thermastor 4025200 User manual

Owner’s Manual — Phoenix Axial Air Mover

Installation, Operation & Service Instructions

1

Toll-Free 1-800-533-7533

Read and Save These Instructions

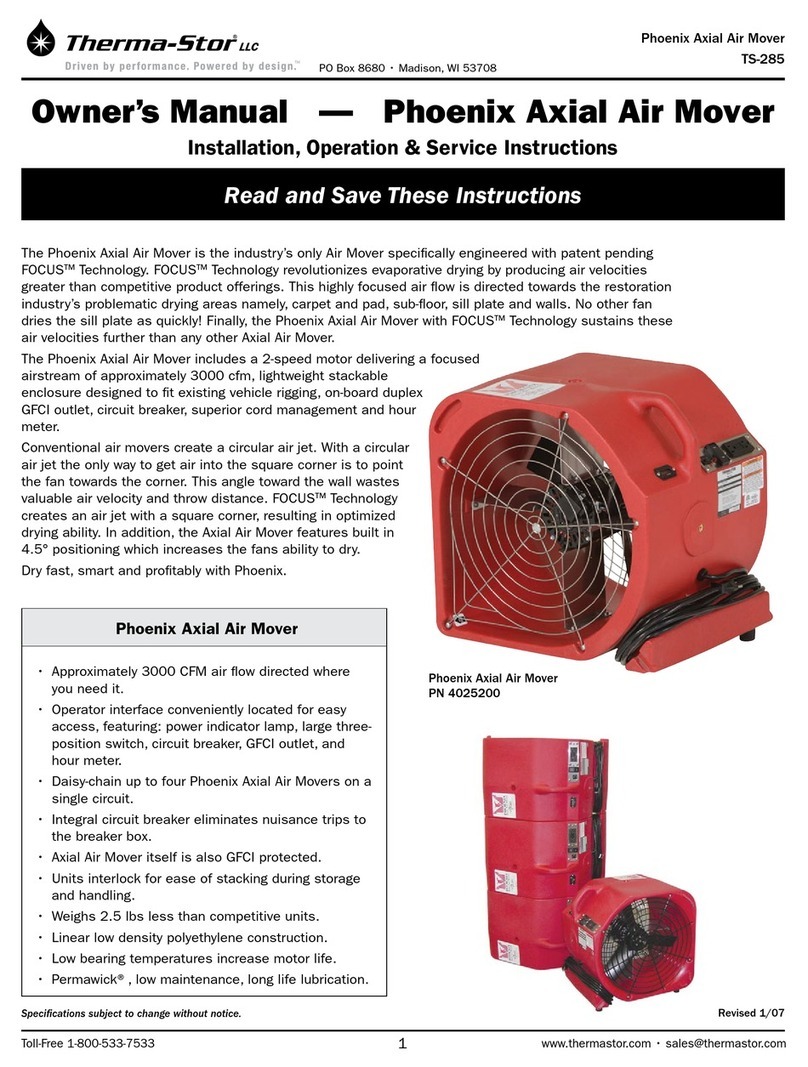

The Phoenix Axial Air Mover is the industry’s only Air Mover specifically engineered with patent pending

FOCUSTM Technology. FOCUSTM Technology revolutionizes evaporative drying by producing air velocities greater

than competitive product offerings. This highly focused air flow is directed towards the restoration industry’s

problematic drying areas namely, carpet and pad, sub-floor, sill plate and walls. No other fan dries the sill

plate as quickly! Finally, the Phoenix Axial Air Mover with FOCUSTM Technology sustains these air velocities

further than any other Axial Air Mover.

The Phoenix Axial Air Mover includes a 2-speed motor delivering

a focused airstream of approximately 3000 cfm, lightweight

stackable enclosure designed to fit existing vehicle rigging,

on-board duplex GFCI outlet, circuit breaker, superior cord

management and hour meter.

Conventional air movers create a circular air jet. With a circular

air jet the only way to get air into the square corner is to point

the fan towards the corner. This angle toward the wall wastes

valuable air velocity and throw distance. FOCUSTM Technology

creates an air jet with a square corner, resulting in optimized

drying ability. In addition, the Axial Air Mover features built in

4.5° positioning which increases the fans ability to dry.

