THERMA-KLEEN Therma-Steem 400 User manual

Therma-Steem® Model 400

February 15, 2019

2

OWNERS MANUAL

Do Not Use This System Without Reading This Manual First

You should be familiar with the information in this manual before you operate your

equipment. The manual is structured so that it can be used for your reference.

Page Description

3 SERVICE INFORMATION

3 MACHINE SPECIFICATIONS

5 SAFETY INFORMATION

8 GROUNDING

9 OPERATING INSTRUCTIONS

10 SHUT-DOWN

10 LOCATION PICTORIAL

11 STEAM CONTROL VALVE

12 RESERVOIR TANK

12 LOW WATER ALARM

12 BOILER

13 DRAIN

14 HOSE & ACCESSORIE MAINTENANCE

14 COOLING FAN

14 GUN TRIGGER

15 MAINTENANCE

16 STAINLESS STEEL BODY

16 FILTER

16 ELECTRICAL REQUIREMENTS

17 OPERATING TEMPERATURES

17 LOWER TEMPERATURE CLEANING

18 ACCESSORIES

24 PARTS LIST

25 TROUBLE SHOOTING

25 WARRANTY

All information, illustrations and specifications contained within this manual are based on

the information available at the time of production.

THERMA-KLEEN®, reserves the right to make changes at any time.

Therma-Steem® Model 400

February 15, 2019

3

SERVICE INFORMATION:

Therma-Steem® Model 400

Please take the time to fill out the form on this page. When completed, this reference

form will provide information essential to the proper servicing and ordering of parts for

your THERMA-STEEM® Industrial 400 Model.

OWNER:

Name of Business: _________________________________________________________

Address: _________________________________________________________________

City, _________________________________ State: __________ Zip Code: __________

Telephone: ____________________ E-mail: ___________________________________

Serial #: __________________________ Date Shipped: _________________________

Our sales and parts department will be glad to answer any questions or provide

troubleshooting help over the phone. All parts will be shipped via UPS unless otherwise

specified. The warranty card must be filled out on our Web Site to activate your

warranty.

www.THERMA-KLEEN.com

THERMA-KLEEN®

P.O. Box 805, 2415 E. Huron Rd. Au Gres, MI 48703

Telephone: 630-718-0212 Fax: 989-876-6640

E-Mail: sales@therma-kleen.com

Therma-Steem® Model 400

February 15, 2019

4

MACHINE SPECIFICATIONS:

Boiler Capacity: 1.5 Gallons Stainless Steel Tank

Reserve Tank Capacity: 2 Gallons Stainless Steel Tank

Steam Pressure: 160 psi / 11 Bar

Temperature: 380 degrees “F” / 193 degrees “C”

Electrical Draw: 120 vac @ 18 amps w/1750-watt heater

240 vac @ 13.0 amps w/2500-watt heater

Weight: 80 lbs. / 36.3 kg with handle

Dimensions 16” W x 16” D x 16” H

Note: Therma-Kleen® reserves the right to change the package contents at any

time, without notice.

Examine the unit and accessories for any possible shipping damage. If your unit is

damaged or fails to operate, notify the shipper immediately.

Note: Only the consignee (the company or person receiving the unit) can file a claim

against a carrier for shipping damage.

Record the serial number of your unit for future reference. It is recommended that you

retain the original shipping carton and packing materials should you need to transport or

ship the unit in the future.

WHAT IS VAPOR STEAM CLEANING:

Vapor Steam Cleaning is a unique way of cleaning. Understanding how vapor cleaning

works will enable you to clean more effectively. The dry vapor, in the form of gas,

penetrates the surface pores and violently expands, forcing dirt and debris to the surface

where the particulate is either suspended in a re-condensed water molecule or driven

into an absorbent cloth. The dry vapor is super-heated and is hot enough to kill bacteria

and sanitize all surfaces. Vapor cleaning does not rely on pressure in order to clean

efficiently. Once the vapor is emitted from the tool head, physics take over and the

vapor works on its own. Therefore, only enough vapors are required to fill the pores

under the tool head, and it is not necessary nor desirable to operate the equipment at

full volume. More effective cleaning results are achieved by turning the volume down

and let the vapor and heat do the cleaning. If the equipment is operated at too high of a

Therma-Steem® Model 400

February 15, 2019

5

volume, the unit will not maintain pressure for extended periods of time, it will use too

much water and oversaturated the surface that you are cleaning.

SAFETY:

READ ALL INSTRUCTIONS BEFORE USING THE VAPOR CLEANING SYSTEM.

Under no circumstances shall Therma-Kleen or its agents be held

responsible for any injury or damage to people or property that may be

caused by failure to follow the instructions below or by improper use of

the equipment.

WARNING:

Your Therma-Steam unit is designed to be an entirely safe if used properly and

incorporates the latest and most state-of-the art safety features.

Paying Close Attention to your system and surroundings are necessary when your Vapor

Steam System is being used.

TO REDUC THE RISK OF ELECTRICAL SHOCK, FIRE OR PERSONAL INJURY, FOLLOW ALL THE

INSTRUCTIONS AND ALWAYS USE BASIC PRECAUTIONS, INCLUDING THE FOLLOWING:

1. ALWAYS - Check the machine, power & steam hose for damage prior to start-up. If

damage is detected, it must be repaired prior to use.

2. CAUTION - Before use check the electrical cord for damage, ware & tare, cuts or

abrasion.

a. DO NOT - use your machine with a damaged electrical cord.

