THERMEAU S65 User manual

OWNER’S Manual

PRINTED IN CANADA

2OWNER’S MANUAL

Introduction 3

General Safety Instructions 5

Thermeau Models’ Specifications 7

Installation Instructions

Location 9

Water piping 10

Multiple Heat Pump Connections 11

Electrical 12

Bonding 12

Bonding and plumbing step-by-step instructions 12

Electrical Connections 13

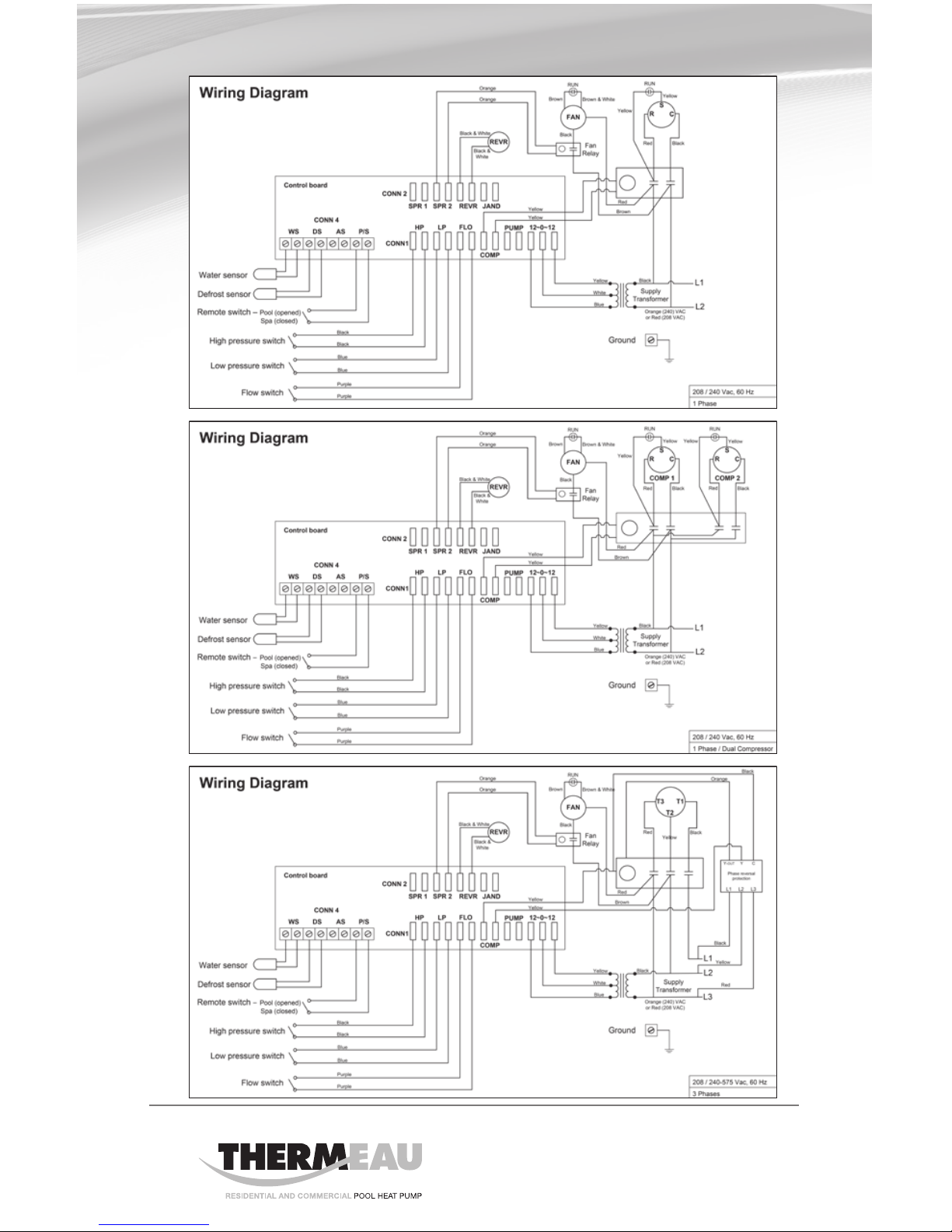

Electrical Diagrams 14

Service Analyzer Control 15

Electronic Temp. Controls 16

Initial Startup 18

Meaning of Display Codes 19

Troubleshooting 20

Requesting Assistance or Service 22

Maintenance 22

Winterizing 22

Pool Heat Pump Warranty 23

Table of contents

3

OWNER’S MANUAL

Thank you for buying

an THERMEAU pool heat pump.