Dry fast, smart and profitably with Phoenix.

Phoenix Axial Air Mover

• Approximately 3000 CFM air flow directed where you

need it.

• Operator interface conveniently located for easy

access, featuring: power indicator lamp, large three-

position switch, circuit breaker, GFCI outlet, and hour

meter.

• Daisy-chain up to four Phoenix Axial Air Movers on a

single circuit.

• Integral circuit breaker eliminates nuisance trips to

the breaker box.

• Axial Air Mover itself is also GFCI protected.

• Units interlock for ease of stacking during storage

and handling.

• Weighs 2.5 lbs less than competitive units.

• Linear low density polyethylene construction.

• Low bearing temperatures increase motor life.

Specifications subject to change without notice.

4201 Lien Rd • Madison, WI 53704

TS-947

09/17 Rev. B

Patent: 7,331,759

Phoenix Axial Air Mover

PN 4025200 (Red)

4030680 (Blue)

Phoenix now offers

this unit in both

Red and Blue

2

1 Safety Information

• Do not operate the unit with a cut or frayed power cord.

Replace cord if it becomes damaged.

• Do not unplug the unit by pulling on the cord. Grasp the

plug firmly and pull it out of the wall socket or power

receptacle.

• Always use a grounded outlet.

• Never operate electrical equipment in standing water.

• Never operate with the safety grills removed. Personal

injury may result.

• Do not stick your fingers or other objects through the

safety grills.

• Do not restrict airflow to the unit. This may cause the unit

to overheat.

• Unit should never be serviced or cleaned while it is

plugged in.

• Do not plug more than 9.0 amps total into the GFCI

outlet.

• Do not sit or stand on the unit or use as a shelf or table.

• Check GFCI protection before each use by pushing “test”

button. If operating properly, “reset” button will pop out.

• Before leaving an Axial Air Mover unattended, ensure

children do not have access to the equipment. Do not

allow children to play with or near the unit or in its air

flow.

• To reduce the risk of fire or electric shock, do not use this

air mover with any solid-state speed control device.

• Do not route cord under furniture or appliances.

LIRE ET CONSERVER CES INSTRUCTIONS

• Risque de choc électrique Peut causer des blessures ou

la mort. Débrancher toutes les alimentations en courant

électrique à distance avant l’entretien ou le nettoyage.

• Ne pas utiliser l’appareil avec un cordon d’alimentation

coupé ou effiloché.

• Ne pas débrancher l’appareil en tirant sur le cordon. Tenir

la fiche fermement et la tirer hors de la prise murale ou la

prise d’alimentation électrique.

• Toujours utiliser une prise mise à la terre.

• Ne jamais utiliser l’équipement électrique dans de l’eau

stagnante.

• Ne jamais utiliser sans les grilles de protection. Des

blessures risquent d’en résulter.

• Ne pas passer les doigts ou d’autres objets dans les

grilles de protection.

• Ne pas diminuer le débit d’air arrivant jusqu’à l’appareil.

L’appareil risque de trop chauffer.

• Ne pas brancher plus de 9 ampères au total au

différentiel.

• Ne pas s’asseoir ou se tenir debout sur l’appareil; ne pas

l’utiliser comme étagère ou table.

• Vérifier la protection du différentiel avant chaque

utilisation en appuyant sur le bouton “ test “. Si l’appareil

Table of Contents

Introduction ...............................................................1

FOCUSTM Technology Features and Benets ....................1

1. Safety Information.................................................2

2. Intended Application..............................................3

3. Safety Certications...............................................3

4. Specications........................................................3

5. Power Requirements..............................................3

5.1 Daisy-Chaining.................................................3

5.2 Recommended Use..........................................3

5.3 Integrated Cord Wrap .......................................4

6. Applications..........................................................4

6.2 Placement ......................................................4

6.3 Orientation of Directional Drying ........................4

7. Operating Instructions............................................5

8. Operator Panel Features.........................................5

8.1 Run-Time Hour Meter .......................................5

8.2 12 Amp Circuit Breaker ....................................5

8.3 Power Indication Lamp .....................................6

8.4 3-Position Drying Selector Switch ......................6

8.5 GFCI Protection ...............................................6

9. Maintenance.........................................................6

9.1 Servicing.........................................................6

9.2 Cleaning .........................................................6

10. Replacement Parts and Optional Accessories ...........7

11. Wiring Diagram .....................................................7

12. Warranty ..............................................................9

Serial No. ___________________________

Purchase Date ______/______/_____

Dealer’s Name ___________________________________

3

fonctionne correctement, le bouton “ reset “ ressort.