3. NEVER - Plug the unit into an un-grounded electrical receptacle.

4. CAUTION - The Electrical Outlet must be a GFI (Ground Fault

Interrupt). If you are unsure the receptacle is grounded, contact a

certified electrician.

a. CAUTION - If the Power Outlet is damaged, have a certified electrician repair

the outlet.

Therma-Steem® Model 400

February 15, 2019

6

b. NEVER - Touch the electrical plug or unplug the unit with

wet hands or while standing in a wet environment.

c. NEVER - Allow the electrical power cord to lie in water

while cleaning.

d. NEVER –Unplug from the receptacle by pulling on the

cord, always grasp the plug itself.

5. NEVER - Touch the system with wet hands or while standing in a

wet environment.

6. NEVER - Allow the machine to get wet as electrical shock may

occur.

7. CAUTION - use extra caution when using the system around water

(Swimming Pools, Spas, Toilets, Etc.)

8. DO NOT - allow the electrical power cord or Steam Hose to be run over, stepped on

or have something placed or dropped on it.

9. DO NOT - allow the Electrical Power Cord or Steam Hose to be caught in a closed

door or pull over a sharp corner.

10.CAUTION - Turn off all controls prior to unplugging the unit.

11.ALWAYS - wear long sleeves, long pants, eye goggles, and gloves

while operating your cleaner.

12.CAUTION - Make sure all attachments are secured before

activating the gun.

a. CAUTION - Only operate the unit when it is in a Horizontal

position.

13.WARNING - To prevent scalding or burning, ALWAYS keep your hands and body

away from the nozzle tip during operation and wear appropriate protective

clothing.

a. DO NOT - touch the steam nozzle while in use, or until after

it cools.

b. DO NOT - grab the hot steam hose without appropriate

gloves.

14.NEVER - Point or direct the wand or steam at any person, animal or

electrical outlet or anything which could be damaged.

15.DO NOT - move or lift the machine by pulling on the electrical cord.

16.DO NOT - move or lift the machine by pulling on the steam hose or gun.

17.DO NOT - bend the steam hose past the 2” bend radius. This will shorten the life of

your hose.

Therma-Steem® Model 400

February 15, 2019

7

18.DO NOT - use you Vapor Steam Cleaner if it has been dropped or damaged.

19.DO NOT - allow the Vapor Steam System to become wet.

20.DO NOT - operate without water, this will damage the cleaner’s heating element,

low water sensor and/ or pump.

21.DO NOT - fill the water reservoir under a water tap. Always use a

funnel and pour from a measured container so as not to over fill the

reservoir. Consult the machine specifications to determine the

reservoir capacity.

22.NEVER UN-SCREW - the boiler fill cap or drain plug while water is still hot or there

is pressure in the unit as this may result in a dangerous release of steam or water

which can cause a scalding hazard.

a. By activating the trigger on the gun will help dissipate pressure in the boiler

23.CAUTION - Hand tighten the boiler fill cap.

a. DO NOT - over tighten as this will lead to premature failure of the sealing

gasket.

24.DO NOT - run chemicals through system, this could be harmful to people and the

cleaner.

25.CAUTION - Use caution when working in confined spaces, as the steam could cause

debris to kick back towards you and the steam may seem greater.

26.DO NOT - use this unit to clean items that may be harmed by steam or linger too

long on surfaces that may cause damage.

27.DO NOT - leave this unit unsupervised when in use or while cooling.

28.DO NOT - allow children to use or handle machinery.

29.CAUTION - Replace worn or damaged power cords, gaskets and “O”-rings.

30.DO NOT - try to repair your machine, contact an Authorized Service Company or

the factory. Retain your box for shipping.

31.DO NOT - allow objects to get into the output nozzle. Do not try to

operate the Vapor Cleaning System with any of the openings

blocked. Keep openings free of dust, lint, hair, or anything which

may reduce the flow of Vapor

32.CAUTION - Always keep all parts of the body away from the output nozzle, moving

parts.

33.CAUTION - Extra care must be taken when using the unit on stairways.

34.CAUTION - Never use the Vapor Cleaner to clean animals.

Therma-Steem® Model 400

February 15, 2019

8

35.CAUTION - If the “Air Vent Cap” becomes damaged or is lost, DO NOT replace with

any other cap as it is not a pressure cap. Please reference the service part section

of this manual and contact Therma-Kleen® for a replacement.

36.ALWAYS - Turn off unit when not in use –and allow to cool before storing.

37.ALWAYS - Unplug the Vapor System Electrical Cord when the system is not in use.

38.ALWAYS - Completely empty all water from the unit when not being used.

39.NEVER - Transport the unit with any water remaining in the machine.

40.NEVER - Leave the unit outside or allow it to be exposed to Freezing

Temperatures.

a. Freezing will severely damage the unit, internal components

and hose.