The THERMEAU pool heat pump is a self-contained unit designed specifically

for pool heating. Each component has been selected with care to achieve a

high-quality product in an effort to exceed all industry standards.

All THERMEAU pool heat pumps have a Scrollcompressor, an electronic board

with service analyzer, a titanium heat exchanger tube warranted for 10 years

against corrosion. All components are of superior quality, which presents you

with an effective, state-of-the-art technology heat pump.

In general, compared to other types of pool heaters, such as gas or oil-

fired, the THERMEAU pool heat pump has a lower heating capacity on a

BTU/hr basis. Therefore, it needs to operate for a longer time to accomplish

the desired results. Occasionally, it may be necessary to run the heat pump for

up to 24 hours per day. However, this should not be of concern to the owner

because the heater is designed to operate continuously. What’s more, despite

continuous operation, it will still heat the pool far more economically than other

types of heaters.

4OWNER’S MANUAL

Service can now be obtained by calling

these phone numbers.

CANADA: 1 855 661-9330

USA: 1 855 385-6480

Please read carefully

Whenever you call to request service for your heater, you must know your

complete model and serial numbers. You can find this information on the

name plate located on the right side of your heater.

Please also record the purchase date of your device and your dealer’s name,

address, and telephone number.

Model Number ____________________________________________________

Serial Number _____________________________________________________

Purchase Date ____________________________________________________

Dealer Name ______________________________________________________

Dealer Address ____________________________________________________

Dealer Phone _____________________________________________________

Keep this book and the sales slip together in a safe place for future reference.

5

OWNER’S MANUAL

General Safety Instructions

We care for our customers

We have provided important safety messages in this manual and on your

heater. Always read and obey all safety messages.

IMPORTANT

The IMPORTANT sign calls attention to a note that provides important

information or information essential to the completion of a task.

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in material damage, particularly to the product,

up to the destruction of part or all of the product.

WARNING

The WARNING sign denotes a hazard. It calls attention to a procedure,

practice, or the like, which, if not correctly performed or adhered to,

could result in personal injury or injury to a third party. These signs are

rare, but are extremely important.

?

!

6OWNER’S MANUAL

CAUTION

All electrical connections must be done by a qualified electrician and

according to the local electrical codes. Always cut off the unit’s main

power whenever the access panel is open or removed. Always install the

machine outdoors (unless otherwise approved by the manufacturer),

while respecting the minimal clearances needed for proper operation

and heating.

!

CAUTION

Proper pool chemistry is vital to the life of your heater. Pay particular

attention to the total alkalinity and TDS. It is highly recommended that you

have your pool chemistry checked often by an independent pool store.

!

Water quality standards that must be strictly observed

Description Normal Range Verification

pH level 7.2 to 7.8 Once/week

Chlorine concentration 1.0 to 3.0 ppm Once/2-3 days

Total alkalinity 80 to 100 ppm Once/2-3 weeks

Total dissolved solids (TDS) Below 1600 ppm (fresh water) Once/month

Below 3000 ppm (salt water) Once/month

Calcium hardness 200 to 300 ppm Once/month

7

OWNER’S MANUAL

A robust and reliable product line

Residential

OPERATING

SPEcIfIcATIONS S65 / TH65 S80 / TH80 S100 / TH100 S125 / TH125 S140 / TH140

Volts 230 230 230 230 230

Hertz 60 60 60 60 60

Phase 1 1 1 1 1

Compressor amps 12.4 A 14.3 A 21.2 A 24.3 A 27.3 A

Fan motor max.