• Avant de laisser un appareil aéraulique axial sans

surveillance, s’assurer que les enfants n’ont pas accès

à l’équipement. Ne pas laisser les enfants jouer avec

l’appareil ou à proximité de l’appareil ou dans l’air qu’il

projette.

• Pour réduire le risque d’incendie ou de choc électrique,

ne pas utiliser ce ventilateur avec un dispositif de

commande de vitesse à semi-conducteurs.

2 Intended Application

The Phoenix Axial Air Mover has changed the drying industry

by minimizing overall drying time on water restoration jobs.

The Phoenix Axial Air Mover uses patent pending FOCUS

Technology to maximize air velocity across floors and along

walls for longer distances. By maximizing the air velocity,

water evaporates more quickly from the carpet, pad, sub-

floor, wall, and sill plate.

3 Safety Certifications

The Phoenix Axial Air Mover (P/N 4025200) conforms to UL

STD 507. Certified to CAN/CSA STD C22.2 No. 113.

4 Specifications

Part No. 4025200 (Red)

4030680 (Blue)

Power 1/4 hp 1-phase 110/120 VAC 2-speed

4-pole, PSC Electric Motor.

CFM Approximately 3000

Cord 20 ft Power Cord

Outlet 15A UL Rated GFCI Duplex Receptacle

Current Draw 2.5 Amps

Voltage 115 VAC

Warranty Year One - 100% parts and labor

(all components)

Year Two - 100% parts only (all components)

Years Three through Seven - Only materials

and workmanship of the housing are covered.

Dimensions

Cabinet

Width 19.9”

Height 19.5”

Depth 15.2”

Weight 29.5 Lbs

5 Power Requirements

5.1 Daisy Chaining

The Phoenix Axial Air Mover draws 2.5 amps. The 12 amp,

on-board circuit breaker will allow four (4) Phoenix Axial Air

Movers on one circuit. When daisy-chaining the Phoenix

Axial Air Mover, turn on one Phoenix Axial Air Mover at a

time to prevent excessive current inrush caused by four units

starting at once.

A ground fault in the Phoenix Axial Air Mover or anywhere on

the circuit will cause the Axial Air Mover’S GFCI to trip. After

rectifying the ground fault, reset the GFCI by pressing the

reset button.

