THERMA-KLEEN 250E User manual

Ultra 250E Electric Steam Cleaner

October 24, 2019

1

THERMA-KLEEN®

Operators Manual

Model 250E Electric Steam Cleaner

Made in the USA

THERMA-KLEEN®

2415 E. Huron PO Box 805

Au Gres, MI 48703

Ph: 630-718-0212 Fax: 989-876-6640

E-mail: [email protected]m

Web Site: www.therma-kleen.com

Ultra 250E Electric Steam Cleaner

October 24, 2019

2

OWNERS MANUAL

Do Not Use This System Without Reading This Manual First

You should be familiar with the information in this manual before you operate your

equipment. The manual is structured so that it can be used for your reference.

Page Description

3 SERVICE INFORMATION

4 MACHINE SPECIFICATIONS

5 SAFETY INFORMATION

6 GROUNDING

7 PHOTOS

9 ACCESSORIES SHIPPED WITH MACHINE

9 3 PHASE WIRING

10 ELECTRICAL CONNECTION PROCEDURE

12 START UP

13 SHUT DOWN

13 PUMP MAINTENANCE

14 WANDS

15 HOSE

16 COMBISTAT

16 FLOW SWITCH

17 NOZZLES

17 PARTS LIST

18 PREVENTATIVE MAINTENANCE

19 TROUBLE SHOOTING

20 WARRANTY

All information, illustrations and specifications contained within this manual are based on

the information available at the time of production.

THERMA-KLEEN®, reserves the right to make changes at any time.

Ultra 250E Electric Steam Cleaner

October 24, 2019

3

SERVICE INFORMATION:

Model 250E Electric Steam Cleaner

Please take the time to fill out the form on this page. When completed, this reference

form will provide information essential to the proper servicing and ordering of parts for

your THERMA-STEEM® Industrial Model 250E.

OWNER:

Name of Business: _________________________________________________________

Address: _________________________________________________________________

City, _________________________________ State: __________ Zip Code: __________

Telephone: __________________ E-mail: _____________________________________

Serial #: _______________________ Date Shipped: ____________________________

Our sales and parts department will be glad to answer any questions or provide

troubleshooting help over the phone. All parts will be shipped via UPS unless otherwise

specified. The warranty card must be filled out on our Web Site to activate your

warranty.

www.THERMA-KLEEN.com

Therma-Kleen®

2415 E. Huron Rd, P.O. Box 805, Au Gres, MI 48703

Telephone: 630-718-0212 Fax: 989-876-6640

E-Mail: sales@therma-kleen.com

Ultra 250E Electric Steam Cleaner

October 24, 2019

4

MACHINE SPECIFICATIONS:

MODEL: ULTRA 250E

Water Pressure: 250 PSI

Max. Water Temp. produced by this unit: 250-300 degrees F

Water Volume: 1.5 gpm

Size: L 35-¼” x W20” x H 34”

Weight - Standard Body 150 lbs.

Weight - Stainless-Steel Body 200 lbs.

Electrical Requirements: 220-volt, 3 phase, 60-amp outlet

480-volt, 3 phase, 30-amp outlet

Amp Draw: 220-volt: 52 amps,

480-volt: 26 amps

Maximum Water Inlet Temperature: 140 degrees F

Maximum Water Temperature Rise: 115-135 degrees F from start

STANDARD UNIT INCLUDES:

25 ft. Steam hose: X

25 ft. Combi. steam hose:

Fan Nozzle: X

Blast Nozzle: X

Trigger Gun: X

4 ft. Wand Deluxe: X

25 ft. Power Cord: X

Power Cord Holder: X

Steam Hose Holder: X

Wand Holder: X

Temperature gauge with adjustable

high limit-combistat-All Models X

Inlet Water Filter: X

21 kw heater: X

Wheels: 3” X

Ultra 250E Electric Steam Cleaner

October 24, 2019

5

SAFETY TIPS:

While your THERMA-KLEEN®, portable, high pressure, steam cleaner is

designed to be an entirely safe cleaning tool, incorporating the latest and

the most state of the art safety features, the following safety tips are

recommended by the manufacturer for the user to implement:

1ALWAYS - Check the machine, power & steam hose for damage prior to start-

up. If damage is detected, it must be repaired prior to use.

2ALWAYS - use appropriate safety googles and gloves while

operating your cleaner.

3ALWAYS - wear long sleeves, long pants, while operating your

cleaner.

4DO NOT touch or grab the steam hose without gloves when

hose is being used or hot.

5CAUTION - Before use check the electrical cord for damage, ware & tare, cuts or

abrasion.

a. DO NOT - use your machine with a damaged electrical cord.

6ALWAYS - use the electrical plug that is on an approved

grounded circuit for this model.

a. CAUTION - If unsure if the circuit is properly grounded or has

the correct voltage\amperage for this machine, contact a

certified electrician.

b. CAUTION - If the Power Outlet is damaged, have a certified electrician repair

the outlet.

c. NEVER - Touch the electrical plug or unplug the unit with wet hands or while

standing in a wet environment.

d. NEVER - Allow the electrical power cord to lie in water

while cleaning.

e. NEVER - Unplug from the receptacle by pulling on the cord,

always grasp the plug itself Make sure the unit is

unplugged.