load amps 2,4 A 2,4 A 2,4 A 2,4 A 2,4 A

Fan motor HP 1/3 1/3 1/3 1/3 1/3

Fan motor speed 825RPM 825RPM 825RPM 825RPM 825RPM

Minimum circuit

ampacity 30 A 30 A 40 A 40 A 50 A

Maximum fuse 40 A 50 A 60 A 60 A 70 A

Refrigerant R-410A R-410A R-410A R-410A R-410A

Optimal water flow

rate (GPM) 30 35 40 55 60

Max. water flow

rate (GPM) 100 100 100 100 100

Max. water

temperature 104F 104F 104F 104F 104F

Dimensions (in.) H:34 L:33 D:39 H:34 L:33 D:39 H:34 L:33 D:39 H:34 L:33 D:39 H:34 L:33 D:39

8OWNER’S MANUAL

A robust and reliable product line

Commercial

MOdEl TH-200 TH-200-3 TH-200-3A

Compressor ( HP ) 2x5 10 10

Compressor type Scroll Scroll Scroll

Heat exchanger Titanium / PVC Titanium / PVC Titanium / PVC

Heating range

(°F / °C)

Up to

104°F / 40°C

Up to

104°F / 40°C

Up to

104°F / 40°C

Voltage Hz/Ph 208-240 60/1 208-240 60/3 575-600 60/3

Required breaker 60 60 30

Minimum circuit ampacity

(MCA) 47 44 16.8

Plumbing connections 2’’ 2’’ 2’’

Water Flow (GPM) 60 to 125 60 to 125 60 to 125

Dimensions in inches

H: 48

W: 33

D: 39

H: 48

W: 33

D: 39

H: 48

W: 33

D: 39

Hot Gas Defrost Yes Ye s Yes

Weight (lb) 445 375 375

9

OWNER’S MANUAL

IMPORTANT

?

Installation Instructions

Location

The placement of the pool heater is very important in keeping installation

costs to a minimum while providing for maximum efficiency of operation, as

well as allowing adequate access for service and maintenance.

The THERMEAU pool heat pump is designed for outdoor installation and

should not be installed in a fully enclosed area, such as a shed, garage, etc.,

unless ventilation is provided to ensure adequate air exchange for proper

operation. Recirculation of cold discharged air back into the evaporator coil

will greatly reduce unit heating capacity and efficiency.

The unit should be located as close as practical to the existing pool pump and

filter to minimize water piping. However, do not forget to provide a 18” clear-

ance at the very least all around your heat pump.

Mount the unit on a sturdy base, preferably a concrete slab or a set of blocks.

The size of the base should not be less than 40” x 40” (100 cm x 100 cm).

All THERMEAU pool heat pump models feature patented, ultrasilent ventilation

systems. Air is pulled through the evaporator coil and discharged through the

top grille. A minimum clearance of 48 inches should be allowed above the unit

for unrestricted air discharge. The unit must not be installed under a porch. Any

side of the unit should be located at least 24 inches from a wall or from any

other obstruction for unrestricted air intake and service access.

Fig. 1

10 OWNER’S MANUAL

IMPORTANT

?

Fig. 2

Water piping

The piping sequence is as follows: pool pump > filter > heater > pool. Auto-

mated chlorine distribution systems, if used, must be placed downstream of

the heater to minimize harm to the pool equipment. Use rigid PVC piping if

possible (SCH40 or SCH80). All joints should be glued with PVC glue. If rigid

PVC is not available, you can use soft or flexible piping with stainless steel

clamps. When the piping installation is complete, operate the pool pump and

check the system for leaks. Then, check the filter pressure gauge to verify

that there isn’t any indication of excessive pump head pressure.

You can also make the connections using high-pressure flexible hose, but

make sure the hose can withstand high pressure. The installation of a bypass

is not necessary unless the water flow exceeds 125 GPM.

