Thermal Care Aquatherm RQE Instruction Manual

Table of Contents

Foreword .................................................................................................................................................................................................................. 1

Safety Guidelines .................................................................................................................................................................................................. 1

Pre-Installation....................................................................................................................................................................................................... 2

Receiving Inspection ....................................................................................................................................................................................... 2

Unit Storage........................................................................................................................................................................................................ 2

Installation - Mechanical.................................................................................................................................................................................... 2

Foundation.......................................................................................................................................................................................................... 2

Unit Location...................................................................................................................................................................................................... 2

Rigging ................................................................................................................................................................................................................. 2

Fluid Distribution Piping................................................................................................................................................................................ 2

Installation - Electrical......................................................................................................................................................................................... 3

Controller Operation ........................................................................................................................................................................................... 4

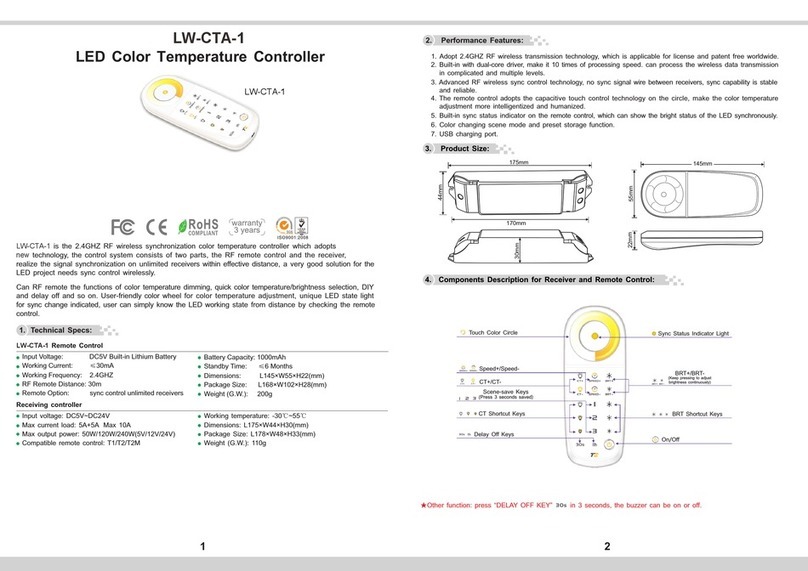

Figure 1 –Standard Controller User Interface .................................................................................................................................. 4

Figure 2 –Premium Controller User Interface .................................................................................................................................. 4

Changing Temperature Display Scale ...................................................................................................................................................... 4

Table 1 - Controller Operating Buttons............................................................................................................................................... 5

Table 2 - Temperature Displays.............................................................................................................................................................. 6

Table 3 - Operating Lights........................................................................................................................................................................ 6

Table 4 - Controller Control Fault Logic.............................................................................................................................................. 7

Program Menu................................................................................................................................................................................................... 8

Table 5 - Program Menu Items............................................................................................................................................................... 8

Seal Saver Sequence Initiation................................................................................................................................................................ 9

Pump Running Hour Display ................................................................................................................................................................... 9

SPI Communications (Optional) ...............................................................................................................................................................10

Table 6 - SPI Option Parameters..........................................................................................................................................................10

Modbus RTU (Optional)...............................................................................................................................................................................11

Table 7 - ModBus Option Parameters................................................................................................................................................11

Start-up...................................................................................................................................................................................................................12

Step 1 –Connecting Main Power ............................................................................................................................................................13

Step 2 –Fill Coolant Circuit ........................................................................................................................................................................13

System Fill Water Chemistry Requirements.....................................................................................................................................13

Table 8 - Fill Water Chemistry Requirements..................................................................................................................................14

Step 3 –Initial Unit Operation...................................................................................................................................................................14

Preventive Maintenance...................................................................................................................................................................................15

Once a Week ....................................................................................................................................................................................................15

Once a Month..................................................................................................................................................................................................15

Troubleshooting..................................................................................................................................................................................................16

Drawings.................................................................................................................................................................................................................16

Page Intentionally Blank

1

Foreword

The temperature control unit is a packaged unit that

typically includes a fluid pump, electric immersion

heater, and temperature control valve in a cabinet.

The purpose is to provide circulation and

temperature control of a cooling fluid.

This manual is to serve as a guide for installing,

operating, and maintaining the equipment. Improper

installation, operation, and maintenance can lead to

poor performance and/or equipment damage. Use

qualified installers and service technicians for all

installation and maintenance of this equipment.

This manual is for our standard product. The

information in this manual is general in nature. Unit-

specific drawings and supplemental documents are

included with the equipment as needed. Additional

copies of documents are available upon request.

Due to the ever-changing nature of applicable

codes, ordinances, and other local laws pertaining to

the use and operation of this equipment, we do not

reference them in this manual.

Safety Guidelines

Observe all safety precautions during installation,

start-up, and service of this equipment. The

following is a list of symbols used in this manual and

their meaning.

General Warning

Electricity Warning

Sharp Element Warning

Hot Surface Warning

Flammable Material Warning

Explosive Material Warning

General Mandatory Action

Wear Eye Protection

Wear Protective Gloves

Wear Ear Protection

Disconnect Before Carrying Out Maintenance or

Repair

Connect an Earth Terminal to Ground

Only qualified personnel should install, start-up, and

service this equipment. When working on this

equipment, observe precautions in this manual as

well as tags, stickers, and labels on the equipment.

WARNING: Any use or misuse of this equipment

outside of the design intent may cause injury or harm.

WARNING: This equipment contains hazardous

voltages that can cause severe injury or death.

WARNING: This equipment contains hot water or

coolant under pressure. Accidental release of hot water

or coolant under pressure can cause personal injury

and or property damage.

WARNING: This equipment may contain fan blades or

other sharp edges. Make sure all fan guards and other

protective shields are securely in place.

WARNING: The exposed surfaces of motors, piping,

and other fluid circuit components can be very hot

and can cause burns if touched with unprotected

hands.

CAUTION: Disconnect and lock out incoming power

before installing, servicing, or maintaining the

equipment. Connecting power to the main terminal

block energizes the entire electric circuitry of the unit.

Shut off the electric power at the main disconnect

before opening access panels for repair or

maintenance.

CAUTION: Wear eye protection when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

2

CAUTION: The equipment will exceed 70 dBA sound

pressure at 1 meter distance and 1 meter elevation

when operating. Wear ear protection as required for

personal comfort when operating or working in close

proximity to the chiller.

