BEFORE USE

1. 9HULI\ that the product and the application are com

SDWLEOH

2. Before XVLQJ this product, read the owner's manual

FRPSOHWHO\ and familiarize \RXUVHOI WKRURXJKO\ with

the product, its components and UHFRJQL]H the haz

ards associated with its use.

5HSODFH VKLSSLQJ SOXJ (red color) with air vent pluJ

EODFN color). This will help release DQ\ pressurized

airwhichPD\ EH trapped within the reservoir.Ensure

the oil level is MXVW EHORZ the VKLSSLQJ SOXJ hole.

$OZD\V FKHFN connectionsEHIRUH XVLQJ.Alteration of

this product is VWULFWO\ SURKLELWHG. 8VH RQO\ those

adaptersandattachmentsprovidedandapproved E\

themanufacturer.

Note: Secure threaded port connections with non

KDUGHQLQJ pipe thread compound. 7LJKWHQ VHFXUHO\ to

preventaccidentalremovalofcomponentswhileinuse.

TDNH care not to introduce compound into port orifices.

OPERATION

1. Connect to VXLWDEOH application, then to air source of

at least &)0 #90 psi.

2. To operate, press on the foot pedal until desired

positionisreached. Stopfurtherapplicationmovement

E\ UHOHDVLQJ pressureontreadle.

. To retract application, press the release valve E\

VWHSSLQJ on the raised, stirrup shaped portion of the

footpedal).

MAINTENANCE

1. Inspect hoses and connections dail\.5HSODFeGDP

DJHG components immediatel\with factor\

authorized replacement parts RQO\

2. 7LJKWHQ connections as needed. 8VH QRQKDUGHQLQJ

pipethread compound when VHUYLFLQJ connections.

8VH RQO\ JRRG TXDOLW\ K\GUDXOLF fluid.:e recommend

0RELO DTE0 orequivalent.

When not in use or during storage

a. Depressurize and disconnect K\GUDXOLF hoses from

application.

E.:ipe clean, WKRURXJKl\.

c. Store in clean, GU\ environment. Avoid e[Wreme

temperatures.

d. )RU transportation or ORQJ VWRUDJH replace air vent

SOXJ EODFN color) with VKLSSLQJ SOXJ (red color).

e.Shieldpumpwithaprotectivecover.

Adding Hydraulic Fluid

1. Depressurize and disconnect K\GUDXOLF hose from

application.

2. :ith pump in its XSULJKW horizontal position, remove

the air vent SOXJ located on the top plate of the

reservoir.

8VH asmallfunneltofillreservoirtowithin (19mm)

of the RSHQLQJ.

Note: 8VH RQO\ a JRRG TXDOLW\ K\GUDXOLF oil. Never use

EUDNHIOXLGWUDQVPLVVLRQIOXLGWXUELQHRLOPRWRURLODO

cohol, JO\FHULQ etc. 8VH of other than JRRG TXDOLW\ K\

draulicoil will voidZDUUDQW\ and GDPDJH thepump,hose,

andapplication.

:LSH up DQ\ spilled fluid and reinstall the air vent

SOXJ.

Changing Hydraulic Fluid

)RU EHVW performanceandORQJHVW life,replacethe

complete fluid VXSSO\ at least once per \Har.

1. Depressurize and disconnect K\GUDXOLF hose from

application.

2. :ith pump in its XSULJKW horizontal position, remove

the air vent SOXJ located on the top plate of the

reservoir.

8VH asmallfunneltofillreservoirtowithin (19mm)

of the RSHQLQJ.

3RXU used fluid into a VHDODEOH container.

5. Dispose of fluid in accordance with local UHJXODWLRQV

. )ill with a JRRG qualiW\ h\draulic oil as recommended

DERYH 5HLQVWDOO airvent SOXJ.

Lubrication

8VH a OLJKt machine oil to OXEULFDWe pivot points, KLQJHV

etc.

