6 + THERMOSTATIC MIXING VALVE MANUAL 7 + THERMOSTATIC MIXING VALVE MANUAL

before you install before you install

Hot water inlet

Cold water inlet

Hot water inlet

Cold water inlet

Read and save these instructions

WARNING

+ This product can expose you to chemicals including lead, which is known to the State of

California to cause cancer and birth defects or other reproductive harm. For more information

go to www.P65Warnings.ca.gov.

+ All work must be performed by qualified personnel trained in the proper application, installation,

and maintenance of systems in accordance with all applicable codes and ordinances.

+ If the thermostatic mixing valve is not installed, commissioned and maintained properly,

according to the instructions contained in this manual, it may not operate correctly and may

endanger the user.

+ Make sure that all the connecting pipework is water tight.

+ When making the water connections, make sure that the pipework connecting the thermostatic

mixing valve is not mechanically over-stressed. Over time this could cause breakages, with

consequent water losses which, in turn, could cause harm to property and/or people.

+ Water temperatures higher than 100°F can be dangerous. During the installation, commissioning

and maintenance of the thermostatic mixing valve, take the necessary precautions to ensure

that such temperatures do not endanger people.

+ To prevent any damage which will cause the electronic mixing valve to not operate correctly,

treat highly aggressive water before entering the thermostatic mixing valve.