CAUTION: Wear protective gloves when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

Pre-Installation

Receiving Inspection

When the unit arrives, verify the information on the

unit nameplate agrees with the order

acknowledgement and shipping papers. Inspect the

equipment for any visible damage and verify all

items shown on the bill of lading are present. If

damage is evident, document it on the delivery

receipt by clearly marking any item with damage as

“unit damage” and notify the carrier. In addition,

notify our Customer Service Department and they

will provide assistance with preparing and filing

freight damage claims, including arranging for an

estimate on repair costs; however, filing the shipping

damage claim is the responsibility of the receiving

party. Do not install damaged equipment without

getting the equipment repaired.

Shipping damage is the responsibility of the carrier.

To protect against possible loss due to damage

incurred during shipping and to expedite payment

for damages, it is important to follow proper

procedures and keep records. Photographs of

damaged equipment are excellent documentation

for your records.

Start unpacking the unit, inspect for concealed

damage, and take photos of any damage found.

Once received, equipment owners have the

responsibility to provide reasonable evidence that

the damage did not occur after delivery. Photos of

the equipment damage while the equipment is still

partially packed will help in this regard. Refrigerant

lines can be susceptible to damage in transit. Check

for broken lines, oil leaks, damaged controls, or any

other major component torn loose from its

mounting point.

Record any signs of concealed damage and file a

shipping damage claim immediately with the

shipping company. Most carriers require concealed

damages be reported within 15 days of receipt of

the equipment. In addition, notify our Customer

Service Department and they will provide assistance

with preparing and filing freight damage claims,

including arranging for an estimate on repair costs;

however, filing the shipping damage claim is the

responsibility of the receiving party.

Unit Storage

When storing the unit it is important to protect it

from damage. Blow out any water from the unit;

cover it to keep dirt and debris from accumulating

on or getting in and store in an indoor sheltered

area that does not exceed 145°F.

Installation - Mechanical

Foundation

Install the unit on a rigid, non-warping mounting

pad, concrete foundation, or level floor suitable to

support the full operating weight of the equipment.

When installed the equipment must be level within

¼ inch over its length and width.

Unit Location

The unit is available in many different configurations

for various environments. Refer to the proposal and

order acknowledgement document for the

equipment to verify the specific design conditions in

which it can operate.

To ensure proper airflow and clearance space for

proper operation and maintenance allow a minimum

of 12 inches of clearance between the sides of the

equipment and any walls or obstructions. Avoid

locating piping or conduit over the unit to ensure

easy access with an overhead crane or lift to lift out

heavier components during replacement or service.

Rigging

The unit has a base with casters to facilitate easy

movement and positioning. Follow proper rigging

methods to prevent damage to components. Avoid

impact loading caused by sudden jerking when

lifting or lowering the unit. Use pads where abrasive

surface contact may occur.

Fluid Distribution Piping

Proper insulation of chilled process fluid piping is

crucial to prevent condensation. The formation of

3

condensation adds a substantial heat load to the

cooling system.

The importance of properly sized piping cannot be

overemphasized. See the ASHRAE Handbook or

other suitable design guide for proper pipe sizing. In

general, run full size piping out to the process and

then reduce the pipe size to match the connections

on the process equipment. One of the most

common causes of unsatisfactory unit performance

is poor piping system design. Avoid long lengths of

hoses, quick disconnect fittings, and manifolds

wherever possible as they offer high resistance to

water flow. When manifolds are required, install

them as close to the use point as possible. Provide

flow-balancing valves at each machine to assure

adequate water distribution in the entire system.

Install shut-off valves at each machine to allow for

isolation of the unit.

Installation - Electrical

All wiring must comply with local codes and the

National Electric Code. Minimum Circuit Amps (MCA)

and other unit electrical data are on the unit

nameplate. A unit specific electrical schematic ships

with the unit. Measure each leg of the main power

supply voltage at the main power source. Voltage

must be within the voltage utilization range given on

the drawings included with the unit. If the measured

voltage on any leg is not within the specified range,

notify the supplier and correct before operating the

unit. Voltage imbalance must not exceed two

percent. Excessive voltage imbalance between the

phases of a three-phase system can cause motors to

overheat and eventually fail. Voltage imbalance is

determined using the following calculations:

% Imbalance = (Vavg –Vx) x 100 / Vavg

Vavg = (V1 + V2 + V3) / 3

Vx = phase with greatest difference from Vavg

For example, if the three measured voltages were

442, 460, and 454 volts, the average would be:

(442 + 460 + 454) / 3 = 452

The percentage of imbalance is then:

(452 –442) x 100 / 452 = 2.2 %

This exceeds the maximum allowable of 2%.

There is a terminal block for main power connection

to the main power source. The main power source

should be connected to the terminal block through

an appropriate disconnect switch. There is a separate

lug in the main control panel for grounding the unit.

Check the electrical phase sequence at installation

and prior to start-up. Operation of the unit with

incorrect electrical phase sequencing will result in

improper pump performance. Check the phasing

with a phase sequence meter prior to applying

power. The proper sequence should read “ABC” on

the meter. If the meter reads “CBA”, open the main

power disconnect and switch two line leads on the

line power terminal blocks (or the unit mounted

disconnect). Do not interchange any load leads that

are from the unit contactors or the motor terminals.

WARNING: This equipment contains hazardous

voltages that can cause severe injury or death.

WARNING: This equipment contains hot water or

coolant under pressure. Accidental release of hot water

or coolant under pressure can cause personal injury

and or property damage.

WARNING: This equipment may contain fan blades or

other sharp edges. Make sure all fan guards and other

protective shields are securely in place.

WARNING: The exposed surfaces of motors, piping,

and other fluid circuit components can be very hot

and can cause burns if touched with unprotected

hands.

CAUTION: Disconnect and lock out incoming power

before installing, servicing, or maintaining the

equipment. Connecting power to the main terminal

block energizes the entire electric circuitry of the unit.

Electric power at the main disconnect should be shut

off before opening access panels for repair or

maintenance.

CAUTION: Wear eye protection when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

CAUTION: Wear protective gloves when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

CAUTION: Wire the unit ground in compliance with

local and national codes.

4

Controller Operation

Figure 1 –Standard Controller User Interface

Figure 2 –Premium Controller User Interface

The temperature control unit includes a controller to

perform all control functions directly from the front

panel. When Control Power is applied, the controller

initiates a diagnostic test of each indicating light and

display segment that temporarily lights them

sequentially. As part of this initial diagnostic test, the

program revision number appears in the

temperature display for a moment. After the initial

diagnostic sequence is completed, the controller is

ready for operation.