7NEVER - Touch the system with wet hands or while standing in

a wet environment.

Ultra 250E Electric Steam Cleaner

October 24, 2019

6

8NEVER - Allow the machine to get wet as electrical shock may occur.

9CAUTION - Use extra caution when using the system around

water (Swimming Pools, Spas, Toilets, Etc.)

10 DO NOT - Allow the electrical power cord or Steam Hose to be

run over, stepped on or have something placed or dropped on it.

11 DO NOT - Allow the Electrical Power Cord or Steam Hose to be

caught in a closed door or pull over a sharp corner.

12 CAUTION - Turn off all controls prior to unplugging the unit.

13 ALWAYS -

14 CAUTION - Make sure all attachments are secured before activating the gun.

a. CAUTION - Only operate the unit when it is in a Horizontal position.

15 WARNING - To prevent scalding or burning, ALWAYS keep your hands and body

away from the nozzle tip during operation and wear appropriate

protective clothing.

a. DO NOT - Touch the steam nozzle while in use, or until after it

cools.

b. DO NOT - Grab the hot steam hose without appropriate

gloves.

16 NEVER - Point or direct the wand or steam at any person,

animal or electrical outlet or anything which could be damaged.

17 DO NOT - Point or direct the wand and nozzle with high

pressure steam at any person/animal as this could result in

burning or harming another person/animal.

18 DO NOT - Point of direct the water spray from the wand

towards an electrical outlet or box.

19 DO NOT - Move or lift the machine by pulling on the electrical cord.

20 DO NOT - Move or lift the machine by pulling on the steam hose or gun.

21 DO NOT - Bend the steam hose past the 2” bend radius. This will shorten the

life of your hose.

22 DO NOT - Operate your unit while the unit stands atop carpeted floors, wood

flooring or linoleum type tiled floor, as the heat from the burner could damage

these items.

23 DO NOT - Operate the machine without water as this may cause damage to the

unit.

24 DO NOT - Disconnect steam hose from the machine while the water

temperature exceeds 100˚F.

Ultra 250E Electric Steam Cleaner

October 24, 2019

7

25 CAUTION - Only operate the machine while it is in an upright

position.

26 DO NOT - Use in small confined areas.

27 DO NOT - Steam clean asphalt driveway material or floor

grouting while using the blast nozzle. To prevent pitting of such materials, we

suggest that you only use the fan nozzle.

28 DO NOT - leave the machine unsupervised while cleaning away from the

machine.

29 NEVER - Pull or tug on the machine with the power cord or steam hose.

30 CAUTION - Make sure all attachments are securely attached before activating

the gun.

31 NEVER - Allow children or un-trained persons to use or handle or operate the

machine.

32 CAUTION - Only operate the unit in an upright position.

33 Only - Use approved THERMA-KLEEN® components and parts in these units.

34 ALWAYS - Empty machine of all water when finished.

35 NEVER - Store machine outside.

36 NEVER - Store machine with water in it.

37 NEVER - Allow the unit to be exposed to freezing temperatures

as severe damage will occur.

WARNING:

Your Therma-Kleen Vapor Steam Cleaner MUST BE PLUGGED INTO A GROUNDED

OUTLET, or electrical shock can occur. Check with a certified

electrician if there is any doubt that the outlet is grounded. Do

not modify the Power Cord/Plug provided with the Therma-Kleen

Vapor System. If it will not fit the outlet, have a properly

grounded outlet installed by a certified electrician.

WARNING:

The motor must be wired so that in rotates in the direction indicated on the

motor. If the motor/pump are allowed to run in the wrong direction, serious

damage will occur to the pump.

WHY THIS UNIT MUST BE GROUNDED:

If the unit should malfunction or break down, grounding provides a path of least

resistance for the electrical current to pass, reducing the risk of electrical shock.

Ultra 250E Electric Steam Cleaner

October 24, 2019

8

All Therma-Kleen units are equipped with a power cord with an equipment

grounding conductor and plug. The plug must be inserted into an appropriate

outlet which is properly grounded in accordance with national & local electrical

codes and ordinances.

NOTE:

The 25 ft. length of the input power cord should not be increased. If additional

length is required, consult the national & local electrical codes and ordinances as

well as seeking the advice of a qualified electrical engineer before proceeding.