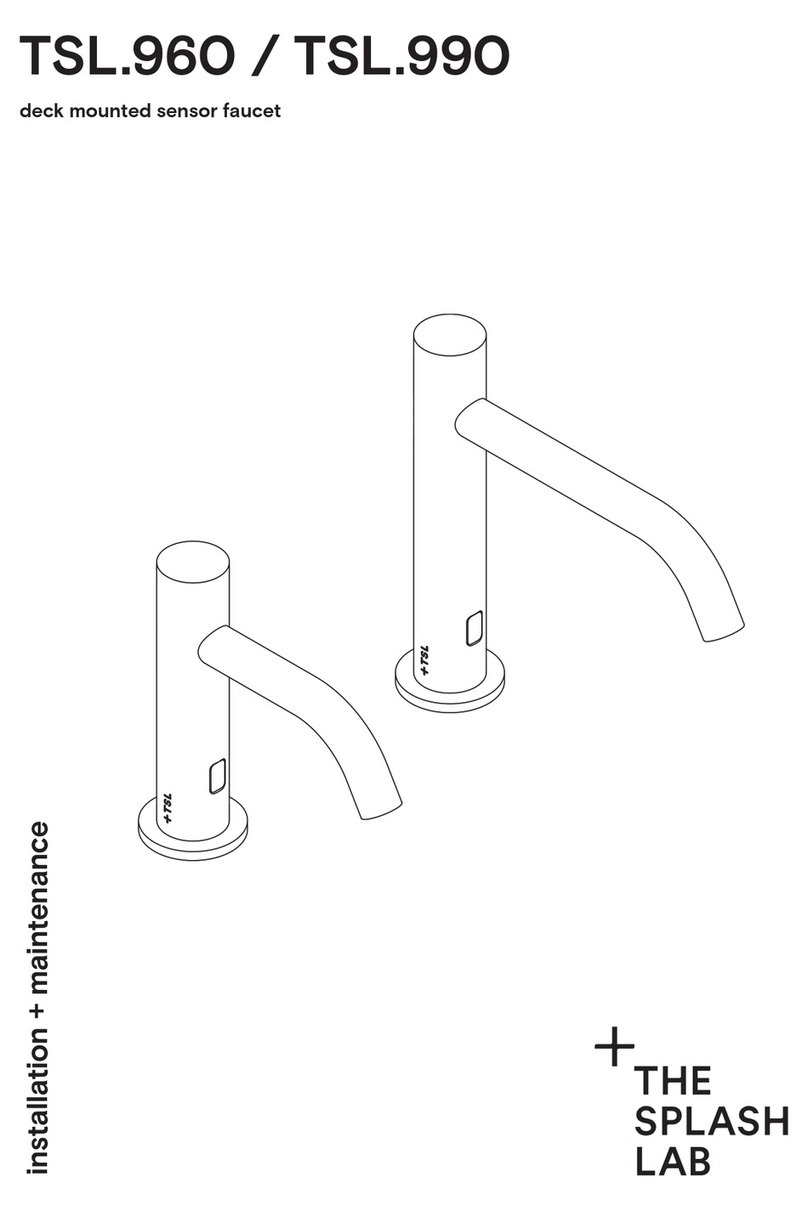

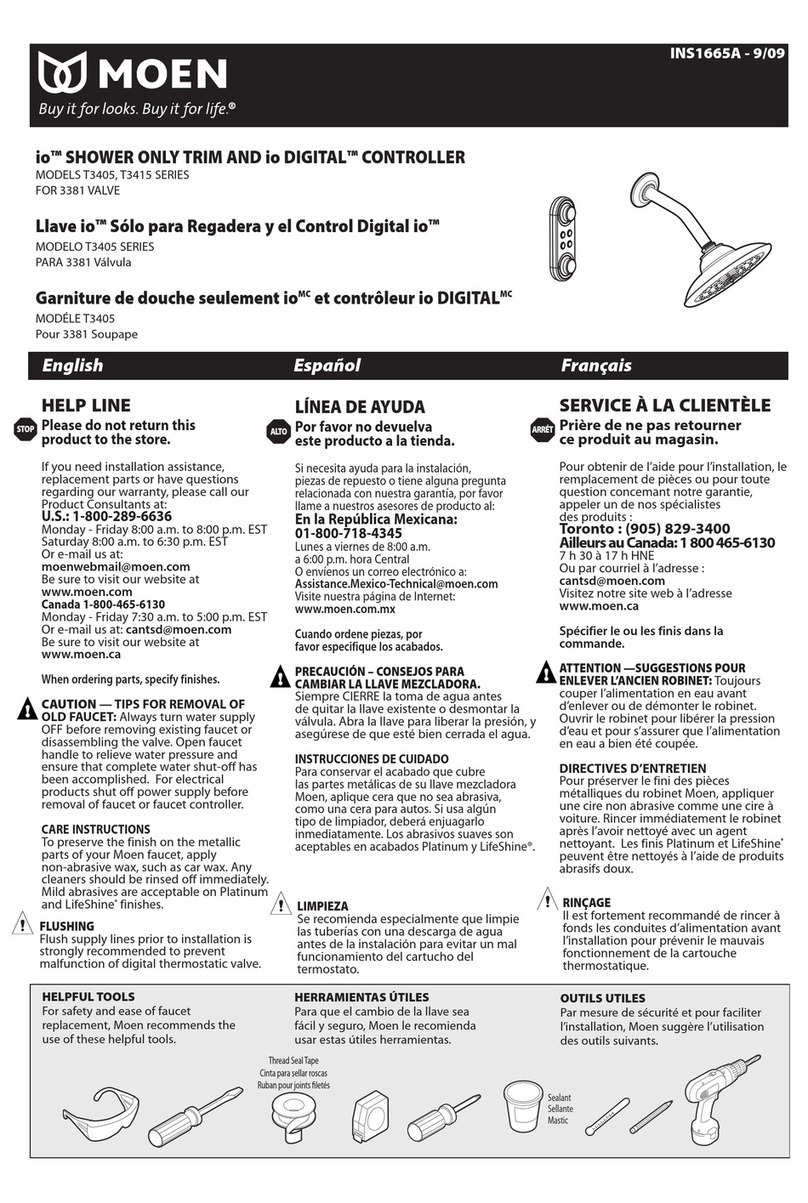

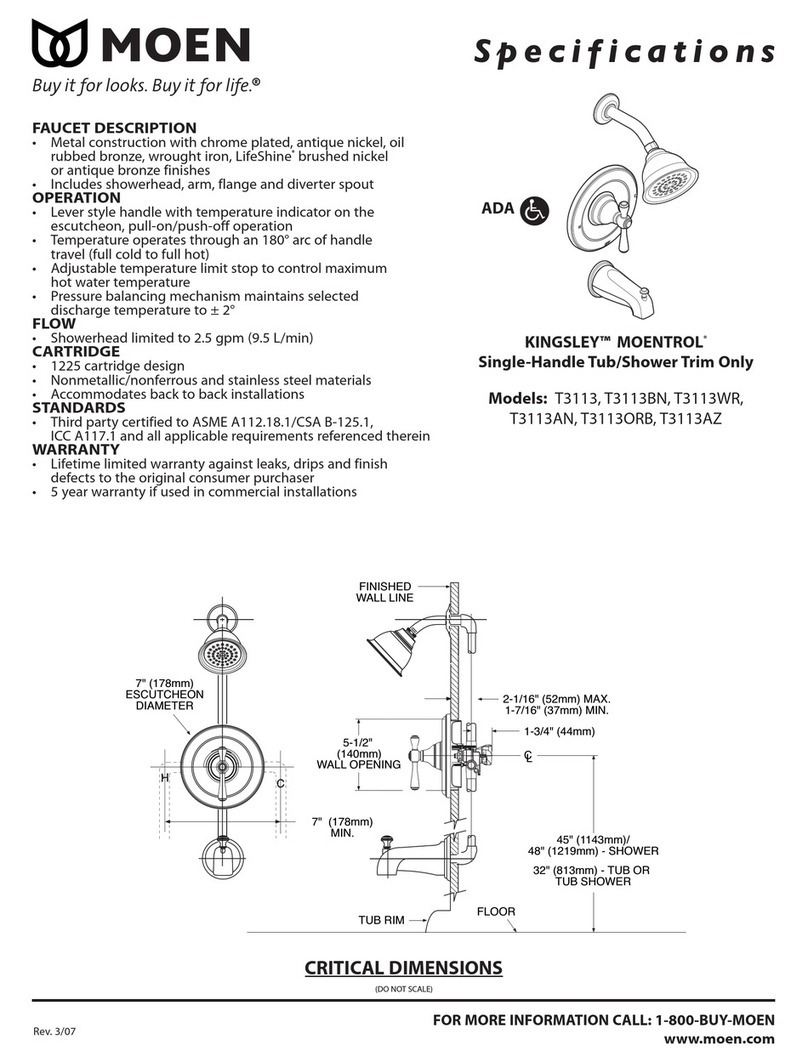

Multiple use with sensor faucet

Single use with sensor faucet

+ Verify that the system conditions (i.e. temperature supply pressures, etc.) fall within the

recommended operating range of the valved (see page 5 for technical specifications)

+ Thoroughly flush and clean the system of debris. Failure to remove debris will affect valve

performance and manufactuerer’s warrnty on the product.

+ Valve can be installed vertically or horizontally.

+ Valve must have sucient access for ongoing maintenance.

+ Install and connect the valve according to current legislation and codes.

+ Installation should be conducted by a licensed plumber.

+ Ensure that piping to and from the valve is not used to support the weight of the valve.

+ Provision should be made to treat highly aggressive water before it enters the valve.

+ Connect hot and cold water supplies in accordance with the indicators on the body of the valve.

+ Where one or both of the incoming supply pressures are excessive, a pressure reducing valve

should be employed to bring pressure within the recommended limits.

+ Must be installed with isolating valves, line strainers, and check valves to ensure optimum

performance.

+ Verify the hot water supply at point fo entry is at least 18ºF higher than the mixed water

discharge temperature.