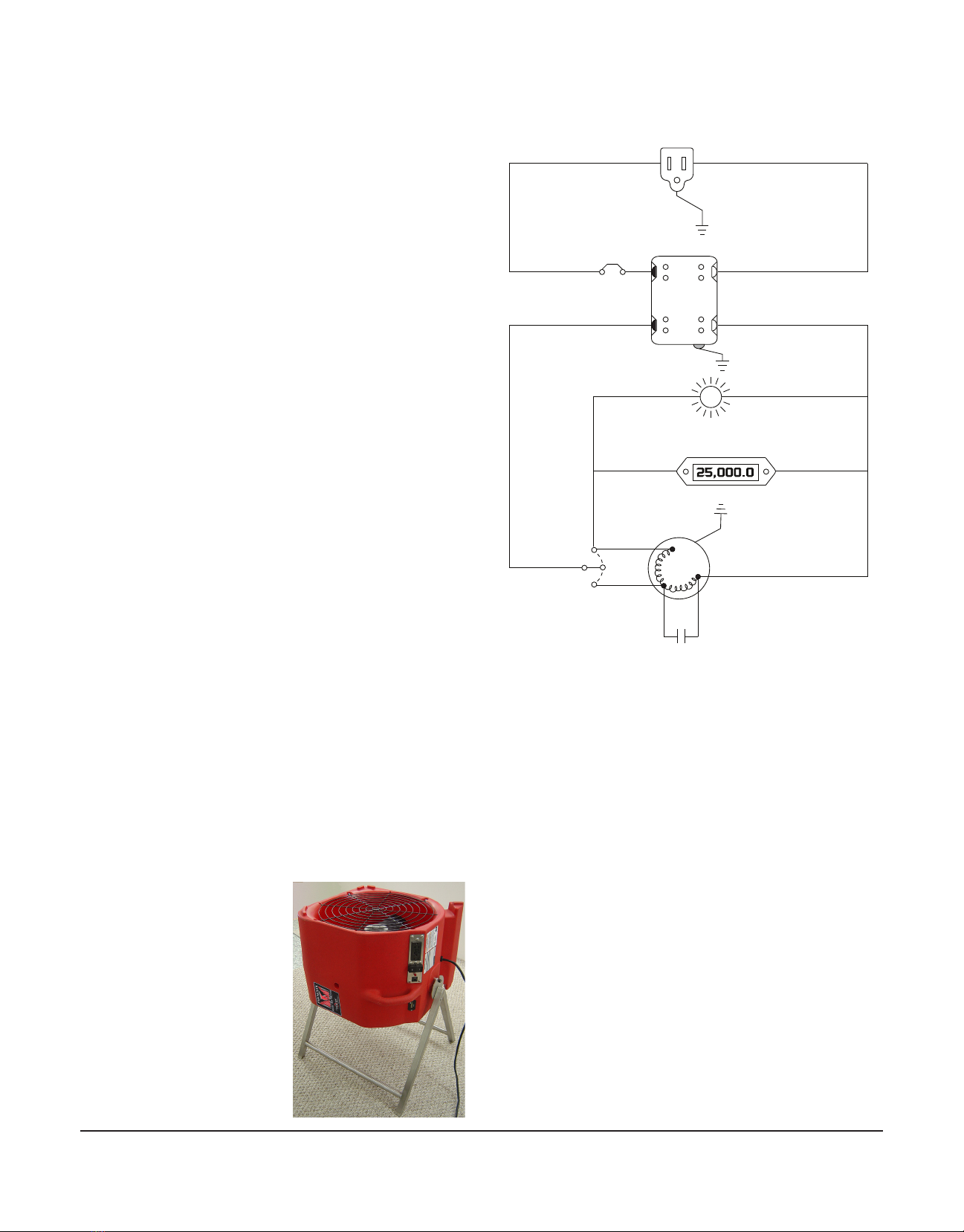

Figure 1: Too many Axial Air Movers daisy-chained

Figure 2: Duplex GFCI use

5

15 Amp

Outlet

15 Amp

Outlet

15 Amp

Outlet

Phoenix 200 MAX

Phoenix Mini-Guardian

5.2 Recommended Use

Recommended use(s) of on-board duplex GFCI are shown.

Note: Standard 115 VAC electrical outlets.

4

5.3 Integrated Cord Wrap

The Phoenix Axial Air Mover features integrated cord

management. Wrap the cord around the cord wrap as shown

and secure the cord with the clasp on the plug.

the FOCUS Technology corner.

The Axial Air Mover sustains this

air flow for more than 20 feet

and maximizes the air velocity

across the floor and along the

wall when placed the at 4.5°

angle from the wall.

By touching the front edge of the

output side of the axial air mover

against the wall and rotating the

rest of the unit against the wall,

the restoration professional will

place the axial air mover at 4.5°

due to the housing’s built-in

design. Industry experts agree

placing Axial Air Movers 45°

angle to the wall wastes air flow

and reduces the performance by

forcing air up the wall.

The best set up angle for quickly and completely drying the

sill plate is 4.5°. Set-up angles greater than 4.5° may be

used under unique circumstances such as corner air flow

and structure variations. Set-up angle should never exceed

23°.

6.3 Orienting of Directional Drying System

The axial air mover dries in counter-clockwise and clockwise

directions for optimum ease of use. The axial air mover ships

with rubber feet on one side of the unit for counter-clockwise

drying.

When the water restoration professional needs to employ

clockwise drying (such as the need to dry a door jamb),

simply rotate the axial air mover 90° so the FOCUS

Technology corner points toward the door jamb and floor for

the clockwise drying.