Changing Temperature Display Scale

The temperature controller is able to display

temperatures in either °F or °C. To determine which

temperature is in use and to change the temperature

scale used stop the unit and press the Power button

to turn off the controller. Press and hold the Stop

Button and then press the Power Button. When the

controller illuminates, release both buttons. The To

Process display will read "Unt". The Set Point display

will show either "F" or "C" depending on the current

display units selected. If "F" is displayed the

temperature display is in °F mode. If "C" is displayed

the temperature display is in °C mode. To change

from °F to °C press the Lower Set Point Temperature

button (down arrow). To change from °C to °F press

the Raise Set Point Temperature button (up arrow).

After changing to the desired scale, the Set Point

display shows the desired display units. Press and

release the Start button to store the new selection

into the controller memory then press and release

the Power button to exit the function. Press and

release the Power button again to restore controller

power. The unit is now ready for operation.

5

Table 1 - Controller Operating Buttons

Button

Description of Operation

Start

Pressing the Start button initiates a vent sequence. The vent sequence removes air to prevent improper operation and

premature heater failure. When initiated, the vent sequence opens the cooling valve for to allow air to escape, after 30

seconds it runs the pump for 30 seconds while the cooling valve is open to remove any remaining air from the system. Once

the vent sequence is complete, the cooling valve closes, the pump remains on, and normal operation begins. When the unit is

running, the Run indicating light is on and green. When enabled, the auto start feature has precedence over the start button.

See the Program Menu section for instructions on how to adjust the auto start feature. The vent sequence cancel prevents the

vent sequence from occurring when the unit has been operating and the fluid temperature is elevated. The factory default

value for the vent sequence cancel is 120°F. See the Program Menu section for instructions on how to adjust the temperature

of the vent sequence cancel. The Start button also performs an enter function while in the programming menu.

Stop

Pressing the Stop button clears all faults and stops the unit. When enable, the auto start feature has precedence over the start

button so if enables and an auto start signal is present, pressing the start button will not stop the unit. The Stop button also

performs a cancel function while in the programming menu.

Alarm Reset

When an alarm condition is present, the alarm light is on and red. Pressing the Alarm Reset button silences the alarm horn

(optional), opens the remote alarm contact (optional), and changes the alarm light from red to yellow. The alarm horn

(optional) and/or remote alarm contact (optional) remain disabled until a subsequent alarm occurs. To reset the state from

Alarm to Normal Operation, press the Alarm Reset button a second time.

Up

The Up button raises the set point temperature. Pressing and releasing the Up button increases the set point temperature one

degree. Pressing and holding the Up button continuously increases the set point temperature until released. The Up button

also adjusts various alarms and set point values when the unit in the programming mode.

Down

The Down button decreases the set point temperature. Pressing and releasing the Down button decreases the set point

temperature one degree. Pressing and holding the Down button continuously decreases the set point temperature until

released. The Down button also adjusts various alarms and set point values when the unit is in the programming mode.

Display/

Program

Pressing the Display/Program button changes the temperature displayed in the Process screen from supply to return. When

the display is set to supply temperature, an orange indicating light is on in the lower right corner of the Process temperature

display. When the display is set to return temperature, there is no orange indicating light in the lower right corner of the

Process temperature display. To toggle the Process temperature display from supply to return temperature, press and release

the Display/Program button. The display will return to the default Supply temperature automatically after 5 seconds without a

button press. In addition to switching between the supply and return process temperature displays, the Display/Program

button initiates and navigates through the program menu. See the Program Menu section for more detail.

Mold Purge

(Optional)1

The Mold Purge button initiates a mold water purge if this option is present and enabled. The mold purge option allows

compressed air to purge the circuit of water by forcing it out through the cooling valve. To initiate a mold purge sequence

stop the unit then press and release the mold purge button. During a mold purge, the cooling water out and mold purge

compressed air solenoid valves open. The mold purge sequence is 1 minute long. To stop the mold purge sequence before it

is completed, press the Mold Purge button again or press the Stop button. See the Program Menu section for instructions on

how to enable or disable this feature.

Crash Cool

(Optional)1

The Crash Cool button opens the crash cool solenoid valve if this option is present and enabled. Pressing the Crash Cool

button initiates a crash cool sequence. The crash cool sequence opens the crash cool valve, opens the vent/cooling valve, and

disables the heater. The Crash Cool sequence is 1 minute long. To stop the crash cool sequence before it is completed, press

the Crash Cool button again, or press the Stop button. See the Program Menu section for instructions on how to enable or

disable this feature.

Seal Saver

(Optional)2

The Seal Saver button initiates a cool-down sequence if the process supply water is above 90°F. The seal saver cool-down

sequence reduces the water temperature before the unit shuts off to extend the life of the pump seal. To initiate a Seal Saver

cool-down sequence, press and release the Seal Saver button. During this sequence, the cooling valve opens and the pump

runs for 120 seconds or until the temperature of the water reaches 90°F, whichever occurs first. During the Seal Saver cool-

down sequence the Set Point display temporarily toggles between the target value 90°F and current set point and the Pump,

Cool, and Seal Saver lights flash green. After the Seal Saver cool-down sequence is complete, the unit stops, the set point

temperature displays in the Set Point display, and the Seal Saver light remains solid green to indicate the completion of the

sequence. Pressing the Start and/or Stop buttons during a Seal Saver cool-down sequence stops the sequence. See the

Program Menu section for instructions on how to enable or disable this feature.

1Requires the Premium Controller option as well as the individual option for this function.

2Requires the Premium Controller option to have a dedicated easy-access control button. To initiate a Seal Save cool-down sequence on a unit

with the standard controller press and hold down the Start button, then press the Stop button and then release both buttons.

6

Table 2 - Temperature Displays

Display

Description of Operation

Set Point

The Set Point display normally shows the set point temperature. A decimal point in the lower right corner of this display indicates

the temperature unit of measure is set to °F, no decimal point indicates the temperature unit of measure is set to °C. See the

Menu Program section to change the temperature scale units of measure. This display also shows alarm codes and programming

information.

Process

The Process Temperature display normally shows supply temperature. A decimal point in the lower right corner of the display

indicates the temperature displayed is the supply temperature, no decimal point indicates the temperature displayed is the return

temperature. To change the display from supply to return temperature, press and release the Display/Program button. The

display will return to the default Supply temperature automatically after 5 seconds without a button press. This display also shows

alarm codes and programming information.

Table 3 - Operating Lights

Light

Description of Operation

Control Power

The Control Power light is on and green when 24VDC control voltage is present.