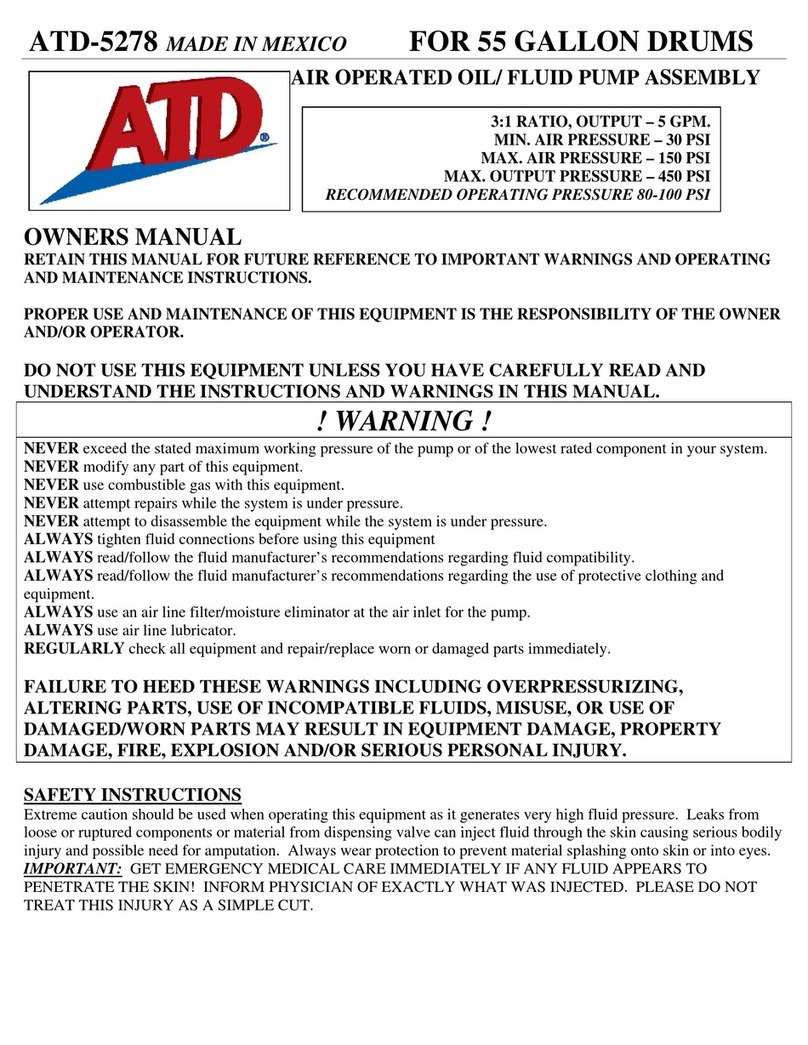

5HDG and understand all ZDUQLQJV and instructional

materialprovidedonandwiththis productEHforeuse.

Do not H[FHHG rated capacit\.

Burst hazard H[LVWV if hose or connection pressure

H[FHHGV rated pressure.

1HYHU operate pump when it is disconnected from

application. This will pressureize the hose and

connections and increases the EXUVW harzard.

8VH JDXJH or other load PHDVXULQJ instrument to

YHULI\ load.

$OZD\s inspect hoses and connections for GDPDJH

prior to use.

$OZD\V wear protective FORWKLQJ and H\H protection

whenoperatLQJ this equipment.

$OZD\V ensure that the chosen application is VWDEOe

toZRUN onandaround.

Do not ZRUN under a lifted load without adequatel\

rated support devices such as MDFN stands.

DonotsXEMHFtthepumpanditscomponentstoshocN

loads.

Donotconnect to application which can return more

oiltothereservoirthanthepumpreservoircanhold.

)DLOXUH to heed this ZDUQLQJ PD\ result in personal

LQMXU\ as well as SURSHUW\ GDPDJH.

!

WARNIN