11

OWNER’S MANUAL

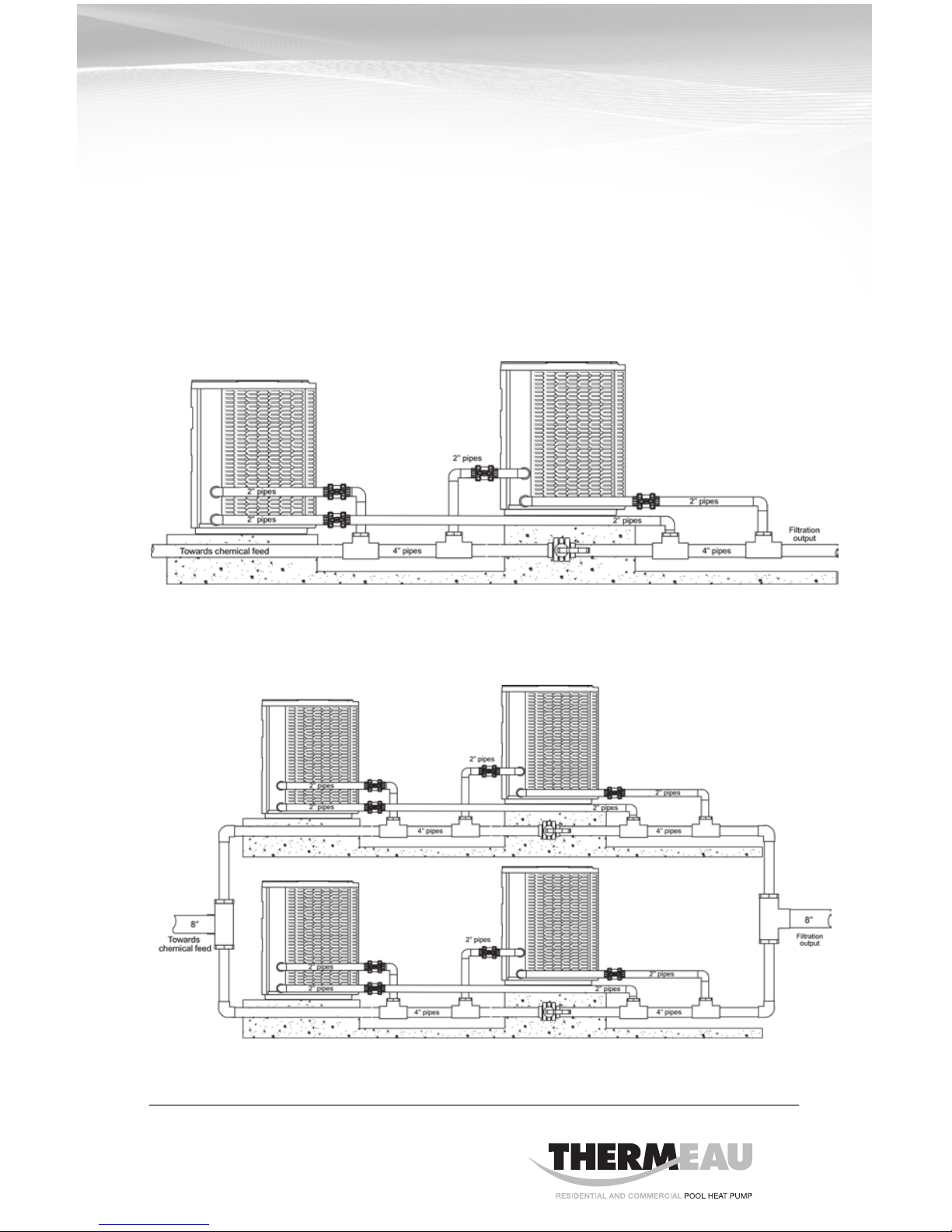

Fig. 3

Fig. 4

Multiple Heat Pump Connections

All plumbing on multiple heat pump installations must be done in parallel. An

equal flow of water to each heat pump is important for optimum operation.

NOTE: It may be necessary to adjust water pressure switch if a unit is installed

below the water level.

Each heat pump allows a maximum flow rate of 125 gpm (473 L/min) and

requires a minimum of 60 gpm (227 L/min).

12 OWNER’S MANUAL

Electrical

The wiring of your THERMEAU pool heat pump should be performed by a

qualified electrician in accordance with local requirements.