2500

2000

1500

1000

500

0

0 Feet 5 10 15 20 25

Air Velocity (fpm)

Immediate high velocity air ow at

the outlet of the fan.

Figure 5: 4.5° to wall

as shown

Figure 6: Placement for counter-clockwise drying

Figure 3: Cord wrap

6 Applications

6.1 Sizing for Water Restoration Jobs

Current industry standards call for one air mover per 10-16

linear feet of wall space, dependent upon the Class of water

damage. For commercial structures, the industry standard

calls for one air mover for every 50-60 square feet.

The water restoration industry based these estimates on the

air mover technology available when writing the standards.

Following these equipment-sizing standards when using the

Phoenix Axial Air Mover will result in dramatically faster dry-

ing times. If the restoration professional desires to merely

achieve industry standard drying times, he can use fewer

Phoenix Axial Air Movers than standard equipment standards

allow.

6.2 Placement

Current industry guidelines suggest placing air movers at a

15° - 45° angle to wall. These guidelines apply to air movers

without FOCUS Technology. FOCUS Technology allows the

restoration professional to place the Phoenix Axial Air Mover

at an angle nearly parallel to the wall.

The test graph shown below depicts immediate air flow at

Figure 4: Airow of the Phoenix Axial Air Mover measured 3.5”

parallel to wall.

5

Figure 7: Birds eye view of room set-up

Figure 9: Axial Air Mover Operator Panel

If the water restoration professional dries in the clockwise

direction often, we suggest attaching the two (factory

provided) rubber feet into the threaded holes on the side

of the unit. By attaching the rubber feet and creating the

optimal downward angle of 4.5°, the Phoenix Axial Air Mover

will maximize air velocity across the floor and wall when

drying in the clockwise direction.

7 Operating Instructions

The Phoenix Axial Air Mover as packaged is ready to be put

into service. Inspect the unit completely for any shipping

damage. Place the unit on the ground. Check the GFCI to

ensure it is not tripped. Orient the unit so the desired air

flow direction is the same as the arrow indicator sticker in

the FOCUS Technology corner on the interior of the unit.

Plug the unit into a grounded outlet and select the drying

mode shown in Figure 9.

CAUTION: The Phoenix Axial Air Mover consumes 2.5 Amps.

Do not plug devices requiring more than 9.0 Amps of

current into the duplex outlet.

8 Operator Panel Features

8.1 Run-Time Hour Meter

The operator interface panel is equipped with an Automatic

LCD (Liquid Crystal Display) Hour meter. This hour meter

displays cumulative run time. The hour meter meets IP65

for moisture and dust protection and is designed to survive

harsh restoration and water recovery applications. The hour

meter features non-volatile eeProm memory. This type of

memory cannot be erased, nor reset. This feature ensures

accurate time tracking.

The display can be used to track time-of-operation and time-

to-dry. Some restoration professionals use the hour meters

to help them establish hourly billables.

8.2 12 Amp Resettable Circuit Breaker

The 12 AMP thermal response resettable circuit breaker

protects the unit and devices connected to its duplex GFCI

outlet.

The circuit breaker is designed to sense the total current

draw through the circuit. The circuit breaker “trips” when

more than 12 amps of electrical current are drawn through

Counter

clockwise

airflow

pattern

Clockwise

airflow

pattern

Making use of factory installed feet (4) Making use of user installed feet (2)

Figure 8: Clockwise feet locations

User installed feet

for use during

clockwise drying

set-ups

Factory installed feet for use

during counter clockwise drying

12 Amp

Circuit Breaker

High Speed: “Ultra”

Drying Power

Low Speed:

Quiet Operation

GFCI: Added Protection

Stainless Steel

Control Panel

6

the device’s power cord. Should an over-current condition

occur, the Axial Air Movers’ on-board circuit breaker prevents

nuisance visits to a remote power junction box.

IMPORTANT: Total amperage of the Axial Air Mover plus all

devices plugged into the receptacle must not exceed 12

amps. The circuit breaker will not allow for loads in excess

of 12 amps, although there is a time delay before the

overloaded circuit is broken.