Autostart Signal

The Autostart Signal light is green when closed (run), yellow when open (stop), and unlit if this feature is disabled. This

feature allows starting and stopping of the unit by a remote contact closure. From the factory, the Autostart feature is

disabled. See the Program Menu section for instructions on how to enable or disable the Autostart feature. Do not

introduce any external voltage to the Autostart contacts; this will result in damage to the controller.

Pump

The Pump light is solid green when the pump is running and flashes red if the pump overload trips.

Heat

The Heat light is on and green when the heating is required.

Cool

The Cool light is on and green while in normal running operation when the cooling valve is open. The light flashes green

during a vent sequence or Seal Saver cool-down sequence.

Coolant Pressure

In

The Coolant Pressure In light will flash red if the inlet cooling water pressure drops below the set point of the low-

pressure safety switch. If a low-pressure condition occurs, the unit will automatically stop and remain de-energized until

the cooling water pressure is above the cut-in setpoint of the pressure switch. The light is solid green if the Coolant Inlet

Pressure is satisfactory. It will flash green while in the Purge mode.

Temperature Limit

The Temperature Limit light flashes yellow if a high or low temperature limit warning occurs and flashes red if a high or

low temperature limit safety occurs. A temperature limit safety stops the unit. Pushing the Alarm Reset button will reset

this alarm.

Electrical Phase

Error (Optional)1

The Electrical Phase Error light flashes red when a line voltage problem exists. This error indicates a loss of phase, phase

reversal, or phase imbalance.

Heat Error

(Optional)1

The Heat Error light is solid red when the controller calls for heat and heating does not occur. The Heat Error light flashes

red when the controller does not call for heat but heating occurs. Both conditions cause the unit to stop.

Seal Saver

(Optional)1

The Seal Saver light flashes green when the unit is executing a Seal Saver sequence. The Cool and Pump lights will also

flash green during a seal saver sequence. After the Seal Saver sequence is complete, the unit stops and the Seal Saver

light remains green to indicate the completion of the sequence. See the Seal Saver Button section for a description of the

Seal Saver function and operation.

Mold Purge

(Optional)2

The Mold Purge light flashes green when the unit is executing a purge sequence. The Cool light will also flash green

during a mold purge sequence. After the Mold Purge sequence is complete, the unit stops and the Mold Purge light

remains green to indicate the completion of the sequence. See the Mold Purge Button section for a description of the

Mold Purge function and operation. See the Program Menu section for instructions on how to enable or disable this

feature.

Crash Cool

(Optional)2

The Crash Cool light flashes green when the unit is executing a Crash Cool sequence. The Cool light will also flash green

during a crash cool sequence. After the Crash Cool sequence is complete, the unit stops and the Crash Cool light remains

green to indicate the completion of the sequence. See the Crash Cool Button section for a description of the Crash Cool

function and operation. See the Program Menu section for instructions on how to enable or disable this feature.

Communications

(Optional)2

The Communications light flashes green when the unit is properly transmitting and receiving a communication signal.

See the Program Menu section for instructions on how to enable or disable this feature.

1Requires the Premium Controller option.

2Requires the Premium Controller option as well as the individual option for this function.

7

Table 3 –Operating Lights (continued)

Light

Description of Operation

Remote Heat/Cool

(Optional)2

The Remote Heat/Cool light is on and yellow when this option is enabled. This feature allows the heating and cooling to

be turned on and off by remote contact closures. Switching a contact from open to close activates the heat or cool

function assigned to the contact. Switching the contact from closed to open deactivates the individual heat or cool

function assigned to the contact. When enabled the controller does not perform any heat or cool functions and relies

exclusively on the external contact closures for these functions; however, the unit maintains all warnings and safety

functions. From the factory, the Remote Heat/Cool feature is disabled. See the Program Menu section for instructions on

how to enable or disable this feature. Do not introduce any external voltage to the Remote Heat/Cool contacts; this will

result in damage to the controller.

Program Mode

The Program Mode light flashes yellow when the control system is in the programming menu.

1Requires the Premium Controller option.

2Requires the Premium Controller option as well as the individual option for this function.

Table 4 - Controller Control Fault Logic

Fault

Alarm

Indication

Pump Shut

Off

Heater

Shut Off

Unit Shut

Off

Alarm

Reset

Required1

Manual

Reset

Required2

Remote

Alarm

Activated3

Low Coolant Inlet Pressure

The Coolant Pressure In Light flashes

red

Yes

Yes

Yes

No

No

Yes

Temperature Limit Safety

The Set Point and Process

Temperatures Flash and the

Temperature Limit Light flashes red

Yes

Yes

Yes

Yes

No

Yes

Temperature Limit Warning

The Temperature Limit Light flashes

yellow

No

No

No

Yes

No

Yes

Pump Motor Overload

The Pump Light flashes red

Yes

Yes

Yes

Yes

Yes

Yes

Supply Probe Fault Hi

The Set Point Temperature Display

shows PRS and the Process

Temperature Display shows EHi

Yes

Yes

Yes

Yes

No

Yes

Supply Probe Fault Lo

The Set Point Temperature Display

shows PRS and the Process

Temperature Display shows ELo

Yes

Yes

Yes

Yes

No

Yes

Return Probe Fault Hi

The Set Point Temperature Display

shows PRR and the Process

Temperature Display shows EHi

Yes

Yes

Yes

Yes

No

Yes

Return Probe Fault Lo

The Set Point Temperature Display

shows PRr and the Process

Temperature Display shows ELo

Yes

Yes

Yes

Yes

No

Yes

Brownout

The Set Point Temperature Display

shows Brn and the Process

Temperature Display shows Out

Yes

Yes

Yes

Yes

No

Yes

3-Phase Power Error

(Optional)4

The Electrical Phase Error light flashes

red

Yes

Yes

Yes

Yes

No

Yes

Heater Contactor Error

(Optional)4

The Heat Error light flashes red

Yes

Yes

Yes

Yes

No

Yes

1Pressing the Alarm Silence/Reset resets alarm.

2A manual reset of the pump motor thermal overload is required to reset this alarm.

3Activates the alarm horn and closes the alarm contact (optional).

4Requires the Premium Controller option.

8

Program Menu

Access to the program menu is password protected

to prevent unintended alteration to the program

settings and parameters. To access the programming

menu the unit must be in a stopped state. To enter

the program menu, stop the unit then press and

hold the Display/Program button for 10 seconds to

put the controller in program mode. The Program

Mode light flashes yellow and the display will show

PAS on the Process display and 000 on the Set Point

display. The unit is now ready to have the password

entered. From the factory, the password is set to

000. Use the Up or Down arrow buttons to increase

the numeric value on the Set Point display until the

correct password value is shown. To enter the

password, press and release the Start button.

