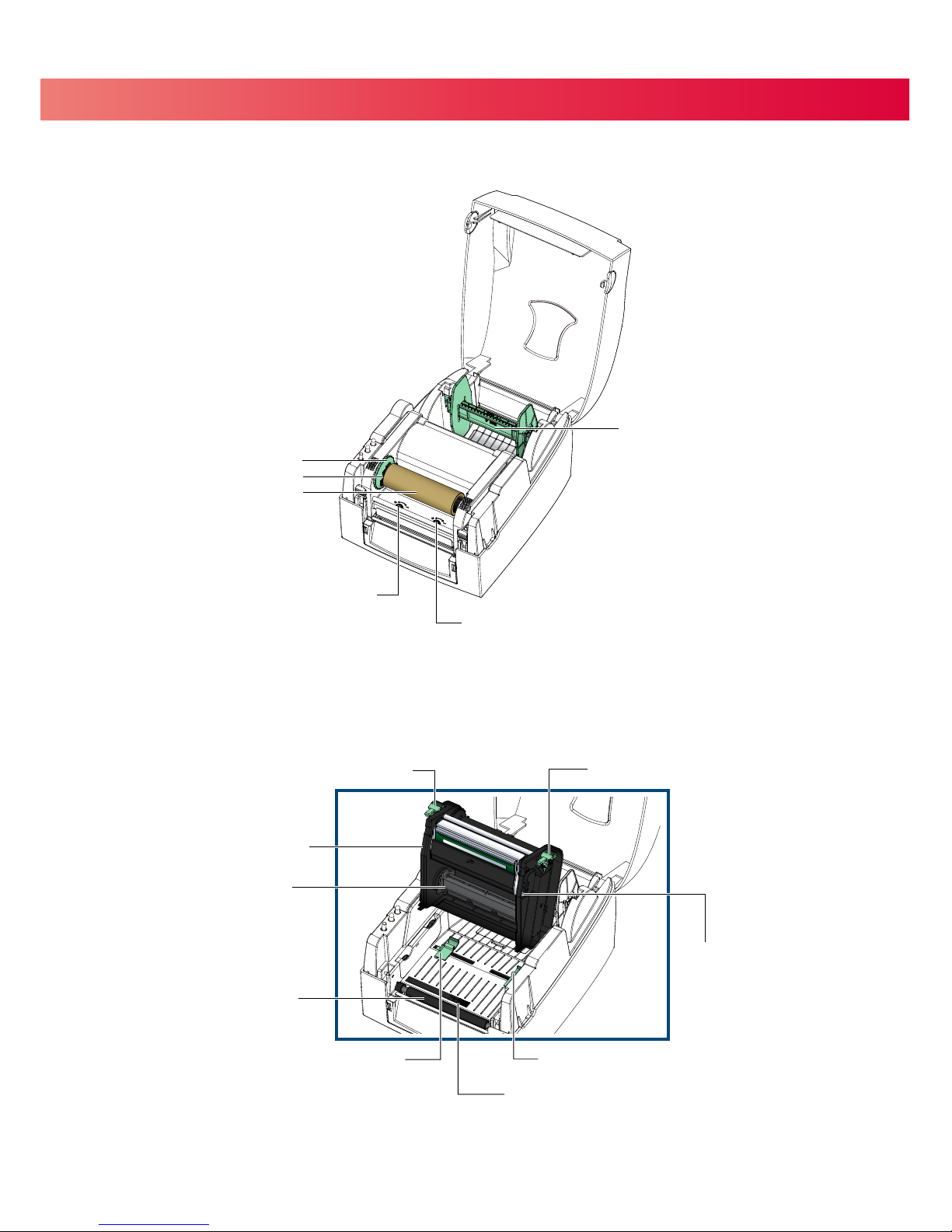

4Open Cover

4Open Print Mechanism

PRINTHEAD PRESSURE ADJUSTMENT SCREW ( LEFT )

PRINTHEAD PRESSURE ADJUSTMENT SCREW ( RIGHT )

LABEL SUPPLY MODULE

- LABEL SUPPLY HUB

- LABEL GUIDE PLATES ( 2 )

RIBBON MODULE

- RIBBON FEED MECHANISM

- RIBBON HUB

- EMPTY RIBBON CORE

LABEL GUIDE ( RIGHT )

RELEASE CATCH ( RIGHT )

RIBBON SUPPLY HUB

RELEASE CATCH ( LEFT )

LABEL GUIDE ( LEFT )

PRINT MECHANISM

PLATEN ROLLER

LABEL SENSOR

PRINT LINE ADJUSTMENT SCREW

3

2 Printer Setup

2.1 Opening the Top Cover

4Open the Top Cover by pressing the release buttons on both sides of the

Top Cover and lift the cover.

2.2 Open the Print Mechanism

4Open the print mechanism by pressing the Release Catches and then lift the Print Mechanism.

Press the button

COVER RELEASE BUTTONS

Press the button

Lift the printer cover

Lift the print mechanism

Press

Press

RELEASE CATCHES

4

2 Printer Setup

2.3 Loading Ribbon

4Place the new ribbon on one of the Ribbon Hubs.

Place an empty ribbon core on the other Ribbon Hub.

Attach the ribbon to the empty ribbon core and wind the ribbon around the core 2~3 times.

RIBBON SUPPLY HUB

Place on the Hub

RIBBON HUB NEW RIBBON

Place on the Hub

EMPTY RIBBON CORERIBBON HUB

RIBBON REWIND HUB

5

Wind the ribbon around the core

2 Printer Setup

4Place the Ribbon Supply Hub at the back of the Print Mechanism.

Pass the ribbon under the Print Head.

Insert the Ribbon Rewind Hub into the Print Mechanism.

Insert into the Print Mechanism

Wind up any slack

Insert into the Print Mechanism

6

Close the Print Mechanism.

Make sure that it clicks into place.

Wind up any slack in the ribbon.

This manual suits for next models

1

Table of contents