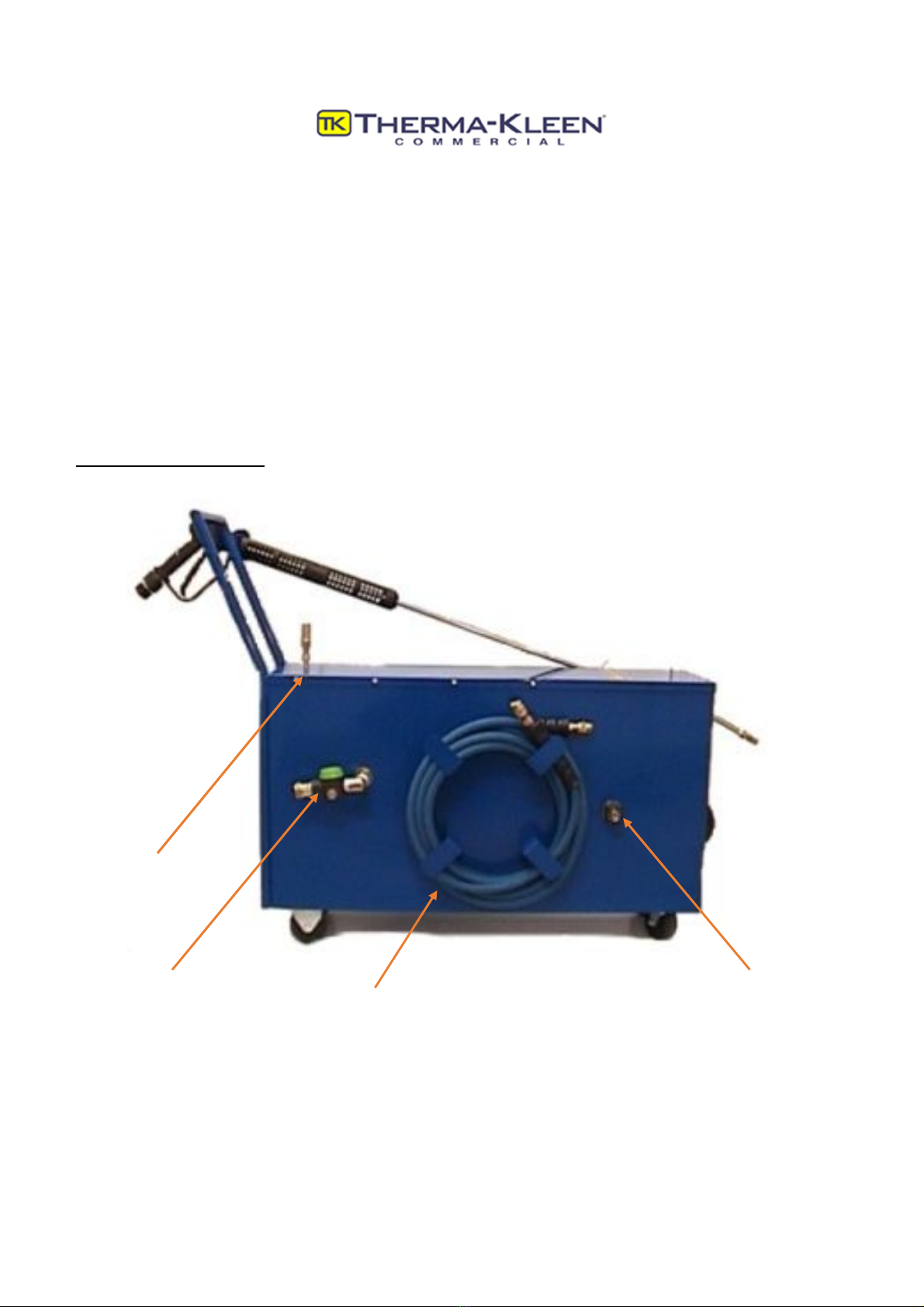

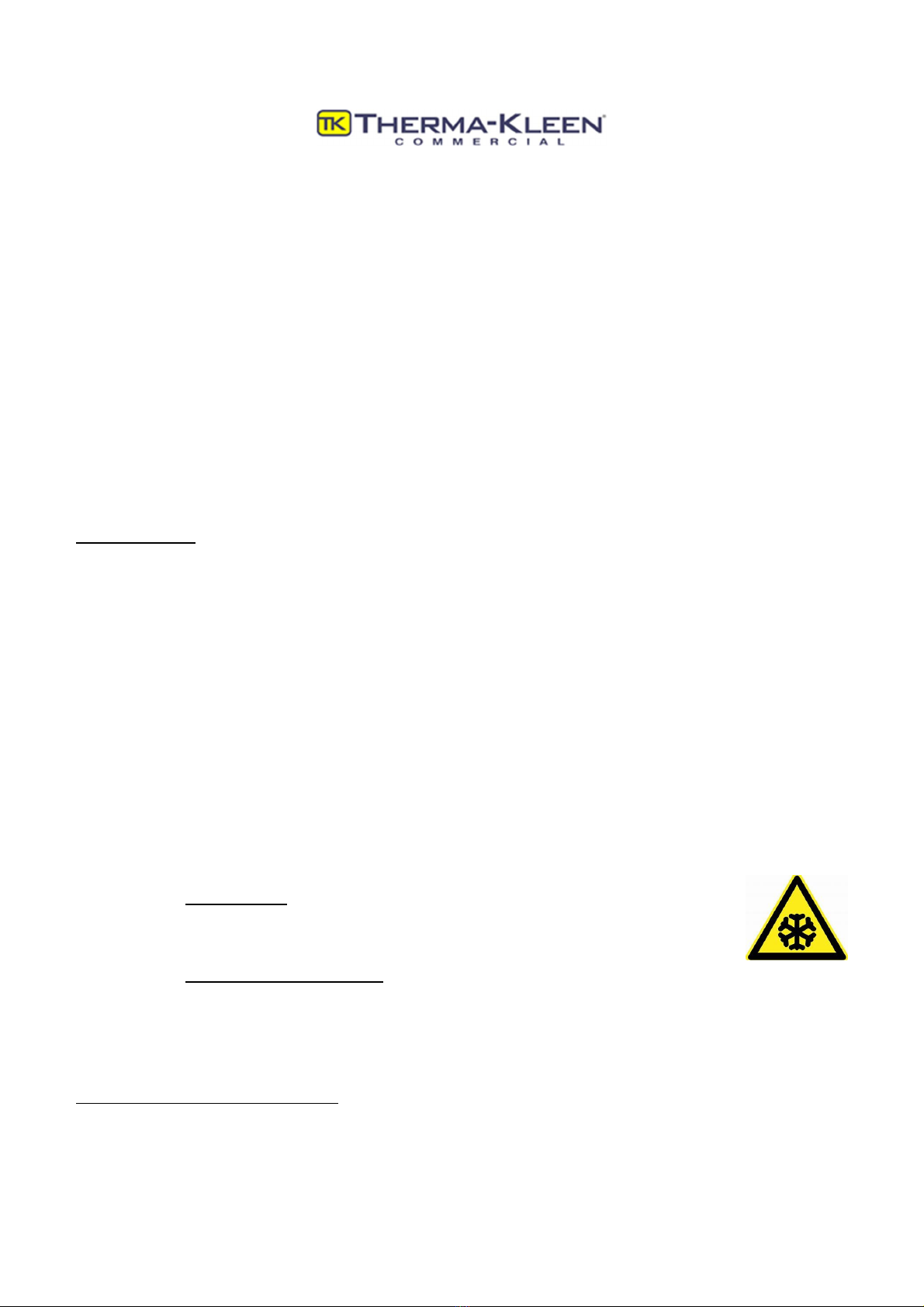

PHOTOS OF MODELS:

Available in Blue Paint or Stainless Steel

A - Nozzle Storage (threaded)

B - Water Input Connection (garden hose)

C - Steam Hose Storage

D - Steam Hose Connection

D

A

C

B

Ultra 250E Electric Steam Cleaner

October 24, 2019

9

Combistat:

For setting

Temperature

setting

Power:

“ON/OFF “Switch

Drain Plug

Ultra 250E Electric Steam Cleaner

October 24, 2019

10

ACCESSORIES SHIPPED WITH YOUR MACHINE

Steam Hose Fan Nozzle

Blast Nozzle

25 ft. Not available with all

pump sizes

4 ft. Deluxe Wand

25 ft, Steam Hose is Standard. A longer length Steam Hose will result in a loss of

pressure.

3 PHASE WIRING DIAGRAM:

Each machine is provided with an input electrical cord similar to the one shown.

Green Wire: Ground

White Wire: Neutral

Black Wire: L1

Red Wire: L2

Each machine has this wiring configuration:

The Customer is to provide their own plug to match their electrical power outlet.

Ultra 250E Electric Steam Cleaner

October 24, 2019

11

The power cord wire is connected to the heater fuse block within the unit.

CAUTION: If the pump runs backwards, change two wires in the power cord to correct

the problem immediately as this can cause damage to the pump.

ULTRA 250E - ELECTRICAL CONNECTION PROCEDURE:

When you install the power cord, the wires can be attached several

different ways. You need to see if you have the plug wired correctly for

the machine.

1. Attach a garden hose to the unit.

2. Turn the garden hose water “ON”. You will see the water come out of the