The unit must always be deactivated before opening the access panel.

Bonding

Because all metals have different electrical potentials, all metal and electrical

components of the pool system must be bonded together. This includes the

metal framework of the pool, the light, the pump, the filter (if made out of metal),

the heater, any automatic chlorine generator, and any other metal or electrical

equipment. On some older pools, this substructure bond wire may not exist.

In these cases, a 6 to 8 foot solid copper rod must be driven into the ground

near the equipment. All electric and metal components must then be bonded

to each other, and then to the copper rod.

WARNING

!

1. A 1/3 lb check valve must be installed between the heater

and any automatic chlorine distribution system (if used).

2. Any kind of automatic chlorine distribution system must be

installed after or downstream of the heat pump.

3. The filter must be placed before or upstream

from the heat pump.

Bonding and Plumbing

step-by-step instructions

CAUTION

!

WARNING

13

OWNER’S MANUAL

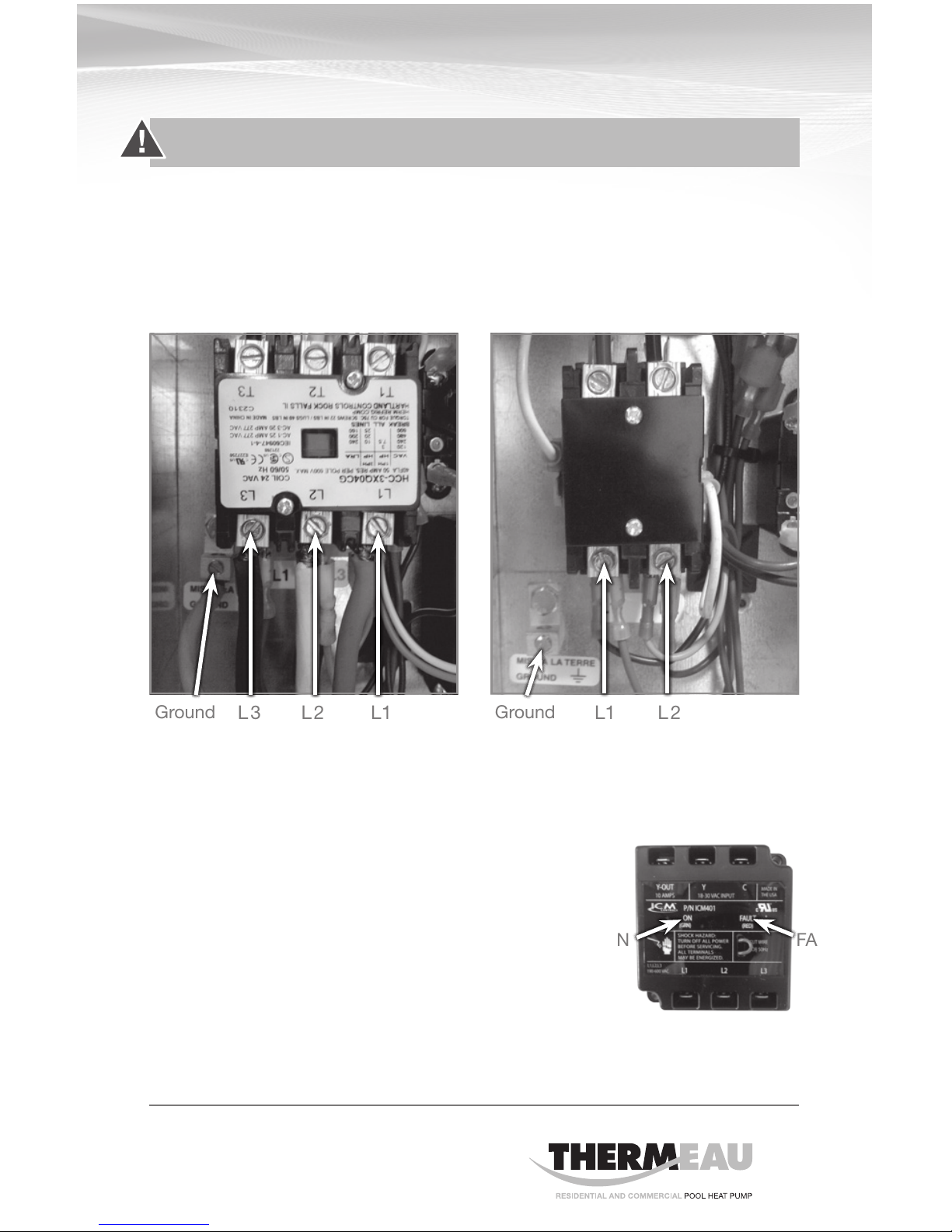

3 Phase loss and reversal protection

Operating mode:

The THERMEAU unit is equipped with SCROLL

compressor which cannot run in both rotations.

When the heating light on the main board will come

on, If all three phase are relatively equal and in pro-

per sequence, the (ON) green light on the phase

protector will be energize and the compressor will

start normally. If the phase are in wrong sequence,

that’ll be the (FAULT) red light that come ON and the

compressor won’t start. If this occurred, you have to

switch the L1 wire with L2 wire.

WARNING

L3 L2 L2L1 L1

Ground Ground

ON FAULT

Electrical Connections

The installation of the THERMEAU pool heater should be performed by a cer-

tified electrician. To connect the electricity, you must unscrew the four screws

of the front panel, then slide the electric cable in the hole located on the left

or the right side of the base, and then insert it in the control box. The electrical

diagram is located on the lid of the control box as well as below.

14 OWNER’S MANUAL

15

OWNER’S MANUAL

Temperature

and parameter

display

Access

to parameters

Heating mode

Compressor running

Heating mode

To raise the desired

temperature or to

change parameters

To lower the desired

temperature or to

change parameters

Service Analyzer Control

The control panel is factory set to display the temperature in Fahrenheit degrees.

Fig. 5

16 OWNER’S MANUAL

Electronic Temp. Controls

