B

A

C

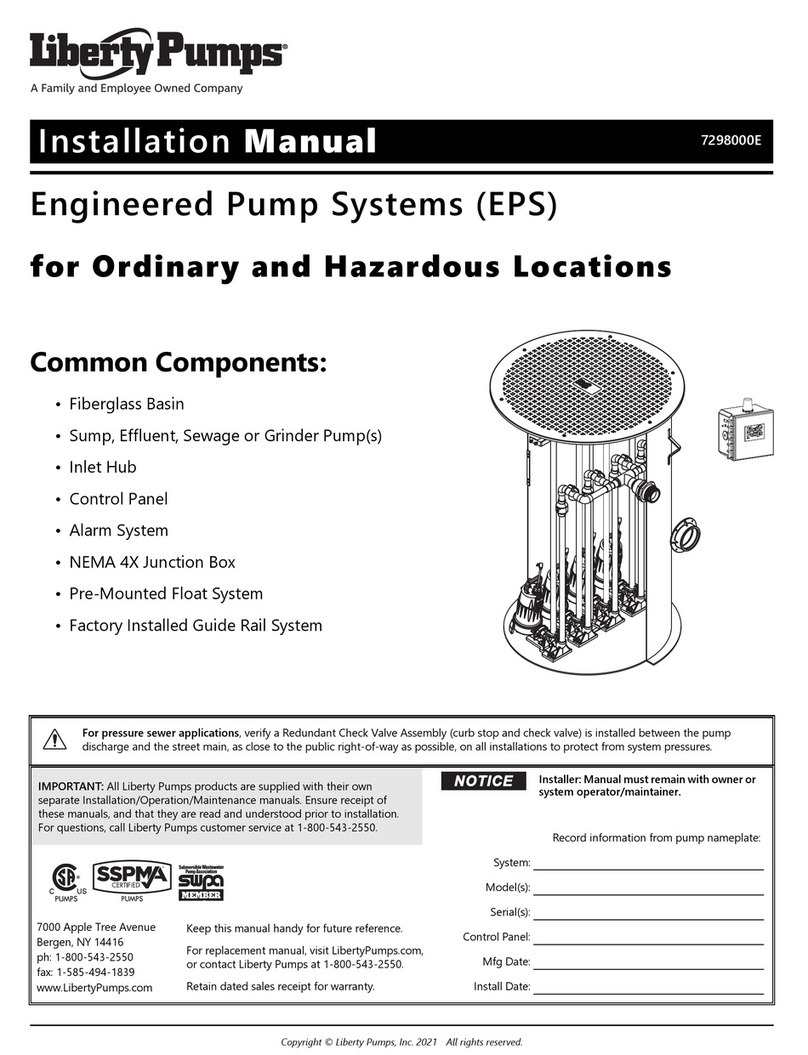

Package Contents

SOLIDFLO™PUMP

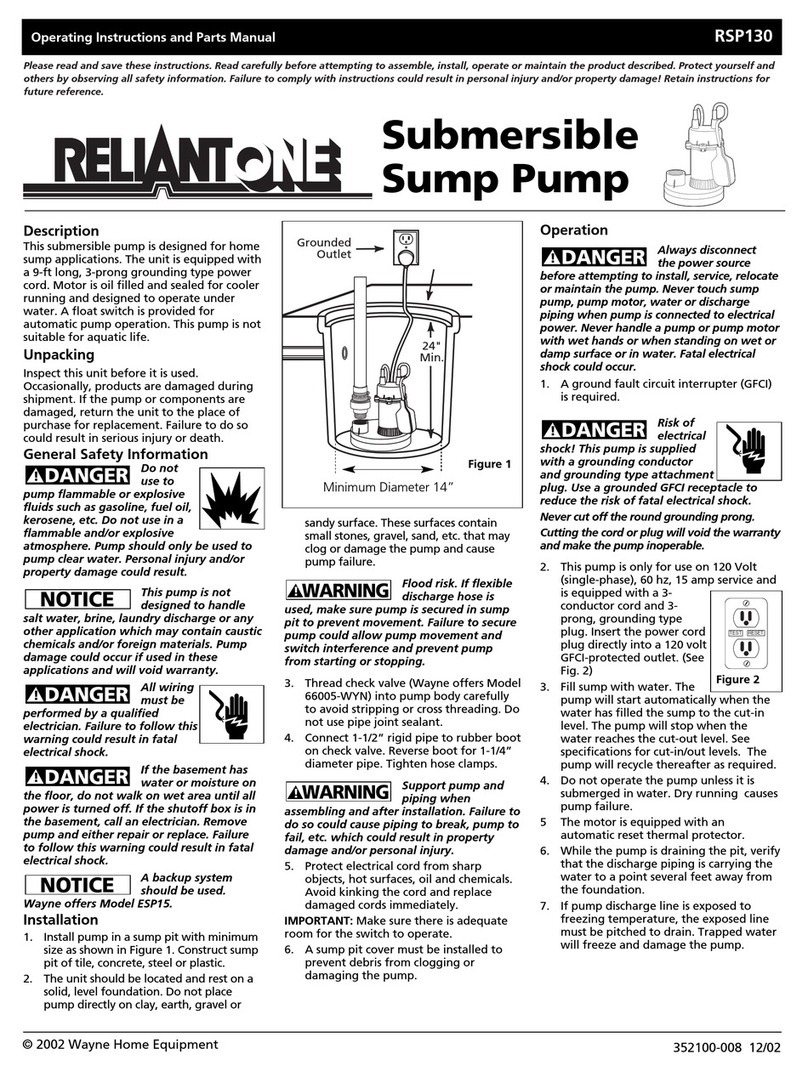

IMPORTANT INFORMATION:

Please read these instructions thoroughly before use. Failure to follow instructions may

result in equipment damage or failure, losses, injury or death.

DANGER:

To avoid possible electric shock:

• If the power cord has been damaged, DO NOT operate, SolidFlo™ Pump should

be replaced.

• Close supervision is necessary when the unit is used by or near children.

WARNING:

To reduce the risk of electric shock:

• Connect only to a properly grounded receptacle, which is serviced by a Ground

Fault Circuit Interrupter and never remove the ground pin from the plug.

• Provide a “drip loop” for the power cord. This is a loop in the cord below the level

of the receptacle or plug that prevents water from traveling along the cord in the

direction of the receptacle.

• ALWAYS unplug the SolidFlo™ Pump from power source when it is not in use, and

before installing, removing or servicing the SolidFlo™ Pump components.

• If an extension cord is necessary, a cord with a proper rating should be used. A cord

may overheat if the cord is rated for less amperes or watts than the unit rating.

• DO NOT immerse the SolidFlo™ Pump plug in water or attempt to use a wet plug.

• The SolidFlo™ Pump is NOT suitable for use in swimming pools, swimming ponds, or

other situations where bodily contact is made with the water.

CAUTION:

To reduce the risk of equipment damage or failure:

• DO NOT place SolidFlo™ Pump near ammable or other dangerous materials

or objects.

• ALWAYS unplug the unit if there is no water running through it to prevent over

heating.

• ALWAYS operate the pump completely submerged for proper cooling.

• DO NOT operate during freezing conditions. Drain SolidFlo™ Pump and store in a

protected location.

IMPORTANT:

The Pond Guy® is not responsible for equipment damage or failure, losses, injury

or death resulting from failure to follow safety precautions, misuse or abuse of

equipment.