If an incorrect password is entered the Set Point

display shows no and the Process display shows

PAS. After 5 seconds, the unit will go back to the

password entry mode and display PAS on the

Process display and "blanks" on the Set Point

display. If no activity occurs for another 5 seconds,

the controller exits the programming mode and

returns to the Stopped state.

Once in the program menu, use the Display/Program

button to scroll through the different adjustable

parameters in Table 5.

To change an item, press the Display/Program

button until the item code displays in the Process

display. Pressing the Alarm Reset button and

Display/Program button at the same time will

reverse the direction the Display/Program button

indexes through the menu items. Once the desired

menu item code displays in the Process display, use

the Up and Down arrow buttons to adjust the value

shown in the Set Point display until the desired value

show. Press the Start button to enter the display

value. Press the Stop button to cancel and revert to

the previously value.

There is a Master Reset function to restore all User

menu parameters to their factory default values. To

initiate a Master Reset the unit must be in a stopped

state. Once the unit stops, press and hold the Alarm

Silence/Reset button and Stop button

simultaneously for 10 consecutive seconds until PRG

is displayed on the Set Point display and RSt is

displayed on the Process display. To confirm a

Master Reset is desired, press and release the Start

button and the system will perform a Master Reset

and reboot. The Master Reset is aborted after the

PRG is displayed on the Set Point display and RSt is

displayed on the Process display by turning the

control power off or taking no action for 10

consecutive seconds.

Table 5 - Program Menu Items

Item Name

Item

Code

Default

Value

Range

Alarm delay for high deviation alarm

AdH

30

0 to 60 minutes (10 to 60 minutes on program versions prior to version 1.33)

Alarm delay for low deviation alarm

AdL

30

0 to 60 minutes (10 to 60 minutes on program versions prior to version 1.33)

Alarm deviation alarm delay after start

ADS

30

0 to 30 minutes on program version 1.33 and later only

Alarm output

AdO

DIS

Disabled (DIS) or Enabled (EnA) on program versions 1.33 and later only

Autostart enable

ASE

ENA

Disabled (DIS) or Enabled (EnA)

Brownout monitor

brn

EnA

Disabled (DIS) or Enabled (EnA)

Communications Baud rate1

bAU

96

12 to 96

Communications Modbus ID1

bId

1

1 to 247

Communications SPI address1

SPA

32

32 to 63

Communications type1

COt

OFF

OFF, Retransmit (rEt), SPI (SPI), Modbus (bUS), Handheld Remote (Han)

Crash Cool enabled1

CCE

DIS

Disabled (DIS) or Enabled (EnA)

Derivative time

dEr

5

0 to 200

1Requires the Premium Controller option as well as the individual option for this function.

9

Table 5 –Program Menu Items (continued)

Item Name

Item

Code

Default

Valve

Range

Display units

Unt

F

F or C

High deviation alarm limit

HId

10

5 to 100 degrees above set point

Integral time

Int

25

1 to 800

Low deviation alarm limit

Lod

10

5 to 100 degrees below set point

Low pressure bypass enabled

pbE

dIS

Disabled (DIS) or Enabled (EnA)

Panel Temperature Alarm

PAe

EnA

Disabled (DIS) or Enabled (EnA)

Panel Temperature Readout

Pte

Display only

Proportional band

bnd

20

1 to 300

Proportional band ratio

Pbr

5

1 to 10

Pump run hours

PrH

0

0 to 999 (x100)

Purge enabled (optional)1

PuE

DIS

Disabled (DIS) or Enabled (EnA)

Remote heat/cool enabled 1

rHC

DIS

Disabled (DIS) or Enabled (EnA)

Remote Setpoint enabled1

rSE

DIS

Disabled (DIS) or Enabled (EnA)

Remote Setpoint high limit1

rSH

260

rSL to 999

Remote Setpoint low limit 1

rSL

10

-99 to rSH

Retransmit high limit1

rEH

260

rEL to 999

Retransmit low limit1

rEL

10

-99 to rEH

Return Temperature Probe Enable

rPE

EnA

Disabled (DIS) or Enabled (EnA)

Seal-Saver enabled

SSE

EnA

Disabled (DIS) or Enabled (EnA)

User high safety limit alarm

HSU

260

Between factory low and high limits

User low safety limit alarm

LSU

22

Between factory low and high limits

User password

UPA

000

0 to 999

Vent sequence cancel temperature

SCt

120

Between factory low and high limits

1Requires the Premium Controller option as well as the individual option for this function.

Seal Saver Sequence Initiation

The Seal Saver cool-down sequence reduces the

water temperature before the unit shuts off to

extend the life of the pump seal. See the Program

Menu section for instructions on how to enable or

disable this feature. During this sequence, the

cooling valve opens and the pump runs for 120

seconds or until the temperature reaches 90°F,

whichever occurs first. During the Seal Saver cool-

down sequence the Set Point display temporarily

toggles between the target value 90°F and current

set point and the Pump, Cool, and Seal Saver lights

flash green. After the Seal Saver cool-down

sequence is complete, the unit stops, the set point

temperature displays in the Set Point display, and

the Seal Saver light remains solid green to indicate

the completion of the sequence. Pressing the Start

and/or Stop buttons during a Seal Saver cool-down

sequence stops the sequence.

To initiate a Seal Saver cool-down sequence on units

with the Premium Controller simply press and

release the Seal Saver button. To initiate a sequence

on units with the standard controller, press and hold

the Start button, then press the Stop button and

release both buttons. The Seal Saver cool-down

sequence begins if the process supply temperature is

above 90°F.

Pump Running Hour Display

The total accumulated pump running hours are

stored for maintenance purposes. See the Program

Menu section for instruction on how to display the

pump running hours. Running hours are in units of

hundreds so a display value of 10 means 1,000

hours. To reset the pump running hours, press the

Start and Alarm Reset buttons at the same time and

hold for 3 seconds.

10

SPI Communications (Optional)

Several members of SPI: The Plastics Industry Trade

Association defined a communications standard for

various pieces of plastic processing equipment to

communicate. They chose to adopt the Serial

Peripheral Interface bus (SPI bus), which coincidently

has the same abbreviation as the trade association.