All units

Description

The control located on the front of your heat pump has a large three-character

display for the water temperature, set points, and diagnostics (see figure 5

for front panel appearance). The three button keypad includes SET, DOWN

arrow, and UP arrow buttons. LED indicators next to the display show if the

heat pump is in the pool mode or in the spa mode and if the unit is running.

Buttons:

Press the SET button to change between modes and use the up and down

arrows to change the selected mode’s settings.

Modes available are :

POOL Allows you to change the pool water temperature set point.

SPA Allows you to change the spa water temperature set point.

P-S Changes between pool and spa settings. LED’s on front panel will

indicate current mode selected.

C-F Display temperature in Fahrenheit or Celsius.

Water Temperature Set Point

Temperature set point range is OFF, and 61°F to 95°F for POL mode. For SPA

mode, set point range is OFF, and 61°F to 104°F. Pushing the UP arrow or

DOWN arrow buttons will prompt the control to display the current set point.

Continuing to press the UP or DOWN buttons will allow the set point values to

scroll until the desired set point is reached. Once the new set point has been

reached, stop pressing the UP or DOWN buttons. Once the unit toggles back

to the current water temperature display, the set point is entered. The controls

have a feature called « Set Point Memory Retention ». If the power is removed

from the unit, it retains the last set point displayed.

17

OWNER’S MANUAL

Connecting to a Remote System

This Pool Heater is compatible with most of all known remote systems in the

industry. The following models’ diagrams show how to connect all of the remote

systems to the Electronic Temp. Controller.

For 2 wire remotes

1. Bring up « POL » setting and arrow temperature down until pool setting

reads « off ».

2. Bring up « SPA » setting and arrow temperature up until spa setting reads 104.

3. Set unit to the « POL » mode.

4. Connect remote system with 2 wires to the P/S terminal on control board.

Figure 6 shows you where to connect the 2 wire remote systems to the

temperature controller.

For 3 wire remotes

1. Bring up « POL » setting and use arrows to select desired pool temperature.

2. Bring up « SPA » setting and use the arrows to select the desired spa tem-

perature.

3. Set unit to « POL » mode.

4. Connect the commun and high (or spa) wires to the « P/S » terminals on

control board (see specific model diagram). Low or pool wire does not get

connected.