wand end after a minute or two.

3. Turn the pump “ON”, if the water stops this is an indicator that the plug is not

wired correctly. Turn the pump switch “OFF” and unplug the unit. Switch any two

wires in the plug and try again. CAUTION: DO NOT engage the heater by turning

the temperature gauge (combistat) knob past the black line at this time. This

could cause the water to go backwards into the garden hose if the pump runs the

wrong way, the customer must use the following procedure for proper power

connection and operation.

WARNING:Failure to follow these procedures could permanently damage the pump

and/or motor assembly. They will not be covered under warranty if they are damaged.

This procedure requires the customer to obtain a “Motor Rotation Test Meter” Ideal #61-

521 from Ideal Industries, Inc., Sycamore, IL 60178, USA, 800-435-0705 or and electrical

supply house.

This is only an example of a test meter that will work. There are other meters that will

also do the same function.

Ultra 250E Electric Steam Cleaner

October 24, 2019

12

1.) Phase Rotation

Input Terminal

2.) Open Phase

Indicator

3.) Phase Rotation

Indicator

1. Using the 3-phase tester half of the rotation test meter (see drawing from

above), connect the RED-YELLOW-BLUE leads on the meter to the 240vac- 3-

phase power source.

2. Observe rotation lamps on meter, is the clockwise rotation lamp (No. 3 on

drawing) lit?

If Yes, go to step 4.

If NO, go to step 3.

3. Switch two of the three test meter lead connections on power source. Then go

back to step 2.