To allow our unit to operate as a slave unit in a

plastic processing system using this protocol, we

offer an option that includes an expansion module

for the control board and a RS-485 communication

port on the unit. The communication hardware

firmware is SPI 3.01 standard compliant.

Units ordered with this option will have this feature

activated at the factory. Use the program menu

Communication Type function as shown in Table 5

to activate or deactivate this function. In addition,

activating the communication type, a baud rate, and

SPI address must be set. These are set using the

Communication Baud Rate and SPI Address function.

If multiple pieces of equipment are on the same

network, the base address of each machine has to be

unique.

Table 6 - SPI Option Parameters

Command

Poll

Select

Description

Echo

20 20

20 21

Controller integrity command used to accept and retain data and provide it in response to a

poll inquiry in an open 4-byte ASCII format with ASCII units.

Version

20 22

Controller version command used to provide a version number following format: AABB, where

AA=SPI assigned version level, BB=vendor assigned version level in an open 4-byte ASCII

format with ASCII units.

Set Point Process

Temperature

20 30

20 31

Target supply coolant temperature leaving the unit in a numeric format in °F.

Alarm, High Temperature

Deviation

20 32

20 33

Value in conjunction with the process set point that determines the high alarm temperature in

a numeric format in °F must always be positive.

Alarm, Low Temperature

Deviation

20 34

20 35

Value in conjunction with the process set point that determines the low alarm temperature in a

numeric format in °F must always be positive.

Status, Process

20 40

Process status in a 16-bit format as follows: 0=controlling, 1=an alarm is present, 2=an alarm

affecting the process has occurred (high or low temperature deviation), 3=an alarm affecting

the machine has occurred (probe fault or pump fault), 4=the controller has exceeded its over

set point deviation, 5=the controller has exceeded its below set point deviation.

Status, Machine 1

20 42

Machine status in a 16-bit format as follows: 0=controlling, 1=an alarm is present, 2=an alarm

affecting the process has occurred (high or low temperature deviation), 3=an alarm affecting

the machine operation has occurred (probe fault or pump fault), 4=the controller has

exceeded its over set point deviation, 5=the controller has exceeded its below set point

deviation.

Status, Machine 2

20 44

Machine status in a 16-bit format as follows: 0=controlling, 1=an alarm is present, 2=an alarm

affecting the process has occurred (high or low temperature deviation), 3=a sensor error has

been detected, 4=an alarm affecting the machine operation has occurred.

Mode, Machine

20 48

20 40

Machine mode is in two 8-bit bytes. When polling 20 48 bit 0 indicated the machine is off. 20

40 bit 0 commands the unit to be turned on or off (on when high or off when low). 20 40 bit 1

is used to recognized the alarm condition.

Temperature, To Process

(Supply)

20 70

Returns the process supply temperature in a numeric format in °F.

Temperature, To Process

(Return)

20 72

Returns the process return temperature in a numeric format in °F.

11

Modbus RTU (Optional)

The Modbus RTU option provides a RS-485 communications port for Modbus RTU communications. Note the

Modbus Parity = None, Stop Bits = 1, and default Baud Rate = 9,600.

Table 7 - ModBus Option Parameters

Register

Description

Read/Write

Format

Notes

4002

Machine State

R

Integer

0=Off, 1=Stop, 2=Run, 3=Run Fault 2, 4=Run

Fault 3, 5=Fault 1, 6=Factory Menu, 7=User

Menu, 8=Get User Password, 9=Master Reset

4007

Derivative

R/W

Integer

4008

Integral

R/W

Integer

4009

Heat Cycle Rate

R

4010

Cool Cycle Rate

R

4011

Low Alarm Delay

R

Integer

4012

High Alarm Delay

R

Integer

4013

Temperature Display Units

R

Integer

0 = °F, 1 = °C

4015

Brownout Enabled

R

Integer

0 = Disabled, 1 = Enabled

4017

Seal Saver Enabled

R

0 = Disabled, 1 = Enabled

4018

Remote Heat Cool Enabled

R

0 = Disabled, 1 = Enabled

4019

Mold Purge Enabled

R

0 = Disabled, 1 = Enabled

4020

Crash Cool Enabled

R

0 = Disabled, 1 = Enabled

4024

Remote Setpoint Enabled

R

Integer

0 = Disabled, 1 = Enabled

4025

Autostart Enabled

R

Integer

0 = Disabled, 1 = Enabled

4027

Communication BAUD Rate

R/W

Integer

0 = 1200, 1 = 2400, 2 = 4800, 3 = 9600

4028

MODBUS Identification

R/W

Integer

4030

SPI Communications Address

R/W

Integer

4038

PID OUT

R

-100 to 100 PID algorithm output

4039

MODBUS Command

R/W

Integer

0 = Do Nothing, 1 = Start, 2 = Stop

8002

Supply Fluid Temperature (°C)

R

Floating Point

Error Hi = 9.9E05, Error Low = -9.9E05

8004

Return Fluid Temperature (°C)

R

Floating Point

Error Hi = 9.9E05, Error Low = -9.9E05

8010

Low Temperature Deviation (°C)

R/W

Floating Point

8012

High Temperature Deviation (°C)

R/W

Floating Point

8014

Low Setpoint Limit Temperature (°C)

R

Floating Point

8016

High Setpoint Limit Temperature (°C)

R

Floating Point

8018

Supply Temperature Retransmit Range Low (°C)

R

Floating Point

8020

Supply Temperature Retransmit Range High (°C)

R

Floating Point

8022

Low Temperature Safety –User Set (°C)

R/W

Floating Point

8024

High Temperature Safety –User Set (°C)

R/W

Floating Point

8026

Proportional Band (°C)

R/W

Floating Point

8002

Supply Fluid Temperature (°C)

R

Floating Point

Error Hi = 9.9E05, Error Low = -9.9E05

8004

Return Fluid Temperature (°C)

R

Floating Point

Error Hi = 9.9E05, Error Low = -9.9E05

8010

Low Temperature Deviation (°C)

R/W

Floating Point

8012

High Temperature Deviation (°C)

R/W

Floating Point

8014

Low Setpoint Limit Temperature (°C)

R

Floating Point

12

Table 7 –Modbus Option Parameters

Register

Description

Read/Write

Format

Notes

8016

High Setpoint Limit Temperature (°C)

R

Floating Point

8018

Supply Temperature Retransmit Range Low (°C)

R

Floating Point

8020

Supply Temperature Retransmit Range High (°C)

R

Floating Point

8022

Low Temperature Safety –User Set (°C)

R/W

Floating Point

8024

High Temperature Safety –User Set (°C)