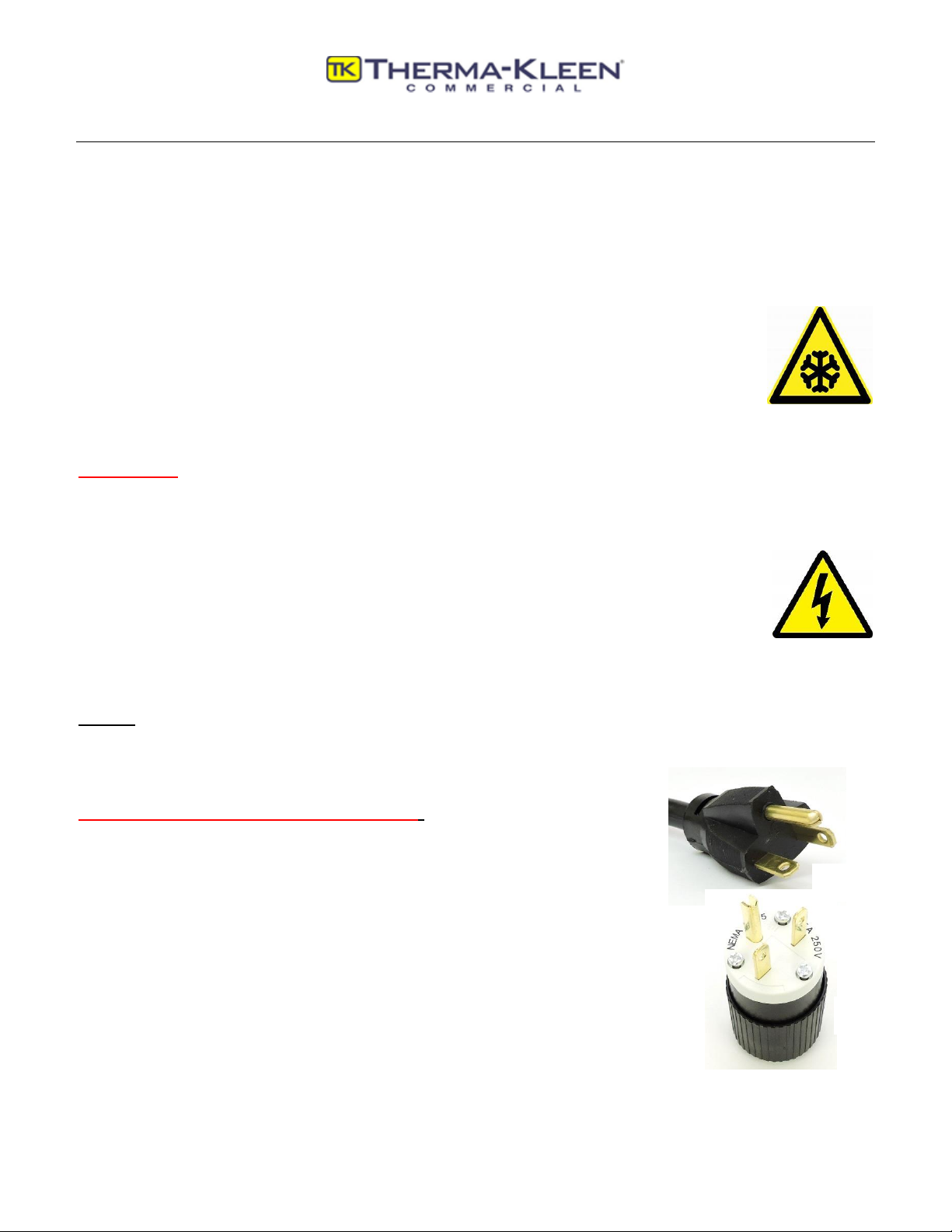

WARNING:

Your Therma-Kleen® Vapor Steam Cleaner MUST BE PLUGGED INTO A

GROUNDED OUTLET, or electrical shock can occur. Check with a

certified electrician if there is any doubt that the outlet is grounded.

Do not modify the Power Cord/Plug provided with the Therma-Kleen

Vapor System. If it will not fit the outlet, have a properly grounded

outlet installed by a certified electrician.

NOTE:

If an electrical extension cord is used with this system, it must be at a minimum,

12-gauge, 3 wire, grounded, SJ Quality, 60 Degree C.

WHY THIS UNIT MUST BE GROUNDED:

If the unit should malfunction or break down, grounding

provides a path of least resistance for the electrical

current to pass, reducing the risk of electrical shock. All

Therma-Kleen units are equipped with a power cord with

an equipment grounding conductor and plug. The plug must

be inserted into an appropriate outlet which is properly

grounded in accordance with national & local electrical codes

and ordinances.

B

A

Therma-Steem® Model 400

February 15, 2019

9

Therma-Kleen Model 400 is designed for use with a normal 120 or 240-volt

grounded circuit. The 120-volt units have a grounded cord and plug such as what

is illustrated in picture “A”, while the 240-volt units have a grounded plug & cord

such as shown in picture “B”.

DO NOT remove the ground prong on the power cord. This will void the warranty

on your machine and can be dangerous because it does not protect the user.

OPERATING INSTRUCTIONS:

NOTE: See owner’s manual for power requirements of your particular model prior to

operating this machine. Always wear gloves, goggles, long sleeve coat or shirt and long

pants or coveralls.

1. Before plugging in the electrical cord, Check to insure ALL switches are in the “OFF”

position.

2. Remove the air vent cap from the reservoir (on top of machine). Using the funnel

provided. Fill the reservoir with clean water, from a measured container, taking

care not to spill or overfill the reservoir tank (approx. 2 gal. when empty). Distilled

water is recommended.

3. Plug the Model 400 Vapor Steam Cleaner into an appropriately grounded 120 or

240-volt outlet as applicable.

a) Removing the ground on the electrical cord is not only dangerous but

will also void the warranty. If an extension cord is to be used, it should

be at least 12-gauge and no longer than 50 ft.

4. Turn the MAIN Power switch to the “ON” position.

5. If the boiler requires water, the reservoir pump will turn on. This is indicted by the

blue light and a vibrating sound.

6. After the pump has stopped, it is now safe to turn the heater switch to the “ON”

position.

IMPORTANT: Never turn the heater switch to the “ON” position until the pump has

stopped, indicating the boiler is full.

7. You can now top off the reservoir, if desire, with water and replace the air vent cap

taking care not to over tighten.