4. Connect RED-BLACK-WHITE leads in the Ultra 600E power cord to the

corresponding power source terminals identified by the RED-YELLOW-BLUE

leads on the test meter.

Match RED to RED, BLACK to YELLOW, WHITE to BLUE.

5. Connect water source, pressure hose and wand to Ultra 600E and prepare to

test for proper operation.

6. Before activating the unit, turn on the water supply and purge all air from the

Ultra 600E by

Ultra 250E Electric Steam Cleaner

October 24, 2019

13

squeezing the trigger gun and waiting for a steady stream of water from the

wand tip.

7. You must be prepared to immediately turn off the Ultra 600E if the pump motor

is observed to run opposite the proper rotation. This is determined by sound

and absence of high pressure at the wand tip. If a humming is heard and no

large increase in pressure is observed at the wand tip, then immediately turn

the unit off. Failure to quickly turn off the pump will result in a burnt-out motor.

8. Test Ultra 600E for proper rotation by switching the unit on momentarily.

9. Did the unit run properly:

If Yes, go to the next step.

If No, STOP all testing and turn off water and power source.

Disconnect the cord from the power source but note which color on the

power cord is connected to which terminal on power source.

Go to Pump Repair Procedure below.

10. Your unit is not operating properly. If your unit is permanently connected to a

power source, then you are finished with this procedure. If you are using

multiple outlets and moving the unit between them, you must wire all other

outlets the same as the working outlet. Using the test meter, verify each outlet

is wired the same as the working outlet.

START UP:

CHECK POLARITY - NEVER let run the unit if the motor is rotating in the wrong direction

as this can cause serious damage to the pump

1. Connect a garden hose to the inlet fitting located on the side of the machine.

2. Connect the steam hose to the outlet by threading the swivel connection to the

hose end. DO NOT over tighten, this will shorten the life of the “O” rings in the

fitting.

3. Connect the wand to the steam hose with the same action as above.

4. Plug the power cord into a grounded 3 phase outlet with the same voltage as

your machine.

5. Turn the red line on the temperature gauge down below the black line. This will

keep the heater from coming “ON”.

6. DO NOT place the nozzle at the end of the wand at this time. Turn the water on

full force. Read the incoming water temperature gauge at this time. The

incoming water should not exceed 140˚F, as higher temperatures could

potentially damage the pump. Turn the pump “ON”. Allow the water to run for

Ultra 250E Electric Steam Cleaner

October 24, 2019

14

a few minutes. Remember, your machine works on a temperature rise from the

incoming water temperature.

7. Release the trigger gun to stop the flow of water through the wand. After 15

seconds, engage the trigger gun. This action helps to speed up any trapped air

in the system. Release the trigger once again to stop the water flow.

8. Place a nozzle on the end of the wand. Engage the trigger gun to allow water to

flow.

9. Turn the knob clockwise on the temperature gauge just past the desired

operating temperature. Fan Nozzle: 250˚ F The heater will engage at this time.

When the red line meets the black line, the heater will cycle “OFF”.

10. When you stop the water flow when the heater is engaged, the heater will shut

off until the water is allowed to flow again by opening the trigger gun.

SHUT DOWN:

1. Turn the RED line DOWN below the BLACK line on the temperature gauge

(combistat). You will hear a “Click” when the heater goes “OFF”.

2. Let the pump continue to run until the temperature reads 100˚F or less. This

will assure that the water coming out of the hoses will be cool when you put

the unit away.

3. Turn the pump switch “OFF”.

4. Turn off the water, disconnect the electricity and water hose.

5. Wrap the power cord onto the power cord holder.

6. Wrap the steam hose onto the steam hose holder.

7. Store the machine where it cannot freeze.

8. If you plan on storing the machine for more than a short period, drain the unit

by removing the drain plug located below the handle and tilting the unit back on

the handle to force the water out of the system.

a. Hard water will cause scale on the heater, so it is best to

remove the water from the system if it is not going to be used

for a while

b. Freezing Temperatures will cause extensive damage to the

machine and its components if any water is left in the unit.

9. Never transport/ship the unit unless all water has been completely drained

from the system.

PUMP MAINTENANC0E: 250E

It is very important to maintain your pump. The seals can be damaged over time by:

Ultra 250E Electric Steam Cleaner

October 24, 2019

15

1.) leaving the machine in by-pass too long creating excess heat to the seals and

misshaping them.

2.) Use of chemicals;

3.) Wear and tear.

4.) The incoming water is TOO hot.

Lubrication:

The pump bearing has lubricant on it to create a smooth seal between the hearing and

plunger. Re-lubricate as needed.

We recommend using the brand Super Lube or any Synthetic grease with PTFE.

Call if you need. Part #6013for the lubrication and part #6012 for the bearing.

Valves:

The valves can be easily replaced on your pump. If your pressure drops, a valve or valves

may be broken. This will cause a low water flow and could cause the machine not to

heat. Call for the valve kit and seals. Kit B is part #6011.