R/W

Floating Point

8026

Proportional Band (°C)

R/W

Floating Point

8052

Pump Running Hours

R

Floating Point

8054

Setpoint Temperature (°C)

R/W

Floating Point

8056

Low Temperature Safety –Factory Set (°C)

R

Floating Point

8058

High Temperature Safety –Factory Set (°C)

R

Floating Point

8070

Supply Temperature Input Offset

R

Floating Point

8072

Return Temperature Input Offset

R

Floating Point

8074

Remote Setpoint Temperature Input Offset

R

Floating Point

8080

Remote Setpoint Limit Temperature (°C)

R

Floating Point

8082

Remote Setpoint High Temperature Limit (°C)

R

Floating Point

Start-up

Every unit is factory set to deliver water in

accordance with the standard operating

specifications for that particular unit. Due to

variables involved with different applications and

different installations, minor adjustments may be

required during the initial start-up to ensure proper

operation. Use a qualified technician to perform the

start-up procedure in sequence. The following serves

as a checklist for the initial start-up and for

subsequent start-ups if the unit is out of service for a

prolonged time.

WARNING: This equipment contains hazardous

voltages that can cause severe injury or death.

WARNING: This equipment contains hot water or

coolant under pressure. Accidental release of hot water

or coolant under pressure can cause personal injury

and or property damage.

WARNING: This equipment may contain fan blades or

other sharp edges. Make sure all fan guards and other

protective shields are securely in place.

WARNING: The exposed surfaces of motors, piping,

and other fluid circuit components can be very hot

and can cause burns if touched with unprotected

hands.

CAUTION: Disconnect and lock out incoming power

before installing, servicing, or maintaining the

equipment. Connecting power to the main terminal

block energizes the entire electric circuitry of the unit.

Electric power at the main disconnect should be shut

off before opening access panels for repair or

maintenance.

CAUTION: Wear eye protection when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

CAUTION: Wear protective gloves when installing,

maintaining, or repairing the equipment to protect

against any sparks, debris, or fluid leaks.

CAUTION: Wire the unit ground in compliance with

local and national codes.

13

Step 1 –Connecting Main Power

Connect main power properly ensuring it matches

the voltage shown on the nameplate of the unit.

Check the electrical phase sequence prior to start-

up. Operation of the unit with incorrect electrical

phase sequencing will cause damage to

components. Check the phasing prior to applying

power. The proper sequence is “ABC.” If the phasing

is incorrect, open the main power disconnect and

switch two line leads on the main power terminal

blocks (or the unit mounted disconnect). All

electrical components are in-phase at the factory. Do

not interchange any load leads that are from the unit

contactors or the motor terminals. After making

proper power connection and grounding, turn the

main power on.

Step 2 –Fill Coolant Circuit

Check to make sure all piping connections are secure

and that all lines are suitable for water or the coolant

in the system at the maximum set point temperature

and cumulative pressure rating of the maximum

pump pressure and the unit fill fluid pressure.

NOTE: A cooling source inlet filter ships loose in the crate with the

unit. Install this in the inlet of the chilled water line before

connecting the cooling source line.

Make sure that the cooling source is the appropriate

temperature and pressure for your application. In

most cases, the cooling source is between 40°F and

85°F. The cooling source fluid pressure must be

above the set point of the pressure switch in order

for the unit to start. For most applications, the

design cooling source supply pressure is between 25

psi and 50 psi. Units with the 300°F operating range

option require an inlet cooling source pressure of 75

psi. If the total pressure in the unit (cooling source

inlet pressure plus the pump pressure) exceeds 150

psi, the pressure relief valve in the unit will open. If

this becomes an issue, install a pressure-regulating

valve (Part #9616548 available from our Parts

Department) on the supply line to help regulate the

pressure to ensure it does not exceed the pressure

rating of the pressure relief valve. For further

assistance in installing a pressure-regulating valve,

please contact our Customer Service Department.

System Fill Water Chemistry Requirements

The properties of water make it ideal for heat

transfer applications. It is safe, non-flammable, non-

poisonous, easy to handle, widely available, and

inexpensive in most industrialized areas.

When using water as a heat transfer fluid it is

important to keep it within certain chemistry limits to

avoid unwanted side effects. Water is a “universal

solvent” because it can dissolve many solid

substances and absorb gases. As a result, water can

cause the corrosion of metals used in a cooling

system. Often water is in an open system (exposed

to air) and when the water evaporates, the dissolved

minerals remain in the process fluid. When the

concentration exceeds the solubility of some

minerals, scale forms. The life giving properties of

water can also encourage biological growth that can

foul heat transfer surfaces.

To avoid the unwanted side effects associated with

water cooling, proper chemical treatment and

preventive maintenance is required for continuous

plant productivity.

Unwanted Side Effects of Improper Water Quality

•Corrosion

•Scale

•Fouling

•Biological Contamination

Cooling Water Chemistry Properties

•Electrical Conductivity

•pH

•Alkalinity

•Total Hardness

•Dissolved gases

The complex nature of water chemistry requires a

specialist to evaluate and implement appropriate

sensing, measurement and treatment needed for

satisfactory performance and life. The

recommendations of the specialist may include

filtration, monitoring, treatment and control devices.

With the ever-changing regulations on water usage

and treatment chemicals, the information is usually

up-to-date when a specialist in the industry is

involved. The table below shows the list of water

characteristics and quality limitations.

14

Table 8 - Fill Water Chemistry Requirements

Water Characteristic

Quality Limitation

Alkalinity (HCO3-)

70-300 ppm

Aluminum (Al)

Less than 0.2 ppm

Ammonium (NH3)

Less than 2 ppm

Chlorides (Cl-)

Less than 300 ppm

Electrical Conductivity

10-500µS/cm

Free (aggressive) Carbon Dioxide (CO2)†

Less than 5 ppm

Free Chlorine(Cl2)

Less than 1 PPM

HCO3-/SO42-

Greater than 1.0

Hydrogen Sulfide (H2S)

Less than 0.05 ppm

Iron (Fe)

Less than 0.2 ppm

Manganese (Mn)

Less than 0.1 ppm

Nitrate (NO3)

Less than 100 ppm

pH

7.5-9.0

Sulfate (SO42-)

Less than 70 ppm

Total Hardness (dH)k

4.0-8.5

† Dissolved carbon dioxide calculation is from the pH and total

alkalinity values shown below or measured on the site using a test

kit. Dissolved Carbon Dioxide, PPM = TA x 2[(6.3-pH)/0.3] where TA =

Total Alkalinity, PPM as CaCO3

Table 9 –Recommend Glycol Solutions

Chilled Water Temperature

Percent Glycol By Volume

50°F (10°C)

Not required

45°F (7.2°C)

5 %

40°F (4.4°C)

10 %

35°F (1.7°C)

15 %

30°F (-1.1°C)

20 %

25°F (-3.9°C)

25 %

20°F (-6.7°C)

30 %

CAUTION: When your application requires the use of

glycol, use industrial grade glycol specifically

designed for heat transfer systems and equipment.