8. When the boiler is at full operating temperature the “HEATER LIGHT” (amber) will

go out. This will go on and off as needed.

9. Put attachments on the gun making sure connections are hand tight and adjust the

flow of steam with the knob located on the side of the machine. Wear gloves.

Therma-Steem® Model 400

February 15, 2019

10

10. When the “ADD WATER” light blinks, the reservoir is empty. Remove the air vent

cap, refill the water reservoir if desired, and resume cleaning. Do not over fill. It is

important to immediately refill the reservoir tank, so the boiler does not run out of

water.

Shut Down:

1. Turn the “HEATER” and “MAIN” power switches to the “OFF” position.

2. Release steam from the boiler by depressing the trigger on the gun.

3. Close the steam knob.

4. Once the system has cooled down and the water has been drained/removed, clean

the machine and Store carefully.

5. Store the unit is a warm dry location.

6. NEVER store the unit in a freezing environment. Frozen water will destroy the unit.

7. NEVER ship or transport the unit unless all the water has been completely drained

from the system.

B

C

D

A

F

G

H

I

J

L

K

M

E

Therma-Steem® Model 400

February 15, 2019

11

OPERATION LOCATIONS:

A. Main Power “On/Off” Switch)

B. Heater “On/Off” Switch

C. Heater Amber indicator light

D. Main Power Green Indicator Light

E. Fuse holder with ABC fuse. 20-amp fuse for 110 volts

F. Pressure Hose Coupling

G. Boiler Filling Light –comes on when boiler is being filled

H. Add Water Indicator Light

I. Steam Control Valve

J. Fan

K. Hot Surface Indicator Decal (Yellow). The word “HOT” appears when surface

becomes hot

L. Air Vent Cap

M. Combistat (Adjustable High Limit Cut-off with Temperature Gauge)

STEAM CONTROL VALVE:

This knob controls the volume of steam. Counter-

clockwise: increase volume, Clockwise: decreases

volume. For maximum pressure and temperature,

leave the knob turned to the highest-pressure settings.

Therma-Steem® Model 400

February 15, 2019

12

RESERVOIR TANK:

The reservoir tank with your Model 400 holds two gallons

of water. The tank is designed to hold the initial water

supply to the boiler and then supply additional water as

the boiler calls for it. When you engage the MAIN power

switch, if the boiler requires water, the reservoir pump

will turn “ON”. DO NOT turn on the heater to the boiler

before the pump stops pumping, which indicates that the

boiler is full. The “Blue Light” indicates when the boiler is

calling for more water. This will go on and off during the

time you are using the machine. The reservoir has an air

vent cap, which covers the fill opening; this can be

removed to add more water at any time. This is not a

pressure cap. Do not substitute any other cap. (Shown

with the Yellow Hot Surface Decal). Do not run the pump

dry. Contact Therma-Kleen® for a replacement.

NEVER use water from a water softener as they use an ion exchange process that

replaces calcium and magnesium minerals in the water with sodium. Sodium can

significantly shorten the lifespan of the boiler system and internal components of you

vapor steam unit.

It is always best to use Distiller Water in your cleaner.

LOW WATER ALARM:

When the tank is out of water and the boiler is almost empty, a low water alarm will

sound to let you know that the heater has shut off and you are out of water. This sensor

protects your heating element. CAUTION: never allow the boiler to be “ON” when there

is no water in the boiler. This will overheat and damage the low water sensor and

heating element.

BOILER:

DISTILLED WATER

We recommend that you use distilled water with you steam cleaner. This would

eliminate the possibility of creating hard water stains while you are cleaning and

prevent excessive build-up of mineral deposits around the heating element in the

boiler. If you are using tap water, remember that the life of the heating element

Therma-Steem® Model 400

February 15, 2019

13

may be shortened due to mineral/scale build up. The heating element will not be

covered under the warranty if this situation happens.

FLUSHING OUT THE BOILER:

Located under your unit is a plug that, when unscrewed, will drain your boiler.

CAUTION do not remove drain plug until the unit has cooled down. Refer to the

temperature gauge to determine the water temperature in you unit. (Your boiler

can retain its heat for several hours.)

CHEMICALS:

VERY IMPORTANT: NEVER INTRODUCE CHEMICALS INTO THE SYSTEM.

It shall void your warranty and could result in malfunction and/or damage to your

system. Also, note that our service department will not work on machines that

have chemicals in the system.

DRY TANK:

VERY IMPORTANT. NEVER ALLOW THE MAIN POWER SWITCH TO BE “ON” WHEN

THERE IS NO WATER IN THE BOILER. THIS WILL OVERHEAT AND DAMAGE YOUR

LOW WATER SENSOR AND HEATING ELEMENT.

DRAIN:

Your machine has two drains, one for the

reservoir and one for the boiler. The boiler drain

plug is located just below the steam control knob

on the bottom of the machine. The reservoir

drain plug is the other. Use a screw driver and

carefully unscrew the cap on the drain plug. This

will release the water. Replace carefully. Use

caution since the water in the boiler stays hot for

a long time.

The Reservoir Drain is the one

nearest the front of the unit.

NEVER store machine with

Water in the tank or boiler.

NEVER expose the machine to freezing temperatures.

NEVER ship or transport unless all water has been completely drained from the system.

Boiler

Drain

Reservoir

Drain

Therma-Steem® Model 400

February 15, 2019

14

HOSE MAINTENANCE:

This unit is supplied with a high temperature stainless steel hose. It is very important to

protect the integrity of this hose by not exceeding the bend radius of 2” as it could cause

premature failure which is not covered under the warranty. If a hose is subjected to

excess wear and tear it could fail and will not be covered under warranty. Please inspect

your hose and cover on a regular basis for any wear. DO NOT USE THIS HOSE IF IT IS

DAMAGED. DO NOT PULL OR MOVE THE MACHINE BY PULLING/TUGGING ON THE HOSE.