Plunger Kit:

The bearing rides on a plunger. If the bearing was allowed to un-thread by running the

motor the wrong direction, this plunger needs to be replaced. Call for the plunger and

seals kit. Kit A is part #6010. If your pump is used while the seals are damaged, this can

cause water to get into the bearing and break it. If it goes too long, it can destroy the

motor winds.

ULTRA 250E Pump:

Needs to be replaced or sent back to be rebuilt by the pump manufacturer.

WANDS:

Optional Accessories (pictured below):

Snub Nose Wand

2.5 ft. Wand

The swivel fitting on the end of your gun that the hose attached to has an “O” ring inside.

When you tighten the swivel fitting to the hose do not over tighten, this will shorten the

life of the “O” ring. Replace as needed to achieve a good seal.

Ultra 250E Electric Steam Cleaner

October 24, 2019

16

4-foot Wand

Trigger Gun

(can be purchased as an individual part if

you need to rebuild your wand)

2.5 foot Wand (optional)

Snub Nose Wand (optional)

HOSE:

This hose is a wire braided hose.

DO’S AND DON’Ts

DO NOT exceed a 2” bend radius.

DO NOT use the hose to pull the machine.

DO NOT pull around corners, this will damage the

hose.

DO NOT replace with another type of hose.

DO wear gloves when moving a hot hose.

Extra hose lengths are available. (25 ft., 50 ft. or 100ft.)

Ultra 250E Electric Steam Cleaner

October 24, 2019

17

COMBISTAT:

The combistat is a temperature gauge and a high limit cut

off switch in one. This gauge also controls the heat and the

heater on this machine. To engage the heat, you must turn

the knob in the middle of the gauge to a higher

temperature than the black indicator line on the gauge.

When the red line is at or below the black line the heater

will not come on. When the red line is above the black line

the heater will engage. You can control the maximum

temperature by setting the red line to the max desired

temperature and then heater will cut-off when the

temperature is achieved.

Caution: Protect the gauge from impact.

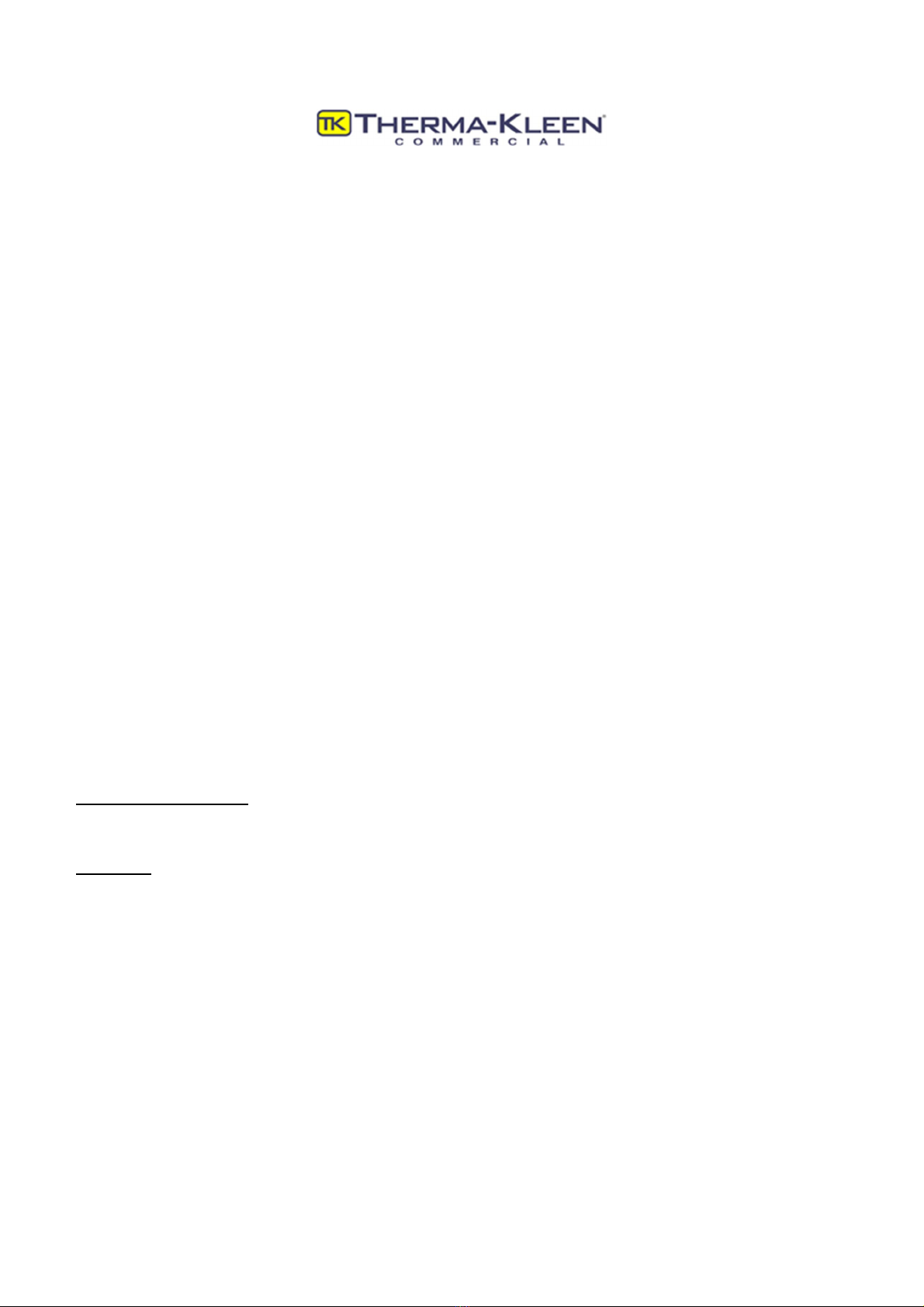

FLOW SWITCH:

The flow switch shuts the heater off when there is an interruption of water flow or the

necessary amount of water flow is too low. This protects

the heater. Check for debris in your nozzle. Also, always use

the correct nozzle size with your model.

Excess air in the water system can cause the flow switch to

flutter. Make sure you purge the system of all air before

using the machine. This will lengthen the life of your flow switch.

Using the trigger gun activates this switch. Excessive “ON” “OFF” action will also shorten

the life of your flow switch.

Ultra 250E Electric Steam Cleaner

October 24, 2019

18

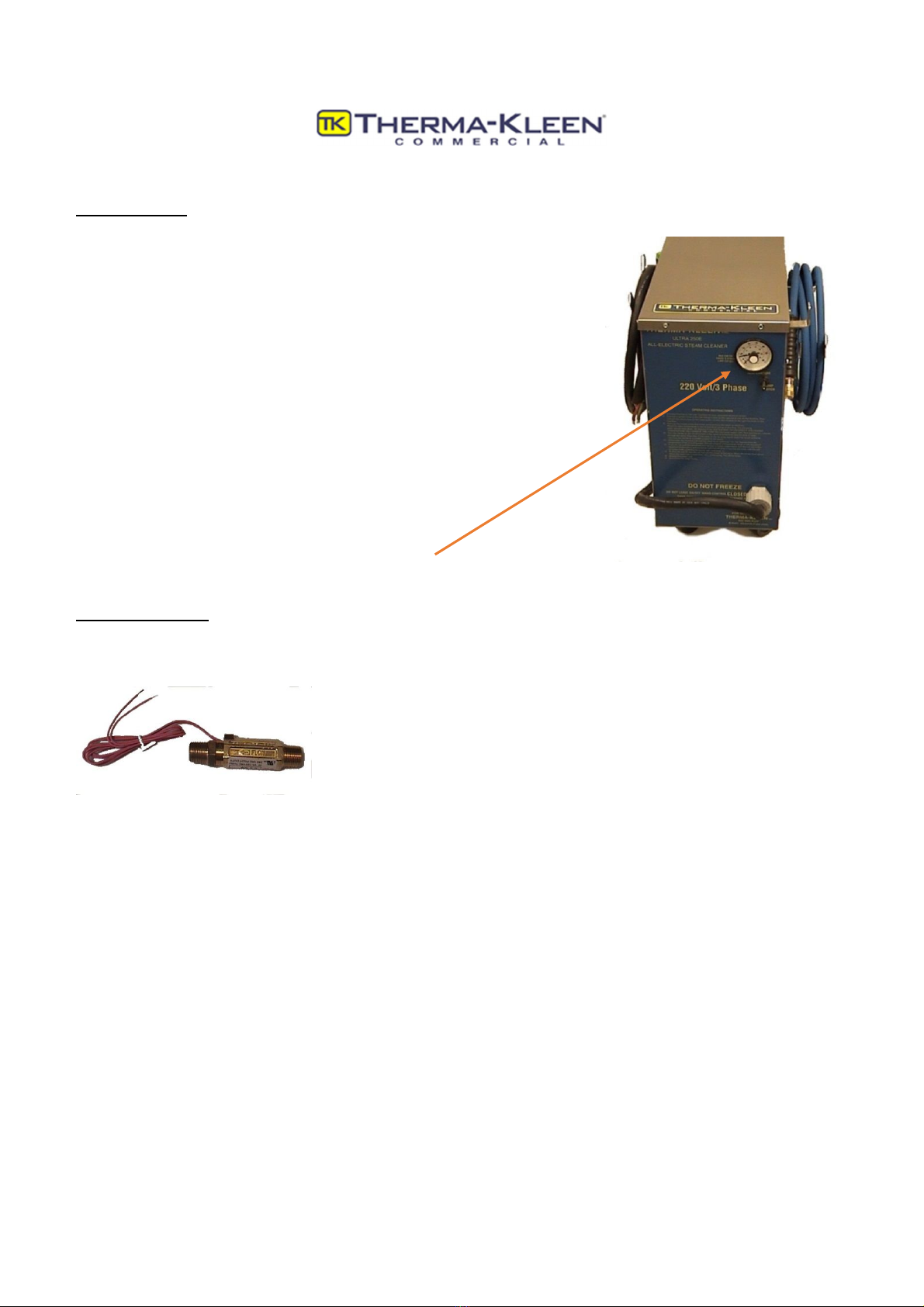

NOZZLES:

Fan Nozzle Use from cold water

25 degree to 250˚ F.