Never use glycol designed for automotive

applications. Automotive glycols typically have

additives engineered to benefit the materials and

conditions found in an automotive engine; however,

these additives can gel and foul heat exchange

surfaces and result in loss of performance or even

failure of the chiller. In addition, these additives can

react with the materials of the pump shaft seals

resulting in leaks or premature pump failures.

WARNING: Ethylene Glycol is flammable at higher

temperatures in a vapor state. Carefully handle this

material and keep away from open flames or other

possible ignition sources.

Step 3 –Initial Unit Operation

Enter the set point temperature. Refer to the Control

Panel Operation section for further information.

Start the unit by pressing the Start button on the

control panel. Pressing the Start button enables the

microprocessor control functions, initiates a-vent

sequence, and turns on the Run indicating light

which is green when on.

The vent sequence removes air that may have

separated out from the water or been entrapped in

the water circuit for some reason. Air in the system

can lead to improper operation and premature

heater failure. When initiated, the vent sequence

opens the cooling valve for 30 seconds to allow air

to escape. This allows the majority of the air to

escape from the system. For further air purging, the

vent sequence energizes the pump for 30 seconds

while the cooling valve is open to remove any

remaining air from the system. While in the vent

sequence, the Pump and Cool lights will flash. Once

the vent sequence is complete, the cooling valve is

closed, the pump remains energized, and normal

operation initiates.

Check the rotation of the pump by visually

confirming the motor shaft rotation matches the

directional arrow sticker on the motor case. If the

pump is running backwards, switch two of the main

power leads, after shutting off the disconnect switch.

The unit is now ready for service.

15

Preventive Maintenance

Once the unit is in service, we suggest following the

maintenance procedures as closely as possible. The

importance of a properly established preventive

maintenance program cannot be overemphasized.

Taking the time to follow these simple procedures

will result in substantially reduced downtime,

reduced repair costs, and an extended useful lifetime

for the unit. The following is a list of suggested

periodic maintenance.

Once a Week

1. Check to make sure that the To Process

temperature is reasonably close to the Set Point

temperature. If the temperature stays more than

2°F away from the set point, there may be a

problem with the unit. If this is the case, refer to

the Troubleshooting section of this manual or

contact our Customer Service Department.

2. Check the pump discharge pressure. Investigate

further if the pressure starts to stray away from

the normal operating pressure.

3. Check the pump for leaks in the seal area.

Replace pump seal if necessary.

Once a Month

Repeat items 1 through 3 listed above and continue

with the following.

4. With the main power shut off, check the

condition of electrical connections at all

contactors, starters, and controls. Check for

loose or frayed wires.

5. Check the incoming voltage to make sure it is

within 10% of the design voltage for the

temperature control unit.

6. Check the amp draws to each leg of the pump

motor and heater to confirm that they are

drawing the proper current.

16

Troubleshooting

Problem

Possible Cause

Remedy

Alternating

overheating and

overcooling or

rapid cycling from

heat to cool

Poor water flow

Check connectors and increase size if necessary. If there are

a large number of hoses and/or they are long, try to

shorten hose runs and use as large of a hose as possible to

minimize water-circuit pressure drop. If quick disconnects

with check valves are used, remove the check valves to

reduce pressure drop through water circuit.

Poor connection or failure of RTD

Check connection, replace if necessary

Failure of the microprocessor

Replace controller

Unable to heat

properly

Cooling valve is stuck in the open position

Flush out the cooling valve by adjusting the Set Point up

and down several times to open and close the cooling

valve. If this does not work, stop the unit and turn off the

electric power, shut off the cooling source, and take the

valve apart for cleaning or replacement.

Leaking connection and/or the manual pressure relief valve

is in an open condition

Check for leaks and replace any faulty valves

Immersion heater is inoperative

Have a qualified electrician check to see if the heater and/or

heater contactor are functioning correctly and replace any

defective components.

Microprocessor controller failure

Replace controller

Failure of RTD

Replace RTD

Unable to cool

properly

Cooling water supply is not sufficient

Check to make sure the cooling water supply is of sufficient

temperature, volume, and pressure for the unit.

Drain (cooling water return line) is not sufficient

Check the drain (cooling water return line) to ensure there

is no restriction preventing water flow to the drain (cooling

water return line).

Cooling valve is inoperative

Check the drain (cooling water return line) and see if you

can feel or hear a change in the flow as the cooling valve

open and closes. If you cannot hear or feel the flow, it is

likely the valve has failed. Replace valve if necessary.

Plugged heat exchanger (only on models with heat

exchanger option)

Clean or replace heat exchanger

High backpressure in the cooling water system

Reduce backpressure

Heater failure

Unit not filled with water

Fill unit with water

Faulty heater

Replace heater

Plugged heater tube / flow restriction

Clear obstruction

Pressure relief

valve leaks

The combined pressure of the incoming cooling water

pressure and the unit pump pressure exceeds the pressure

rating of the pressure relief valve

Install a pressure-reducing valve on the incoming cooling

water line. Review the start-up procedure for cooling water

pressure requirements at various operating temperatures.

Pressure relief valve stuck in open position

Replace valve

Drawings

We have prepared a custom set of drawings for your unit and placed them on top of the unit prior to shipment.

Please refer to these drawings when troubleshooting, servicing, and installing the unit. If you cannot find these

drawings or wish to have additional copies, please contact our Customer Service Department and reference the

serial number of your unit.

Other manuals for Aquatherm RQE

1

Table of contents

Other Thermal Care Temperature Controllers manuals

Thermal Care

Thermal Care Aquatherm RQT Premium Instruction Manual

Thermal Care

Thermal Care Aquatherm RQE Instruction Manual

Thermal Care

Thermal Care Vactherm RV Instruction Manual

Thermal Care

Thermal Care Aquatherm RQT Standard Instruction Manual

Thermal Care

Thermal Care RA Series User manual

Thermal Care

Thermal Care Oiltherm RO Instruction Manual

Thermal Care

Thermal Care Aquatherm RQT Advanced Instruction Manual