Installation I 3-3

3

Installation

Preparing for Installation

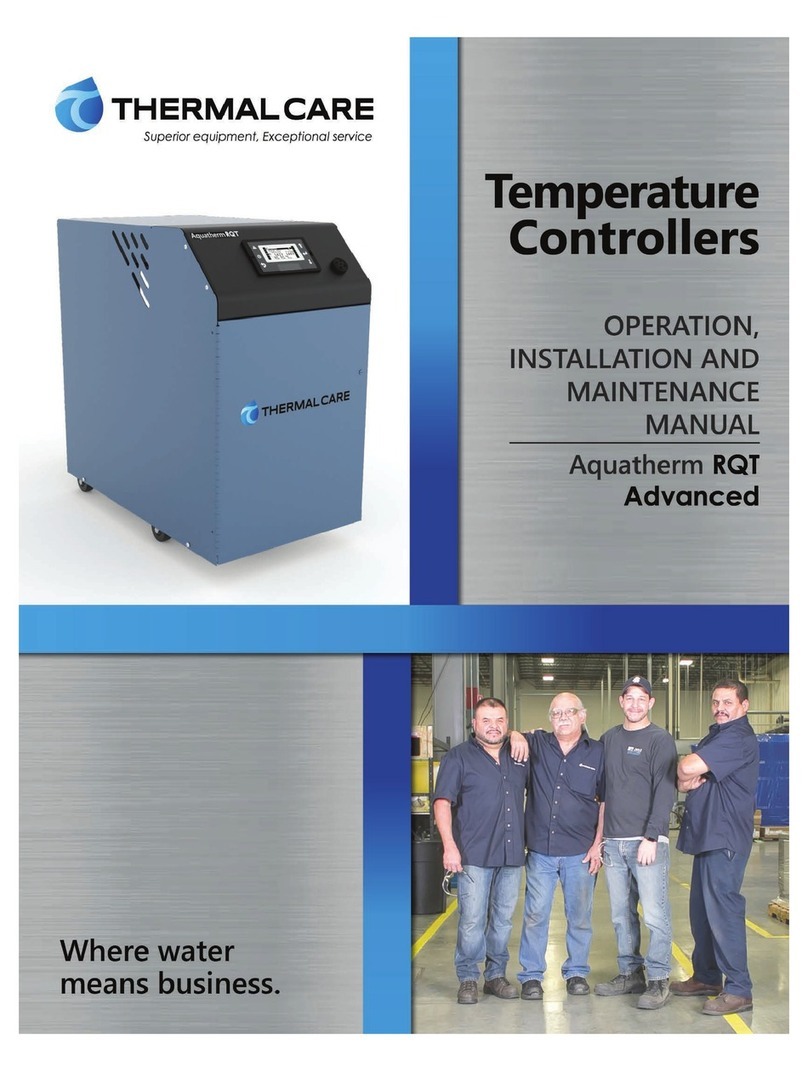

The RQT Standard is easy to install, if you plan the location and prepare the area

properly.

WARNING: Improper installation, operation, or servicing may result in equipment

damage or personal injury.

This equipment should only be installed, adjusted, and serviced by qualied technical

personnel who are familiar with the construction, operation, and potential hazards of

this type of machine.

All wiring, disconnects, and fuses should be installed by qualied electrical technicians

in accordance with electrical codes in your region. Always maintain a safe ground. Do

not operate the equipment at power levels other than what is specied on the machine

serial tag and data plate.

1 Position the RQT Standard as close to the process machine as possible.

2 Make sure the installation area provides:

UA three-phase power source supplying the correct cur-

rent for your RQT Standard model. Check the serial tag

on the unit for required voltage, phase, frequency, and full

load amps. Check the electrical prints for the disconnect

fuse size and minimum wire connection size. All wiring

should be completed by qualied personnel and should

comply with your region’s electrical codes.

UCompressed, dry air (<100psi) if your RQT Standard is equipped with the Mold

Purge option.

UA clean, well-ventilated environment. The room temperature should not exceed

104° F {40° C} with 95% non-condensing humidity and should not fall below

32° F {0° C}.