ACCESSORIE MAINTENANCE:

It is recommended that you clean your accessories on a regular basis. You can do this by

one of several method:

1. Use the nozzle, with or without a small circular brush.

2. Use another nozzle to hold small brushes to be cleaned

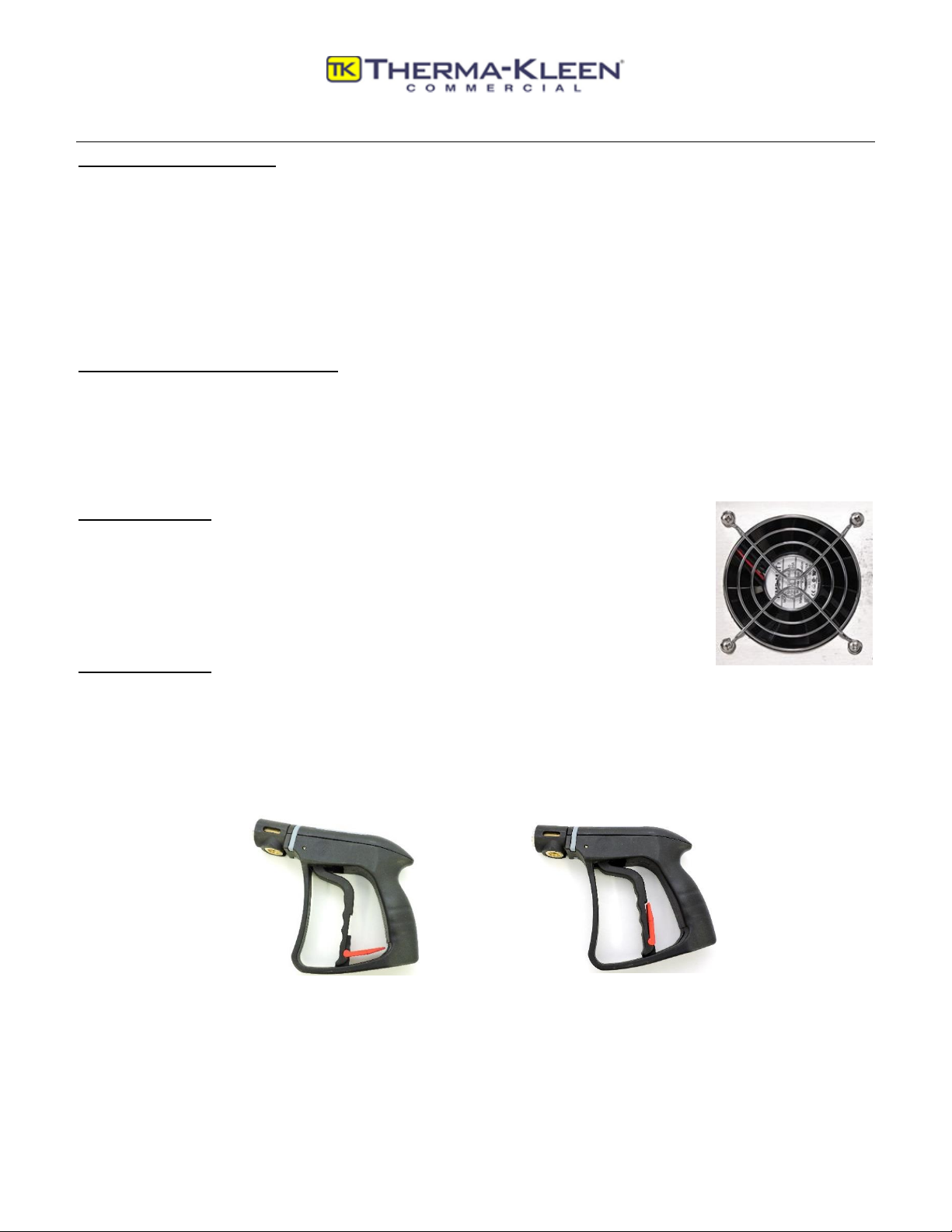

COOLING FAN:

The THERMA-STEEM® Industrial 400 Vapor Steam System has a

cooling fan built into the housing to reduce internal temperature. DO

NOT use this machine if the fan is not operating. The fan is located on

the side of the machine

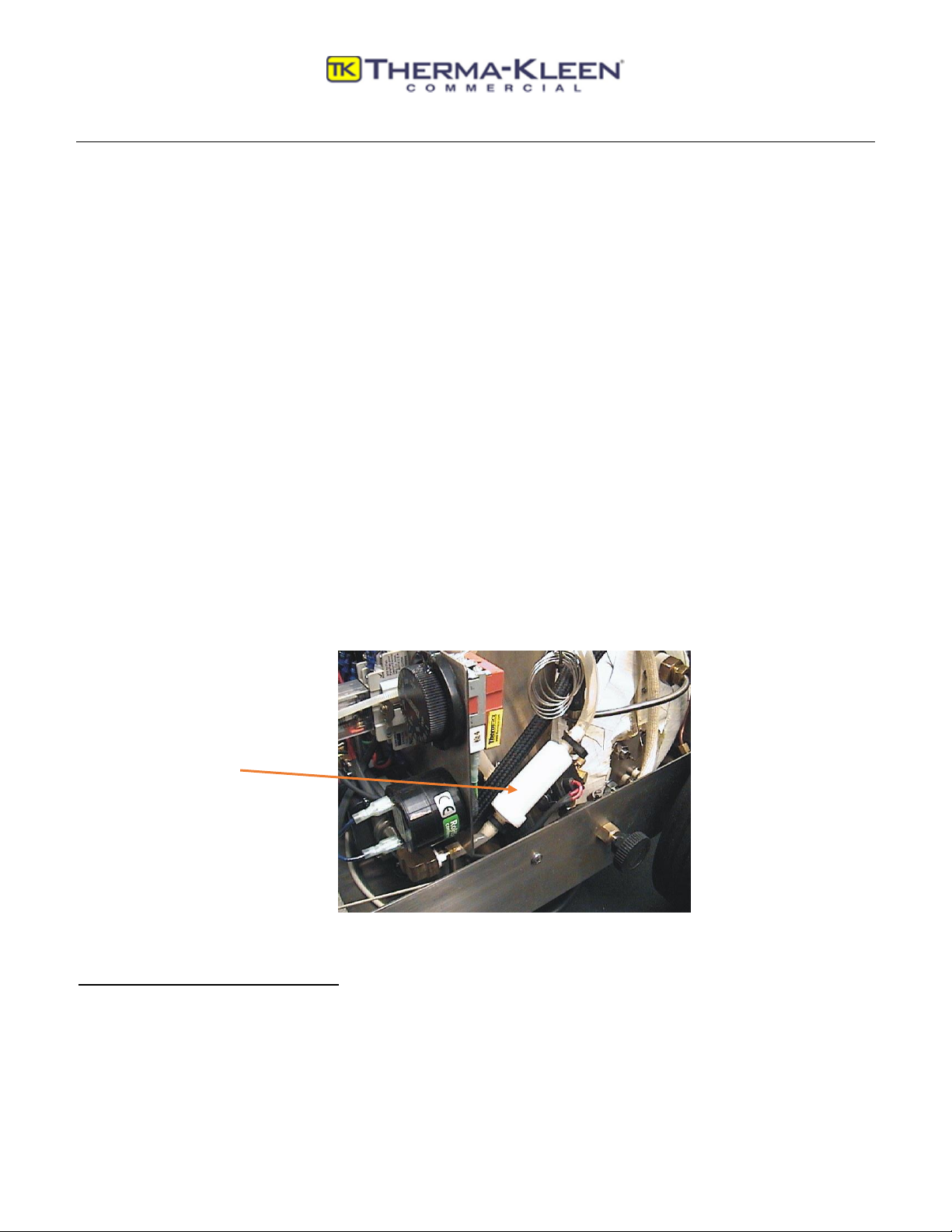

TRIGGER GUN:

Your machine comes with a trigger gun on the end of the steam hose. When you change

attachments, it is very important you place the guns trigger in the locked position, so you

cannot accidently squeeze the trigger and release steam. To lock the trigger, slide the red

lever down towards the handle.

Locked Unlocked

Therma-Steem® Model 400

February 15, 2019

15

MAINTENANCE:

BOILER:

The only maintenance required on the THERMA-STEEM® Industrial 400 is to flush out the

mineral deposits from the boiler every so often. A good way of monitoring the mineral

build up in the tank is by bleeding the system. If the water residue is discolored in a

towel, flush the boiler, using tap water until the water runs clear.

Removing hard water scale is often the most common and overlooked of vapor steam

cleaner maintenance, because if involves the part of the unit no seen. As water is heated

and converted to steam any minerals in the water can be left behind in the form of

mineral deposits/scale in the boiler tank. This will at some point impede the flow of

water and steam through the system. Decaling the boiler is not as difficult as it may

seem.

DESCALING: There are two benign methods of removing scale.

Baking Soda:

i. Empty the tank

ii. Mix 1 ½ ounces of baking soda with one quart of distilled water.

iii. Fill the empty tank with this mix

iv. Tighten the cap and allow the unit to heat up and stay warm for 1 to 2

hours

v. Run the unit for about one minute, turn off and unplug the power cord

and allow the unit to cool, usually about for 3 to 4 hours

vi. Remove the drain plug and empty the tank

vii. Flush the tank as many times as necessary to remove all debris in the

tank

viii. Reinstall the drain plug

Vinegar:

i. Remove the drain plug on the bottom of the unit

ii. Mix together a solution of ½ distilled vinegar & ½ distilled water

iii. Using the funnel, fill the water tank with this solution

iv. Turn on the unit, allow it to heat up and steam out about ½ of the

mixture

Therma-Steem® Model 400

February 15, 2019

16

v. Turn off the unit and let it rest for 30 minutes

vi. Repeat this process until the steam flow returns to normal (could be 2

to 3 times). NOTE there is an odor associated with this process

After each use the water tank should be emptied. We realize that it’s tempting to just

leave the water in the tank for the next cleaning go-around but taking the time to empty

the tank before storing will lessen scale build up from mineral deposits. Not to mention

avoiding the musty odor that can be produced from steaming with stagnant water.

STAINLESS STEEL BODY:

The housing and handle of your THERMA-STEEM® Industrial 400 are made of stainless

steel. We recommend that you preserve the finish by keeping the machine dry and

polished. Use a good stainless-steel cleaner, being careful not to rub off any instructions.