8.3 Power Indication Lamp

The red, sealed, high intensity AC voltage power indication

lamp allows operators to visually identify the operation

status of several Phoenix Axial Air Movers at a distance,

with a single glance. The power indication lamp will remain

lit when the AC power cord is plugged into a standard

“powered” AC power outlet and the 3-position drying

selector switch is in either the HIGH or LOW operation

position. The power indication lamp will remain unlit when

the AC power cord is unplugged, the 3-position drying

selector switch in the OFF position, the on-board GFCI or 12

Amp circuit breaker is tripped, or the connected, standard

AC wall outlet power has been turned off.

8.4 3-Position Drying Selector Switch

The 3-position drying mode selector switch. This switch

is used to select the Phoenix Axial Air Mover’s mode of

operation. The 3 modes of operation are OFF, LOW or HIGH.

IMPORTANT: When the Phoenix Axial Air Mover is plugged

into a standard “powered” wall outlet the Phoenix Axial Air

Mover’s duplex outlets are electrically “HOT” and AC voltage

is present.

OFF - The Phoenix Axial Air Mover is not drying. The power

indication lamp is unlit. If the unit is plugged into a standard

“powered” wall outlet all devices connected to the unit’s

duplex GFCI outlet receive AC voltage.

LOW - The Phoenix Axial Air Mover is in “Normal” Drying

mode. This mode provides rapid drying and very quiet

operation. The power indication lamp will be lit. All devices

connected to the devices duplex GFCI outlet will receive AC

voltage.

HIGH - The Phoenix Axial Air Mover is in “Fast” drying mode.

This mode provides the industries most rapid drying while

maintaining low noise operation. The power indication lamp

will be lit. All devices connected to the devices duplex GFCI

outlet will receive AC voltage.

8.5 GFCI Protection and the On-Board Duplex

VAC Outlet

The standard AC voltage outlet GFCI (Ground Fault Circuit

Interrupter) protection promotes operator safety in wet

applications. GFCI devices trip when a fault to electrical

“ground” is sensed.

It is recommended to check the GFCI protection prior to

operation. To check, push the “TEST” button located on

the GFCI duplex outlet. If operating properly the “RESET”

button on the GFCI outlet will pop out. Depending on your

Axial Air Movers specific equipment, a tripped GFCI may be

indicated by a small LED. The device can only be “RESET”

when the Axial Air Mover is connected to a wall outlet

providing standard voltage. This duplex AC outlet allows the

inter-connection of other AC powered devices. The sum total

amperage of all devices plugged into the receptacle must

not exceed 9 amps.

9 Maintenance

WARNING: Disconnect the unit from power before servicing

or cleaning. Replace the wire safety grill after

servicing or cleaning.

9.1 Servicing

Before each use inspect for damage, blocked inlet or outlet,

or any excess buildup of foreign material.

Inspect the GFCI to ensure it is not in a “tripped” condition.

Push “RESET” to reset the GFCI.

When the Phoenix Axial Air Mover is first turned on, check

for excessive vibration. If the unit vibrates excessively or if

blade rubs on housing, turn off the unit immediately. Have a

service technician inspect the unit to locate the problem.

9.2 Cleaning

The housing is made of a durable and washable

polyethylene. When cleaning, the use of solvents is NOT

recommended.

When washing inside the unit, disconnect the unit from its

power source. Protect the operator interface panel with a

cloth. Clean inner barrel, grills and blade. Wipe down motor

exterior with a damp cloth. If the motor gets wet during

cleaning, simply allow ample time for motor to dry out

completely before restarting.

If you wash the Axial Air Mover and do not plan to use it

within 24 hours, allow the fan to drip dry for 10 minutes and

then let run for 5 minutes.

7

10 Replacement Parts and

Optional Accessories

Contact the factory at 1-800-533-7533 to order

replacement parts, or optional accessories

4035752 Breaker, CKT, 12A

4025204 Switch, Rocker, On-Off-On

4036225 Outlet, Duplex, GFCI, 15A

4025320 Grill, Safety, Intake

4025321 Grill, Safety, Exhaust

4025460 Axial Air Mover Stand

4025299 Stand Hardware Kit

4036823 Motor

4025095 Blade

4028795 Hour Meter

Figure 11: Optional stand

allows the Axial Air Mover’s

air ow to be directed in a

360° range of movement.