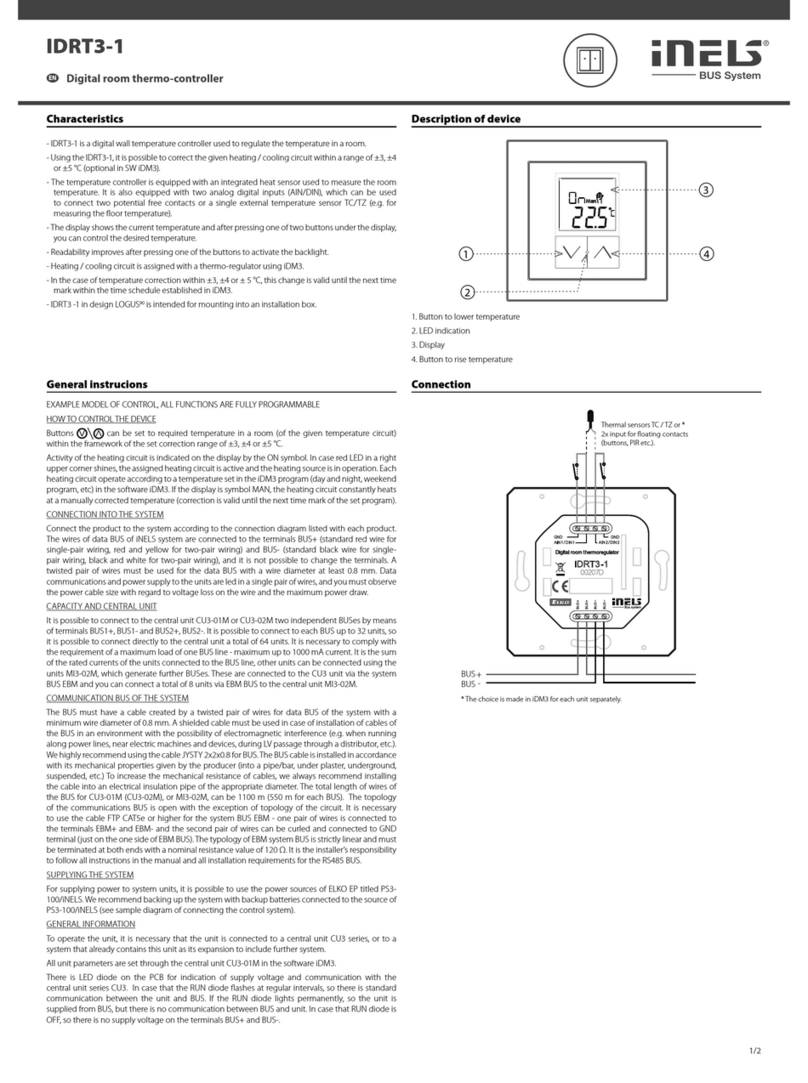

UMinimum clearance for safe operation and maintenance. The diagram at

the right shows minimum clearance for operation. You also need enough

clearance in rear for water hookups. For maintenance, you should move

the RQT Standard to provide at least 36 inches {91 cm} on any side of the

RQT Standard. Additionally, your required electrical codes may require a larger

service area in front of the electrical panel.

UA source of water for cooling. City, tower or chiller water may be used, as long

as the supply pressure is at least 25 psi and not more than 90 psi for 2 HP models

(95 psi for 3/4 HP models).

UCheck to make sure all piping connections are secure and that all lines are

suitable for water or the coolant in the system at the maximum setpoint tem-

perature and cumulative pressure rating of the maximum pump pressure and the

cooling water supply pressure, or the nameplate rating of the pressure relief valve

(150psi), whichever is greater.

UA location to mount an external three-phased, fused, and grounded electrical

disconnect.

ULockable isolation devices for all utilities, including electrical disconnect, cool-

ing water line valves, and compressed air supply disconnect and bleed-o.

RQT

Process

Machine

Alternate

locations

LowProcess

STOPPED

Setpoint

200°F

InletPres

To

Process

198°F

RUN MP

12 inches

{305 mm}

12 inches

{305 mm}

20 inches

{508 mm}

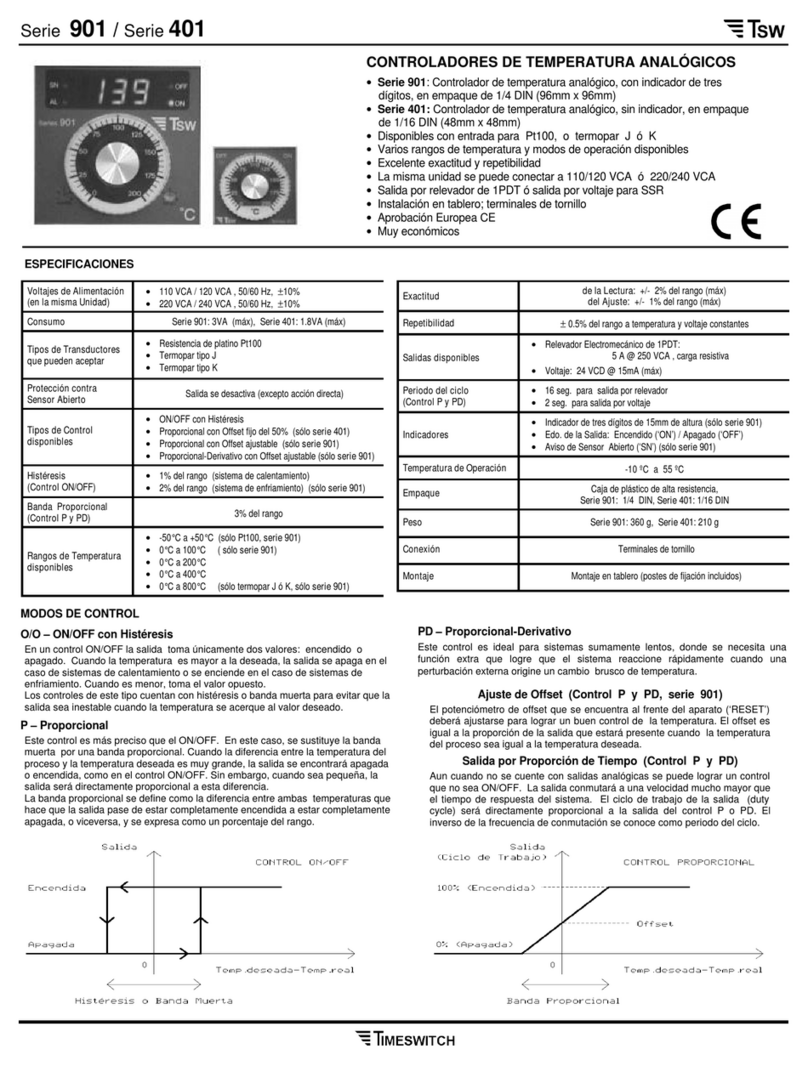

Pump HP Max Cooling

(PSI)

3/4 95

1 90

2 90

3 85

5 75

7.5 65

10 50

NOTE: If your cooling water

pressure exceeds the cooling water

pressure chart referenced previously,

install a pressure-regulating valve

before the cooling inlet.