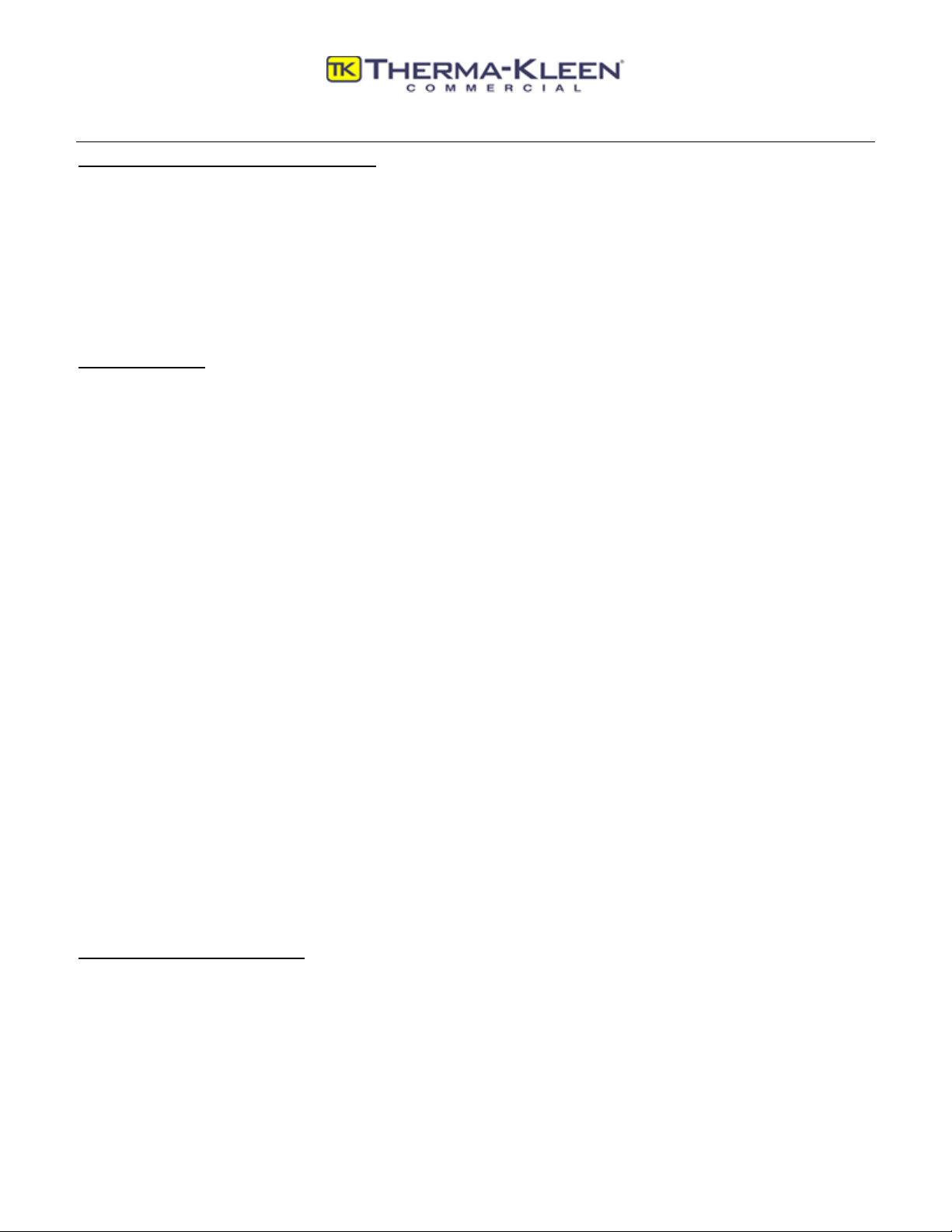

FILTER CONNECTED TO THE PUMP:

The filter connected to the pump (see below) needs to be checked on a regular basis.

Even if distilled water is being used in the machine, the filter may still become clogged.

To check the filter, look for discoloration and/or detach it from the pump and see if you

can blow air through it. If it is discolored or Resistance to the passage of air through the

filer, the filter should be replaced.

ELECTRICAL REQUIREMENTS:

Check your serial plate on the back of your machine to determine the voltage. This

machine is available in 120 volts or 240-volt, single phase.

Filter

Therma-Steem® Model 400

February 15, 2019

17

120-volt models:

This unit draws 18 amps and requires a 20-amp fuse. Always make sure that your MAIN

POWER SWITCH is in the “OFF” position when you plug your unit into an electrical outlet.

If possible, plug the unit into a designated 20-amp electrical outlet, as the combined

electrical amperage of the Model 400 and other items on the same electrical circuits may

cause a circuit breaker to trip.

If you use an extension cord it must be it must be at a minimum, 12-gauge, 3 wire,

grounded, SJ Quality, cord and make sure it is rated for the amp draw of the system and

does not exceed 25 ft in length.

240-volt models:

This unit draws 13 amps and requires a 15-amp ABC fuse. Always make sure that your

MAIN POWER SWITCH is in the “OFF” position when you plug your unit into an electrical

outlet. If possible, plug the unit into a designated 20-amp electrical outlet, as the

combined electrical amperage of the Model 400 and other items on the same electrical

circuits may cause a circuit breaker to trip.

If you need to replace a fuse:

1. Turn all the switches to the “OFF” position.

2. Unplug your machine from the power outlet.

3. Push down and twist the fuse cap to release the cap and fuse.

4. Pull the fuse from the cap and replace with an ABC 20-amp fuse if 120 volt or ABC

15-amp fuse if 240v volt system.

5. Place the fuse and cap back in the fuse holder and push down while twisting. This

will lock the cap into place. Make sure it is locked.