(PN 4025460)

11 Wiring Diagram

Specifications subject to change without notice.

HOT

NEUTRAL

LOAD

LINE

DUPLEX

GFCI

HOUR METER

BLOWER

CAPACITOR

NEON LAMP

LOW (1)

HIGH (3)

(2) OFF

12 AMP

CIRCUIT

BREAKER

BLK

BLK

VIO BLU

BLUYEL

YEL

BRN

RED

GRY

BLK

BLU

WHT

BLU

9

Phoenix Axial Air Mover Limited Warranty

Warrantor:

Therma-Stor LLC

4201 Lien Rd

Madison, WI 53704

Telephone: 1-800-533-7533

Who Is Covered: This warranty covers Phoenix Axial Air Movers.

First Year Warranty: 100% parts and labor (all components)

Second Year Warranty: 100% parts only (all components)

Years Three through Seven: Only materials and workmanship of the housing are covered.

If a defect in materials or workmanship occurs within the warranty period, Therma-Stor LLC will

repair or replace the defect.

End-User Responsibilities: Warranty service must be performed by a servicer authorized by Therma-

Stor Products. To obtain warranty service you must obtain a return material authorization (RMA). To

obtain an RMA you must present proof of purchase or (lease), by use of a warranty card, original

sales receipt or other reasonable and reliable means.

To obtain an RMA call Therma-Stor LLC at the above number and ask for the Therma-Stor LLC

Service Department, which will then issue an RMA# and arrange for, at our option, either repair or

replacement.

Freight: Freight to and from the servicer is the responsibility of the end-user. The end-user is

responsible for normal care and proper return packaging.

Limitations and Exclusions: This warranty does not cover any defect, malfunction, etc. resulting

from misuse, abuse, lack of normal care, corrosion, freezing, tampering, modification, unauthorized

or improper repair or installation, accident, acts of nature or any other cause beyond Therma-Stor

LLC’s reasonable control.

If any Phoenix Axial Air Mover part is repaired or replaced, the new part shall be warranted for the

balance of original warranty (but all warranty periods will be extended by the period of time, if any,

that the Phoenix Axial Air Mover with FOCUS Technology is out of service while awaiting covered

warranty service).

Warranty service will be performed during normal working hours.

UPON THE EXPIRATION OF THE WRITTEN WARRANTY APPLICABLE TO THE PHOENIX AXIAL

AIR MOVER OR ANY PART THEREOF, ALL OTHER WARRANTIES IMPLIED BY LAW, INCLUDING

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL ALSO EXPIRE. ALL

WARRANTIES MADE BY THERMA-STOR LLC ARE SET FORTH HEREIN, AND NO CLAIM MAY BE

MADE AGAINST THERMA-STOR BASED ON ANY ORAL WARRANTY. IN NO EVENT SHALL THERMA-

STOR LLC, IN CONNECTION WITH THE SALE, INSTALLATION, USE, REPAIR OR REPLACEMENT OF

ANY PHOENIX AXIAL AIR MOVER OR PART THEREOF BE LIABLE UNDER ANY LEGAL THEORY FOR

ANY SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES INCLUDING WITHOUT LIMITATION WATER

DAMAGE (THE END USER SHOULD TAKE PRECAUTIONS AGAINST SAME), LOST PROFITS, DELAY, OR

LOSS OF USE OR DAMAGE TO ANY REAL OR PERSONAL PROPERTY.

Some states do not allow limitations on how long an implied warranty lasts, and some do not

allow the exclusion or limitation of incidental or consequential damages, so one or both of these

limitations may not apply to you.

Legal Rights: This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

This manual suits for next models

2

Table of contents

Other thermastor Fan manuals

thermastor

thermastor Ultra-Aire 120V User manual

thermastor

thermastor Phoenix AirMax User manual

thermastor

thermastor Phoenix TS-285 Operation manual

thermastor

thermastor Phoenix Operation manual

thermastor

thermastor Quiet-Vent Ventilation System User manual

thermastor

thermastor Phoenix AirMAX User manual