4VSD Pump - June 17

The instructions listed below are purely indicative and in no way limited. The pump must always

be handled with the most care.

▪ The pump was designed for use in a closed circuit, in clean water at a temperature between 5° C and 50° C.

▪ Do not modify the pump in any way ; the guarantee will automatically be invalidated in the event of a pump

modication.

▪ For all repair work, only use spare parts supplied by the manufacturer; the latter will not be held liable in the event

of damage caused by the use of non-original spare parts or parts which have been modied without prior approval of

the manufacturer.

▪ The safety and correct operation of the pump are guaranteed only if all the installation and commissioning

instructions have been followed.

▪ The pump must be installed in compliance with the applicable standards in force in the country of installation and

use, especially HD 384.7.702; we recommend you contact a professional for the pump installation.

▪ Cut off the electricity supply to the pump prior to any intervention.

▪ The limits specied in the technical data table must never be exceeded under any circumstances.

▪ In the event of a malfunction or failure, please contact your nearest manufacturer’s representative or the

manufacturer’s Technical Support Service.

▪ Hot surface in the area around the motor.

This document contains basic information for the safety of persons and property, as well as the start-up of the

pump. The user and the installer must read the information contained in this document before installation and

commissioning. This reference document must be kept.

▪ Never operate the pump without the prelter.

▪ Never operate the pump without any water.

▪ Your pump is tted with a prelter basket designed to collect any large impurities which could damage

the turbine.

▪ To ensure the correct operation of the pump:

- Always operate the pump with the prelter in place,

- The pump must be installed horizontally and secured in place.

▪ Its performance is optimized if the pump is positioned below the swimming pool’s water level.

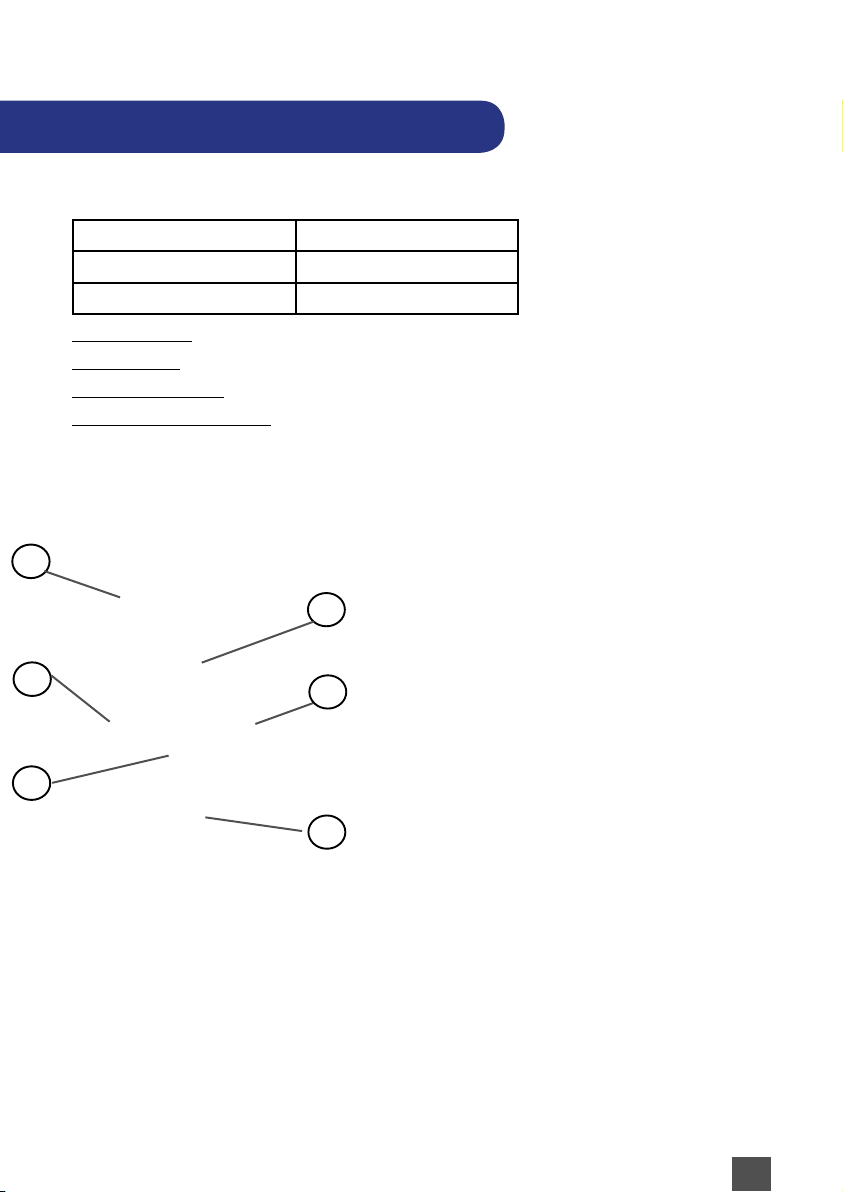

▪ If the pump has to be installed above the swimming pool’s

water level, the height must not exceed 1,5 m and the length

of the suction pipe will have to be as short as possible in

order to avoid signicant suction times and pressure losses

(diagram).

▪ For the correct air circulation and to ensure effective

cooling,the fan grid must be located more than 30cm from

Drawing n°1

Max = 2 m

2. SAFETY INSTRUCTIONS

A. For the pump

B. Operating Precautions