6. Plug the machine into an electrical outlet.

OPERATING TEMPERATURES:

The maximum temperature of the steam in the vessel for the Model 400 is 380˚F. This is

controlled by the high limit red line on the temperature gauge. At this temperature, your

unit will also achieve its highest pressure of 160 PSI. It is very easy to stay in the 380˚

range if you open and close the gun while cleaning. The closed position will allow the

unit to re-heat to greater temperatures before the wand is opened again. If you clean with the

wand in the open position for a sustained period of time, you will begin to see the

temperature and consequent pressure drop quickly.

Therma-Steem® Model 400

February 15, 2019

18

LOWER TEMPERTURE CLEANING:

There may be times when you want the temperature to be lower than the 380˚F. At

these times, you may want to adjust the red line on the temperature gauge to a lower

temperature. Turn the knob and therefore the red line to the desired temperature. At

this time, the heater may shut off and cycle back on later as needed. The temperature

will stay at this or below the set temperature until the temperature is re-set. Remember

as you lower the temperature, the pressure will also decrease.

ACCESSORIES:

YOUR MACHINE SHIPS WITH THESE STANDARD TOOLS:

•(1) 15’ S.S. Hose w/Gun #4030

•(1) Curved Nozzle #4013

•(3) 1” Nylon Brushes #4010

•(1) Zero Degree Blast Nozzle #4014

•(3) 1” Brass Brushes #4011

•(3) Stainless Steel Brushes #4012

•(1) 2-1/2” Nylon Brush #4009

•(1) Triangle Brush #4016

•(1) Floor Brush #4061

•(1) Small Micro-fiber Cloth #3534

•(1) Large Micro-fiber Cloth #3910

•(2) Terry Cloth Towels #3119

•(1) Hand Held Squeegee #3570

•(1) Funnel #3499

•(1) Pair of High Temperature Gloves #4052

•(1) Goggles #4053

•20” Extension #5008

•3 ft. Extension $5009

OPTIONAL ACCESSORIES:

•1” Round Horse Hair Brush

•2-1/2” Round Horse Hari Brush

•2-1/2” Round Brass Brush

•2-1/2” Round Stainless-Steel Brush

Therma-Steem® Model 400

February 15, 2019

19

ACCESSORIE DESCRIPTION:

All attachable accessories for the Model 400 use threaded ends due to the higher

pressures.

Each of your accessories and attachments are recommended of the following specific

cleaning tasks:

Triangle Brush:

The Triangle Brush may be used for diverse applications

on many surfaces. It can be used on almost any dry

surface type including (but on limited to), Fabric, All

Metals, Ceramic, Stone, Porcelain, Vinyl, Leather and

Plastic.

Generally, use of the triangle brush is dictated by the size of the object or surface being

cleaned, rather than a specific surface type. The Triangle Brush is used when the surface

is too large to be cleaned with the Detail Tool or too small to be cleaned by the Wide

Brush. The Triangle Brush can also be used on large areas that are too dirty for the Wide

Brush to work effectively.

Use of a Cloth: The Triangle Brush can be used with or without a cloth. If a cloth is to be

used, there are clips on the brush to attach the cloth. When used

without a cloth on a hard surface, the surface will need to be

wiped with a clean, dry cloth immediately after passing over the

surface with the Triangle Brush.

Rough Textured surfaces: It is more desirable to clean without a

cloth or mitten over the brush.

Fabrics: A cloth is or is not necessary when cleaning fabrics. Placing a cloth over the

brush is not necessary when the desired goal is to sanitize the fabric more than to clean

it. To remove certain carpet stains, place a terry cloth or microfiber cloth on the stain

and gently apply the brush to the stain. The stain will incrementally be driven into the

cloth. Gradually move the cloth to absorb the stain into the clean areas of the cloth, until

the stain is gone.

Most of the time, better results will be achieved by placing a terry or microfiber cloth

over the Triangle Brush. This is done by placing the cloth on a smooth surface and neatly

Therma-Steem® Model 400

February 15, 2019

20

folding the cloth over the brush. Push down on the clips (located on top of the brush)

and tuck the cloth underneath. Release the clips and the cloth will be securely fastened

to the brush. When covered with an absorbent cloth, cleaning becomes a one-step

process. Simply wipe the surface slowly and all dirt and debris will be driven into the

cloth, hard surfaces will usually dry in less than a minute.

WIDE BRUSH:

The 12” Wide Brush is used to clean larger areas. The Wide

Brush is faster that a mop and certainly does a more effective

job. The Wide Brush is generally used more for daily or weekly

cleaning & sanitization rather than restoration.

MATERIALS –Fabrics, Metals, Ceramic, Stone, Porcelain, Vinyl,

Leather, Plastic, Wooden Floors, Waxed Floors –Carpet (200

degrees or less for Nylon carpets), Upholstered Chairs, Draperies, Etc. or any other

surface that extreme heat does not harm the surface which you intend to clean.

USE –the size of the area more than the type of surface dictates the use of the Wide

Brush.

CLOTH –Use of a Cloth: The Triangle Brush can be used with or without a cloth. If a cloth

is to be used, there are clips on the brush to attach the cloth.

When used without a cloth over it, on a hard surface, the

surface will need to be wiped with a clean, dry cloth or mop

immediately after passing over the surface. When cleaning a

rough textured surface, it is more desirable to clean without a cloth over the brush.

Fabric surface –same as Triangle Brush.

VAPOR VOLUME –adjust the volume to about 3/8. Occasionally more volume will be

required, however volume should always be less than ½. If the volume is turned too high

the surface will become oversaturated, requiring more time to dry, also it will become

difficult for the unit to maintain pressure for extended periods of time

Table of contents

Other THERMA-KLEEN Steam Cleaner manuals