Blast Nozzle Best cleaning temperature

Zero degree 280-300˚ F.

(Does not come with every model)

PARTS LIST:

ULTRA 250E PART#

3749 - 1/3 hp. 3 phase Motor 3805 - 25 ft. Steam Hose

3738 - 250 Pump 3798 - 25 ft. Combi Steam Hose

3739 - 250 Pump 1.0 gpm 3265 - Plus Model #-Fan Nozzle

3746 - 250 Pump 0.5 gpm 3213 - Plus Model #-Blast Nozzle

3781 - Adaptor for Pump/Motor 3661 - 4 ft. Wand

3786 - Lovejoy 3754 - 3” Rigid Wheel

3752 - 25 amp. Contactor-220/480 volt 3756 - 3” Swivel Wheel

3776 - 60 amp. Contactor- 220 volt 3671 - Male Coupler for End of Gun

3762 - 30 amp. Contactor- 480 volt 3788 - 6/4 25 ft. Power Cord-220 volt

3758 - 30 amp. Fuse Block-220 volt 3790 - 8/4 25 ft. Power Cord- 480 volt

Ultra 250E Electric Steam Cleaner

October 24, 2019

19

3802 - 3 amp. Fuses -220 volt 3799 - Strain Relief Cord Grip

3779 - 60 amp. Fuse Block- 220 volt 3766 - 30 amp. Fuse Block-480 volt

3778 - 60 amp. Fuses- 220 volt 3765 - 30 amp. Fuses (heater)

3763 - Toggle Switch 3764 - 15 amp. Fuse Block-480 volt

3024 - Toggle Switch Cover 3760 - 5 amp. Fuses- 480 volt

3769 - Transformer 3923 - 21 kw Heater- 220 volt

3240 - Combistat (Temperature Gauge) 3985 - 21 kw Heater-480 volt

OPTIONS

3673 - 50 ft. Steam Hose

3160 - 100 ft. Steam Hose

3674 - Coupler for Hose Extension

3905 - 2 ½ ft. Wand

3668 - Snub Nose Wand

PREVENTATIVE MAINTENANCE:

1. Periodically inspect and clean the water inlet screen located just behind your

garden hose onnection. The Ultra 600E model has a water inlet filter, the Ultra

250E has a water screen inside the garden hose fitting and at the base of the

pump. Particles in the water can be abrasive and damage your pump.

2. Periodically inspect the nozzles to make sure they are not clogged. Restricted

water flow or a broken spray pattern is an indication of an obstruction in the

nozzle.

3. Hardness or mineral content in water along with steam temperatures could create

a coating or buildup of scale in the heater and water system. Excess scale will

shorten the heater life and interfere with temperature controls.

4. DO NOT FREEZE the machine. Freezing can ruin the flow switch, pump,

temperature gauge (combistat) as well as the heater. To protect, remove the drain

plug from the heater and tilt the machine until the water is emptied from the

system. Replace the plug.

5. Never allow the pump to run without the presence of water. This will damage your

pump.

6. Excessive use of the trigger gun can shorten the life of your flow switch, contactors,

heater and pump. DO NOT OVER USE.

Ultra 250E Electric Steam Cleaner

October 24, 2019

20

7. The Ultra 600E pump seals should be inspected regularly for wear. Add additional

lubricant, as needed, for the pump and motor. The pump plunger should be

protected.

8. Do not tamper with safety features of these models.

9. Pump seals that are not replaced, as needed, can cause damage to the bearing and

motor as water is allowed into these items.

TROUBLE SHOOTING:

HEATER does not come on?

1. Make sure the red line on the temperature gauge is set to a higher temperature

than the black line, if the red line is set lower than the black line then the contactor

will not engage. The contactor will make a “click” sound when the combistat opens

it.

2. Make sure you have purged the system of air locks when you first start the unit.

Close the trigger gun while the pump is running and count to 15. Then, release the

gun and do again. This will help smooth out the system. Excess air in the system

could cause an erratic “ON” “OFF” action.

3. Make sure the water flow to and through the machine is not restricted, i.e. a clog in

the nozzle, a kink in the garden hose, the water is not on all the way at the garden

hose, the water pressure in the water system is too low, or the pump is not

pumping enough water through the system. Check the pump water volume per

minute and the pump pressure. The flow switch needs to sense a certain flow per

minute, if not, then the contactor will not engage.

TEMPERAURE RISE:

1. If you are not achieving enough temperature rise this could be due to using the

wrong nozzle or the heater is failing. If your combistat is reading correctly, then

check the orifice size on the nozzle. If needed, replace with factory authorized

nozzle and orifice.

PUMP SEALS ARE DAMAGED:

1. Make sure that the incoming water temperature is not greater than 140˚F.

Allowing the pump to stay in the “by-pass” mode for long periods of time will

increase the chance of the pump water temperature rising past the approved

temperatures. Do not leave the trigger gun closed for more than 2 minutes.

This manual suits for next models

1

Table of contents

Other THERMA-KLEEN Steam Cleaner manuals