Fig. 6

18 OWNER’S MANUAL

IMPORTANT

?

Initial Startup

Before starting the pool heater for the first time, it is important to verify that

the breaker is in the ON position.

Also make sure that the water circulates freely and that the pool pump is activited.

Then, you will need to set the water temperature you desire. The fan will

immediately start. The compressor will start after a 3 to 4-minute delay.

When the compressor is running, the HEATING/CHAUFFAGE indicator located

on the right (see “Service Analyzer Control,” p.15) should be lit. At initial startup,

it is normal for the unit to run 24 hours a day.

It is also normal to see water dripping from the holes at the base of the unit.

This is simple condensation.

Connection to AquaLink, Compool, Hayward, AquaLogic or any other 2 wire

remote system with their own thermostat :

• Removegrayjumperfromterminals1and2onTB1

• Bringthetwowiresfromtheremotesystemtoterminals1&2onTerminal

Block 1 (TB1)

• TheTemperatureControlknobmustbeturnedclockwise(highesttemp.

setting) for the remote system to operate the Pool Heater properly.

19

OWNER’S MANUAL

Meaning of Display Codes

Service Analyzer Codes

Most problems will be detected by the service analyzer and a code will be

displayed on the digital display of your heater.

Display Meaning of codes

OFF The desired programmed temperature point is lower than 60°F (15°C).

LP & LP3 Shortage of refrigerant gas in the unit or faulty low pressure

control. The digital display will show LP3 after 3 LP faults and shut

down your pool heater. The pool pump will also be stopped for pro-

tection if the unit’s internal time clock feature is used. If LP or LP3

occurs you should call for service.

HP & HP3

Low water flow TO the unit or faulty high pressure control. Check

water flow. Backwash filter and/or heater. The unit will show HP3

after 3 HP faults. This will stop your heater for protection.

Po Water temperature probe connected to #1 and #2 on electronic board

may be disconnected. If it is not, the probe may be open or defective.

Pc Water temperature probe is short circuited or may be defective.

FLo & FL3

Possible causes:

- The FIL parameter must always be set to OFF.

- The filter is in backwash position.

- The filter pump is stopped.

- The filter is dirty.

- Shortage of water to pool pump.

- Water pressure switch must be adjusted or it is broken.

- The unit is in the protection mode and will show FL3, press

any key to restart the unit. FL3 code will stop your heater for

protection.

dPo Suction temperature probe connected to #3 and #4 on electronic

board may be disconnected. If it is not, the probe may be open or

defective.

dPc

Suction temperature probe is short circuited or may be defective.

FS

Unit currently in defrosting cycle (the fan works but the compressor

is stopped). This is normal operation when outside temperatures

are cold.

20 OWNER’S MANUAL

Troubleshooting

The heat pump is in protection

mode.

The unit is on defrost

cycle.

In this case, there may be

a 5-minute delay before

restarting.

Digital display should indicate FS.

The compressor will automatically

start again a few minutes after the

display stops indicating FS.

The fan is running, but the compressor is not.

Pool pump is not running.

Filter is dirty, restricting

the water flow.

Turn the pool pump on.

Backwash and clean filter.

The heater is displaying “o” and it will not start.

Heat pump control set to OFF.

Desired water temperature

is reached.

Main breaker is tripped.

Raise temperature set point above

60°F (15°C).

Unit will automatically restart

when the water temperature goes

below the set point.

Reset it.

The pool heater is not running.

This manual suits for next models

12

Table of contents

Other THERMEAU Swimming Pool Pump manuals

Popular Swimming Pool Pump manuals by other brands

Pentair

Pentair STA-RITE SWIMMEY Series instruction manual

Elecro Engineering

Elecro Engineering Swimming Pool Heat Pump Owner's installation & operations manual

Wayne

Wayne WAPC250 Operating instructions and parts manual

Intex

Intex 128366NP owner's manual

Kripsol

Kripsol KS Evo VS 150 user guide

COMFORTPOOL

COMFORTPOOL FUZZYCLEAN manual