SolidFlo™Series

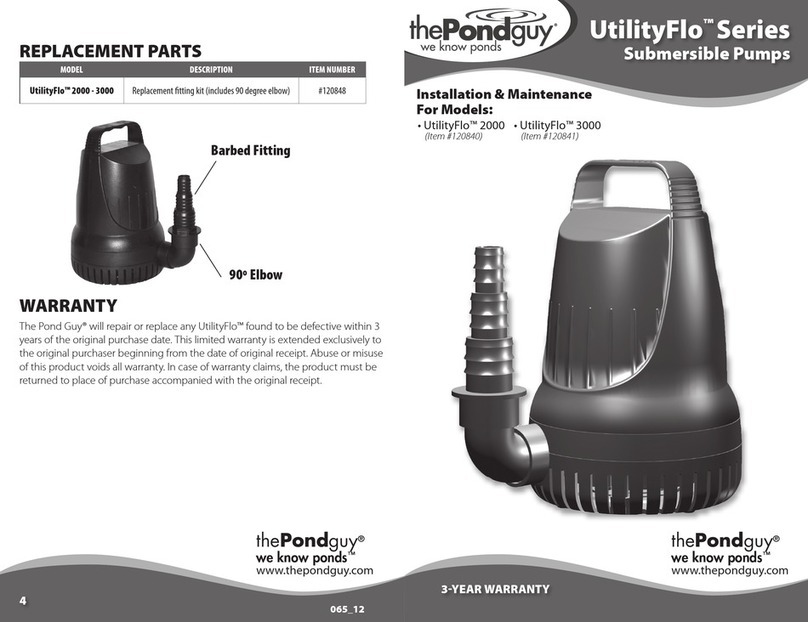

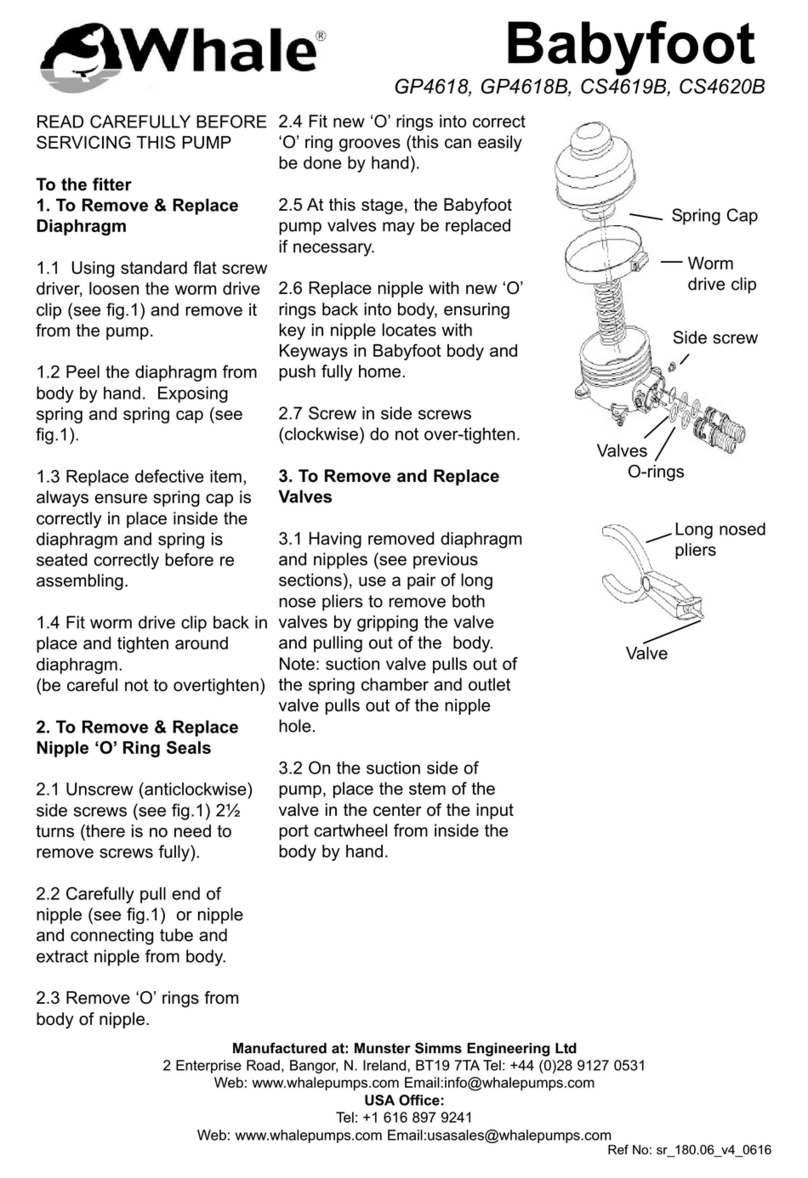

ASolidFlo™ Pump Unit

BBarbed Fitting

CKnuckle

TECHNICALSPECS :

MODEL POWER WATTAGE GPH @

0’ HEAD

GPH @

3’ HEAD

GPH @

6’ HEAD

SHUT OFF

HEIGHT

PLUMBING SIZE

(STEP DOWN

BARB FITTING)

POWER

CORD

LENGTH

SolidFlo™ 600 120V / 60 Hz 35 Watts 600 GPH 475 GPH 250 GPH 8’ 1”, 1¼”, 1½”

20’

SolidFlo™ 1200 120V / 60 Hz 85 Watts 1,200 GPH 975 GPH 750 GPH 10’ 1”, 1¼”, 1½”

SolidFlo™ 1600 120V / 60 Hz 115 Watts 1,600 GPH 1,325 GPH 975 GPH 11.5’ 1”, 1¼”, 1½”

SolidFlo™ 2100 120V / 60 Hz 155 Watts 2,100 GPH 1,700 GPH 1,500 GPH 15’ 1”, 1¼”, 1½”

SolidFlo™ 2600 120V / 60 Hz 175 Watts 2,600 GPH 2,100 GPH 1,700 GPH 16’ 1”, 1¼”, 1½”

thepondguy.com | 866-POND-HELP (766-3435) 15425 Chets Way | Armada, MI 48005

2 3